Professional Documents

Culture Documents

Determinacion de La Porosidad en Pozos Horizontales

Uploaded by

Juan IbarraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determinacion de La Porosidad en Pozos Horizontales

Uploaded by

Juan IbarraCopyright:

Available Formats

SPWLA 39th Annual Logging Symposium, May 26-29,199s

POROSITY DETERMINATION IN HORIZONTAL WELLS S. Calvert*, M. Lovell*, P. Harvey*, J. R. Samworth+ & J. Hook+

ABSTRACT

Experience demonstrates that there is a need to assess whether or not logging tools are providing acceptable porosity values in horizontal wells. The economic viability of a field crucially depends on accurate porosity determination. Porosity can be derived from a number of different wireline and LWD tools; neutron, density, sonic, NMR and resistivity. Porosity estimates together with core measurements that provide important constraints for the range of porosity estimations. There are a number of unusual effects that have been seen in horizontal well porosity log data when compared with vertical wells through the same formation, typically resulting in increased porosity values from some of the porosity logs (notably density). A number of reasons can be proposed, such as: permeability aniztropy leading to irregular invasion variable water saturation above and below the borehole, differential stress, micro-fractures and disturbed tool placement. Often the porosity values derived from the well data are applied field wide, this is regardless of whether the well location represents a reasonable sample of the reservoir parameters or not. The well data are the best information available that can shed light on these quantities. Hence, there is a need to assess which logs provide acceptable porosity estimates. Horizontal wells allow a greater volume of the field for investigation than vertical wells and therefore represent a statistically better sampled population of the field parameters. In the case study examined, examples of vertical well and horizontal side track data from the North Sea demonstrated inconsistencies in porosity values. The vertical well wireline derived porosity values and LWD neutron are less than the core porosity.

* Department of Geology, Leicester University Wireline Technologies Ltd Enterprise Oil Plc

But, in the horizontal well, the LWD maximum density derived porosity and neutron porosity values are lower than expected from the vertical well values. This suggests that through the horizontal section either the formation porosity is lower; increased gas effects are observed or borehole conditions are degrading the quality of the log values. For the dataset examined, the LWD maximum density derived porosity provided the best porosity estimator in the horizontal well and the borehole conditions are the most likely cause of the reduced porosity estimate. The values have been validated, calibrated and compared to assert the fundamental causes of the inconsistencies. The integrated data sets have then been used to formulate algorithms and approaches to interpretation by using a range of numerical methods to constrain the derived porosity values.

INTRODUCTION

The Southern North Sea is still an active area of hydrocarbon exploration and a rich source of gas for north-western Europe. As Britain turns increasingly to gas fired generators to help meet the proposed reduction in carbon dioxide emissions, there is an increase in demand for natural gas. As a result, the Southern North Sea has had a new lease of life for gas production. The exploitation of previously uneconomic reserves and exploration for new reservoirs has stimulated the use of more elaborate methods of extraction to extend the life of fields. One of these methods has been the use of horizontal wells. Drilling horizontal wells offshore is expensive and must normally be justified as the most cost effective manner of overcoming a specific production problem or simply the most cost efficient way to drain the reservoir. The production problems that may be encountered are: . Tight formations. Horizontal open up more migration wells can paths or

BBB

SPWLA 39th Annual Logging Symposium, May 26-2991998

possibly be used for future use as an injector well to induce fractures into the formation. Drilling formations. Fractured perpendicular to the formation fracture orientation means as many fractures as possible are intersected. This often requires horizontal drilling. Channel sands. Drilling horizontally to intersect as many channels as possible. Water and/or gas coning problems. delay the Horizontal wells can water/gas break through. Permeability barriers. Horizontal wells can drain otherwise inaccessible parts of the formation.

the west of the basin to the Polish-Russian boarder in the east. The hydrocarbon fields of the offshore UK sector of the Southern North Sea are predominantly gas producing. The North Sea basins (North and South) were formed as a result of tensional stresses in the Hercynian foreland during the late Carboniferous and early Permian (Walker and Cooper 1986). Towar,ds the end of the Hercynian orogeny, there was a period of uplift that affected the North Sea basins. This uplift lead to a period of erosion accompanied by volcanism during the late Carboniferous and the early Permian. The Sole Pit sub-basin formed during the early Permian and lies off ,the North coast of East Anglia, England (Figure 1). The Sole Pit basin gas was derived from devolatilitied coal from the underlying Carboniferous coal measures (Walker and Cooper 1986). The reservoir rocks are predominantly Permian, Rotliegendes aeolian/fluvial sands. Generally, the aeolian sand members have greater porosity than the fluvial members. The cap rock is forme,d by the basal Permian, Zechstein mudstone (Kuperschiefer) and the overlying evaporite sequences. The basin has suffered two periods of inversion. The first during the Late Jurassic/Early Cretaceous that stripped away most of the Upper Jurassic sediments and another in the mid-Tertiary as a result of the Alpine orogeny. Rotliegendes aeoliamfluvial sands were formed on the Southern North sea basin margins and are known as the Leman sands. The primary sediment source was from erosion of the Carboniferous coal measures (Westphalian) from the nearby LondonBrabant massif that lay to the south of the Sole Pit basin (Ziegler 1975 and Glennie 1990). The sediment was carried by ephemeral fluvial channels into the basin. Here, on the flood plain, rhe sediment was acted on by the strong trade winds from the North to North-east to form aeolian deposits. Immediately overlying the Rotliegendes is the basal mudstone of the Zechstein. An initial rapid marine transgression (Jenyon and Cresswell 1986) lead to an increase in moisture allowing a covering of vegetation to form that later provided the basal mudstone of the Zechstein. Later, the basin

