Professional Documents

Culture Documents

Durastor Tank Brochure PDF

Uploaded by

hamadaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Durastor Tank Brochure PDF

Uploaded by

hamadaniCopyright:

Available Formats

DuraStor Prestressed Concrete Tanks

ENGINEERING REINFORCEMENT SYSTEMS CONSTRUCTION REPAIRS & MODIFICATIONS www.durastortank.com A Structural Group Company

VSLs DuraStor Tanks are cast-in-place, prestressed concrete liquid storage tanks primarily reinforced with post-tensioning tendons. High-strength steel tendons apply compression to the tank floor, walls and roof to counteract the applied forces and provide residual compression. This method actively reinforces the structure and significantly enhances its watertightness and longterm durability. The design and construction of DuraStor Tanks are governed by national building codes ACI 350 and AWWA D115. Additionally, the Post-Tensioning Institute (PTI) provides numerous specifications and guides on the design, fabrication, handling, storage, placement and inspection of post-tensioning systems. Post-tensioning is proven technology with decades of successful applications on thousands of structures worldwide including bridges, high-rise buildings, foundation systems, parking structures, silos for granular material storage and liquid storage tanks.

TANK FEATURES:

Durable

Low maintenance Joint-free floor and roof Reduced mild reinforcement Efficient construction schedule Reduced material and labor costs Seismic resistance Multiple layers of corrosion protection Built in all weather conditions Walls may be finished to meet architectural requirements Suitable for all types of liquids and granular materials Variety of shapes and sizes from 250,000 gallons to over 30 million gallons

Photo courtesy of Bates Engineering

Photo courtesy of Bates Engineering

Floor post-tensioning and formwork prior to concrete placement

Uniquely shaped post-tensioned tanks under construction

Durable. Watertight. Economical. Versatile.

Versatile

VSLs DuraStor Tanks can be constructed in many shapes to suit project needs. Shapes include circular, rectangular, rectangular with rounded corners, egg-shaped digesters, irregular-shaped polygons, and oval there are no practical limitations with this method of construction. Tanks have been constructed with capacities ranging from 250,000 gallons to above 30,000,000 gallons. DuraStor Tanks are appropriate for all types of liquid containment including chilled and potable water, storm water retention, sludge, wastewater, digesters, ethanol, petroleum products, and liquefied natural gas. They also are used in the storage of granular materials such as coal, grains, ash, cement, clinker, and nuclear containment. Site conditions may require that the tank be constructed fully-buried, partially-backfilled, above-grade, in sloped backfill or in conditions where ground water is above the tank floor. VSLs DuraStor Tank is adaptable to any of these conditions. Additionally, if required, walls can have any architectural finish to meet project requirements.

Durable

Because of its durability, cast-in-place post-tensioned concrete is recognized as the preferred method of construction for many types of structures exposed to the environment and other corrosive elements. Post-tensioning tendons have multiple layers of corrosion protection including the highly pre-compressed concrete cover, thick polyethylene ducts filled with high-performance grout or a corrosion-inhibiting coating, encapsulated anchorages and watertight duct connections. With the highly developed design methodology, structural detailing, and applications in high seismic zones - prestressed concrete tanks have the proven ability to withstand severe earthquakes.

Constructable

VSL DuraStor Tanks require no proprietary construction methods or construction equipment - the potential for project delays due to unavailable proprietary equipment or materials is not an issue. The post-tensioning allows for thinner members resulting in reduced materials, placement labor, construction schedules and costs compared with other types of concrete tanks. Additionally, the construction sequencing of a post-tensioned concrete tank allows for multiple tasks to be accomplished simultaneously resulting in a highly efficient use of manpower and short construction duration. Work can progress under freezing conditions with proper protection and curing of concrete members.

1 2

Photos courtesy of Bates Engineering Photos courtesy of Jorgensen & Close Associates, Inc.

