Professional Documents

Culture Documents

2010mar Test1

Uploaded by

Portia ShilengeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2010mar Test1

Uploaded by

Portia ShilengeCopyright:

Available Formats

DEPARTMENT OF MECHANICAL ENGINEERING MARCH 2010 SEMESTER TEST 1

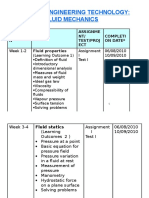

SUBJECT DURATION TOTAL MARKS FULL MARKS REQUISITES : : : : : SMT 101T/211T/SMM201T 90 MINS 50 50 2 = 100 Non-programmable pocket calculators and drawing instruments may be used. : : 2 0

NUMBER OF PAGES (INCLUDING THIS PAGE) ANNEXURES ATTACHED EXAMINERS: INSTRUCTIONS: ANSWER ALL QUESTIONS. D DESAI, L BENEKE

********************************************************************************** QUESTION 1 a) Explain briefly what you understand by the term creep. b) Define the term Poissons ratio. c) Explain the difference between true stress and engineering stress. QUESTION 2 The results of a tensile test on a mild steel specimen are as follows: original diameter = 20 mm; original gauge length = 40 mm; proportional limit load = 80 kN; extension at proportional limit = 0.048 mm; yield point load = 85 kN; maximum recorded load = 150 kN; final length between gauge points = 55.6 mm and final minimum diameter (neck) = 15.8 mm. Calculate: a) the modulus of elasticity for mild steel; b) the proportional limit stress; c) the ultimate tensile stress; d) the percentage elongation. (6) (3) (4) (2) [15] QUESTION 3 The inclined ladder AB supports a house painter (82 kg) at C and the self weight (q = 36 N/m) (3) (2) (3) [8]

of the ladder itself. Each ladder rail (tr = 4 mm) is supported by a shoe (ts = 5 mm) which is attached to the ladder rail by a 8 mm diameter bolt (dp = 8 mm). a) Find the support reactions at A and B (note: directions of reactions are assumed in the figure). (6) b) Find the resultant force in the shoe bolt at A. c) Find the maximum average shear and bearing stresses in the shoe bolt at A. (3) (6)

[15] QUESTION 4 A rigid bar of weight W = 800 N hangs from three equally spaced vertical wires (length L = 150 mm, spacing a = 50 mm): two of steel and one of aluminum. The wires also support a load P acting on the bar. The diameter of the steel wires is ds = 2 mm, and the diameter of the aluminum wire is da = 4 mm. Assume Es = 210 GPa and Ea = 70 GPa. (a) What load Pallow can be supported at the midpoint of the bar (x = a) if the allowable stress in the steel wires is 220 MPa and in the aluminum wire is 80 MPa? (See figure below).

[12] TOTAL MARKS = (50) FULL MARKS = 50 2 = [100] 2

MEMORANDUM

MARCH 2010 SEMESTER TEST 1

QUESTION 1 a) When some materials are loaded for long periods of time, they develop additional strains. This phenomenon is known as creep. b) The ratio of lateral strain to axial (longitudinal) strain. c) True stress : The actual cross-sectional area at the narrow part of the neck is used to calculate the stress. Engineering stress : The initial (original) cross-sectional area at the narrow part of the neck is used to calculate the stress (3) [8] (3) (2)

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Partial Discharge Patterns in High Voltage InsulationDocument7 pagesPartial Discharge Patterns in High Voltage Insulationfery zenNo ratings yet

- Can - Csa-S16.1-94, Csa-S37-94 PDFDocument263 pagesCan - Csa-S16.1-94, Csa-S37-94 PDFUppala Krishna ChaitanyaNo ratings yet

- Cyclotron Bunker ShieldDocument6 pagesCyclotron Bunker ShieldDomenico Barillari100% (2)

- Inertial Navigation SystemDocument34 pagesInertial Navigation Systemsameer7mohammadNo ratings yet

- Modern Magnetic Materials - The ReviewDocument15 pagesModern Magnetic Materials - The ReviewMihaela LostunNo ratings yet

- 17-Processing Iron Ore PDFDocument12 pages17-Processing Iron Ore PDFPortia Shilenge100% (1)

- Quantum Mechanics. Theory and Experiment PDFDocument529 pagesQuantum Mechanics. Theory and Experiment PDFHemanta Upadhaya100% (1)

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- UAE University College of Engineering Training and Graduation Project UnitDocument100 pagesUAE University College of Engineering Training and Graduation Project UnitPortia ShilengeNo ratings yet

- Calculation of Resistance To GroundDocument10 pagesCalculation of Resistance To Groundalfonso.parker50% (2)

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengeNo ratings yet

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeNo ratings yet

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengeNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- Preconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterDocument20 pagesPreconcentration of Ug2 Platinum Ore: Economic Benefits To Mine, Plant, and SmelterPortia ShilengeNo ratings yet