It has been noted that horizontal well porosity data from the Southern North Sea in any given reservoir tends to be greater than vertical well data the corresponding suggests, A number of previous authors have investigated this problem (Bigelow and 1992; Cuddy et. al., 1994; Cleneay, Cunningham et. al., 1990; Day and Petler, 1990; Holenka et. al., 1995; Prilliman et. al., 1995; Schroeder et. al., 1991; Went and Fisher. 1997; Wolcott et. al., 1995; Woodhouse et. al., 1991), but the matter still remains unresolved. The likely cause of these inconsistencies will probably be a culmination of effects ranging from tool responses to environmental effects. In the North Sea, new vertical wells are often logged with LWD and wireline tools, but horizontal wells are generally only logged with LWD tools. The LWD derived porosity values from horizontal well are often found to read higher values than through equivalent formations in the vertical wells. This behaviour suggests that the differences between the porosity values in the wells are not just due to natural lateral variations in reservoir porosity, but as a result of the change in tool response due to the change in tool orientation and logging environment.

BACKGROUND

GEOLOGY

The Southern North Sea has been an area of active hydrocarbon exploration and production since the early 1960s. This area covers what is known as the Southern Permian basin that stretches from the mid North Sea high and the north-east England in

SPWLA 39th Annual Logging Symposium, May 26-29,1998

became extremely dry with intermittent recharging of the basin that provided the source for the deposition of evaporities. There are five cycles of evaporities known, indicating at least five marine transgressions during the Zechstein. Owing to the thickness of the evaporities (ignoring later thickening due to halokinesis), the basin must have been regularly recharged with saline water. This conclusion is further supported by local interbedded thin evaporities (Taylor 1990). Although, some gas is found in the dolomitic members of the Zechstein. The most important reservoir rock is the aeolian sandstones of the Rotliegendes. The aeolian sandstones are generally better sorted and cleaner than the fluvial members that contain more siltaceous material.

is capped by a minor gas reservoir consisting of -30ft (- 10m) of dolomite. Above the dolomite, -8ft (-2m) of anhydrite followed substantial thickness of by a halite/polyhalite. The datasets consist of measured values from a vertical well and its horizontal sidetrack (Figures 3 and 4). Both wells were drilled using 8.5 bits with barite free oil based mud (70% oil, 30% water) with a mud weight of -10.5 lbm/gal (1.26 g/cm3). The vertical well is deviated at -57 through the reservoir and has both wireline and LWD datasets with accompanying core. The wireline tools include gamma ray, bulk density, caliper, neutron porosity, acoustic travel time, induction and formation tester. The LWD tools run were gamma ray, density (average density, maximum density, densiiy correction, density maximum derived caliper), neutron porosity, amplitude and phase resistivity. The core data include horizontal helium porosity, vertical and horizontal permeability and grain density (Figure 5). The horizontal side-track kicks off in the halite and is horizontal (-88O) in the Leman sands. The horizontal dataset consists of LWD average density, maximum density, density maximum density correction, derived caliper and neutron porosity data (Figure 4). VERTICAL WELL

COMPARISON

Firstly, it must be established that the vertical well data is of good quality and provides consistent reservoir porosity values core and LWD derived with wireline, porosity data. Once acceptable reservoir porosity values have been estimated, a transform is formulated to calculate acceptable reservoir porosity values from the LWD measurements, normally a linear shift. The transformed LWD values provide estimates of porosity from the LWD measurements in the horizontal well. The reservoir is assumed to be homogeneous and laterally continuous with low dip (Went and Fisher 1997). Then if the LWD tools are working in the same manner in a horizontal well as in the vertical well, the porosity transform should provide the best estimate reservoir porosity values at the equivalent true vertical depth.

EXAMPLE

The example used for the study is a gas reservoir in the Rotliegendes Leman sands. The Leman sands are underlain by the Westphalian coal measures (the source rock) and overlain by a thin -2ft (< lm) mudstone and dolomitic limestone - lft (-0.5m) (Figure 2). Above the dolomitic limestone is -40ft (-13m) of anhydrite with some thin dolomite interbeds. The anhydrite

In the vertical well, the wireline density derived porosity (matrix density = 2.65 g/cm3, fluid density = 0.9 g/cm3) provides the best estimate of the core porosity, which is used as a reference for the reservoir porosity. All the other porosity estimates appear only to require a linear shift to be in good agreement with the core porosity values (Table 1). The borehole condition appears to very good for the vertical well with both wireline and LWD caliper values indicating the hole is in-gauge and smooth. The respective density corrections are also small showing that there is minimal mudcake thickness. The core permeability values and the formation tester responses agree well

BBB

SPWLA 39th Annual Logging Symposium, May 26-29, 1998

indicating that the interval (x138 ft to x222 fi) is porous and permeable. Above this interval the core and chippings show that anhydrite cement (most probably derived from the overlying anhydrite bed) is affecting the reservoir quality. The base of the interval is the PermianKarboniferous unconformity, below which mudstones with minor sands are encountered. The high porosity/permeability interval is the target for the horizontal side-track. The interval can be identified from the LWD logs from expected porosity values of - 16% density (LWD average and maximum porosity) and -13% (LWD neutron porosity) high permeability with accompanying indicated by low LWD amplitude and phase resistivity values of -3 0hm.m (Table 2). Also, it should be noted that the acoustic derived porosity (matrix acoustic velocity = 55 psec/ft, fluid acoustic velocity = 220 psec/ft) is within good agreement (+l with core derived standard deviation) porosity over this interval. However, this is not the case above x138fi, where the may be adversely anhydrite cement affecting the measured acoustic travel time. This high porosity and permeability interval is considered throughout the vertical to horizontal well comparison. HORIZONTAL WELL

