Professional Documents

Culture Documents

Earth Leakage Relays ELRV30-2-A RMS PDF

Uploaded by

DEADMANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Leakage Relays ELRV30-2-A RMS PDF

Uploaded by

DEADMANCopyright:

Available Formats

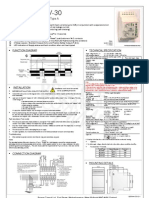

True RMS Earth Leakage Relay (Variable) - Type A

q q q q q q q q q q q

70mm DIN rail housing Designed to monitor and detect true RMS, earth fault currents (up to 30A) in conjunction with a separate toroid Fast response time of <25mS1 to fault currents that are 5 x greater than the set trip current Digital LED Display shows measured leakage current, various user settings and diagnostics Microprocessor controlled with internal monitoring (self-checking) Sensitivity (In) and time delay (t) adjustable using simple 2-button operation Display push button allows user to view settings without needing to open the tamperproof cover. The last recorded peak trip current can also be recalled using the same push button Dims: Single button operation for Test / Reset and connection facility for remote Test and Reset push buttons to DIN 43880 Connection for remote lamp facility warning user prior to a trip condition (level adjustable by user) W. 70mm Toroid open and short circuit detection (unit forced to trip during open circuit condition) 2 x SPDT relay output 8A. LED indication of user settings / fault condition after unit has tripped 1 inst. time delay setting / fault current <30A

Type: ELRV-30

Terminal Protection to IP20

FUNCTION DIAGRAM

fault current

supply interrupted

TECHNICAL SPECIFICATION

Supply voltage Un (1, 3): 12 60V DC (85 115% of U) 24, 115, 230, 400V AC (85 115% of Un) Galvanic isolation between the supply and the toroid and remote test / reset connections on AC supply versions. Supply frequency: 50/60/400Hz (AC supplies) Isolation: Over voltage cat. III Please state Supply Rated impulse voltage when ordering. withstand voltage: (1.2 / 50S) IEC 60664 800V (24V AC supply 2.5kV (115V AC supply) 4kV (230V, 400V AC supplies) Power consumption (max.): 6VA (AC supplies), 5W (DC supply) Monitored leakage current: 2mA to 30A (50/60/400Hz)(through external toroid with 1000:1 ratio and connected to terminals 11 and 13) Sensitivity In: Trip level: Hysteresis: Accuracy: Time delay t: 6, 10, 30, 50, 75, 100, 300, 500, 750mA 1, 3, 5, 7.5, 10, 15, 20, 25, 30A (user selectable) 75% of In (nominal) 8% of In or 2mA, whichever greater 15% (valid range 10 . 110% of In or 2mA, whichever greater) inst., 50, 250, 500mS, 1, 2.5, 5, 10 sec. (user selectable)

Note: For In settings of 30mA or less, the time delay is fixed to inst. (instantaneous, <25mS) and is not adjustable.

Trip level (In) Reset level

failure of connection to toroid

Standard output Positive safety output

td

t

"reset" "test"

td

(combined test/reset button pressed)

Installation work must be carried out by qualified personnel. BEFORE INSTALLATION, ISOLATE THE SUPPLY. Connect the unit as shown in the diagram below (N.B. certain features may not be required and therefore do not need to be connected). Operational and setting information can be found on the reverse of this data sheet.

INSTALLATION

This unit should be installed in conjunction with the latest wiring regulations and practices (IEE, etc)

Measured current: Display Resolution: Reset time: Power on delays: (from application of supply to terminals 1 and 3) Memory:

Displayed on auto ranging 2 digit 7-segment red LED display

100uA min. <200mS (from supply interruption)

Delay before P.S.O. relay energises td: 600mS (Note: relay will energise during self test period assuming no fault present) storage of the leakage fault and reset with test / reset button

Self test duration: <5 secs.

CONNECTION DIAGRAM

L1 L2 L3 N E

reset

test

Ambient temp: Relative humidity:

50m* max.

50m* max.

