Professional Documents

Culture Documents

Long Stability

Uploaded by

Ilian DinkovCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Long Stability

Uploaded by

Ilian DinkovCopyright:

Available Formats

Fuel 86 (2007) 25962602 www.fuelrst.

com

Long storage stability of biodiesel from vegetable and used frying oils

Aracil Abderrahim Bouaid, Mercedes Martinez, Jose

*

Department of Chemical Engineering, Faculty of Chemistry, Complutense University, 28040 Madrid, Spain Received 31 August 2006; received in revised form 1 February 2007; accepted 6 February 2007 Available online 13 March 2007

Abstract Biodiesel is dened as the mono-alkyl esters of vegetable oils. Production of biodiesel has grown tremendously in European Union in the last years. Though the commercial prospects for biodiesel have also grown, there remains some concern with respect to its resistance to oxidative degradation during storage. Due to the chemical structure of biodiesel the presence of the double bond in the molecule produce a high level of reactivity with the oxygen, especially when it placed in contact with air. Consequently, storage of biodiesel over extended periods may lead to degradation of fuel properties that can compromise fuel quality. This study used samples of biodiesel prepared by the process of transesterication from dierent vegetable oils: high oleic sunower oil (HOSO), high and low erucic Brassica carinata oil (HEBO and LEBO) respectively and used frying oil (UFO). These biodiesels, produced from dierent sources, were used to determine the eects of long storage under dierent conditions on oxidation stability. Samples were stored in white (exposed) and amber (not exposed) glass containers at room temperature. The study was conducted for a period of 30-months. At regular intervals, samples were taken to measure the following physicochemical quality parameters: acid value (AV), peroxide value (PV), viscosity (m), iodine value (IV) and insoluble impurities (II). Results showed that AV, PV, m and II increased, while IV decreased with increasing storage time of biodiesel samples. However, slight dierences were found between biodiesel samples exposed and not exposed to daylight before a storage time of 12 months. But after this period the differences were signicant. 2007 Elsevier Ltd. All rights reserved.

Keywords: Biodiesel; Vegetable oils; Used frying oil; Storage stability

1. Introduction Biodiesel is an alternative diesel fuel consisting of alkyl monoesters of fatty acids prepared from vegetable oils. It has been the focus of a considerable amount of recent research because it is renewable, reduces the emission of some pollutants, and is also readily biodegradable in the environment [1]. Biodiesel has become a fast growing renewable liquid biofuel within the European Union. In order to ensure customers acceptance, standardization and quality assurance are key factors for the market introduction of biodiesel as fuel for transport and heating. One of the main criteria

Corresponding author. Tel.: +34 91 394 4167. E-mail address: jam1@quim.ucm.es (J. Aracil).

for the quality of a biofuel is its storage stability. The problems arising from the deterioration of the fuel properties of biodiesel during storage are expected to be more severe than for commercial diesel fuel. Resistance to oxidative degradation during storage is an increasingly important issue for the successful development and viability of alternative fuels. Oxidation of unsaturated esters in biodiesel occurs by contact with air and other pro-oxidizing conditions during long term storage. Thus, oxidative stability is an important issue that biodiesel research must address since oxidation product may impair fuel quality and, subsequently, engine performance. Bondioli et al. and Thompson et al. [2,3], studied the deterioration of rapeseed oil methyl esters (RME) under dierent storage conditions, including changes in acidity, peroxide value, and viscosity, and found that acid value

0016-2361/$ - see front matter 2007 Elsevier Ltd. All rights reserved. doi:10.1016/j.fuel.2007.02.014

A. Bouaid et al. / Fuel 86 (2007) 25962602

2597

Nomenclature SSL SSD HOSO HEBO LEBO UFO ME samples stored in the daylight samples stored in the dark high oleic sunower oil high erucic Brassica carinata oil low erucic Brassica carinata oil used frying oil methyl ester APE BAPE AV PV m IV II allylic position equivalent bis-allylic position equivalent acid value peroxide value viscosity iodine value insoluble impurities

