Professional Documents

Culture Documents

Crane Component Selection Chart

Uploaded by

singh_amandeepCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Component Selection Chart

Uploaded by

singh_amandeepCopyright:

Available Formats

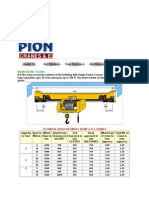

CRANE DUTY GEAR BOX SELECTION CHART

S. NO. 1 2 3 4 5 6 7 8 9

SAFE WORKI NG LOAD (TONNES) 3 5 7.5 10 12.5 15 20 25 30

CENTER DISTANCE OF INPUT-OU TPUT OF GEAR BOX(MM) 350 475 650 650 700 800 800 950 1100

GEAR COUPLING SELECTION CHART

S.NO. 1 2 3 4 5 6 7 8 9

SAFE WORKI NG LOAD (TONNES) 3 5 7.5 10 12.5 15 20 25 30

HOISTING 101 102 102 103 103 103 103,104 104 105

LT/CT 100 101 101 102 102 103 103 103 014

EHT BRAKE SELECTION CHART

S.NO. 1 2 3 4 5 6 7 8 9 10

MOTOR HP , 6 POLE 2 3.5 6 9 12 18 23.5 33 41.5 48

RPM 915 943 950 967 968 970 972 975 978 982

LT/CT 100/18 100/18 100/18 160/18 200/18 200/18 200/18 200/34 250/18 --

HOISTING 100/18 100/18 160/18 200/18 200/18 200/34 200/34 250/34 300/34 300/34

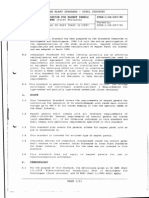

HOISTING MOTOR CALCULATION AS PER IS 3177

Where, M = Mass of the hook assembly plus the rated safe working load of the crane, in Tonnes V = Free running speed in metres/minute Cv=Service Factor for Vertical Motion, 0.67 for AC Motors, 0.5 for DC Motors Cdf=Duty Factor as per Class of Duty Values in Table below Class of Duty I II III IV m = Number of Pairs of Gears n = Number of Rotating Sheaves, passed over by each part of rotating rope attached to the drum Camb=Derating Factor depending upon the Ambient Temperature of operation as in Table below Cdf For Vertical Motion 1.32 1.50 1.60 1.60

Ambient Temperature of operation of Crane 40C 45C 50C 55C 60C

Camb 1.00 0.95 0.88 0.83 0.75

HOISTING MOTOR SELECTION CHART FOR COMMON SWLs ASSUMPTIONS :Hoisting Speed Class of Duty Ambient Temperature Motor S.NO. 1 2 3 4 5 6 7 8 9 : 5 meters / minute : III : 40C : 40 % CDF, 6 Pole SWL, Tonnes 3 5 7.5 10 12.5 15 20 25 30 COMPUTED MOTOR KW, 4 FALLS 3.02 5.35 8.05 10.76 13.42 16.09 21.43 --COMPUTED MOTOR KW, 6 FALLS ----13.70 16.41 21.87 28.75 34.49 COMPUTED MOTOR KW, 6 FALLS -----16.75 22.31 29.33 35.19

6-Pole, Slipring,CDF 40% KW 1.5 1.8 2.6 4.5 6.7 9 13.2 17.6 24.6 30.5 36 42 53.5 66 93 116 HP 2 2.4 3.5 6 9 12 17.5 24 33 41 48 56 72 89 126 156 RPM 935 920 925 925 960 940 950 960 970 970 965 980 975 975 980 979 KW 0.17 0.37 0.55 0.75 1.1 1.5 2.2 3.7 5.5 7.5 9.3 11 15 18.5

6-Pole, SQ Cage, CDF40% HP 0.23 0.50 0.74 1.01 1.48 2.01 2.95 4.96 7.38 10.06 12.47 14.75 20.12 24.81 RPM 865 880 890 890 935 880 900 910 925 920 970 970 970 975

MOTOR CALCULATION FORMULA HORIZONTAL MOTION IN CRANES AS PER IS 3177

Where, M = Mass of the crane or trolley plus the rated safe working load of the crane, in Tonnes V = Free running speed in metres/minute

s = Service Factor for Motor Plugging, 0.95 for motors without plugging and 1 for motors with plugging