A1 (+ve) A2 (-ve)

Note: The voltage across the fault level output MUST NOT exceed 240V~ (For 400V~ units used in 3-Phase installations, connect the load between terminal 2 and neutral)

-5 to +60C -5 to +40C (in accordance with IEC 755) +95% 2 x SPDT relay (4, 6, 8 / 10, 12, 14) AC1 250V 8A (2000VA) AC15 250V 2.5A DC1 25V 8A (200W) 150,000 ops at rated load 2kV AC (rms) IEC 60947-1 4kV (1.2 / 50S) IEC 60664 Requires two N.O. contacts. (i.e. push buttons) >100mS 50% of In (factory set) User adjustable from 10 - 65% in 5% increments 8% of In or 2mA, whichever greater 40mA max. @ 240V

Output : Output rating: Electrical life: Dielectric voltage: Rated impluse withstand voltage: Remote test / reset (5, 7, 9) Contact closure time: Fault level output (1, 2): Hysteresis: Load (resistive):

toroid

1 3 5 7 9 11 13

E

Fault level output* (i.e. lamp)

Both relays are shown in the de-energised state (i.e. where power is not present on terminals 1 and 3)

8 10 12 14

positive safety standard output output

* Only available on AC supply models

The Earth MUST NOT pass through the toroid. For single phase applications, only the live and neutral need to be passed through the toroid. *Cabling: For distances >1m, use twisted pair cable between the unit and toroid. Always ensure cables to toroid and remote test / reset switches ARE KEPT AWAY from mains and data cables in the same installation.

Note: A remote lamp can only be connected when terminals 1 and 3 are being supplied with an AC supply

MOUNTING DETAILS

85 45

Housing: Weight: Mounting option: Terminal conductor size: Approvals:

Insert screwdriver to release clip

Grey flame retardant Lexan UL94 VO 250g (AC supplies), 170g (DC supply) On to 35mm symmetric DIN rail to BS5584:1978 (EN50 002, DIN 46277-3) 2.5mm2 stranded. 4mm2 solid Conforms to: IEC 755. IEC 61543 (EMC) Radiated Immunity: IEC 61000-4-3: 1.89GHz @ 30V/m and pending. CE and Compliant.

Options Accessories Toroids

Toroid Type: BZCT035 BZCT070 BZCT120 BZCT210 Internal diameter: 35mm 70mm 120mm 210mm In (min.) A 0.03 0.03 0.1 0.3

For other supply voltages, alternative trip levels or time delays, please consult the sales office.

63.5 49.5 33

Note: ( ) Numbers in brackets shown above refer to terminal numbers on the relay housing.

Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. England 012366 Page 1 of 2 Telephone: +44 (0) 1902 773746 Facsimile: +44 (0) 1902 420639 Email: sales@broycecontrol.com Web: http://www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the users own risk.

ELRV30-2-A RMS

OPERATING INSTRUCTIONS AND SETTINGS

The operating function of this unit is classed as a Type A for which tripping is ensured for residual true RMS sinusoidal alternating currents and residual pulsating direct currents, whether applied suddenly or slowly rising. Additionally, this unit is protected against nuisance tripping. Apply power, the "positive safety output" relay will energise and contacts 6 and 8 will close after delay td. The "standard output" relay will remain de-energised (contacts 12 and 14 open). After carrying out a self test (all segments illuminate on the LED display for a short period), then indicate the In setting, followed by the measured leakage current that may be present in the installation. The yellow LEDs to the left of the display show whether the current is mA or A.

Description

Applying power (assuming no leakage current present)

Viewing and changing the user settings.

Note: The unit is factory set to 30mA trip and instantaneous delay. The remote fault level output is set to 50%. Adjustment of these settings can be made if required to suit the requirements of the installation. A seal is supplied with the unit allowing the user to secure the clear window and hence prevent any unnecessary adjustment of the settings. The settings can be viewed and checked by pressing the Display push button as shown. Carrying out adjustments to these settings requires the tamperproof cover to be lifted in order to gain access to the two push buttons underneath. If during the adjustment of any settings, a push button is released, the display will revert back to indicating the measured leakage current after a short duration.

1st press In setting (i.e. 300mA) 2nd press t setting (i.e. 50mS) 3rd press fault level output (i.e. 40%) 4th press Recorded current causing unit to trip on last occassion (i.e. 330mA) Max. recordable current is <42A

sec.

sec.

DISPLAY TEST/ RESET

sec.

sec.