(AV), peroxide value (PV) and viscosity (m) increased with time. Other authors [4] found a correlation between the oxidation stability and the content of tocopherol (natural antioxidant). Additives, such as antioxidants and stabilizers, are frequently added to diesel fuels to inhibit fuel degradation and prolong storage life. In the BIOSTAB [57] project several expert teams from Research Institutes, Universities and biodiesel producers were pooled in order to nd answers to the several still open questions concerning biodiesel stability. They found that several typical diesel fuel additives and the antioxidant, tert-butylhydroquinone (TBHQ), in combination with a fuel additive, were investigated for their eectiveness in inhibiting sediment formation during aging in the biodiesel, one petrodiesel, and biodiesel/petrodiesel blends. The results showed a large difference in eectiveness between the additives, and also a large dierence in additive response between petrodiesel and biodiesel. According to [8,9], the oxidation of fatty derivatives such as biodiesel is aected by other factors, such as elevated temperature, light, the presence of metals, and other parameters that may accelerate oxidation. Generally, the rate of oxidation of fatty compounds depends on the number of double bonds and their position [10]. The oxidation chain reaction is usually initiated at the positions allylic to double bounds. Thus fatty acids (FA) with methylene-interrupted double bonds, for example, linoleic acid [(9Z,12Z)-octadecadienoic acid], are more susceptible to oxidation because they contain methylene groups that are allylic to two double bonds. Fatty acids with conjugated double bonds, for example, linolenic acid [(9Z,12Z,15Z)-octadecatrienoic acid], are even more susceptible to oxidation. Modern analytical methods are often being used for the purpose of determining structure indices such as iodine value (IV). The IV, which measures total unsaturation, has even been included in some standards for industrial products such as biodiesel. However, the IV index is too general to allow the correlation of physical and chemical properties with FA compositions. The IV is treated in a theoretical fashion regarding biodiesel- and oxidative stability-related issues. That the concept of iodine value as a structure index is unsatisfactory and need to be investigated in more detail, has led to the development of alternative indices that take into account more accurately compound structure and properties [11]. Possible alterna-

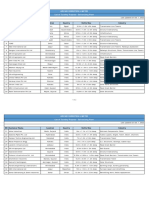

tives are the allylic position equivalent (APE) and the bisallylic position equivalent (BAPE), which better relate structure and amount of common component of fatty acids in vegetable oils to observed properties. The APE and BAPE indices are based on the number of reactive positions in oxidation. The use of the APE and BAPE indices instead of IV also implies that oxidative stability may be more strongly inuenced by the presence of small amounts of more highly unsaturated fatty compounds than by increasing amounts thereof. In this work the storage stability of biodiesel made from three dierent vegetable oils and used frying oil was investigated over a storage time of 30-months under dierent storage conditions. Analysis of fuel properties such as peroxide value (PV), acid value (AV), iodine value (IV), viscosity (m), and insolubles impurities (II) were made from samples taken from each storage container for a 30-month period. It is expected that the results will lead to a better understanding of the inuence of storage conditions on the quality of pure biodiesel. 2. Materials and methods High oleic sunower oil, high erucic and low erucic Brassica carinata oil were purchased from Koipe (Sevilla, Spain) and used frying oil obtained from the University Complutense restaurant. Certied methanol of 99.8% purity was obtained from Aroca (Madrid, Spain). The catalyst, potassium hydroxide, was pure grade from Merck (Barcelona, Spain). Three liters of biodiesel were made in our laboratory according to a methodology previously described [12,13], for dierent vegetable oils, high oleic sunower oil (HOSO), high erucic Brassica oil (HEBO), low erucic Brassica oil (LEBO) and used frying oil (UFO) at the beginning of the study. Table 1 shows the characteristics of the oils used in this study. 2.1. The storage conditions and analysis The biodiesel samples (3000 mL each) were stored for 30-months at room temperature at dierent storage conditions. Samples were stored in glass bottles that were closed to the air and exposed (B1B5) or not exposed (B1 0 B5 0 ) to daylight. During storage, samples were taken out periodi-

2598 Table 1 Characteristics of oils used in this study Characteristic High oleic sunower oil 0.05 90.43 10.1 High erucic Brassica oil 0.833 114.6 27.1

A. Bouaid et al. / Fuel 86 (2007) 25962602

Low erucic Brassica oil 1.161 132.5 43.8

Used frying oil 2.73 119.6 37.7

Acid number (mg kOH/g) Iodine number (I2/100 g) Peroxide number (meq per/kg) Viscosity (40 C) (mm2/s)