Completed tank structure prior to burial

Placement of roof slab concrete

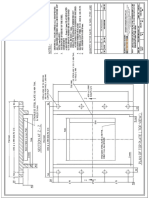

Rectangular Post-Tensioned Tank

Circular Dome-Roof Post-Tensioned Tank

Circular Flat-Roof Post-Tensioned Tank

Formwork construction prior to concrete placement

Placement of roof slab concrete

Tank Components

The main structural components of the DuraStor Tank are the floor slab, walls, and roof slab or concrete dome. The floor slab is a membrane type concrete slab normally five inches in thickness with a thickened perimeter footing. Membrane floors are designed to be highly ductile with the capability of accepting gradual differential movements without affecting watertightness. The concrete is cast in a single placement with no doweling, penetrations, or construction joints which can allow liquids to leak out of a tank creating the possibility of adversely affecting the environment and/or undermining the structures foundation. Joints may also allow substances to seep into the tank and potentially contaminate the contents. The post-tensioning tendons are placed orthogonally and are stage-stressed within 48 hours of casting the floor slab to eliminate shrinkage cracks by providing immediate precompression to the concrete. Walls are composed of full-height segments frequently 12-inches thick. Theyre cast in lengths of approximately 75 feet with no horizontal construction joints. Post-tensioning tendons placed horizontally may be tensioned at pilasters or pilasters may be eliminated depending on the project requirements. Tendons are also placed vertically to provide compression to the concrete and accommodate vertical bending moments and thermal stresses. On large tanks it is possible to place as many as four wall segments per week. Column footings and columns are cast concurrently with the wall to minimize the duration of construction. If required, walls may have any architectural finish, form liner or coating to meet the projects aesthetic requirements. The roof slab, much like the floor, is cast in a single placement with no construction joints. This method results in a watertight slab that eliminates the possibility of substances entering the tank and contaminating the contents. The roof slab is columnsupported with typical spans in the 30-foot range each way. Slab thickness is approximately 8 inches. Roof shoring is placed immediately following the column and column footing placement to minimize construction time. Post-tensioning tendons are placed orthogonally as in a typical two-way suspended slab and are stage stressed in the same manner as the floor slab tendons. After the tendons are stressed, the shoring is removed through access hatches. Column-supported flat roofs are often chosen for buried tanks or where a less visible tank is desired. A cast-in-place concrete dome is an efficient option for circular tanks where a flat roof is not required.

A Structural Group Company

VSL OPERATING CENTERS:

888-489-2687 www.vsl.net

ATLANTA CINCINNATI DALLAS DENVER FT. LAUDERDALE WASHINGTON, D.C.

VSL CORPORATE HEADQUARTERS: BALTIMORE, MARYLAND 7455 New Ridge Road, Suite T Hanover, MD 21076 410-850-7000

2/2010 1M VSL_TANK 6/2008

You might also like

- Diaphragm Wall ConstructionDocument14 pagesDiaphragm Wall ConstructionAkshay Kumar Sahoo100% (5)

- Designing Low Retaining WallsDocument2 pagesDesigning Low Retaining WallsRoscii RulezNo ratings yet

- PRESTRESSED CONCRETE: INTRODUCTION TO THEORY AND PROCESSDocument135 pagesPRESTRESSED CONCRETE: INTRODUCTION TO THEORY AND PROCESSNishant AgrawalNo ratings yet

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- Deep Basements & Cut & Cover - 2Document113 pagesDeep Basements & Cut & Cover - 2bsitler100% (2)

- Introduction To Prestressed ConcreteDocument27 pagesIntroduction To Prestressed ConcreteDarlene Kate MonterdeNo ratings yet

- Bored Pile Retaining Wall Systems for Basements & InfrastructureDocument2 pagesBored Pile Retaining Wall Systems for Basements & InfrastructurejdkelleyNo ratings yet

- 2013 Ud Elective Ashok BhairiDocument12 pages2013 Ud Elective Ashok BhairivaishnaviNo ratings yet

- High-strength concrete explained for tall buildingsDocument5 pagesHigh-strength concrete explained for tall buildingsGlyrah Marie Dela TorreNo ratings yet

- Research I Reinforcement Concrete II Prestressed Reinforced ConcreteDocument6 pagesResearch I Reinforcement Concrete II Prestressed Reinforced ConcreteHamez HabibiNo ratings yet

- Reinjectable Waterstop System for Concrete JointsDocument11 pagesReinjectable Waterstop System for Concrete JointsSam Roger100% (1)

- Concrete Crib Walls Provide Low-Cost Retaining Wall Option Under 40 CharactersDocument4 pagesConcrete Crib Walls Provide Low-Cost Retaining Wall Option Under 40 CharactersJulie BajadoNo ratings yet

- Precast ConcreteDocument69 pagesPrecast Concretejaffna100% (2)

- CE 7 - Construction Methods - ConcreteDocument34 pagesCE 7 - Construction Methods - ConcreteAprille EllenNo ratings yet

- Prestrest ConcreteDocument6 pagesPrestrest ConcreteWan ImranNo ratings yet

- Precast ConcreteDocument8 pagesPrecast ConcreteHemant VermaNo ratings yet

- TKBT Anchor EquipmentDocument32 pagesTKBT Anchor EquipmentLuca Brandi100% (1)