column by pivoting about the bit and possibly the LWD tool stabilisers. However, filtering will only remove the periodic perturbation from the log curves, but it does not remove other anomalies. The horizontal well LWD caliper and photoelectric factor are both significantly greater than the equivalent log responses in the vertical well. The LWD caliper has increased on average by -0.5 and the photoelectric factor by -1.9 B/e (Table 1). The LWD caliper is derived from differential rotational density (derived from the short spaced detector count rate variance) and the difference between the matrix density and the effective mud density (Best et. al. 1990). The matrix density used to record the log was limestone, so correcting for the lithology (sandstone) will increase the LWD caliper by -0.02 and will not make the caliper measurement signifcantly worse. However, the greater than expected photoelectric response indicates that a material with a high Z material is present. The oil based mud used to drill both wells was low density and barite free. This would suggest that with the increased stand-off of of the -0.5 (- depth of investigation photoelectric factor measurement), the photoelectric factor should be measuring the photoelectric factor of the mud, -0.2 B/e. Therefore, the photoelectric factor values should decrease to approximately equal to the mud photoelectric value. The LWD density values (maximum and average) do not indicate large increase in density. Also, in an overlying anhydrite bed, the photoelectric factor measured in the vertical well was -6 B/e and close in value for both wireline and LWD tool. However, the equivalent anhydrite bed measured ~12 B/e in the horizontal well (wel:! deviation >70) by the LWD tool. The photoelectric factor measurement is responding to lithology changes, the values are far greater than expected. Therefore, the photoelectric measurement in the horizontal well is suspect. The photoelectrlc measurement problem suggests that there may be more quality issues with the LWD density measurements than is evident from the data. Without the detector count rates it is

Since, the log responses are similar, it is expected that the LWD data in the horizontal side-track will be very similar to the vertical well data. The high porosity and permeability zone can be easily picked out (x905 ft - x1655 ft Figure 4.), but immediately it can seen that the measured values are not those expected from the vertical well (Figures 3 and 5). Also, there is a periodic signature with a wavelength of -8fi. The periodic waveform can be smoothed by a moving point filter or a Wiener filter, which preserves more of the features within the data. The periodic behaviour hints that the borehole had a corkscrew shape (Cuddy et. al. 1994) or that tool is being physically lifted by the drilling process. The LWD tool (and the drill string) may then be lifted repeatedly from the borehole floor or in fact be oscillating completely within the mud

SPWLA 39th Annual Logging Symposium, May 26-29,199s

difficult to come any satisfactory conclusion as to the cause of the perturbations. The average density and maximum density are calculated on the basis of the count rate distribution recorded during rotation (Best et. al. 1990). The average density is calculated from the mean count rate and the maximum density is calculated from the minimum count rate. Note, the tool is run with a three finned stabiliser providing a 1 stand-off. Windows in the fins of the stabiliser provide low absorption passages for the gamma-rays. The actual mean and standard deviation of the count rate distribution are compared with the expected count rate and standard deviation of an in-gauge hole. The difference between the two (actual and expected) is the basis of the derived caliper measurement. Therefore, caliper the measurement is not independent of the density measurement and any unusual values in the density measurement will be reflected directly in the caliper values and thus it is very difficult to identify the source of the measured density perturbation. It is not clear whether the perturbation is caused by the borehole condition or a tool measurement problem. The corrections density (traditional correction is a function of the long spaced minus the short spaced density and rotational correction is a function of the variance density) are applied to the maximum density measurement. In a horizontal well, the maximum density measurement could be expected to measure the density of the low side of the borehole, although from the data there is no way of knowing where around the circumference of the borehole maximum the density measurement is sampled. It is possible to envisage situations in which the maximum density would not read the density along the lower side of the borehole. However, it is accepted that in a low density mud, the maximum density measurement should provide the best estimate of the formation density. The traditional wireline density tool correction is applied to the LWD density measurements corrects for parallel stand-off of up to -1 and the rotational density correction should correct for the tool

curvature to borehole curvature, as well as perturbation of the borehole shape i.e. not circular (affects the total amount of mud around the tool). However, the traditional wireline density correction will only correct for the parallel stand off along a strip from the source to the detectors. The rotational density correction applies a correction based on a circumferential variance from the average density count rate, which would have no or very little effect on the maximum density measurement if the tool is in contact with the borehole floor. Although, the correction corrects for the mismatching tool and borehole curvature. Thus, the rotational density correction will over correct the maximum density measurement and thereby reduce the derived porosity values. However, the maximum density measurement provides a relatively good estimate of expected core porosity (from the vertical well) in the horizontal well. It is also interesting to note that the average LWD density correction in the vertical was -0.011g/cm3, but +0.026g/cm3 in the horizontal well (Table 1). Although, it is easy to understand a positive density correction with a low density mud, a negative correction is difficult to explain unless the borehole/LWD tool axes are not aligned. The average density measurement is reading -0.14 g/cm lower (-8 pu. greater) than the maximum density measurement in the horizontal well. The tool response is quite different from that seen in the vertical well. Either the borehole condition is significantly more rugose and/or the borehole is noncircular, in which case a single set of estimated caliper values with circumferential data is useful only as an indicator of poor borehole condition, The increased caliper value could be explained by poor tool detector/formation contact. Although, the maximum density derived porosity values are in good agreement with the expected porosity values from the vertical well core porosity values. This would indicate that at least for some of the tool rotation the stabiliser fins are pointing into the formation with little mud to perturb the measurements. The LWD average density values average 2.28gkm3. The LWD maximum density