46.61

55.07

37.88

80.81

Peroxid number (meqPer/kg sample)

cally (each month) and dierent quality parameters (PV, AV, IV, m and II) were monitored. Samples were analyzed according to the following procedures, PV (AOCS Cd 853), AV (AOCS Ca 5a-40), m (ISO 3104), IV (AOCS Cd 1-25), insoluble impurities (AOCS Ca 3a-46), the method determines dirt, meal and other foreign substances insoluble in kerosene and petroleum ether is applicable to all normal fats and oils and allows the calculations of insoluble impurities, % = gain in mass of crucible/mass of sample taken for moisture * 100 [14]. In order to obtain a quickly comparison between the two units (%) and mg/100 mL, we include the conversion factor (*88.4) between the above mentioned units. B1: biodiesel from high oleic sunower oil (moisture content 0.69%), B2: biodiesel from high oleic sunower oil (moisture content 0.10%), B3: biodiesel from high erucic Brassica carinata oil, B4: biodiesel from low erucic Brassica carinata oil, B5: biodiesel from used frying oil. 3. Results and discussion The information about biodiesel samples from dierent raw materials and storage conditions are shown in Table 2. 3.1. Peroxide value (PV) Although PV is not specied in current biodiesel fuel standards, this parameter inuences cetane number (CN),

Table 2 Biodiesel samples and storage conditions Sample B1 B1 0 B2 B2 0 B3 B3 0 B4 B4 0 B5 B5 0 Oil Source High oleic sunower moisture content (0.69%) High oleic sunower moisture content (0.1%) High erucic Brassica Low erucic Brassica Used frying oil Volume (mL) 3000 3000 3000 3000 3000 Storage conditions Daylight Dark Daylight Dark Daylight Dark Daylight Dark Daylight Dark Temperature range (C) Room Room Room Room Room Room Room Room Room Room

a parameter that is specied in the fuel standard. Increasing PV increases CN, this may reduce ignition delay time [15], but also have negative eects and in particular there are concerns about compatibility with certain plastics and elastomers. Peroxide values, measured in milliequivalents of peroxide per kilogram of sample for each sampling period, are shown in Fig. 1a (SSL) and Fig. 1b (SSD). Samples exposed to daylight showed an increase in peroxides with time, which increased acceleration after the 6th month. This was especially noted for samples (B1 and B1 0 ), where peroxide numbers reached a value of over 200 meq per/kg sample; this result may be due to the presence of traces of water (0.69% moisture content) which causes oxidation of the sample. The same tendency was observed for the samples stored in the dark; these samples showed a dierence with an increase at a slower rate compared to other samples exposed to daylight, except for B4 0 , the sample from LEBO stored in the dark; this result may be due to the storage condition of this sample with a large air surface contact. 3.2. Acid value (AV) As expected, the acid number increased with an increase in peroxides because the esters were rst oxidized to form

a

600 500 400 300 200 100 0 0 5

B1 B2 B3 B4 B5

Daylight

10

15

20

25

30

35

Months of storage Peroxid number (meq Per/Kg sample)

Dark

600 500 400 300 200 100 0 0 5 10 15 20 25 30 35

B1 B2 B3 B4 B5

Months of storage

Fig. 1. Evolution of the peroxide value of biodiesel samples over a 30-months storage period: (a) exposed, (b) not exposed to light.

A. Bouaid et al. / Fuel 86 (2007) 25962602

2599

a

Acid number (mg KOH/g sample)

3 2,5 2 1,5 1 0,5 0 0 5 10

Daylight

B1 B2 B3 B4 B5

15

20

25

30

35

Months of storage

have reached a certain level. During storage, the viscosity of the methyl esters increases by the formation of more polar, oxygen containing molecules and also by the formation of oxidized polymeric compounds that can lead to the formation of gums and sediments that clog lters. In this work all biodiesel samples under these storage conditions showed a slight increase in viscosity after being stored for 30-months (Fig. 3), except for samples with high moisture contents (B1and B1 0 ) and samples with a relatively high iodine value (IV = 130) (B4 and B4 0 ) that showed a significant increase in viscosity. There may be a slight dependence between IV and an increase of viscosity. 3.4. Iodine value (IV)

b

Acid number (mg kOH/g sample)

3 2,5

Dark

B1

2 1,5 1 0,5 0 0 5 10 15 20 25 30 35

B2 B3 B4 B5

Months of storage

Fig. 2. Evolution of the acid number of biodiesel samples over a 30-months storage period: (a) exposed, (b) not exposed to light.

