Professional Documents

Culture Documents

Slings and Rigging: Workforce Safety & Insurance

Uploaded by

Dedi MulyadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slings and Rigging: Workforce Safety & Insurance

Uploaded by

Dedi MulyadiCopyright:

Available Formats

Workforce Safety & Insurance

www.WorkforceSafety.com

_____________________________________________________________________________________________

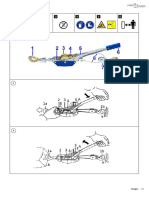

SLINGS AND RIGGING

1. 2. Employees will be properly and thoroughly trained in the use of slings and rigging. The entire length of the sling must be visually inspected prior to use, at regular intervals, and after any incident. Clean the sling before inspecting it. Dirt and grime can hide damage, especially on chain and wire rope. Slings will be relaxed when you inspect them. Damaged or defective slings must be discarded. When disposing of a defective or damaged sling, cut the sling in half or otherwise destroy it so there is no danger of it being reused. When inspecting steel alloy chainslings, pay special attention to nicks, gouges, cracks, corrosion pits, stretching, and distorted or worn fittings. Replace the entire sling if any part is damaged, has more than 10% wear or 5% stretch, and if the hook is twisted more than 10 degrees or opened up more than 15% at the throat. Wire rope slings must be replaced if there is severe corrosion, localized wear (shiny worn spots), a 1/3 reduction in outer wire diameter, excessive stretching, damage or displacement of end fittings, more than 10 broken wires in one lay, or evidence of damage to the rope structure such as kinking, crushing, birdcaging, or other distortion. Do not use synthetic web slings that have burns, broken or worn stitches, excessive stretch, exposed warning stitches (usually red yarn), snags, punctures, tears or cuts, or distorted fittings. Inspect for broken wires in metal mesh slings, lack of sling flexibility, kinks or twists in the edge, 25% reduction in wire diameter due to abrasion, and broken brazed joints or welds on the edge. Store slings vertically on a rack of wall to minimize the risk of damage and for easy access. Lift only from solid attachment points. Before making the lift, make sure the weight and balance of the load are known and the sling is securely positioned around the load. Guard against shock loading by taking up slack in the sling slowly. Operators must know and must not exceed the working load limit (rated capacity) of the sling. The working load limit is calculated by dividing the breaking strength of the sling by five. Do not lift items that exceed the working load limits of the sling.

3.

4.

5. 6. 7. 8. 9. 10. 11. 12.

Safe Practices for Using Chains 1. 2. 3. 4. Take up slack slowly and see that every link in the chain seats properly. Never put strain on a kinked chain. If the links do not slide freely within each other, the chain is damaged and must be removed from service. Do not use a hammer to force a hook over a chain link. See that the load is always properly set in the bowl of the hook. Never attempt to repair the welded components on a sling. A broken chain must not be spliced with a bolt or any other type of coupling.

Safe Practices for Using Wire Rope Slings 1. 2. Lubricate the chain for longer service life. Before applying lubricant, make sure the sling is as dry and clean as possible. Lubricating a dirty or damp sling promotes corrosion. Avoid bending wire rope around small radius bends.

Safe Practices for Synthetic Web Slings. 1. 2. Synthetic web slings cannot be repaired; damaged slings must be discarded. Do not join slings by knotting. Stretching is the only accepted method of attaching end fitting or forming eyes.

June 2003

Workforce Safety & Insurance

www.WorkforceSafety.com

_____________________________________________________________________________________________

3.

If you hear a noise like popcorn popping when using a synthetic sling, it is a signal that the sling is breaking. Immediately set the load down, remove the sling, and inspect it.

Safe Practices for Metal Mesh Slings 1. 2. Do not twist or kink the edges of a metal mesh sling. Never use knots, bolts, or any other unauthorized method to shorten a sling. Consult the manufacturer if it must be shortened.

______________________________________ Date

June 2003

You might also like

- Illustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringFrom EverandIllustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringNo ratings yet

- Sling SafetyDocument16 pagesSling SafetyanjireddyNo ratings yet

- Harness LanyardInspectionReportDocument3 pagesHarness LanyardInspectionReportHamza Shehzad100% (1)

- EOTcrane SafetyDocument54 pagesEOTcrane SafetyRafique AjmeriNo ratings yet

- Harness (And Body Belt) Inspection: WebbingDocument3 pagesHarness (And Body Belt) Inspection: WebbingUlviyye ElesgerovaNo ratings yet

- Safe Rigging/proper Rigging/safety in Rigging/rigging/safetyDocument49 pagesSafe Rigging/proper Rigging/safety in Rigging/rigging/safetyJun Kho100% (1)

- Rope and Tackle Block SafetyDocument1 pageRope and Tackle Block SafetyKyaw Kyaw AungNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- Idler Service Manual 2016-08-31Document8 pagesIdler Service Manual 2016-08-31Sergio Rodrigo Miranda GuajardoNo ratings yet

- Common Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentDocument11 pagesCommon Problems With Rigging Equipment: #1 - Missing or Illegible Identification/Tags On Rigging EquipmentEngr Arfan Ali DhamrahoNo ratings yet

