Professional Documents

Culture Documents

Inspection and Testing Plan (En) - 18.01.10

Uploaded by

Thi PhamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Testing Plan (En) - 18.01.10

Uploaded by

Thi PhamCopyright:

Available Formats

INSPECTION AND TESTING PLAN (ITP)

Doc. No.: QF-QC-17 Issue Date: 18/01/10 Rev: 1 Page: 1 of 2

Job # / Project name: _____________________________ Job Site Location: _______________________________ Customer: ______________________________________ Reference specifications: MBMA ------------Metal Building Manufacturers Association IBC ---------------- International Building Code AWS D 1.1 ------- American Welding Society SSPC -------------- Steel Structures Painting Council ASTM--------------American Society for Testing and Materials AISC----------------American Institute of Steel Construction

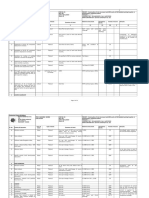

Sr #

Stage of Production Material Selection and Verification: Plates, Sheets, hot and cold rolled shapes, tubular, fasteners, etc. Welding: WPS /PQR, WPQR

Applicable Specification / Procedures 1. ASTM standards or equiv. 2. AISC Codes & Standards 3. AWS D1.1 (2006) AWS D1.1 (2006) 1. Shop Drawings 2. MBMA 3. Standard Fab. tolerances 1.Shop Drawings 2.AWS D1.1 (2006) 3.MBMA 4.Standard Fab Tolerances. Web Flange fillet weld shall be single side welding (unless noted otherwise)

Activity Extent of Inspection Record / Forms # PEB 1. Dimensional 5% 2. Review of MTRs -100% 3. Visual 30% Review & Verification 100% 1. Visual 25% 2. Dimensional 25% CUST.

1.

1. PO 2. QF QC 01 & 02

I/R/H

DR

2.

3.

Preparation Stage

Approved WPS/PQR, WPQR 1. Shop Drawings 2. QF QC 08

DR

W/I

DR

4.

Fabrication: Built up, Cold Formed & Roll Formed.

1. Visual 25% 2. Dimensional 25%

1. Shop Drawings 2. QF QC 07, 08 & 09

W/I

DR

INSPECTION AND TESTING PLAN (ITP)

Doc. No.: QF-QC-17 Issue Date: 18/01/10 Rev: 1 Page: 2 of 2

Sr #

Stage of Production

Applicable Specification / Procedures 1. AWS D1.1 (2006) 2. Standard Weld Map (Unless Note Otherwise) 1. AWS D1.1 (2006)

Activity Extent of Inspection Record / Forms # PEB CUST.

5.

In Process Welding

1. Visual 100% 2. Dimensional 25%

1. QF QC-14

W/I/H

RI

6.

NDT other than visual: UT for

1. UT 10%

10mm butt joint

7. Surface Preparation & Painting 1. PIF 2. SSPC 1. Visual 100% 2. DFT Gauging 10%

1. QF-QC-05 & 18 2. NDT report 1. QF-QC-06 2. QF-QC-12

W/H/R

DR

W/I

DR

8.

Final Inspection 1. Preparation for Shipment 2. Documentation

1. Shop Drawing

1. Visual 30% 1. Visual 20% 2. Review of documents 20%

1. QF-QC-13

W/I/H

RI

9.

Procedure QPRCSD-03

1. Shipping List

W/RI/SD

DR

Legend: R = Review W = Witness H = Hold Point I = Inspection MTR = Manufacturers Test Report P.O = Purchase Order DR = Document Review RI = Random Inspection S = Submit Document

You might also like

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- Site Audit FormDocument16 pagesSite Audit FormNasir IbrahimNo ratings yet

- ITP SampleDocument4 pagesITP SampleKarthik S100% (1)

- MarcoDocument1 pageMarcobimboNo ratings yet

- 7100 XXXX HDPEDocument2 pages7100 XXXX HDPEIgor IvanovskiNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Inspection and Test Plan: PT. People MecDocument3 pagesInspection and Test Plan: PT. People MecHaryanto RNo ratings yet

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocument5 pagesContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Quality Assurance and QA PlansDocument13 pagesQuality Assurance and QA PlansAKHIL JOSEPH100% (1)

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Itp TankageDocument7 pagesItp TankageIr FankovicNo ratings yet

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit SinghNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Installation of HVAC Damper Louver and AccessoriesDocument1 pageInstallation of HVAC Damper Louver and Accessoriesfmkhan21No ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Quality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Document12 pagesQuality Tools and Techniques-Cause - and - Effect - Diagram - Fall20Ashik ShariarNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- QSP-010 R0 QSP For Field Inspection & Test PlanDocument21 pagesQSP-010 R0 QSP For Field Inspection & Test PlanjennyNo ratings yet

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- SP 2154Document26 pagesSP 2154Anoop gokhaleNo ratings yet