Oxidation consists of a complex series of chemical reactions characterized by a decrease in the total unsaturated content of biodiesel due to elimination of hydrogen adjacent to a double bond and the formation of free radicals [16]. Iodine values of all the samples exposed and not exposed to day light showed a slight decrease with a lower IV for samples stored in daylight (SSL) compared with the samples kept in the dark after storage time (Fig. 4). Except for B1, B1 0 B4, and B4 0 samples, may be due to the reasons cited before the presence of traces of water (0.69% moisture

a

peroxides, which then undergo complex reactions including a split into more reactive aldehydes which further oxidize into acids. Acids can also be formed when traces of water causes hydrolysis of the esters into alcohol and acids Fig. 2. The acid value (AV) of biodiesel samples also increased with increasing storage time as a result of hydrolysis of fatty acids methyl esters (FAME) to fatty acids (FA). The specication limit of 0.5 mg KOH/g was exceeded with the methyl esters (ME) samples exposed to daylight (B3, B4 and B5) after a storage time of 12 months, whereas for samples without light exposure only (B 0 4) led to a value exceeding 0.5 mg KOH/g. This may be due to the storage conditions with a large air surface contact of the sample (B 0 4) and probably due to the fatty acids composition of the vegetable oils used as raw materials. The acid values remained constant until the 4th month and then took a signicant upward trend except for used frying oil methyl ester (UFOME), which showed an increase over time. During the frying of vegetable oils, most of the antioxidants are consumed [8], and it is possible to assume poor oxidative stability of biodiesel made from used frying oil. The fuel stored in the daylight increased its AV at a faster rate than the fuel stored in the dark after 4 months of storage. 3.3. Viscosity (m) Oxidation of methyl ester begins with build-up of peroxides; viscosity starts to increase only after the peroxides

14,000 12,000 10,000

Daylight

8,000 6,000 4,000 2,000 0,000 0 10 20 30 40

R1 R2 R3 R4 R5

Viscosity

Months of storage

Dark

14,000 12,000 10,000 B1 B2 B3 B4 B5

Viscosity

8,000 6,000 4,000 2,000 0,000 0 10 20 30 40

Months of storage

Fig. 3. Evolution of the viscosity of biodiesel samples over the 30-months storage: (a) exposed, (b) not exposed to light.

2600

A. Bouaid et al. / Fuel 86 (2007) 25962602

a

140,000 120,000 100,000 Iodine value 80,000 60,000 40,000 20,000 0,000 0 10

Daylight

B1 B2 B3 B4 B5

20 Months of storage

30

40

b

140,000 120,000 Iodine value (IV) 100,000 80,000 60,000 40,000 20,000 0,000 0 10

Dark

Biodiesel sample from HEBO, B3 (IV = 114.9) and biodiesel sample from LEBO, B4 (IV = 130.4) had dierent IV, dierent BAPE and showed considerable dierences in oxidation stability referring to other parameters (PV, AV, m). This result may be due to it is dierence in chemical structure and storage conditions. B3, with a relatively high IV compared to other biodiesel samples (HOSO), has high oxidative stability and is much less susceptible to oxidation. This sample contains a high level of monosaturated (C18:1 and C22:1) FAME (Table 3) and low levels of polyunsaturated (C18:2, C18:3) FAME, and gives a low BAPE value. Table 3 shows BAPE values for all biodiesel samples, low BAPE show a high oxidative stability. As an example, B2, B3 and B5 biodiesel samples with a BAPE value (24.74, 19.89, 26.06) lower than B4 (36.51) are less susceptible to oxidation. Generally, the present results conrmed the observation that small amounts of more highly unsaturated fatty