- Harness Insp. and Maint. Daily ChecklistDocument3 pagesHarness Insp. and Maint. Daily ChecklistSarojini VeeraraghavanNo ratings yet

- Lesson 1 9867Document9 pagesLesson 1 9867EricNo ratings yet

- Sling SafetyDocument20 pagesSling SafetySrijit Puthen100% (1)

- A-Wire Rope Slings12345Document12 pagesA-Wire Rope Slings12345MANOJ KUMARNo ratings yet

- Instructions For The Safe Use Of: Wire Rope SlingsDocument2 pagesInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNo ratings yet

- Use and Care of Wire RopeDocument8 pagesUse and Care of Wire RopeAnonymous 7fsk6ZFMNo ratings yet

- Safe Rigging PracticesDocument46 pagesSafe Rigging PracticesErik100% (1)

- Chains and Lifting Gear - 8890Document2 pagesChains and Lifting Gear - 8890anisaanNo ratings yet

- HCH Series Hand Chain Hoist ManualDocument14 pagesHCH Series Hand Chain Hoist ManualRoni AdiNo ratings yet

- Instructions For The Safe Use Of: EyeboltsDocument2 pagesInstructions For The Safe Use Of: Eyeboltsdsn_sarmaNo ratings yet

- Handling Ropes and WiresDocument22 pagesHandling Ropes and WiresSeaman NavigatorNo ratings yet

- Chain Block ManualDocument3 pagesChain Block ManualPhan Van Loi0% (1)

- AEMA2231 Lab 3 Chain DriveDocument3 pagesAEMA2231 Lab 3 Chain DriveAbdurrazaqNo ratings yet

- Hoisting & RiggingDocument5 pagesHoisting & RiggingRam SinghNo ratings yet

- RiggerDocument156 pagesRiggerFasil Paruvanath100% (6)

- Chain Block Do's & Dont'sDocument7 pagesChain Block Do's & Dont'sRajanbabu100% (3)

- Bucket Elevator Chain InstallationDocument27 pagesBucket Elevator Chain Installationm s sankar raoNo ratings yet

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

- Catalogue 02 02Document26 pagesCatalogue 02 02Alejandro GilNo ratings yet

- CAT-11 Hoist, Sling, and Chain Safety-EnglishDocument21 pagesCAT-11 Hoist, Sling, and Chain Safety-EnglishGemNo ratings yet

- Safe Rigging PracticesDocument86 pagesSafe Rigging Practicesmagantiramudu94% (33)

- Chain Maintenance ManualDocument8 pagesChain Maintenance ManualLam DesmondNo ratings yet

- Tg06 21 Inspecting Lanyards PDF enDocument2 pagesTg06 21 Inspecting Lanyards PDF enZeeshan BajwaNo ratings yet

- Lesson 6 - 785Document11 pagesLesson 6 - 785EricNo ratings yet

- Proper Wire Rope UseDocument10 pagesProper Wire Rope Usekartoon_38No ratings yet

- CLO2Document5 pagesCLO2saifNo ratings yet

- Slings ShacklesDocument5 pagesSlings ShacklesDhana ShekarNo ratings yet

- Wire Rope Slings Si 2 - 2 EmmDocument2 pagesWire Rope Slings Si 2 - 2 EmmheppyfaebanffNo ratings yet

- Body Belts InspectionDocument4 pagesBody Belts InspectionI LucianaNo ratings yet

- Chain Slings SI 1.3Document2 pagesChain Slings SI 1.3reda mesbahNo ratings yet

- BlueSky BlueLock ProcedureDocument2 pagesBlueSky BlueLock ProcedurealtexsteveNo ratings yet

- And Health Requirements Manual EM385-1-1, Revised September, 1996Document28 pagesAnd Health Requirements Manual EM385-1-1, Revised September, 1996Jason RobertsNo ratings yet

- Correct Usage Instructions For Lifting EquipmentDocument6 pagesCorrect Usage Instructions For Lifting Equipmentmiraç burak navruzNo ratings yet

- Pulley Alignment ProceduDocument9 pagesPulley Alignment ProceduJosh Watts100% (2)

- 2. Инструкции Apple Ръчна лебедкаDocument2 pages2. Инструкции Apple Ръчна лебедкаeliaNo ratings yet

- Fugro Geotechnics Vietnam LLC: 1. General InstructionsDocument4 pagesFugro Geotechnics Vietnam LLC: 1. General InstructionsNhân Nguyễn - CptNấmNo ratings yet

- Materials Handling: in ConstructionDocument41 pagesMaterials Handling: in ConstructionSatya NaiduNo ratings yet

- Osha Guidance On Safe Sling UseDocument6 pagesOsha Guidance On Safe Sling UsePerwez21No ratings yet

- Rigging Inspection Safety TrainingDocument92 pagesRigging Inspection Safety TrainingD Srinivasa RaoNo ratings yet

- Safety Bulletin-Chain SafetyDocument2 pagesSafety Bulletin-Chain SafetyKuOneMohdAzrulNo ratings yet

