Professional Documents

Culture Documents

BTEX Emission

Uploaded by

Heny MarthaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTEX Emission

Uploaded by

Heny MarthaCopyright:

Available Formats

BTEX Emissions Reduced By 99.

9% in Pilot Project

Pilot Project Success In a pilot project the first of its kind, Kenilworth Combustion and an Alberta based Oil and Gas Producer has successfully reduced BTEX emissions created by glycol dehydrators in gas processing by 99.9%. BTEX stands for a complex of toxic emissions, the most important of which is Benzene- a highly toxic substance emitted through the process of dehydrating natural gas, which has received substantial attention by the oil and gas production industry due to its harmful effects on humans and the environment. Oil & Gas Industry Steps To Control BTEX Emissions The Canadian Oil and Gas industry through a program developed by Environment Canada & CAPP (Canadian Association of Petrochemical Producers) has been proactively reducing BTEX emissions over the past 15 years. The joint government and industry panel set a goal of reducing total emissions generated by glycol dehydrators by 90% of 1995 levels, with 75% reduction in emissions already achieved. This pilot project has the potential to exceed the target and virtually eliminate BTEX emissions. Canada still has over 38,000 Glycol Dehydrators in use with BTEX emissions generated by the industry amounting to several hundred tonnes emitted into the atmosphere each year. Kenilworth Combustion Kenilworth is an Alberta based firm that has been developing combustion solutions for the Western Canadian Energy Industry since 1981. This pilot project adds BTEX emission reduction capabilities to a product line of CSA B149.3 compliant natural draft burner systems (single and multi-pass capabilities) which already boast substantial improvements to thermal efficiency while reducing emissions of hazardous elements. The most notable is the reduction of NOx Emissions to as low as 15 PPM, CO Emissions to as low as 0-5 PPM and excess oxygen content down to as low as 3% with noise emissions ranging between 78-84 db achieved with Kenilworth products. Emissions Results From Pilot Project

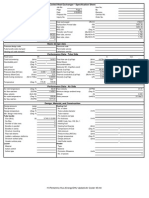

Component Methane Ethane Propane Isobutane N-Butane Isopentane N-Pentane N-Hexane Cyclohexane Other Hexanes Heptanes Methylcyclohexane 2,2,4- Trimethylpentane Before (tonnes/yr) 40.4498 10.1656 7.6955 1.5865 2.9097 0.7746 0.8515 0.2786 0.3673 0.0133 0.6713 0.2976 0.0108 After (tonnes/yr) 0.0042 0.0011 0.0008 0.0002 0.0003 0.0001 0.0001 <0.0001 <0.0001 <0.0001 0.0001 <0.0001 <0.0001 % Change 99.990% 99.989% 99.990% 99.987% 99.990% 99.987% 99.988% 99.964% 99.973% 99.248% 99.985% 99.966% 99.074%

Benzene Toluene Ethylbenzene Xylenes

C*+ Heavies

Total Hydrocarbon Emissions Total VOC Emissions Total HAP Emissions

2.2604 2.0240 0.2017 0.2916

1.2206

72.0704 21.4551 5.0670

0.0002 0.0002 <0.0001 <0.0001

0.0001

0.0075 0.0022 0.0005

99.991% 99.990% 99.950% 99.966%

99.992% 99.990% 99.990% 99.990%

Total BTEX Emissions

Total Emissions

4.7776 72.0704

0.0005 99.990% 0.0075 99.990%

Further Emissions Benefits Emission testing was conducted by a major field analytics firm using 3 independent trials on the system under normal operating conditions. In addition to the major reduction in BTEX emissions, analytics report indicated the pilot project achieved emissions benefits beyond the BTEX reduction. While gases are normally vented to atmosphere in the gas drying process, these gasses are now being routed and utilized in the facilities process heating resulting in a net hydrocarbons emissions reduction of 72 tonnes per year! The net payback of a BTEX Burner Upgrade (estimated based on process heating fuel savings) is an estimated 12-24 months. The payback of the project is made possible by Kenilworth Combustions Patented Low Pressure Burner and Flue Gas Recycle technology which enables the toxic gas to be routed to the facilities process heaters at low operating pressures and combusted at high efficiencies. To contact Kenilworth regarding this story: Toll Free @ 1-866-744-3974 Sales & Technical: Heine Westergaard ext 27 Cell: 1-780-853-7775 Email: Heine@Kenilworth.ca Technical: Per Westergaard ext 32 Cell: 1-780-808-4039 Email: Per@Kenilworth.ca WWW.KENILWORTH.CA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Glycol Dehydrators - Rev 0Document10 pagesGlycol Dehydrators - Rev 0Suleman TariqNo ratings yet