B1 B2 B3 B4 B5

Table 3 Fatty acids composition of biodiesel samples Veg. oil samples Methyl ester FA C16:0 C18:1 C18:2 C18:3 C20:1 C22:1 Other minor components C16:0 C18:1 C18:2 C18:3 C20:1 C22:1 Other minor components C16:0 C18:1 C18:2 C18:3 C20:1 C22:1 Other minor components C16:0 C18:1 C18:2 C18:3 C20:1 C22:1 Other minor components Amount (%) 4.23 80 10 2.83 0.29 0.11 Rest to 100 3 32.75 9.29 5.3 9.8 40.84 Rest to 100 4.75 59.39 21.95 7.28 2.43 1.46 Rest to 100 8.85 61.52 16.24 4.91 0.91 Rest to 100 Iodine value 90.3 APEa 185.6 BAPEb 24.74

20 Months of storage

30

40

HOSO

Fig. 4. Evolution of the iodine number of biodiesel samples over a 30months storage: (a) exposed, (b) not exposed to light.

content) B1, B1 0 and samples with a relatively high iodine value (IV = 130) (B4 and B4 0 ), which could accelerate the oxidation in the biodiesel at a faster rate. The IV is a structure-related index in FA chemistry that relates to the total number of double bonds in a fat or oil (or derivatives thereof). A major drawback of the IV is that it does not distinguish structural dierences present in different fatty compounds such as nature, position in the chain, etc., and amount olenic carbons. Iodine value considers these as being equally reactive. The lack of correlation between oxidative stability, as well as other properties of biodiesel and iodine value, has been noted previously by other researchers [17,18]. However, the alternative concept of the allylic position equivalent (APE) and bis-allylic equivalent (BAPE) is based on the relative rates of oxidation of these positions in unsaturated FA as well as their amounts [19] and gives more useful results. The BAPE value is the more signicant for oxidation of unsaturated fatty compounds due to the signicantly higher relative rate of oxidation of bis-allylic CH2 positions [20]. The iodine value of the vegetable oils used in this study was below the recent specied limit, 120, in the draft of European Union Standards, except for low erucic Brassica carinata oil (IV = 130).

HEBO

14

03.68

19.89

LEBO

130.43

177.24

36.51

UFO

118.8

165.34

26.06

APE: allylic position equivalent. Calculated from Eq. (7) in Ref. [22]. BAPE: bis-allylic position equivalent. Calculated from Eq. (7) in Ref. [22].

b

A. Bouaid et al. / Fuel 86 (2007) 25962602

2601

compounds containing bis-allylic carbons have a disproportional strong eect on oxidative stability. 3.5. Insolubles impurities (II) With diesel fuel, most tests focus on the development of insoluble products that can block fuel lters or fuelling systems, which are important factors for a consumer of diesel fuel. In addition, the information contained in the literature [21], indicates that many of the mechanisms for the changes in diesel fuel are most likely not present in biodiesel and vice-versa. The analysis of biodiesel has demonstrated the tendency to form deleterious particles in the dierent biodiesel samples. The total insoluble content of biodiesel samples increased with increasing storage time. Fig. 5 shows an increase in insolubles impurities for all biodiesel samples, except for B5 that show a faster increase. Samples stored in the daylight showed the same tendency as the dark ones with an increase at a faster rate for (B1, B4 and B5) and lower rate for B2 and B3. In this work the storage stability, especially (oxidative stability) for the biodiesel made from used frying oil, showed a fast increase in insoluble impurities (II) compared with that of other biodiesel samples may be due to the