- Concrete diaphragm slurry walls PA conferenceDocument18 pagesConcrete diaphragm slurry walls PA conferenceJosé Chávez100% (3)

- Saint Louis College: BT3 (AR A315D)Document9 pagesSaint Louis College: BT3 (AR A315D)Dennis Roel T. DulayNo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteMonica Reddy Mainampati100% (3)

- Types of Embedded Earth Retaining WallsDocument17 pagesTypes of Embedded Earth Retaining WallsTun Sheikh HambaleeNo ratings yet

- Industrial Building Architectural and Structural Design 1Document6 pagesIndustrial Building Architectural and Structural Design 1api-655156856No ratings yet

- Tilt Up Construction PDFDocument32 pagesTilt Up Construction PDFLauren Grant100% (2)

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteMariz Ellaine BaltazarNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentRemya R. KumarNo ratings yet

- Pre Stressed ConcreteDocument32 pagesPre Stressed ConcreteRon VoraNo ratings yet

- Construction Methods and Structures As Expression of Architectural DesignDocument19 pagesConstruction Methods and Structures As Expression of Architectural DesignRen MariNo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteSheryll de GuzmanNo ratings yet

- Pre Cast ConstructionDocument55 pagesPre Cast ConstructionAmalaNo ratings yet

- Sheet PilingDocument24 pagesSheet PilingniyatiNo ratings yet

- Prestressed ConcreteDocument32 pagesPrestressed ConcretejaffnaNo ratings yet

- 7 Concrete PavementDocument65 pages7 Concrete Pavementmarc edwin vergaraNo ratings yet

- PRESTRESSED CONCRETE: HISTORY, METHODS AND APPLICATIONSDocument12 pagesPRESTRESSED CONCRETE: HISTORY, METHODS AND APPLICATIONSSajithaNo ratings yet

- Waterproofing Techniques For Bored Tunnels: Crystalline SystemsDocument4 pagesWaterproofing Techniques For Bored Tunnels: Crystalline Systemskulbrsingh4975No ratings yet

- The TermDocument29 pagesThe TermAngelica CatungalNo ratings yet

- Supercast PVCDocument8 pagesSupercast PVCVenkata RaoNo ratings yet

- Repair RehabilitationDocument16 pagesRepair RehabilitationbaburshahmandozaiNo ratings yet

- BUILDING CONSTRUCTION RESEARCH PICCDocument17 pagesBUILDING CONSTRUCTION RESEARCH PICCMachalyn Chua50% (2)

- Precast Cladding Panel BenefitsDocument12 pagesPrecast Cladding Panel BenefitsShreenidhi JoshiNo ratings yet

- Precast Concrete23Document37 pagesPrecast Concrete23Nisshant Singh SaudNo ratings yet

- Expansion Joints in RoofingDocument10 pagesExpansion Joints in Roofingwaterproofing_bestNo ratings yet

- Prefabricated ConcreteDocument17 pagesPrefabricated ConcreteNishimaNo ratings yet

- Precast Construction: Prepared By: Parth S. Patel SD1510Document55 pagesPrecast Construction: Prepared By: Parth S. Patel SD1510Gireesh Gowda GiriNo ratings yet

- Cast-In-Place Concerte WallsDocument3 pagesCast-In-Place Concerte WallsInzaghi BirdNo ratings yet

- Supercast PVCDocument4 pagesSupercast PVCVenkata Raju KalidindiNo ratings yet

- Methods of Prestressing Concrete StructuresDocument32 pagesMethods of Prestressing Concrete StructuresVinayaga Murthy GNo ratings yet

- Diaphragm Walls, Cut-Off Walls and Slurry Walls: Implenia Spezialtiefbau GMBHDocument9 pagesDiaphragm Walls, Cut-Off Walls and Slurry Walls: Implenia Spezialtiefbau GMBHNemanja BralovicNo ratings yet

- Soil Stabilization: Benefits CostDocument5 pagesSoil Stabilization: Benefits CostMizs' DewieNo ratings yet

- Precast Castinplace ConcreteDocument61 pagesPrecast Castinplace ConcreteNeanderthalNo ratings yet

- Cast in Place SystemsDocument4 pagesCast in Place SystemsMariel Paz MartinoNo ratings yet

- Mall of Asia Construction MethodsDocument10 pagesMall of Asia Construction MethodsCarla Madlangbayan MalenabNo ratings yet

- Post Tension StructuresDocument10 pagesPost Tension Structurestwinkle4545No ratings yet