Cdf=Duty Factor as per Class of Duty Values in Table below Class of Duty I II III IV Cdf For Horizontal Motion 1.12 1.25 1.40 1.50

T = 1.7 for motors having Pull out Torque of 275% of their Full Load Torque F = Overall Friction Factor, 8 Kgf per tonne for wheels on Anti Friction Bearings a = Average Linear Acceleration Factor as per Table Below Condition Speed to be reached in meters/minute 240 190 150 120 100 60 40 25 15 10 Acceleration in cm/sec , Low and Moderate Speed ---22 19 15 12 10 8 7

2 2 2

Acceleration in cm/sec , Moderate and high Speed (Normal Application) 50 44 39 35 32 25 19 16 ---

Acceleration in cm/sec , for High Speed with High Acceleration 67 58 52 47 43 33 -----

N =Mechanical Efficiency of Gearing, For Spur and Helical Gearing it can be taken as 0.95 per reduction

CT MOTOR SELECTION CHART FOR COMMON SWLs ASSUMPTIONS :Class of Duty Reduction of Gear Box Motor : III : Two Stage : 40 % CDF, 6 Pole, without plugging

Safe Working Load, Tonnes 3 5 7.5 10 12.5 15 20 25 30

KW @ 15 mpm, low acceleration 0.28 0.93 1.79 2.71 4.33 6.01 9.82 15.03 20.22

KW @ 25 mpm, low acceleration 0.48 1.58 3.02 4.57 7.28 10.09 16.46 25.17 33.83

KW @ 25 mpm, moderate acceleration 0.53 1.67 3.14 4.72 7.46 10.32 16.74 25.52 34.24

You might also like

- Crane wheel load data calculationDocument1 pageCrane wheel load data calculationJebin JacobNo ratings yet

- Approval Return Status DocumentDocument17 pagesApproval Return Status Documentsatendra sharmaNo ratings yet

- Conveyor Speed Calculation: ResultsDocument2 pagesConveyor Speed Calculation: ResultsyusefriNo ratings yet

- Rotating TrolleyDocument12 pagesRotating TrolleyInderdeep TatlaNo ratings yet

- Hoist DesignDocument16 pagesHoist DesignluisparedesNo ratings yet

- Conveyor CapacityDocument3 pagesConveyor Capacityx30patelNo ratings yet

- 2015 12 SCM EngDocument33 pages2015 12 SCM EngkqNo ratings yet

- Basic Study - Cranes and Hoist PDFDocument7 pagesBasic Study - Cranes and Hoist PDFKUNALJAYNo ratings yet

- Design and Fabrication of Pneumatic Crane StartDocument6 pagesDesign and Fabrication of Pneumatic Crane StartHimani MahetaNo ratings yet

- Design of Cane Carrier Roller Conveyor Chain of 150MM Pitch and Testing Under UtmDocument7 pagesDesign of Cane Carrier Roller Conveyor Chain of 150MM Pitch and Testing Under UtmIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- 1996 Edition Part-3 Under Ground Coal Mining IdlersDocument14 pages1996 Edition Part-3 Under Ground Coal Mining Idlersyadiki1964No ratings yet

- Salary Break-Up DesignDocument4 pagesSalary Break-Up Designjeet0394No ratings yet

- Modular Spreader BeamsDocument13 pagesModular Spreader BeamsyogihardNo ratings yet

- Calculate motor power for 35t LRF transfer carDocument2 pagesCalculate motor power for 35t LRF transfer carmech_abhiNo ratings yet

- ABB Drive Selection GuideDocument12 pagesABB Drive Selection Guideprasad_rvsNo ratings yet

- 3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFDocument1 page3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFpawan100% (1)

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- 5T X 25.5m DG CraneDocument10 pages5T X 25.5m DG CraneRv VaghasiaNo ratings yet

- Bevel Helical Cooling Tower Gear Box GuideDocument16 pagesBevel Helical Cooling Tower Gear Box GuideR BhattacharyaNo ratings yet

