Professional Documents

Culture Documents

Ramesh Wpq-1g 32nb

Uploaded by

DeepakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ramesh Wpq-1g 32nb

Uploaded by

DeepakCopyright:

Available Formats

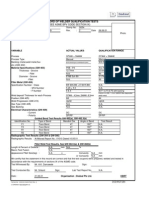

Tech-Sharp engineers (P) Ltd

QW-484A SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONS (WPQ)

(See QW-301, Section IX, ASME Boiler and Pressure Vessel Code) Welder's name: N.RAMESH Identification No. TSW-004 Test Description Identification of WPS followed TS/QA/TS/QCP/004, Rev-0 Test coupon Production weld Specification of base metal(s) SA333 Gr 6 Thickness 5.5 Testing Conditions and Qualification Limits Welding Variables(QW-350) Welding process(es) Type(ie;manual,semi-auto)used Backing(metal,weld metal,double-welded,etc) Plate Pipe(enter diameter if pipe or tube) Base metal P-or S-Number to P-or S-Number Filler metal or electrode specification(s) (SFA)(info.only) Filler metal or electrode classification(s) (info.only) Filler metal F-Number(s) Consumable insert (GTAW or PAW)

Filler type (solid/metal or flux cored/powder) (GTAW or PAW)

Actual Values GTAW MANUAL N/A 1 P1 SFA 5.18 ER 70S2 F6 INMS-1 SOLID 5.5

Range Qualified GTAW MANUAL N/A 1 AND ABOVE P1-P1 F6 INMS-1 SOLID 11.0

Deposit thickness for each process

Process 1: GTAW 3 layers minimum Yes No Process 2:_______________ 3 layers minimum Yes No

Position Qualified (2G,6G,3F,etc) 1G ______ 1G Vertical progression (uphill or downhill) UPHILL UPHILL Type of fuel gas (OFW) N/A N/A Insert gas backing (GTAW,PAW,GMAW) N/A N/A Transfer mode(spray/globular or short circuit-GMAW) N/A N/A GTAW current type/polarity(AC,DCEP,DCEN) DCEN DCEN RESULTS Visual Examination of Completed Weld (QW-302.4 : WELD VISUAL FOUND SATISFACTORY Bend test; Transverse root and face[QW-462.3(a); Longitudinal root face [QW-462.3(b); Side (QW-462.2); Pipe bend specimen, corrosion-resistant overlay [QW-462.5(c)]; Plate bend specimen, corrosion-resistant overlay[QW-462.5(d); Macro test for fusion[Qw-462.5(b); Macro test for fusion(Qw-462.5(e); ] Type Result Type Result Type Result

Alternative radiographic examination results (QW-191): RIR NO. TS/0126, Dated :- 16/11/08 Fillet weld fracture test (QW-180) N/A Length and percent of defects N/A Macro examination (QW-184) N/A Fillet size (in.) N/A x_N/A Concavity/convexity (in.) N/A Other tests N/A Film or specimens evaluated by S.K.RAI Company IIT ENGINEERS Mechanical tests conducted by N/A Laboratory test no. N/A Welding supervised by A.K.Jha We certify that the statements in this record are correct and that test coupon were prepared, welded and tested in accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code. Organization TECH-SHARP Date 16/11/2008 By: M.KAMAL

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRAhmed Shaban KotbNo ratings yet

- Icml Mla IiDocument3 pagesIcml Mla IiDeepak100% (2)

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocument5 pagesMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Ultrasonic inspection report for transmission grillage beamsDocument1 pageUltrasonic inspection report for transmission grillage beamsDeepak100% (1)

- Icml Mla IDocument3 pagesIcml Mla IDeepak100% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- 1015 To Hastelloy VickoDocument14 pages1015 To Hastelloy Vickovgestantyo100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Saravanan Wpq-5g 50nbDocument1 pageSaravanan Wpq-5g 50nbDeepakNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocument1 pageWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- WPQ Welder Performance QualificationsDocument1 pageWPQ Welder Performance Qualificationsjoshrathburn1980No ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojNo ratings yet

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQDocument2 pages161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- QW484BDocument1 pageQW484BMohamed Ahmed MaherNo ratings yet