- Damp Proof Paper 101019Document13 pagesDamp Proof Paper 101019Tamilchelvam MurogayahNo ratings yet

- PRECAST ELEMENTS REPORTDocument17 pagesPRECAST ELEMENTS REPORTpradz4No ratings yet

- 265 Reinforced Concrete Box and Three-Sided Culverts: 265.1 GeneralDocument14 pages265 Reinforced Concrete Box and Three-Sided Culverts: 265.1 GeneralNatiNo ratings yet

- BT 5Document3 pagesBT 5Earl UbiñaNo ratings yet

- URBAN DESIGN unit-IVDocument16 pagesURBAN DESIGN unit-IVmrunalini KolaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

- Seismic Design of Steel BuildingDocument1 pageSeismic Design of Steel BuildinghamadaniNo ratings yet

- Earthquake EN PDFDocument128 pagesEarthquake EN PDFDebasisMohapatraNo ratings yet

- Endochronic ModelingDocument46 pagesEndochronic ModelinghamadaniNo ratings yet

- ANSYS Advantage V5 I3 2011Document52 pagesANSYS Advantage V5 I3 2011j_c_garcia_dNo ratings yet

- Paper FeraboliDocument33 pagesPaper FeraboliTatiana KalininaNo ratings yet

- CompositesDocument1 pageCompositeshamadaniNo ratings yet

- Seismic Design To S16-09 PDFDocument13 pagesSeismic Design To S16-09 PDFDarryn McCormickNo ratings yet

- Ansyscapabilities180 PDFDocument21 pagesAnsyscapabilities180 PDFhamadaniNo ratings yet

- Buyer's Guide For Top Running & Gantry Type Multiple Girder Electric Overhead Traveling CranesDocument24 pagesBuyer's Guide For Top Running & Gantry Type Multiple Girder Electric Overhead Traveling CraneshamadaniNo ratings yet

- Applsci 09 00946 Pressure PulsationDocument21 pagesApplsci 09 00946 Pressure PulsationhamadaniNo ratings yet

- Applsci-09-00946 Pressure Pulsation 1 PDFDocument21 pagesApplsci-09-00946 Pressure Pulsation 1 PDFhamadaniNo ratings yet

- Ansys Release 9 PresentationDocument93 pagesAnsys Release 9 PresentationhamadaniNo ratings yet

- Cantilever End LoadDocument7 pagesCantilever End LoadgayathridharshiniNo ratings yet

- Parametric PDFDocument20 pagesParametric PDFhamadaniNo ratings yet

- Buyer's Guide For Top Running & Gantry Type Multiple Girder Electric Overhead Traveling CranesDocument24 pagesBuyer's Guide For Top Running & Gantry Type Multiple Girder Electric Overhead Traveling CraneshamadaniNo ratings yet

- Specifications For Top Running Bridge & Gantry Type Multiple Girder Electric Overhead Traveling CranesDocument8 pagesSpecifications For Top Running Bridge & Gantry Type Multiple Girder Electric Overhead Traveling CraneshamadaniNo ratings yet

- The US ConstitutionDocument1 pageThe US ConstitutionhamadaniNo ratings yet

- Classical LiberalismDocument1 pageClassical LiberalismhamadaniNo ratings yet

- Fracture MechanicsDocument1 pageFracture MechanicshamadaniNo ratings yet

- Material FatigueDocument1 pageMaterial FatiguehamadaniNo ratings yet

- Legacy Clusters: Fluent Job SubmissionDocument1 pageLegacy Clusters: Fluent Job SubmissionhamadaniNo ratings yet

- Fatigue Tutorial v81Document11 pagesFatigue Tutorial v81cooljovinNo ratings yet

- Seismic Behaviour of Historic Masonry BuildingsDocument13 pagesSeismic Behaviour of Historic Masonry BuildingshamadaniNo ratings yet

- Tightening Torque GuideDocument2 pagesTightening Torque Guideoct3178No ratings yet

- 2006 Int Ansys Conf 43Document9 pages2006 Int Ansys Conf 43bathinsreenivasNo ratings yet

- FEA TheoryDocument49 pagesFEA Theoryof_switzerlandNo ratings yet

- Von MisesDocument1 pageVon MiseshamadaniNo ratings yet

- EarthquakesDocument1 pageEarthquakeshamadaniNo ratings yet

- Introduction To FEADocument20 pagesIntroduction To FEAhamadaniNo ratings yet

- Data StructuresDocument1 pageData StructureshamadaniNo ratings yet

- Concrete ClothDocument21 pagesConcrete ClothFasee UllahNo ratings yet

- CMV Fracture Toughness ArticleDocument10 pagesCMV Fracture Toughness ArticleFlo RenceNo ratings yet