- Aerospace Composite AutoclaveDocument7 pagesAerospace Composite Autoclaveaecsuresh35No ratings yet

- Passenger and Material Hoist According To TRA 1100 / EN 12159Document2 pagesPassenger and Material Hoist According To TRA 1100 / EN 12159PhanHathamNo ratings yet

- Cooling Tower FundamentalsDocument78 pagesCooling Tower FundamentalsHamid ArizNo ratings yet

- CENTERLINE Butterfly Valves GuideDocument29 pagesCENTERLINE Butterfly Valves GuideNNNo ratings yet

- Hopper Calculation-9Document1 pageHopper Calculation-9Ujwal KhandokarNo ratings yet

- Beam Deflection CalculationDocument2 pagesBeam Deflection CalculationAriful IslamNo ratings yet

- The Basics of The Calculations of Conveyor Belt Design ParametersDocument5 pagesThe Basics of The Calculations of Conveyor Belt Design ParametersHITESH GAHLOTNo ratings yet

- WWW Mechanicalengineeringblog Com 2Document6 pagesWWW Mechanicalengineeringblog Com 2Mashudi FikriNo ratings yet

- Pipe Incompresable Fluid Pressure Drop Calculations: Input DataDocument9 pagesPipe Incompresable Fluid Pressure Drop Calculations: Input DataPratik KachalwarNo ratings yet

- Crane Guide 2 E5 PDocument6 pagesCrane Guide 2 E5 PsergiooiNo ratings yet

- Tico Excellent Floor Mounted Jib Crane Hoist Features: Special Design: Box Type Support Frame DesignDocument4 pagesTico Excellent Floor Mounted Jib Crane Hoist Features: Special Design: Box Type Support Frame DesignRommellNo ratings yet

- Conical Base Cylindrical PE Tanks SpecsDocument4 pagesConical Base Cylindrical PE Tanks SpecsAmoolia Ngo0% (1)

- Calculation of Working Moment & Power For Vibrating Grizzly FeederDocument1 pageCalculation of Working Moment & Power For Vibrating Grizzly FeederzahoorNo ratings yet

- Endcarriage - KZL-S 315Document116 pagesEndcarriage - KZL-S 315Josip Nuno CoricNo ratings yet

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- Check List To Select GearboxDocument4 pagesCheck List To Select Gearboxsammas0988No ratings yet

- Helix Dynamic Sample Conveyor CV202 5500tph ST4500 3x1000kW 500kgm2 Flywheels ISODocument39 pagesHelix Dynamic Sample Conveyor CV202 5500tph ST4500 3x1000kW 500kgm2 Flywheels ISOthiemxmcpNo ratings yet

- Circlip For Bores-3075 - 2 PDFDocument12 pagesCirclip For Bores-3075 - 2 PDFRajasekaran MuruganNo ratings yet

- Nominal Size 15mm (/ In) : Flange TablesDocument19 pagesNominal Size 15mm (/ In) : Flange TablesSagirahmed Ansari100% (1)

- Md-17 Shaft Design StepsDocument12 pagesMd-17 Shaft Design StepsRamji RaoNo ratings yet

- 25.rotary Actuator CalculationDocument12 pages25.rotary Actuator Calculationcarthik_babu100% (1)

- Indian StandardDocument108 pagesIndian StandardAlvin SmithNo ratings yet

- Agitator Guide for Mixing and Stirring Tank ProductsDocument10 pagesAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591No ratings yet

- Skid Frame Calculation Sheet: LPG MeteringDocument11 pagesSkid Frame Calculation Sheet: LPG MeteringidilfitriNo ratings yet

- External Gear Pump Parameter Calculation SheetDocument3 pagesExternal Gear Pump Parameter Calculation SheetsahirprojectsNo ratings yet

- Crane Solutions and ModelsDocument24 pagesCrane Solutions and ModelsAmandeep NandaNo ratings yet

- 5-50t Electric Hook Overhead CraneDocument28 pages5-50t Electric Hook Overhead Cranemohamed100% (1)