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengeNo ratings yet

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeNo ratings yet

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengeNo ratings yet

- Milling Multotec ProjectDocument15 pagesMilling Multotec ProjectPortia ShilengeNo ratings yet

- Kroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFDocument32 pagesKroondal - 1 - Comminution - Circuit - Diagnosis - Study Dec 01 2014 PDFPortia ShilengeNo ratings yet

- Derrick Screen ProjectDocument15 pagesDerrick Screen ProjectPortia ShilengeNo ratings yet

- Ball Mills For Blue Ridge PDFDocument2 pagesBall Mills For Blue Ridge PDFPortia ShilengeNo ratings yet

- 0204finalreportbrgm PDFDocument88 pages0204finalreportbrgm PDFPortia ShilengeNo ratings yet

- Mini Report of Duties Done in The Ug2 PlantDocument9 pagesMini Report of Duties Done in The Ug2 PlantPortia ShilengeNo ratings yet

- Report in The Ug2 PlantDocument8 pagesReport in The Ug2 PlantPortia ShilengeNo ratings yet

- Lateral Earth Pressures For Seismic Design of Cantilever Retaining WallsDocument8 pagesLateral Earth Pressures For Seismic Design of Cantilever Retaining Wallsredpol100% (2)

- Lecture 12 - Measurement of PressureDocument51 pagesLecture 12 - Measurement of PressureMohsin BashirNo ratings yet

- SCI 10 Module 2 Assignment 1 Perform Activity 1.1 A Critique of Hubble S Classic Paper A Century ADocument3 pagesSCI 10 Module 2 Assignment 1 Perform Activity 1.1 A Critique of Hubble S Classic Paper A Century AMay GloriaNo ratings yet

- Senior Presentation Old FormatDocument14 pagesSenior Presentation Old FormatkosNo ratings yet

- CFD Application Tutorials 2Document35 pagesCFD Application Tutorials 2Jubril AkinwandeNo ratings yet

- Damped Free VibrationDocument6 pagesDamped Free Vibrationraffiq85No ratings yet

- 5 - Questions On AstronomyDocument19 pages5 - Questions On AstronomyJohn ChiltonNo ratings yet

- Tugas 1 Advanced CrystallographyDocument7 pagesTugas 1 Advanced CrystallographyMuhammad Hisyam FMIPANo ratings yet

- 1.1 A Magnetic Circuit With A Single Air Gap Is Shown in Fig. 1.24. The Core DimensionsDocument31 pages1.1 A Magnetic Circuit With A Single Air Gap Is Shown in Fig. 1.24. The Core DimensionsAsim AliNo ratings yet

- Thermo NotesDocument12 pagesThermo NotesSamriddha Das GuptaNo ratings yet

- Ingles Tecnico Ii ELI-300: Star-Delta StarterDocument2 pagesIngles Tecnico Ii ELI-300: Star-Delta StarterEnrique Valdez JordanNo ratings yet

- Docc 1996Document8 pagesDocc 1996swchen100% (2)

- Assignment 2 Module of Free Vibration Engineering 1st SEMESTER S.Y. 2016 - 2017Document14 pagesAssignment 2 Module of Free Vibration Engineering 1st SEMESTER S.Y. 2016 - 2017Narry StrummerNo ratings yet

- Mec235 - Thermo FluidsDocument10 pagesMec235 - Thermo FluidsManish JainNo ratings yet

- Una Nueva Fórmula Explícita de Factor de Fricción para Flujos Laminares, de Transición y Turbulentos en Tuberías Lisas y RugosasDocument6 pagesUna Nueva Fórmula Explícita de Factor de Fricción para Flujos Laminares, de Transición y Turbulentos en Tuberías Lisas y Rugosasdaniel quispe mezaNo ratings yet

- Current ElectricityDocument12 pagesCurrent ElectricityKumbhar SaketNo ratings yet

- PhET Projectile Motion LabDocument7 pagesPhET Projectile Motion LabMon AdanoNo ratings yet

- Nabl Scope 2020Document65 pagesNabl Scope 2020sharanNo ratings yet

- Aerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilDocument15 pagesAerospace: Numerical Simulation of The Anti-Icing Performance of Electric Heaters For Icing On The NACA 0012 AirfoilNaveen NaviNo ratings yet

- MINI Project Report: " Machine Design - I-LAB "Document23 pagesMINI Project Report: " Machine Design - I-LAB "Saket PatelNo ratings yet

- PHYSICSDocument4 pagesPHYSICSalmiraNo ratings yet

- The Fluencia e BookDocument141 pagesThe Fluencia e Bookali noorNo ratings yet

- Detailed Lesson Plan in General Chemistry 11: at The End of The Lesson, The Learner Should Be Able ToDocument14 pagesDetailed Lesson Plan in General Chemistry 11: at The End of The Lesson, The Learner Should Be Able ToMercy De VeraNo ratings yet