BBB

SPWLA 39th Annual Logging Symposium, May 26-29,1998

average value was 2.42g/cm3 and is accepted as a better estimate of the formation density. The mud density is - 1.26g/cm3, then the average density measurement was measuring 1 part mud to 4 parts formation. Therefore, the average density measurements can viewed as an error bar for the maximum density values rather than a useful parameter for formation evaluation. Under these conditions the LWD average density values are unreliable for use as a porosity estimator. The LWD neutron porosity values are slightly lower in the horizontal well than those observed in the vertical well. This confuses the picture of the LWD tool increased stand-off during experiencing measurement, in which case the apparent porosity would increase (Day and Petler, 1990). It is worthwhile noting that there was serious damage to the LWD tools during the drilling of the horizontal well. The damage suggests that the tools were not only being worn by abrasion, but also from being continuously knocked into the borehole walls. The variability in the LWD caliper (-1.5) proves some indication of the amount of movement of the tools within the borehole. SUMMARY

There is a periodic signature in LWD caliper values, which is in phase with the periodicity found in the orher density derived values.

CONCLUSIONS

1. LWD maximum density derived porosity provides the best eslimate of the true formation porosity in the horizontal well studied. LWD caliper measurement 2. An of the density independent measurements is essential. This is now addressed by a number of companies by the introduction of an ultrasonic caliper measurement. factor response in the 3. Photoelectric horizontal well is suspect and hints at possible problems with all the density measurements. 4. LWD average density and photoelectric factor indicate poor conditions. 5. Horizontal well LWD neutron porosity and LWD maximum density derived porosity are both decreased with respect to the vertical well values suggesting that the formation porosity is lower through the horizontal section. Although, increased gas effects and poor borehole conditions are possible causes.

FURTHER

Both, the LWD maximum density derived porosity and the LWD neutron porosity values are slightly lower in horizontal well than expected from the vertical well, but are considered to provide a good estimate of the core porosity once a linear shift is applied. The horizontal well LWD maximum density derived porosity is lower by -1.5 p.u. and the LWD neutron porosity by -2.3 p.u.. The porosity reduction is possibly due to lateral formation porosity heterogeneity. The photoelectric factor increase remains unexplained, but is possibly due to poor tool measurement. The LWD average density in the horizontal well was much lower than expected from the vertical well values. The average density measurement is thought to indicate that borehole is non-circular and that the tool is reading more mud than can be compensated for.

CO.MMENTS

1. Running wireline logs including imaging logs in horizontal wells would provide a check on the LWD derived parameters. 2. Side-wall core plug porosity would be a useful constraint on porosity derived from logs run in horizontal wells. 3. LWD density and n,eutron tool count rates would be a useful additional quality control parameter allowing the log analyst to better constrain the source of any anomaly.

BIBLIOGRAPHY

Best, D., Wraight, P. and Holenka, J., 1990, An innovative approach to correct density measurements while drilling for hole size SPWLA 31 Annual Logging effect, Symposium transactions.

SPWLA 39th Annual Lugging Symposium, May 26-29,1998

Bigelow, E. L. and Cleneay, C. A., 1992, A new frontier: Log interpretation in horizontal Logging SPWLA 33d Annual wells, Symposium transactions. Brooks, J. and Glennie, K. W. (Eds.), 1986, Petroleum Geology of North West Europe, Proceedings of the 3rd Conference on Petroleum Geology of North West Europe, Graham & Trotman, London, pp. 263-305. Cuddy, S., Day, S., Page, G. and Fletcher, J., 1994, The observed effects of high deviation wells on porosity measurements, Evaluation Formation 16 European Symposium. Cunningham, A. B., Bullion, D. and Opstad, E. A., 1990, Use of MWD formation evaluation in the Endicott reservoir north USA, 131h European Alaska, slope, Symposium Evaluation Formation Transactions. Day, S. N. J. and Petler, J. S., 1990, Tool motion and borehole environment effects on MWD neutron porosity measurements, 131b European Formation Evaluation Symposium Transactions. Glennie, K. W., 1990, Upper Permian Rotliegend, in Giennie, K. W. (Ed.), 1990, Introduction to the Petroleum Geology of the Scientific Blackwell North Sea, Publications, London, pp. 120- 152. Holenka, J., Best, D., Evans, M., Kurkoski, P. and Sloan, W., 1995, Azimuthal porosity while drilling, SPWLA 36 Annual Logging Symposium transactions. Jenyon and Cresswell, 1986, The Southern Zechstein salt basin of the British North Sea, as observed in regional seismic traverses, in Brooks, J and Glennie, K W. (Eds.), 1986, Petroleum Geology of North West Europe, Proceedings of the 3rd Conference on Petroleum Geology of North West Europe, Graham & Trotman, London, pp. 277-292. Prilliman, J. D., Allen, D. F. and Lehtonen, L. R., 1995, Horizontal well petrophysical using LWD, SPE Annual evaluation Technical Conference and Exhibition 1995, SPE Paper No. 30549.

Schroeder, T. S., Zoeller, W. A., Hammons, L. R. B. and Kane, P. J. P., 1991, Integration of measurement-while-drilling and wireline formation evaluation data, 14 European Formation Evaluation Symposium Transactions. Taylor, J. C. M., 1990, Upper Permian Zechstein, in Glennie, K. W. (Ed.), 1990, Introduction to the Petroleum Geology of the North Sea, Blackwell Scientific Publications, London, pp. 153-190. Walker, I. M. and Cooper, W. G., 1986, The structural and stratigraphic evolution of the northeast margin of the Sole Pit Basin, in Brooks, J and Glennie, K. W. (EL&.), 1986. Petroleum Geology of North West Europe, Proceedings of the 3rd Conference on Petroleum Geology of North West Europe, Graham & Trotman, London, pp. 263-275. Went, D. J. and Fisher, W. C., 1997, Integration of horizontal well geological into reservoir descriptions: data Rotliegendes sandstone, Lancelot area, Southern North Sea, AAPG Bulletin. V.81 No.1, pp. 135-154. Wolcott, D. S., Shafer, D. and Vittachi, A., 1995, Characterization of a heterogeneous formation using azimuthal logging-whiledrilling measurements, SPWLA 36h Annual Logging Symposium transactions. Woodhouse, R., Opstad, E. A. and Cunningham, A. B., 1991, Vertical migration of invaded fluids in horizontal wells, SPWLA 32d Annual Logging Symposium transactions. Ziegler, W. H., 1975, Outline of the Geological History of the North Sea, in Woodland A. FFT(Ed.), 1975, Petroleum and the Continental shelf of North-West Europe, Elsevier Applied Science Publishers, Barking, pp. 165- 189.