- Crane Design DataDocument4 pagesCrane Design DatapradeepqNo ratings yet

- DFC Install MaintDocument40 pagesDFC Install MaintAvinash Gamit100% (1)

- Measuring Flow with a Venturi MeterDocument11 pagesMeasuring Flow with a Venturi MeterPrakein RajNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Water Pump Pressure Control Switch Adjustment Nut Direction1Document12 pagesWater Pump Pressure Control Switch Adjustment Nut Direction1ver_at_workNo ratings yet

- CEMA 6 Belt Conveyors Belt AlignmentDocument2 pagesCEMA 6 Belt Conveyors Belt Alignmentali kajbafNo ratings yet

- CasoEstudio PervaporaciónDocument17 pagesCasoEstudio PervaporaciónValentina SánchezNo ratings yet

- Gosan - Barrel Coupling - AGBSDocument7 pagesGosan - Barrel Coupling - AGBSAndré RosolemNo ratings yet

- Design Loads and Components of Gantry GirdersDocument54 pagesDesign Loads and Components of Gantry GirdersKatherine StuartNo ratings yet

- GALVI Shoe Brakes BrochureDocument53 pagesGALVI Shoe Brakes BrochureCANH NGUYENNo ratings yet

- Heavy Duty Conveyor Pulley CatalogDocument100 pagesHeavy Duty Conveyor Pulley Catalogkosmc123No ratings yet

- Hydraulic AcuatorDocument32 pagesHydraulic AcuatorM S Gokul100% (1)

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- Motor M2BA Cat. 315 355 Frame PGDocument5 pagesMotor M2BA Cat. 315 355 Frame PGdhaval3gNo ratings yet

- Price List For Bearings For A 10 T EOT Crane, URBDocument1 pagePrice List For Bearings For A 10 T EOT Crane, URBsingh_amandeepNo ratings yet

- Major steel plants and induction furnace manufacturers in IndiaDocument4 pagesMajor steel plants and induction furnace manufacturers in Indiasingh_amandeepNo ratings yet

- Jfe Eh SteelDocument16 pagesJfe Eh SteelAnonymous ueh2VMT5GNo ratings yet

- StiffenerDocument11 pagesStiffenerAdigwe George ChimaNo ratings yet

- StiffenerDocument11 pagesStiffenerAdigwe George ChimaNo ratings yet

- AMCDocument3 pagesAMCsingh_amandeepNo ratings yet

- Application of Planetary Reduction Gear in Operation of The Two Rope GrabDocument5 pagesApplication of Planetary Reduction Gear in Operation of The Two Rope GrabSumanth VasistaNo ratings yet

- Major steel plants and induction furnace manufacturers in IndiaDocument4 pagesMajor steel plants and induction furnace manufacturers in Indiasingh_amandeepNo ratings yet

- Technical Catalogue Bearings NBCDocument109 pagesTechnical Catalogue Bearings NBCBhusarapu Srinivas50% (2)

- SPECIFICATIONDocument13 pagesSPECIFICATIONsingh_amandeepNo ratings yet

- Crane TipsDocument10 pagesCrane TipskhayagskiNo ratings yet

- Rites TenderDocument60 pagesRites Tendersingh_amandeepNo ratings yet

- Crane TipsDocument10 pagesCrane TipskhayagskiNo ratings yet

- AMCDocument3 pagesAMCsingh_amandeepNo ratings yet

- Crane Hook Design PDFDocument39 pagesCrane Hook Design PDFsunil48150% (4)

- Design Analysis-Jib CraneDocument22 pagesDesign Analysis-Jib Cranesainal100% (3)

- 1 04 037 99Document11 pages1 04 037 99singh_amandeepNo ratings yet

- ShabadsDocument1 pageShabadssingh_amandeepNo ratings yet

- Dimensiuni NPTDocument2 pagesDimensiuni NPTGrosu CosminNo ratings yet

- GearboxesDocument24 pagesGearboxesPrithviraj Daga100% (2)

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Jakob's Ten Usability Heuristics: Nielsen Norman GroupDocument11 pagesJakob's Ten Usability Heuristics: Nielsen Norman GroupPiyush ChauhanNo ratings yet