- Process Engineer Job Desc - 1Document2 pagesProcess Engineer Job Desc - 1Heny MarthaNo ratings yet

- Air Cooler 45 Case1 PDFDocument2 pagesAir Cooler 45 Case1 PDFHeny MarthaNo ratings yet

- Basic Operation and Function of Control Valves. Cashco PDFDocument65 pagesBasic Operation and Function of Control Valves. Cashco PDFEdgar Huanca0% (1)

- JPT2003 09 Gas FocusDocument7 pagesJPT2003 09 Gas FocusHeny MarthaNo ratings yet

- Application Engineer Job Desc - 1Document1 pageApplication Engineer Job Desc - 1Heny MarthaNo ratings yet

- CBE 362L 1 Double PipeDocument8 pagesCBE 362L 1 Double PipeDodOng GwapoNo ratings yet

- Catalogue AIR TORQUE N° 4thG.-R-BDocument6 pagesCatalogue AIR TORQUE N° 4thG.-R-BnegrinNo ratings yet

- Mass Balances On CO2 AbsorptionDocument8 pagesMass Balances On CO2 AbsorptionsahilchemNo ratings yet

- 8100 Series Brochure PDFDocument12 pages8100 Series Brochure PDFHeny MarthaNo ratings yet

- AirTorqueBrochuremetric PDFDocument26 pagesAirTorqueBrochuremetric PDFHeny MarthaNo ratings yet

- Spec Heat Q ADocument1 pageSpec Heat Q ARony Putera NapitupuluNo ratings yet

- PRH 04Document6 pagesPRH 04Heny MarthaNo ratings yet

- BSPT Thread ChartDocument1 pageBSPT Thread ChartAli FikarNo ratings yet

- HMTDocument11 pagesHMTHeny MarthaNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- CNG Cylinders Type I: Material & ProductionDocument16 pagesCNG Cylinders Type I: Material & Productionawrche020676100% (2)

- ORNL Mark 7 Improvements r1Document19 pagesORNL Mark 7 Improvements r1Heny MarthaNo ratings yet

- OneSteel Piping Systems Data ChartDocument18 pagesOneSteel Piping Systems Data Chartpete0980100% (1)

- BSPT Thread ChartDocument1 pageBSPT Thread ChartAli FikarNo ratings yet

- Soq EnergyDocument31 pagesSoq EnergyHeny MarthaNo ratings yet

- BKI Class PDFDocument99 pagesBKI Class PDFArdhika HermigoNo ratings yet

- HMTDocument11 pagesHMTHeny MarthaNo ratings yet

- OneSteel Piping Systems Data ChartDocument18 pagesOneSteel Piping Systems Data Chartpete0980100% (1)

- Heat Equation PDFDocument4 pagesHeat Equation PDFnoxleekNo ratings yet

- CoalescerDocument16 pagesCoalescerHeny Martha100% (2)

- Stack CalculationDocument1 pageStack CalculationHeny MarthaNo ratings yet

- How To Estimate Reid Vapor Pressure (RVP) of A BlendDocument10 pagesHow To Estimate Reid Vapor Pressure (RVP) of A BlendRashedul IslamNo ratings yet

- Refrigeration Basics and LNGDocument43 pagesRefrigeration Basics and LNGEnrico GambiniNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Combustion Ratio ControlDocument8 pagesCombustion Ratio ControlMourougapragash SubramanianNo ratings yet

- MIG Welding - Gas Metal Arc Welding (GMAW)Document5 pagesMIG Welding - Gas Metal Arc Welding (GMAW)Mohamed AtefNo ratings yet

- 2nd Preliminary Examination 2023 - 2024 Grade 10 ScienceDocument2 pages2nd Preliminary Examination 2023 - 2024 Grade 10 ScienceJerome Tala-ocNo ratings yet