- Quality PlanDocument40 pagesQuality PlanSakthi Kasi RajanNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0010 - A Surface Prepa and Painting Proce - Code BDocument72 pagesHFY 3800 0000 VED 192 QC PD 0010 - A Surface Prepa and Painting Proce - Code BMohamed FarisNo ratings yet

- Procedure Qualification RecordsDocument2 pagesProcedure Qualification RecordsRM ENTERPRISESNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Inspection and Test Plan For Storage TankDocument8 pagesInspection and Test Plan For Storage TankAndreas AlexanderNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Document Control Specialist Expeditor in Houston TX Resume Denise DaughertyDocument2 pagesDocument Control Specialist Expeditor in Houston TX Resume Denise DaughertyDeniseDaughertyNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemssojeckNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Iwp Cable Tray Installation Checklist: Appendix - 9Document3 pagesIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 pageVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNo ratings yet

- Asf Itp 1171 001Document7 pagesAsf Itp 1171 001el_sharkawy2011No ratings yet

- Dimensional Inspection Report: Sample Production Lot/BatchDocument1 pageDimensional Inspection Report: Sample Production Lot/BatchCristina TinaNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- Amal Hrsg-1 Project - Material Tracking Sheet: Procurement Manufacturing & Delivery StatusDocument4 pagesAmal Hrsg-1 Project - Material Tracking Sheet: Procurement Manufacturing & Delivery StatusNadim JilaniNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- Samples ITPDocument4 pagesSamples ITPHassan SajidNo ratings yet

- NDT As Per B31.3Document2 pagesNDT As Per B31.3invilink87No ratings yet

- InspectionTest Plan SampleDocument3 pagesInspectionTest Plan SampleWONG TSNo ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- Ul CalibrationrequirementsDocument7 pagesUl CalibrationrequirementsAlexandre HesslerNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDocument1 pageLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- QP SPC L 002 Rev 1Document80 pagesQP SPC L 002 Rev 1Vinod Kumar100% (3)

- Piping Design BasisDocument26 pagesPiping Design BasisAnjani Prabhakar100% (4)

- Larsen & Toubro Limited: Ecc DivisionDocument4 pagesLarsen & Toubro Limited: Ecc Divisionmanu_gite100% (2)

- 6.1 List of Qualified WeldersDocument1 page6.1 List of Qualified WeldersThi PhamNo ratings yet

- 4.2.welding ProcedureDocument5 pages4.2.welding ProcedureThi PhamNo ratings yet

- 3.1 Inspection & Testing ProgramDocument1 page3.1 Inspection & Testing ProgramThi PhamNo ratings yet

- 4.1 Welding Procedure SpecificationDocument1 page4.1 Welding Procedure SpecificationThi PhamNo ratings yet

- 5.1 Welding MapDocument1 page5.1 Welding MapThi PhamNo ratings yet

- 7.1 Various Inspection FormsDocument1 page7.1 Various Inspection FormsThi PhamNo ratings yet

- 3.2 Standard1Document1 page3.2 Standard1Thi PhamNo ratings yet

- 2 ContentsDocument1 page2 ContentsThi PhamNo ratings yet

- Pebs ManualDocument59 pagesPebs ManualThi Pham100% (6)

- Brochure AluPeb EnglishDocument8 pagesBrochure AluPeb EnglishThi PhamNo ratings yet

- 1 CoverDocument1 page1 CoverThi PhamNo ratings yet

- Panel ChartDocument2 pagesPanel ChartThi PhamNo ratings yet

- Marketing Letter-VN (Logo) - 07junDocument2 pagesMarketing Letter-VN (Logo) - 07junThi PhamNo ratings yet

- Insulation EnglishDocument4 pagesInsulation EnglishThi PhamNo ratings yet

- Brochure Thailand 36pagesDocument18 pagesBrochure Thailand 36pagesThi PhamNo ratings yet

- Brochure GreenforLifeDocument6 pagesBrochure GreenforLifeThi PhamNo ratings yet

- MBMA Fabricate & Erection Tolerance 18.01.10Document2 pagesMBMA Fabricate & Erection Tolerance 18.01.10Thi Pham100% (3)

- Updated Quality PlanDocument23 pagesUpdated Quality PlanThi PhamNo ratings yet

- Boltless System: V-500 V-600 V-650 V-650S V-750Document1 pageBoltless System: V-500 V-600 V-650 V-650S V-750Thi PhamNo ratings yet

- Waviness Tolerance 18.01.10Document1 pageWaviness Tolerance 18.01.10Thi PhamNo ratings yet

- Product SpanishDocument14 pagesProduct SpanishThi PhamNo ratings yet

- WhyPEB KRDocument4 pagesWhyPEB KRThi PhamNo ratings yet

- Brochure Thailand 36pagesDocument18 pagesBrochure Thailand 36pagesThi PhamNo ratings yet

- WhyPEB ChineseDocument4 pagesWhyPEB ChineseThi PhamNo ratings yet

- Fall Prevention and Protection Training (New)Document32 pagesFall Prevention and Protection Training (New)Thi PhamNo ratings yet