ACKNOWLEDGEMENTS

One of the authors (SC) thanks the London Society and Petrophysical Leicester University for funding the research and SPWLA for a grant to enable the author to attend the conference. The oil companies are thanked for supplying the data.

BBB

SPWLA 39th Annual Logging Symposium, May 26-29,1998

ABOUT

THE AUTHORS

is presently studying Stefan Calvert petrophysics for a PhD at Leicester University, UK. He is sponsored by the London Petrophysical Society and Leicester University. He joined Leicester University Borehole Research after completing an M.Sc. in Geophysics at Durham University, UK in 1996 and also holds a B.Sc. in Physics from the University of Birmingham, UK. Mike Love11 is Reader in Petrophysics at the University of Leicester. He obtained a B.Sc. Geophysics from the in Geological University of Reading in 1977, and gained an M.Sc. in Marine Geotechnics in 1979. He was awarded a PhD for research in to the physical properties of sediments from the University of Wales in 1984. In 1992-93 he was Visiting Professor in Borehole Geophysics at the Universidade Federal do Para in Belem, Brazil. Peter Harvey a BSc. in Geology from the Bristol University in 1964 and a PhD in the same university in 1967. From 1967 to 1989 he was a lecturer/senior lecturer in Geology at the University of Nottingham, with an interval 197 1172 at the Geological Survey of Kansas. He transferred to the University of Leicester in 1989 where his research is concerned with nuclear and electrical logging, and computer modelling. Roger Samworth is Research Director with Wireline Technologies Ltd. (formerly BPB). He graduated from Manchester University in 1968 with an Honours Physics degree and joined BPB in 1972. At Wireline Technologies, he has been mainly concerned with improving the Companys borehole logging techniques and in developing new tools and methods. He has published papers at previous SPWLA and SPE symposia. Jeff Hook is a Senior Staff Petrophysicist with Enterprise Oil plc. He holds a B.Sc. in Physics from Imperial College, University of London and a Ph.D. from Durham University. He has previously worked in core analysis with Corex Labs Ltd and as a petrophysicist with Britoil plc and Mobil North Sea Ltd. He is currently President of the London Petrophysical Society.

SPWLA 39th Annual Logging Symposium, May 26-29,199s

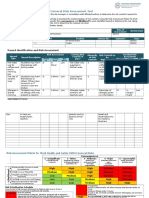

Vertical well. hiph oorositv and Dermeability zone Variable

/ Photoelectric

Factor (B/e)

Horizontal well. hieh oorositv and Dermeabilitv zone

Table 1. Log value statistics for the high permeability and porosity zone.

BBB

SPWLA 39th Annual Logging Symposium, May 26-29,199s

Vertical well. high porosity and Derrneability zone Variable LWD Average Density Porosity (%) Maximum Density Porosity (%) Neutron Porosity (limestone p.u.) Core Horizontal Helium Porosity (%) Horizontal Permeability (mD) Wireline Acoustic Porosity (%) Density Porosity (%) Neutron Porosity (limestone p.u.) Horizontal well. high oorositv and permeabilitv zone Minimum Maximum

10.700 0.670 7.584 9.657 6.945

18.300 90.000 17.268 18.914 14.410

Table 2. Derived porosity value statistics for the high permeability

and porosity zone.

SPWLA 39th Annual Logging Symposium, May 26-29,199s

0 6

Rate of Penetration 5) Gamma Ray (AP b

50

Resistivity

10

(0hm.m)

100 1000 10000 2.15

Density (g/cc)

2.32 2.48 2.650.10

Density Correction (g/cc)

-0.05 0.00 0.05 0.10

loo 150 200 1

8 I 9 I I Ill11ll

Caliper (inches)

7 I

10001 01

Core Horizontal Helium Porosity . (mD)

1 10 I I I,,,,, II I,,,,,, _.

Core and Neutron Porosit (%) Photoelctric Factor (6 Y e)

1 I Iu 0

Acoustic Travel Time (usec/ft)

120 100 80 60 4

ll~l~l.~I~.IIlrIII~Il ..:_ ..--. -XT..-,.

x If

Wirehe

,, ---., r:-:-. -, --.

. .;

-... *.-- I

Wirelinc oustI

W---CCJE Horizontal Permeability

\. .: _ .G..., ..-., --.. .- *-.:(._ : ,I. * ..:..;._--_-. .---:. I._ . ;:.-a -2 :- ,-- f::. LWO ::.:. :.:

Density Conectlon --:.; 1:. ; c-- -a1: : -::a . :.-. .-

.. . ::

.. .:.: ::. -.-.:)

\ l -. ..* Wireline m---L

Repissity

X ._. --, -__. -,. .:_ .:a ... ,-*-.. ..~ , .a . .: . . . . I.- __...-c... ._ 2 . .. a-.. -: 1

Figure 3. Vertical well, LWD and wireline log curves with core porosity and permeabilities. Note, wireline density porosity best matches core porosity. Caliper values in guage and density corrections are in the opposite sense for wireline and LWD. Low resistivity correlates with high permeability.