- Sodeca Pressurization System Presentation EN 12101-6 Part2Document20 pagesSodeca Pressurization System Presentation EN 12101-6 Part2PeroMentoroNo ratings yet

- SGV Series: Storage Filling PumpDocument2 pagesSGV Series: Storage Filling PumpAnupam MehraNo ratings yet

- Hse HSG139Document43 pagesHse HSG139alain_oregioniNo ratings yet

- Mozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011Document12 pagesMozambique Offshore: Rovuma Offshore Gas Discoveries 2010 and 2011tsar mitchelNo ratings yet

- Refrigeration Past Board Exam PDFDocument12 pagesRefrigeration Past Board Exam PDFKaiser CarloNo ratings yet

- Ce 370 - Centrifugal Pump CharacteristicsDocument29 pagesCe 370 - Centrifugal Pump CharacteristicsMohamed Abd El RahmanNo ratings yet

- Fluid FrictionDocument10 pagesFluid FrictionUmesh PatilNo ratings yet

- SpiraxSarco The Steam and Condensate Loop Block 1 14 PDFDocument498 pagesSpiraxSarco The Steam and Condensate Loop Block 1 14 PDFsudhakarrajam20020% (1)

- Kaeser Mobile CompressorDocument12 pagesKaeser Mobile CompressorAbdullah Al BayatiNo ratings yet

- Comparison of Triode and Diode Ion PumpDocument7 pagesComparison of Triode and Diode Ion PumpAarkayChandruNo ratings yet

- 2017 Winter Question Paper PDFDocument4 pages2017 Winter Question Paper PDFJanardan JakhadNo ratings yet

- LabReport Gas DiffusionDocument21 pagesLabReport Gas DiffusionSharing Caring83% (6)

- Chapter 2: Properties of Fluids ESOE 505221 Fluid Mechanics 1Document27 pagesChapter 2: Properties of Fluids ESOE 505221 Fluid Mechanics 1Hazem AlmasryNo ratings yet

- Student Practice Questions For Chemical Engineering Calculations For CombustionDocument6 pagesStudent Practice Questions For Chemical Engineering Calculations For CombustionDonPedrew60% (5)

- Flow Through A Circular TubeDocument8 pagesFlow Through A Circular TubeAnas Iqmal0% (1)

- OTC-27686-MS A Revolutionary Hybrid Solution To The Grand Challenge of Developing Deepwater Stranded GasDocument8 pagesOTC-27686-MS A Revolutionary Hybrid Solution To The Grand Challenge of Developing Deepwater Stranded GasArlette Ramirez ValdesNo ratings yet

- LPG Fuel System Engine Mazda M4-2.0GDocument23 pagesLPG Fuel System Engine Mazda M4-2.0GArmando OrtaNo ratings yet

- Ceca Newsletter April 2012Document1 pageCeca Newsletter April 2012ghasem_726990287No ratings yet

- Refrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APDocument2 pagesRefrigeration Compressed Air Dryer Buran SD 0010 A - SD 1650 APAljoša HribarNo ratings yet

- Standard 3Document28 pagesStandard 3Muhammed SulfeekNo ratings yet

- Tutorial 4. Modeling Unsteady Compressible FlowDocument44 pagesTutorial 4. Modeling Unsteady Compressible FlowMohamad AsadiNo ratings yet

- Nusselt Number CorrelationsDocument6 pagesNusselt Number CorrelationsSecruss CiceroNo ratings yet

- Govt - Engineering College, Barton Hill, Thiruvananthapuram Second Series Test-S7 Mechanical Engineering Refrigeration & Air ConditioningDocument3 pagesGovt - Engineering College, Barton Hill, Thiruvananthapuram Second Series Test-S7 Mechanical Engineering Refrigeration & Air ConditioningRakesh NairNo ratings yet

- 10 Structure, Function and Maintenance Standard 3 ParteDocument80 pages10 Structure, Function and Maintenance Standard 3 ParteAugusto OliveiraNo ratings yet

- Rheology TannerDocument11 pagesRheology TannerRajashree ParidaNo ratings yet

- Real Oil & Gas Services SDN BHD: (C/W Cylinder & Valve)Document1 pageReal Oil & Gas Services SDN BHD: (C/W Cylinder & Valve)Hafiz ZabidiNo ratings yet