characteristic of the raw material, which has been heated over 300 C during frying. 4. Conclusions According to results from this 30-month study of HOSME (high oleic sunower oil methyl ester), HEBO (high -erucic Brassica oil) ME, LEBO (low erucic Brassica oil) ME and UFO (used frying oil) ME, all biodiesel samples are very stable because they did not demonstrate rapid increase in peroxide value (PV), acid value (AV), viscosity (m), and insoluble impurities (II). However, there was a deterioration of the fuel after 12 months of storage. Significant dierences were, however, found in the value of the measured parameters for all fuels type and storage conditions with the passage of time. For all biodiesel samples, the peroxide, acid values, viscosity, and insoluble impurities, tended to increase and iodine value (IV) to decrease over time. Fuels exposed to daylight tended to degrade at faster rate than did the others fuels, particularly as indicated by their peroxide and acid values. The specication limit of the parameters studied was exceeded with biodiesel samples after a storage time of 12 months. The use of the APE and BAPE indices instead of IV also implies that oxidative stability may be more strongly inuenced by the presence of small amounts of more highly unsaturated fatty compounds than by increasing amounts thereof. The oxidation stability depends not only on how the oil is pressed and rened but also on the raw material and on the production process of biodiesel. Biodiesel sample from low erucic Brassica carinata oil showed worse oxidation stability than the other biodiesel samples. This may be due to its quite elevated level of linoleic and linolenic acid (characterized by two and three unsaturated bonds). The results obtained in this work have conrmed the literature information that biodiesel storage promotes a rise in the peroxide number, acid number, viscosity, and insolubles of the fuel. Long-term storage study gives a better understanding of the eect of the dierent conditions and chemical composition on the stability of biodiesel. In conclusion, it can be observed that water content and air exposure are two important factors aecting the degradation of biodiesel. Results of this study suggest that to obtain a highly stable biodiesel and to avoid oxidation, it is necessary to take especial precaution during the storage such as limiting access to oxygen and exposure to light and moisture. These promising results need to be completed by a more detailed study of the eect of parameters such as elevated temperature, light, air contact and other parameters that aect the oxidation stability of biodiesel. Acknowledgement Financial support from the (CICYT), Spanish project CTQ-2006-10-467-PPQ is gratefully acknowledged.

a

1 0,9 0,8

Daylight

Impurties (%)

0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 10 20 30 40

B1 B2 B3 B4 B5

Months of storage

Dark

1,0 0,9 0,8

Impurties (%)

0,7 0,6 0,5 0,4 0,3 0,2 0,1 0,0 0 10 20 30 40

B1 B2 B3 B4 B5

Months of storage

Fig. 5. Insoluble impurities for a 30-months storage period for methyl esters.

2602

A. Bouaid et al. / Fuel 86 (2007) 25962602 [12] Bouaid A, Diaz Y, Martinez M, Aracil J. Catal Today 2005;106:1936. [13] Aracil J, Martinez M, Bautista LF, Guijarro MI, WO 03/062358 A1 Patent (2003). [14] AOCS. Method Ca 3a-46: Insoluble impurities, Ocial Methods and Recommended Practices of the American Oil Chemists Society. fth ed. Champaign, USA: American Oil Chemists Society, Illinois; 1998. [15] Dunn RO. Fuel Process Technol 2005;86:107185. [16] Naz S, Sheikh H, Siddiqi R, Sayeed SA. Food Chem 2004;88:2539. [17] Bondioli P, Folegatti L. Riv Ital Sostanze Grasse 1996;73:34953. [18] Prankl H, Worgetter M. Proc Third Liquid Fuel Conf. St. Joseph, MI: American Society of Agricultural Engineers; 1996. p. 1916. [19] Knothe G, Dunn RO. JAOCS 2003;80:10216. [20] Buettner G, Schafer FQ, Oxygen Society Annual Meeting, New Orleans, LA, November 1922, 1999. p. 125. [21] Leo L, Howell S, in: Proc of the 7th Int Conf on Stability, IASH (2000). [22] Litwinienko G, Daniluk A, Guttman Tk. J Am Oil Chem Soc 1999;76:6557.

References

[1] Zhang Q, Feldman M, Peterson CL. Diesel engine durability when fueled with methyl ester of winter rapeseed oil, American Society of Agricultural Engineers, paper no. 881562. ASAE, St. Joseph, MI, 1988. [2] Bondioli P, Gasparoli A, Lanzani A, Fedeli E, Veronese S, Sala M. Am Soc Agric Eng (ASAE) 1995;72:699702. [3] Thompson JC, Peterson DL, Reece DL, Beck SM. Trans ASAE 1998;41:9319. [4] Simkovsky NM, Ecker A. Erdol Erdgas Kohle 1999;115:3178. [5] Bondioli P, Gasparoli A, Bella LD, Tagliabue S. Eur J Lipid Sci Technol 2002;104:77784. [6] Available from: www.blt.bmlf.gv.at. [7] Lacoste F, Lagardere L. Eur J Lipid Sci Technol 2003;105:14955. [8] Mittelbach M, Gangl S. JAOCS 2001;78(6):5737. [9] Monyem A, Canakci M, Van Gerpen JH. Appl Eng Agric 2000;16:3738. [10] Frankl EN. Lipid Oxidation. Scotland: The Oily Press; 1998. p.19. [11] Knothe G. JAOCS 2002;79(9):84754.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Charge Air System of Alco LocosDocument44 pagesCharge Air System of Alco LocosmajjisatNo ratings yet