SPWLA 39th Annual Logging Symposium, May 26-29,199s

Rate of Penetration (5) Gamma Ray (API) 100 150 0 54 Caliper (inches)

6

Xi:

Resistivity

2031 10

(0hm.m)

100 10032.15

Density (g/cc)

2.32 2.48 2.65 -0.10

Density Correction

-0.05 0.00

(g/cc)

0.05 0.10

Core Horizontal Helium Porosity (mD) I,,,,,,II,,,

30.-

-l--u-

LWD bnplitude

..

Xi!

A

X

Wireline Medium induction

I Core Hotizonta

Permeabilit

50,:

X X

x1;

70.x

X

\ : . . . -* : . f *. .

f

/ Wirelint AcoustL Quality

& .c Ii 0 ) Xl! Pm I ( LWD C&per ii GammaRay I

LWD :. :. . Density . . . G3rrection~, .. *. :.I; :*:

X X X X X

!I

X210.: i

Wireline Glliit i, Rateof Penetration ,I LWD Phase 3esistivtty

X

i.; \ If

x230,

Figure 5. Vertical well, high porosity and permeability zone, LWD and wireline log curves with core porosity and permeabilities. Note, wireline density porosity best matches core porosity. Caliper values in guage and density corrections are in the opposite sense for wireline and LWD. Low resistivity correlates with high permeability.

SPWLA 39th Annual Logging Symposium, May 26-29,199s

Density

200 2.15 2.32

Rate of Penetration (5) $mma@y (ATljo Caliper (inches)

(g/cc)

2.46 2.65

Resistivity

(0hm.m)

Core and Neutron Porosity (%) Photozectric Fapr (B!e) o

M30

Density Correction

.lO -0.05 0.00

(g/cc)

0.05 0.1

>> -LWD Amplitude bsistivity

Xl10

iWD Phase Resistivity

E 5 8 0

:. .,

x1x

:,

: _-: -

:._ :...-. I. -. :: I ,:: . . .

Xl%

._ ,_. :

..

, : ._ -1.

,: : I : ., _ : I :.

Figure 6. Horizontal well, high porosity and permeability zone, LWD log curves. Note, low LWD average density and LWD neutron porosity values, the LWD maximum density values are greater than expected. The LWD caliper is out of guage and the LWD density correction is positive.

You might also like

- Basin ScalefluidmovementpatternsrevealedbDocument27 pagesBasin ScalefluidmovementpatternsrevealedbRAFIK BEN SALAHNo ratings yet

- New Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityFrom EverandNew Perspectives on Deep-water Sandstones: Origin, Recognition, Initiation, and Reservoir QualityNo ratings yet

- Effect of Glauconite On Petrophysical Properties As Revealed by Core AnalysisDocument12 pagesEffect of Glauconite On Petrophysical Properties As Revealed by Core AnalysisanjumbukhariNo ratings yet

- Impact of Deformation Bands On Fluid Flow and Oil Recovery: Graue, A.Document6 pagesImpact of Deformation Bands On Fluid Flow and Oil Recovery: Graue, A.Rosa K Chang HNo ratings yet

- Novel Approach To Quantifying Deepwater Laminated Sequences Using Integrated Evaluation of LWD Real-Time Shear, Porosity, Azimuthal Density and High-Resolution Propagation ResistivityDocument16 pagesNovel Approach To Quantifying Deepwater Laminated Sequences Using Integrated Evaluation of LWD Real-Time Shear, Porosity, Azimuthal Density and High-Resolution Propagation ResistivityshantanurilNo ratings yet

- Hydroplaning and Submarine Debris FlowsDocument17 pagesHydroplaning and Submarine Debris FlowsAdrija ChakrabortyNo ratings yet

- Well Logs: Prof. Dr. Hassan Z. HarrazDocument80 pagesWell Logs: Prof. Dr. Hassan Z. HarrazEzzadin BabanNo ratings yet

- Greculaetal 2014 Ormen LangeDocument29 pagesGreculaetal 2014 Ormen LangeminahlehNo ratings yet

- Petrophysics MSC Course Notes.Document281 pagesPetrophysics MSC Course Notes.CARLOS RODRIGUEZNo ratings yet

- Petroleum GeoscienceDocument19 pagesPetroleum Geosciencepatricksullivan6682No ratings yet

- Walford - Et - Al - 2005 - Zamberi - Solid Sediment Load History of The Zambezi DeltaDocument15 pagesWalford - Et - Al - 2005 - Zamberi - Solid Sediment Load History of The Zambezi DeltaShelton UamusseNo ratings yet

- PC-X Olatunji 2022 51Document14 pagesPC-X Olatunji 2022 51ogheneochukoererejuiletNo ratings yet

- THE δ 1 8 0 AND δ 13C ISOTOPIC COMPOSITION OF SECONDARY CARBONATES FROM BASALTIC LAVAS CORED IN HOLE 642E, OCEAN DRILLING PROGRAM LEG 104Document7 pagesTHE δ 1 8 0 AND δ 13C ISOTOPIC COMPOSITION OF SECONDARY CARBONATES FROM BASALTIC LAVAS CORED IN HOLE 642E, OCEAN DRILLING PROGRAM LEG 104Dave LoveNo ratings yet

- Shale Barrier Performance in Petroleum Systems Implications For CO2 Storage and Nuclear Waste DisposalDocument18 pagesShale Barrier Performance in Petroleum Systems Implications For CO2 Storage and Nuclear Waste Disposalbagus918No ratings yet