- WQT 1236Document1 pageWQT 1236mir31721No ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- PT ZUG WELDING QUALIFICATIONDocument1 pagePT ZUG WELDING QUALIFICATIONMuhammad Fitransyah Syamsuar Putra100% (1)

- DQR Project Quality Control Form for Welder PerformanceDocument1 pageDQR Project Quality Control Form for Welder PerformanceminhnnNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSAlesol EquipmentNo ratings yet

- WPQRDocument1 pageWPQRShani MalikNo ratings yet

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 pagesQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- Welder qualification record templateDocument1 pageWelder qualification record templateAnonymous 4e7GNjzGWNo ratings yet

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Welder Qualification TestsDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Welder Qualification Testsrohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- FORM QW-484B WELDING OPERATOR QUALIFICATIONSDocument1 pageFORM QW-484B WELDING OPERATOR QUALIFICATIONSKautiilaNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification Recordravi00098No ratings yet

- Welder Performance Qualification (WPQ)Document1 pageWelder Performance Qualification (WPQ)JBStringerNo ratings yet

- 14033Document2 pages14033Priyanathan ThayalanNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- BPVC Ix QW-483Document2 pagesBPVC Ix QW-483ganesh82No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- WPQ ASME IXDocument1 pageWPQ ASME IXEDEN GONZALEZNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- FortiGate 30DDocument4 pagesFortiGate 30DIulianNo ratings yet

- BS English 17-04-2020Document10 pagesBS English 17-04-2020DeepakNo ratings yet

- OCTL E Atalogue 2018Document32 pagesOCTL E Atalogue 2018DeepakNo ratings yet

- M 8Document2 pagesM 8DeepakNo ratings yet

- Grade 4 Math Test on Multiplication Aug 2016Document1 pageGrade 4 Math Test on Multiplication Aug 2016DeepakNo ratings yet

- CL 4 PPT Animal World For Flipped LearningDocument7 pagesCL 4 PPT Animal World For Flipped LearningDeepakNo ratings yet

- 6 1 17Cl4EngtestportionDocument1 page6 1 17Cl4EngtestportionDeepakNo ratings yet

- 22 7 16Cl4EnglishTestPortionDocument1 page22 7 16Cl4EnglishTestPortionDeepakNo ratings yet

- Cover PageDocument192 pagesCover PageDeepakNo ratings yet

- 29 7 16Cl4EETestPortionDocument1 page29 7 16Cl4EETestPortionDeepakNo ratings yet

- Subject - Hindi Class IV Date of Test: 08-07-16 TopicDocument1 pageSubject - Hindi Class IV Date of Test: 08-07-16 TopicDeepakNo ratings yet

- Syllabus Barc Rtl2 160714Document7 pagesSyllabus Barc Rtl2 160714DeepakNo ratings yet

- 4-Appendix 1 Part 1b Ultrasonic 3rd Edition June 2011Document13 pages4-Appendix 1 Part 1b Ultrasonic 3rd Edition June 2011menn555No ratings yet

- Check List & Proforma Permit.Document3 pagesCheck List & Proforma Permit.DeepakNo ratings yet

- Wireless Product MatrixDocument8 pagesWireless Product MatrixDeepakNo ratings yet

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- My Gurukulam: A Look Inside EE-2 Delhi Public SchoolDocument2 pagesMy Gurukulam: A Look Inside EE-2 Delhi Public SchoolDeepakNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentDeepakNo ratings yet

- Tripride 1 Equivalent PDFDocument4 pagesTripride 1 Equivalent PDFDeepakNo ratings yet

- Q.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDocument2 pagesQ.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDeepakNo ratings yet

- NDT Methods AvailableDocument1 pageNDT Methods AvailableDeepakNo ratings yet

- Survey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDocument2 pagesSurvey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDeepakNo ratings yet

- Nozzle Location Plate Identification Thickness Location E W N SDocument9 pagesNozzle Location Plate Identification Thickness Location E W N SDeepakNo ratings yet

- Life Without LimitsDocument31 pagesLife Without LimitsDeepakNo ratings yet

- CaptionsDocument3 pagesCaptionsDeepakNo ratings yet

- XL Go Data SheetDocument4 pagesXL Go Data SheetDeepakNo ratings yet