- IP BookDocument96 pagesIP Booknew mediaNo ratings yet

- Niche PartitioningDocument3 pagesNiche PartitioningKhang LqNo ratings yet

- 2017 09Document164 pages2017 09sowabar100% (1)

- CS4000 Data SheetDocument6 pagesCS4000 Data SheetJuan Luis EspinosaNo ratings yet

- Phase-Field Models For The Evolution of Complex SystemsDocument37 pagesPhase-Field Models For The Evolution of Complex SystemsMathis PlappNo ratings yet

- M & E Eyerusalem TesfayeDocument12 pagesM & E Eyerusalem Tesfayeeyerusalem tesfayeNo ratings yet

- Floor Heating Controls Wiring Instructions for FS and BA Master Weather CompensationDocument12 pagesFloor Heating Controls Wiring Instructions for FS and BA Master Weather Compensationjamppajoo2No ratings yet

- A Thesis 123Document77 pagesA Thesis 123Meli SafiraNo ratings yet

- Improved Sleep, Cognitive Processing and Enhanced Learning and Memory Task Accuracy With Yoga Nidra Practice in NovicesDocument19 pagesImproved Sleep, Cognitive Processing and Enhanced Learning and Memory Task Accuracy With Yoga Nidra Practice in Novicessankar ganeshNo ratings yet

- Ms Word McqsDocument12 pagesMs Word McqsUraiBa AnsaRi0% (1)

- Hyponymy and Hypernymy: Jump To Navigationjump To SearchDocument8 pagesHyponymy and Hypernymy: Jump To Navigationjump To SearchSteven HamNo ratings yet

- Frankfurt School taxes and ideology critiqueDocument5 pagesFrankfurt School taxes and ideology critiqueErnesto BulnesNo ratings yet

- Particulate Contamination in Aviation Fuels by Laboratory FiltrationDocument11 pagesParticulate Contamination in Aviation Fuels by Laboratory FiltrationMuhammad KhairuddinNo ratings yet

- From Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheDocument31 pagesFrom Self Disorders To The Schizophrenic Self: Riccardo Piero Dalle LucheMichel de NostredameNo ratings yet

- Airtel Case Study Channel StrategyDocument2 pagesAirtel Case Study Channel StrategyTushar GuptaNo ratings yet

- Floor Boxes and Power Supplies OverviewDocument32 pagesFloor Boxes and Power Supplies OverviewAbdoNo ratings yet

- Viking Tech ARG03FTC2551 - C217943Document8 pagesViking Tech ARG03FTC2551 - C217943ALIRIO SOLANONo ratings yet

- Tester Sursa Gembird CHM 03 ManualDocument15 pagesTester Sursa Gembird CHM 03 Manualzavaidoc70No ratings yet

- To Signals and SystemsDocument57 pagesTo Signals and SystemsMUHAMMAD HAFIZUDDINNo ratings yet

- List of Syonoyms: Word Synonym SynonymDocument6 pagesList of Syonoyms: Word Synonym SynonymPraveen KumarNo ratings yet

- Exercise 7 - The Avian EggDocument5 pagesExercise 7 - The Avian EggSebastian SmytheNo ratings yet

- The Ultimate Guide to Building an Engaged CommunityDocument24 pagesThe Ultimate Guide to Building an Engaged CommunityCarla UttermanNo ratings yet

- Manifest Merger Debug ReportDocument14 pagesManifest Merger Debug ReportRam PankhaniyaNo ratings yet

- Student's Guide To Year 9 and 10 Science (Stage 5)Document38 pagesStudent's Guide To Year 9 and 10 Science (Stage 5)dan964100% (1)

- 12 New Trends in ManagementDocument18 pages12 New Trends in ManagementSaqib IqbalNo ratings yet

- 1st Periodic Test - Math 9Document2 pages1st Periodic Test - Math 9Anna Rose Godes AntioquiaNo ratings yet

- JURNALfidyaDocument20 pagesJURNALfidyaIrma NasridaNo ratings yet

- Vspa 50Document5 pagesVspa 50elfo111No ratings yet

- 330 Computer Reset AddendumDocument75 pages330 Computer Reset AddendumA WongNo ratings yet