- Worthington2021 Article FactorsAffectingTheVariationOfDocument12 pagesWorthington2021 Article FactorsAffectingTheVariationOfJoséAndrésTrejoCorzoNo ratings yet

- Chapter 5-Formation EvaluationDocument38 pagesChapter 5-Formation EvaluationAban Robert100% (2)

- DrillingDocument41 pagesDrillingOUMAIMA OULD SALTANANo ratings yet

- O'Brien Et Al, 2002 APPEA - HRDZ PDFDocument16 pagesO'Brien Et Al, 2002 APPEA - HRDZ PDFZakaullah BabarNo ratings yet

- Reservoir Sensitivity To Water Flooding: An Experimental Study of Seawater Injection in A North Sea Reservoir AnalogDocument20 pagesReservoir Sensitivity To Water Flooding: An Experimental Study of Seawater Injection in A North Sea Reservoir AnalogchirazNo ratings yet

- Laura Del Valle Rodriguez - 2015 SPE LACPEC Paper - SPE 17715Document13 pagesLaura Del Valle Rodriguez - 2015 SPE LACPEC Paper - SPE 17715HENRY MACIASNo ratings yet

- Sca2010 41Document6 pagesSca2010 41Rosa K Chang HNo ratings yet

- Pockmarks and Methanogenic Carbonates AbDocument13 pagesPockmarks and Methanogenic Carbonates AbAnjeliana HalohoNo ratings yet

- Engineer's Perspective A Review of Braided Fluvial Hydrocarbon Reservoirs: The PetroleumDocument36 pagesEngineer's Perspective A Review of Braided Fluvial Hydrocarbon Reservoirs: The PetroleumASKY PNo ratings yet

- 2006 Schrottkeetal GML26 1Document15 pages2006 Schrottkeetal GML26 1rullyirwandiNo ratings yet

- OH LoggingDocument135 pagesOH LoggingKarar AL-DahlkiNo ratings yet

- Stream Sediment GeochemistryDocument12 pagesStream Sediment GeochemistryAndika Putra50% (2)

- tmpE8A4 TMPDocument11 pagestmpE8A4 TMPFrontiersNo ratings yet

- Mackay AUC2008Document15 pagesMackay AUC2008klomps_jrNo ratings yet

- Term Paper ENCH 649 - FINAL PDFDocument12 pagesTerm Paper ENCH 649 - FINAL PDFPratik D. SuryavanshiNo ratings yet

- Accommodation and Sedimentary Architecture of IsolDocument22 pagesAccommodation and Sedimentary Architecture of IsolmangkotiNo ratings yet

- How Coriolis Forces Can Limit The Spatial Extent of Sediment Deposition of A Large-Scale Turbidity CurentDocument5 pagesHow Coriolis Forces Can Limit The Spatial Extent of Sediment Deposition of A Large-Scale Turbidity Curenttin2huynhNo ratings yet

- TOC From Well LogsDocument23 pagesTOC From Well Logslilim020776No ratings yet

- The Defining SeriesDocument13 pagesThe Defining SeriesSAMUELAMPAHNo ratings yet

- Sinuous Deep Water ChannelsDocument47 pagesSinuous Deep Water ChannelsSamuel CorreaNo ratings yet

- Columbus Basin 2Document12 pagesColumbus Basin 2Luis Abdul-MelendezNo ratings yet

- Mud-Weight Control During Arctic Drilling OperationsDocument11 pagesMud-Weight Control During Arctic Drilling Operationslord azraelNo ratings yet

- OTC-25192-MS Developments in Marine Gas Hydrate ExplorationDocument8 pagesOTC-25192-MS Developments in Marine Gas Hydrate ExplorationJackyNo ratings yet

- Tight Gas ReservoirsDocument13 pagesTight Gas ReservoirsPablo RaffinNo ratings yet

- Chapter 5-Formation EvaluationDocument38 pagesChapter 5-Formation EvaluationArpan BiswasNo ratings yet

- Val HallDocument16 pagesVal HallSergio FloresNo ratings yet

- Causes and Treatment Measures of Submarine Pipeline Free-SpanningDocument21 pagesCauses and Treatment Measures of Submarine Pipeline Free-Spanningzoe bairNo ratings yet

- Journal Eks BBDocument26 pagesJournal Eks BBFhardi SugandaNo ratings yet

- Fundamentals of Formation EvaluationDocument84 pagesFundamentals of Formation Evaluationabuobida100% (2)

- CHAPTER-11 Well LoggingDocument14 pagesCHAPTER-11 Well LoggingArpit UpadhyayNo ratings yet

- The Role of Faults in Hydrocarbon Migration: Isabelle MorettiDocument18 pagesThe Role of Faults in Hydrocarbon Migration: Isabelle MorettiAntonio ChikaleNo ratings yet

- Exploration and ReservoirDocument87 pagesExploration and ReservoirRian Suari Aritonang100% (2)

- Limnology Ocean Methods - 2009 - Berg - Eddy Correlation Measurements of Oxygen Uptake in Deep Ocean SedimentsDocument9 pagesLimnology Ocean Methods - 2009 - Berg - Eddy Correlation Measurements of Oxygen Uptake in Deep Ocean SedimentsDiego Alejandro Pulgarin MontoyaNo ratings yet

- C FakepathLectureDocument97 pagesC FakepathLectureSakina AsgarliNo ratings yet

- SPE-170822-MS Modeling of Induced Hydraulically Fractured Wells in Shale Reservoirs Using Branched' FractalsDocument27 pagesSPE-170822-MS Modeling of Induced Hydraulically Fractured Wells in Shale Reservoirs Using Branched' Fractalstomk2220No ratings yet

- Petroleum Geology PDFDocument111 pagesPetroleum Geology PDFEva Marinovska100% (1)