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- Green For LifeDocument6 pagesGreen For LifeThi PhamNo ratings yet

- whyPEB VNDocument4 pageswhyPEB VNThi PhamNo ratings yet

- WhyPEBSteel 2011Document4 pagesWhyPEBSteel 2011Thi PhamNo ratings yet

- Driver Manual Scania New - 1011 - en-GB PDFDocument905 pagesDriver Manual Scania New - 1011 - en-GB PDFfajardiniant100% (7)

- 1-Relative Velocity in Special Relativity: Page898 CollegeDocument26 pages1-Relative Velocity in Special Relativity: Page898 CollegeAbdulrhman fNo ratings yet

- Unit 3 Lateral Earth Pressure1Document19 pagesUnit 3 Lateral Earth Pressure1Julia FlorencioNo ratings yet

- COFMOW Compendium 2021-22 & 2022-23Document36 pagesCOFMOW Compendium 2021-22 & 2022-23Senior Divisional Mechanical Engineer100% (4)

- 18-Experiences With Nonsynchronous Forces Vibration Centrifugal Compressors - DRS&JCW PDFDocument0 pages18-Experiences With Nonsynchronous Forces Vibration Centrifugal Compressors - DRS&JCW PDFvcharlesNo ratings yet

- Astm A 490Document6 pagesAstm A 490Pedro Diaz UzcateguiNo ratings yet

- Mock Final ExamDocument15 pagesMock Final ExamMing SuNo ratings yet

- محاضرات هندسة الاساسات د. طارق نجيب P3Document42 pagesمحاضرات هندسة الاساسات د. طارق نجيب P3Hasan100% (2)

- Servo Gun v2.8 (Eng) ObaraDocument63 pagesServo Gun v2.8 (Eng) Obaralogaing13No ratings yet

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyDocument9 pages2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosNo ratings yet

- 315B Forest Swing Machine Electrical System: 7RZ284-UPDocument2 pages315B Forest Swing Machine Electrical System: 7RZ284-UPGilvan JuniorNo ratings yet

- Varaosat Landini Leyland SameDocument37 pagesVaraosat Landini Leyland SamehaiderNo ratings yet

- PDAM Detail JunctionDocument4 pagesPDAM Detail JunctionC. A. ArdhaniNo ratings yet

- Design Report FinalDocument68 pagesDesign Report FinalAsiri MihiranNo ratings yet

- Presentation On CFD Analysis of The Engine Room Ventilation System of A Ship Inland Cargo Ship (Dos) Inland Cargo Ship (Class)Document10 pagesPresentation On CFD Analysis of The Engine Room Ventilation System of A Ship Inland Cargo Ship (Dos) Inland Cargo Ship (Class)TARIQUL EMONNo ratings yet

- Pneumatic Valve - Viking Xtreme Series - Catalogue PDE2569TCUKDocument64 pagesPneumatic Valve - Viking Xtreme Series - Catalogue PDE2569TCUKBranko BabicNo ratings yet

- Wu-Performance of LS-DYNA Concrete Constitutive ModelsDocument14 pagesWu-Performance of LS-DYNA Concrete Constitutive ModelsaktcNo ratings yet

- Conectores Rele Arranque Aveo 2005Document3 pagesConectores Rele Arranque Aveo 2005Jose Luis Velasquez RomeroNo ratings yet

- (K), (M), (P) 480TB/G: Installation Instructions For Separable Tee Connector - Type C InterfaceDocument10 pages(K), (M), (P) 480TB/G: Installation Instructions For Separable Tee Connector - Type C InterfaceFrancisco Armando Contreras DeviaNo ratings yet

- Experimental Study of Pressure Gradients Occurring During Continuous TwoDocument2 pagesExperimental Study of Pressure Gradients Occurring During Continuous TwoAbdulrahman NasirudeenNo ratings yet

- Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation SheetDocument28 pagesCalculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheethyoung65No ratings yet

- Design and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj BanhattiDocument3 pagesDesign and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj Banhattidurgesh3guptaNo ratings yet

- Ch8. Welding Symbols PDFDocument66 pagesCh8. Welding Symbols PDFMEHMET SIDDIK TEKDEMİRNo ratings yet

- 1082019-1 CLA SIENZ (Frusan) PDFDocument19 pages1082019-1 CLA SIENZ (Frusan) PDFrodrigoNo ratings yet

- As Answers Camb 2003 June A Level Paper 1 2 9702-1-2Document3 pagesAs Answers Camb 2003 June A Level Paper 1 2 9702-1-2jmok92100% (1)

- Geely 16Document416 pagesGeely 16Ferran AlfonsoNo ratings yet

- Burns, Parry - Effect of Mean Shear Stress On The Fatigue IDocument9 pagesBurns, Parry - Effect of Mean Shear Stress On The Fatigue IDavid C HouserNo ratings yet

- Materials System SpecificationDocument9 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Installation of Rotating Equipment Rev.01Document17 pagesInstallation of Rotating Equipment Rev.01SefaNo ratings yet