- Annex C (Informative) Recommendations For Safe Use and InspectionDocument3 pagesAnnex C (Informative) Recommendations For Safe Use and InspectionMina MaherNo ratings yet

- Swivel Head Fittings.: Blocks - Care and MaintenanceDocument1 pageSwivel Head Fittings.: Blocks - Care and MaintenanceMin SoeNo ratings yet

- Wire Rope Slings SI 2.3Document2 pagesWire Rope Slings SI 2.3reda mesbahNo ratings yet

- Wire Locking & SafetyingDocument4 pagesWire Locking & SafetyingKarthikeyanNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Anchor Systems Used For Detention Hollow Metal Systems: Standard Test Methods ForDocument16 pagesAnchor Systems Used For Detention Hollow Metal Systems: Standard Test Methods ForAlevj DbNo ratings yet

- Vice Cosmetics Duo Finish FoundationDocument14 pagesVice Cosmetics Duo Finish FoundationChunne LinqueNo ratings yet

- Iso 9624Document12 pagesIso 9624Ayman S. AshourNo ratings yet

- Techinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Document68 pagesTechinical Guide ZF 078 Thru 150 R410A Predator Single Packaged Unitr (Generation 6) - 528194-Ytg-M-0813Rolando VenegasNo ratings yet

- FINAL-ESTIMATES Cacho Garalde Larbio Mateo Morales PetrolaDocument28 pagesFINAL-ESTIMATES Cacho Garalde Larbio Mateo Morales PetrolaDr. WhoNo ratings yet

- Lecure Two. ReactorsDocument56 pagesLecure Two. ReactorsSophia WambuiNo ratings yet

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocument4 pagesA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalNo ratings yet

- Permalife Full CatalogDocument76 pagesPermalife Full Catalogarchitecturalelement0% (1)

- Reactive ExtrusionDocument253 pagesReactive ExtrusionFederico ForeroNo ratings yet

- Ball MillDocument8 pagesBall MillHumbulaniNo ratings yet

- Alluvial Soil Paper PDFDocument12 pagesAlluvial Soil Paper PDFawanishNo ratings yet

- Structural Shapes: Arcelormittal International North AmericaDocument16 pagesStructural Shapes: Arcelormittal International North AmericaLeonardo SarriaNo ratings yet

- 01-08-2023 Quality Assurance certificate-RERADocument3 pages01-08-2023 Quality Assurance certificate-RERAMohsin ShaikhNo ratings yet

- Two Years' Operational Experience and Further Development of Full-Scale Co-Firing of StrawDocument7 pagesTwo Years' Operational Experience and Further Development of Full-Scale Co-Firing of StrawvatttenfallNo ratings yet

- Wind Turbine DesignDocument294 pagesWind Turbine DesignKathuli Patrick100% (4)

- QBE2002-PDocument4 pagesQBE2002-PAnonymous 7z6OzoNo ratings yet

- Designing of Chain Drive MechanismDocument1 pageDesigning of Chain Drive MechanismrasgeetsinghNo ratings yet

- Honeywell Searchpoint OptimaPlus MAN0551Document140 pagesHoneywell Searchpoint OptimaPlus MAN0551Sameer KapareNo ratings yet

- Analisis de Canalizaciones Subterraneas de Cables de Potencia - ETAP 14.1 - Version - 2Document156 pagesAnalisis de Canalizaciones Subterraneas de Cables de Potencia - ETAP 14.1 - Version - 2D Jose A. SuarezNo ratings yet

- Effect of Sand Grading On Characteristics of MortarDocument48 pagesEffect of Sand Grading On Characteristics of Mortarmaniram7100% (4)

- Superpave Mix DesignDocument21 pagesSuperpave Mix DesignRenaldy AzharNo ratings yet

- Technical SpecificationsDocument10 pagesTechnical Specificationsxubi_xNo ratings yet

- Corrosion Report PDFDocument22 pagesCorrosion Report PDFFong Wei Jun0% (1)

- Delco Remy Diagnostic Procedures Manual PDFDocument32 pagesDelco Remy Diagnostic Procedures Manual PDFjohansen05100% (2)

- Duo FlexDocument8 pagesDuo FlexIsaac Martínez AlcocerNo ratings yet

- Woodturning - Pen Makers Guild - Pen Maker's Guild Article in Stylus Magazine (PT 2 of 2) by Mel Strohminger & Howard EdelsteinDocument6 pagesWoodturning - Pen Makers Guild - Pen Maker's Guild Article in Stylus Magazine (PT 2 of 2) by Mel Strohminger & Howard Edelsteinrambo_style19No ratings yet

- Uj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationDocument2 pagesUj440I Jaw Crusher Pioneering Solutions For You: Technical SpecificationMeth MalimouNo ratings yet

- Tubing Tables ReferenciasDocument18 pagesTubing Tables Referenciasginozky100% (6)

- Machine Guarding StandardDocument68 pagesMachine Guarding StandardDave CNo ratings yet

- Carrier 30s InstallationDocument30 pagesCarrier 30s InstallationpuzsooNo ratings yet