- Hydrofracture Properties Via Signals From Hydraulic Pumps: An OverviewDocument6 pagesHydrofracture Properties Via Signals From Hydraulic Pumps: An OverviewTJPRC PublicationsNo ratings yet

- North & Prosser 1993 Fluvial Reservoir CharacterisationDocument7 pagesNorth & Prosser 1993 Fluvial Reservoir CharacterisationASKY PNo ratings yet

- Limnology Oceanography: MethodsDocument21 pagesLimnology Oceanography: MethodsStefano PontarelliNo ratings yet

- Origins of Hydrocarbons in The Geneva Basin: Insights From Oil, Gas and Source Rock Organic GeochemistryDocument28 pagesOrigins of Hydrocarbons in The Geneva Basin: Insights From Oil, Gas and Source Rock Organic GeochemistryMak RamNo ratings yet

- Oil and Gas Wells and Their IntegrityDocument16 pagesOil and Gas Wells and Their IntegrityEjaj Siddiqui100% (1)

- Open PitDocument18 pagesOpen PitSaid RzikiNo ratings yet

- 1 s2.0 S0040195116303092 MainDocument20 pages1 s2.0 S0040195116303092 MainFreeepNo ratings yet

- Journal of Contaminant Hydrology: James Bethune, Jackie Randell, Robert L. Runkel, Kamini SinghaDocument11 pagesJournal of Contaminant Hydrology: James Bethune, Jackie Randell, Robert L. Runkel, Kamini SinghaMuslih AliNo ratings yet

- Eage2011 LNDocument6 pagesEage2011 LNkatcourtNo ratings yet

- Blue Prism Questions and Answers Based On HintsDocument21 pagesBlue Prism Questions and Answers Based On Hintssowndarya vangalaNo ratings yet

- Neil Armstrong Interview (1969)Document8 pagesNeil Armstrong Interview (1969)Aviation/Space History LibraryNo ratings yet

- Future of Transportation - Shai AgassiDocument10 pagesFuture of Transportation - Shai AgassiBetter PlaceNo ratings yet

- Index of WorkshopDocument4 pagesIndex of Workshopapi-3709247No ratings yet

- Step Back 5x5 PresentationDocument8 pagesStep Back 5x5 Presentationtim100% (1)

- Data Mining and Business IntelligenceDocument2 pagesData Mining and Business IntelligenceDreamtech PressNo ratings yet

- Ballistic Target Flight Trajectory Simulation (A Matlab Program)Document14 pagesBallistic Target Flight Trajectory Simulation (A Matlab Program)Marcelo MartinezNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentAshraful HasanNo ratings yet

- Bell Crank White PaperDocument9 pagesBell Crank White PaperagniflameNo ratings yet

- Wind Exposure CategoriesDocument3 pagesWind Exposure CategoriesShadin Asari ArabaniNo ratings yet

- Six Sigma of MotorolaDocument15 pagesSix Sigma of Motorolabobby_03544978No ratings yet

- Comed Sample BillDocument2 pagesComed Sample BillAlberto Cayetano100% (1)

- Raja of CorruptionDocument335 pagesRaja of CorruptionMadhu Mohan100% (1)

- Text FileDocument5 pagesText FileJaid KhanNo ratings yet

- ADS Summer 2022 Market Monitor vF2Document14 pagesADS Summer 2022 Market Monitor vF2Nadja Josefine GavrilukNo ratings yet

- Risk Assessment Grandparents DayDocument5 pagesRisk Assessment Grandparents Dayapi-436147740No ratings yet

- Priyanka MFT NIFTDocument2 pagesPriyanka MFT NIFTPriyanka JanaNo ratings yet

- Toyota Motor Corporation and TPSDocument5 pagesToyota Motor Corporation and TPSMaitri BiswadharaNo ratings yet

- Change ManagementDocument20 pagesChange ManagementDrRameesha KalraNo ratings yet

- The Goal Book ReviewDocument6 pagesThe Goal Book ReviewRakesh SkaiNo ratings yet

- Airwork Helicopter Maintenance 3Document8 pagesAirwork Helicopter Maintenance 3subha_aeroNo ratings yet

- SINOPEC Lubricant CompanyDocument2 pagesSINOPEC Lubricant CompanyRaisul Islam NayanNo ratings yet

- 489-Diseno de MicropilotesDocument379 pages489-Diseno de MicropilotesfabioNo ratings yet

- 2 Principles of Roof Truss DesignDocument8 pages2 Principles of Roof Truss Designnaveenbaskaran1989No ratings yet

- Galileo Z Drive Assembly ManualDocument32 pagesGalileo Z Drive Assembly ManualTeddy RoyNo ratings yet

- 333 Extremultus-Compendium 02-2017 enDocument108 pages333 Extremultus-Compendium 02-2017 enGuilherme Augusto100% (1)

- Legends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CADocument7 pagesLegends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CAMohammed FaizNo ratings yet

- P.R. Cements LTD Fixed Assets ManagementDocument71 pagesP.R. Cements LTD Fixed Assets ManagementPochender vajrojNo ratings yet

- A2 Planche Tanja+Tim Print UKDocument1 pageA2 Planche Tanja+Tim Print UKTim Nøhr ElkærNo ratings yet

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (595)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishFrom EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishRating: 4 out of 5 stars4/5 (30)

- Microscopy of Numerology: Numerology SimplifiedFrom EverandMicroscopy of Numerology: Numerology SimplifiedRating: 5 out of 5 stars5/5 (2)

- The Hidden Life of Trees: What They Feel, How They CommunicateFrom EverandThe Hidden Life of Trees: What They Feel, How They CommunicateRating: 4 out of 5 stars4/5 (1003)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (11)