- UP Technical University Mechanical Engineering SyllabusDocument18 pagesUP Technical University Mechanical Engineering SyllabusChetan SwaroopNo ratings yet

- 1 - Final Attic Stock MonitoringDocument1 page1 - Final Attic Stock MonitoringJQ INTERNATIONAL CONSTRUCTION COMPANYNo ratings yet

- 1007 Top PlateDocument1 page1007 Top PlateAanand SinghiNo ratings yet

- Pipe Rack Design PhilosophyDocument14 pagesPipe Rack Design PhilosophyFarhan DanishNo ratings yet

- Mylar Type A - Datasheet - 1 - ReleasedDocument2 pagesMylar Type A - Datasheet - 1 - ReleasedpqockqNo ratings yet

- Astm A500-3Document1 pageAstm A500-3asnawi89No ratings yet

- Properties and Uses of Zinc MetalDocument9 pagesProperties and Uses of Zinc Metalshahin azNo ratings yet

- Jaquar FaucetsDocument20 pagesJaquar Faucetssonalsonal303No ratings yet

- Hydraulic ForkliftDocument52 pagesHydraulic Forkliftsiddharth100% (3)

- OPSS - PROV 903 Apr16Document24 pagesOPSS - PROV 903 Apr16Mark PermaulNo ratings yet

- A Seminar Report On Affordable Rapid Mass Housing Using GFRG PanelsDocument26 pagesA Seminar Report On Affordable Rapid Mass Housing Using GFRG PanelsSuman90% (29)

- Mainspring DynamicsDocument10 pagesMainspring Dynamicsmszlazak4179No ratings yet

- Sabroe Product Profile: / - Get Refrigeration RightDocument24 pagesSabroe Product Profile: / - Get Refrigeration RightVadimNo ratings yet

- Solution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHDocument62 pagesSolution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHJohn A. CenizaNo ratings yet

- 22 Cryometrix Ultra Low Temp Freezers - End UserDocument11 pages22 Cryometrix Ultra Low Temp Freezers - End Userapi-220622714No ratings yet

- Asahi Wafer Check ValveDocument1 pageAsahi Wafer Check ValveDuy Nguyen DucNo ratings yet

- Viscoelastic Finite Element Evaluation of Transient and Residual Stresses in Dental Crowns Design Parametric StudyDocument14 pagesViscoelastic Finite Element Evaluation of Transient and Residual Stresses in Dental Crowns Design Parametric StudyLinda Garcia PNo ratings yet

- Carbon Carbon CompositesDocument4 pagesCarbon Carbon CompositesHuzaifa ShabbirNo ratings yet

- Ce2202 - Mechanics of FluidsDocument3 pagesCe2202 - Mechanics of FluidsPrashant GaradNo ratings yet

- Widmanst Atten Ferrite: Materials Science & Metallurgy Part II Course C9, AlloysDocument3 pagesWidmanst Atten Ferrite: Materials Science & Metallurgy Part II Course C9, AlloysfdcarazoNo ratings yet

- Pushover AnalysisDocument12 pagesPushover AnalysisabdulmananNo ratings yet

- Condensing and Cooling Efficiently with Adiabatic SystemsDocument17 pagesCondensing and Cooling Efficiently with Adiabatic SystemsIon ZabetNo ratings yet

- Non-Ferrous Alloys and Structure-Properties RelationshipsDocument12 pagesNon-Ferrous Alloys and Structure-Properties RelationshipstareasgratisNo ratings yet

- Geometric Shape Imperfections in Welding - Causes and Acceptance StandardsDocument16 pagesGeometric Shape Imperfections in Welding - Causes and Acceptance StandardsGabriel PanaNo ratings yet

- Brochure Sugar IndustryDocument2 pagesBrochure Sugar Industrykamals55No ratings yet

- Prevent Heat Exchanger Corrosion with PoluAl XT CoatingDocument2 pagesPrevent Heat Exchanger Corrosion with PoluAl XT CoatingOlaf MartingNo ratings yet

- Fastenr GradesDocument5 pagesFastenr GradesVipul ShereNo ratings yet

- Reinforcing Plate Vessel Shell: API 579-1/ASME FFS-1 2016 Fitness-For-ServiceDocument60 pagesReinforcing Plate Vessel Shell: API 579-1/ASME FFS-1 2016 Fitness-For-ServiceALEXANDER ALFONSO100% (1)