- GC - How It Works - Agilent - SusanPérezDocument19 pagesGC - How It Works - Agilent - SusanPérezsusanbperezNo ratings yet

- EXPERIMENT 7 Organic Chem LabDocument5 pagesEXPERIMENT 7 Organic Chem LabRenz Roger Esteves BuendichoNo ratings yet

- Air Break and Air GapDocument2 pagesAir Break and Air GapZarex BorjaNo ratings yet

- Gas Coalescing Filters 1Document6 pagesGas Coalescing Filters 1maría joséNo ratings yet

- Comparison of Purification Methods For Biodiesel. Berrios PDFDocument7 pagesComparison of Purification Methods For Biodiesel. Berrios PDFMariuxiNo ratings yet

- Fans SoftDocument291 pagesFans SoftAmitava PalNo ratings yet

- Shell Pakistan Stock in Trade: Horizontal AnalysisDocument12 pagesShell Pakistan Stock in Trade: Horizontal Analysisfahad pansotaNo ratings yet

- AC Spec SheetDocument3 pagesAC Spec SheetRavi SoondurNo ratings yet

- Instruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDDocument438 pagesInstruction Manual Directional Overcurrent Protection Relay Grd140 - XXXDEpsp MedNo ratings yet

- What Is The Principle Behind XRDDocument4 pagesWhat Is The Principle Behind XRDCesar CRNo ratings yet

- 3.4 Burner Lance ManualDocument3 pages3.4 Burner Lance ManualANTONIO MEDINA RIOSNo ratings yet

- Attenuation ProjectDocument12 pagesAttenuation Projectapi-352698073No ratings yet

- ENG-UEGO Connection PDFDocument2 pagesENG-UEGO Connection PDFpejcicbozidarNo ratings yet

- Physics Volume 3B Work, P, Energy KeyDocument15 pagesPhysics Volume 3B Work, P, Energy KeySesha Sai KumarNo ratings yet

- Chapter 33. Light and IlluminationDocument12 pagesChapter 33. Light and IlluminationAndrey Ugalde50% (2)

- Installation and Operation Manual - enDocument2 pagesInstallation and Operation Manual - enArt RaNo ratings yet

- Operation of Lime KlinDocument4 pagesOperation of Lime Klinhemendra499No ratings yet

- Reliance InfrastructureDocument15 pagesReliance InfrastructurePrasannaKumar93No ratings yet

- Ahu Transfer RoomDocument7 pagesAhu Transfer RoomCITACOM UTAMANo ratings yet

- FY B.Sc. Light Reactions IDocument5 pagesFY B.Sc. Light Reactions IVijendraNo ratings yet

- D10.4 R1986PVDocument7 pagesD10.4 R1986PVGabriela AxinteNo ratings yet

- Analysis of Harmonics Infiltration Produced by Electrification Railroad On 220kv and 35kv NetworkDocument6 pagesAnalysis of Harmonics Infiltration Produced by Electrification Railroad On 220kv and 35kv NetworkMenad SalahNo ratings yet

- Greenhouse EffectDocument15 pagesGreenhouse EffectNoor AdlinNo ratings yet

- BT Reach Truck PARTS Manual - RRE200CCDocument337 pagesBT Reach Truck PARTS Manual - RRE200CCAl FajarNo ratings yet

- VW Diesel GateDocument10 pagesVW Diesel GateMarius AndrieșNo ratings yet

- Natural Gas Dehydration: October 2012Document21 pagesNatural Gas Dehydration: October 2012ShakerMahmoodNo ratings yet

- 6202360Document726 pages6202360AlexeiNo ratings yet

- Client List - Arvind Corrotech Ltd.Document2 pagesClient List - Arvind Corrotech Ltd.Ricardo Javier Cotamo De la espriellaNo ratings yet

- In and Ex System DescDocument5 pagesIn and Ex System DescAli KuncoroNo ratings yet