A In t mA

A mA

A mA

A mA

SET

Press "Display" button (If the push button remains pressed, the display will alternate between the "In" and "t" settings)

DISPLAY TEST/ RESET DISPLAY TEST/ RESET DISPLAY TEST/ RESET

To modify settings (Release "Display" button first)

5th press reverts display back to measured leakage current or starts the "settings" sequence again.

In

SET

In

SET

I n

SET

Note that the above is only an example of how the unit could be set.

1st press displays I n setting. Press again to change setting. Press and hold to automatically increment setting. (Yellow "mA" or "A" LED's flash according to range). 1st press displays t setting. Press again to change setting. (Yellow "Sec." LED flashes) Press and hold I n and t buttons. Setting will increment automatically ("mA" and "A" yellow LED's flash simultaneously)

Note: After a change to a setting has been made, the new setting will only be stored once the yellow LED has stopped flashing.

Fig. 1

Fault simulation (Test mode)

The unit can be placed into a fault condition by pressing the "Test/Reset" button on the front of the unit (or by pressing the remote Test button - if fitted). If the unit is already in a no fault condition, i.e., not tripped, the first press will trip the unit. The output relays operate accordingly. The display shows the characters as in Fig.2 Press the same button again to reset the unit. The display reverts back to any measured leakage current that may be present. The unit can also be reset using the external Reset button (if fitted) or by interrupting the TEST/ DISPLAY power supply. RESET Sec. To satisfy regulations, it is recommended the device is tested periodically to ensure correct operation.

A

Fault conditions

Leakage currents

In

SET

mA

Fig. 2

If during normal service, the leakage current increases above the setting for the fault level output, the remote lamp will illuminate (if fitted) and the display will flash to give the user early warning of a possible fault condition. If the fault persists and the level of leakage current exceeds the trip level setting, the unit will trip. The "positive safety output" relay will de-energise and contacts 6 and 8 will open. The "standard output" relay will energise and contacts 12 and 14 will close. The red fault LED will illuminate and the display will stop flashing. Pressing the Test/Reset button returns the unit back to normal operation, assuming the fault has cleared. Note that the level of current that caused the unit to trip is now stored and can be re-called by pressing the Display button (see Fig.1). Note that the recorded trip current is only stored whilst power is applied and cleared if the power supply is interrupted. If the wiring between the unit and toroid becomes damaged (open circuit), the unit will trip. The display shows the following characters as in Fig.3 After the fault has cleared, press the Test/Reset button to return the unit back to normal operation. Note that the unit cannot be reset remotely following an open circuit condition.

DISPLAY

Sec. A mA

Toroid open circuit

TEST/ RESET

In

SET

Fig. 3

Toroid short circuit Shorts that are present across terminals 11 and 13 (typically < 33 and purely resistive) will force the unit to display the characters as shown in Fig.4. However, the unit still remains functional other than not being able to detect and display fault currents.

Sec. A mA

Supply voltage fault If the applied supply voltage is <70% of Un (typical), the unit will not operate and the display shows the following characters as in Fig.5. During this condition and assuming the supply is also >50% of Un, the lamp connected to the fault level output will flash. After the correct voltage has been established, the unit will revert to normal operation.

Fig. 4

DISPLAY

Sec. A

TEST/ RESET

Troubleshooting

mA

In

SET

Fig. 5

If the unit fails to operate correctly other than that described above, then the fault will more than likely be with the wiring to the unit. Check all wiring and that the connections are good. Ensure the supply to the unit is present on terminals 1 and 3 and is within the operational limits specified. For DC units, ensure the polarity of the supply is correct.

Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. England 012366 Page 2 of 2 Telephone: +44 (0) 1902 773746 Facsimile: +44 (0) 1902 420639 Email: sales@broycecontrol.com Web: http://www.broycecontrol.com

The information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the users own risk.

ELRV30-2-A RMS

You might also like

- Earth Leakage Relays Elrm44v-1-ADocument1 pageEarth Leakage Relays Elrm44v-1-Aapi-230026640No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Earth Leakage Relays ELRM44V30-2-ADocument1 pageEarth Leakage Relays ELRM44V30-2-Akalesh005No ratings yet

- Earth Leakage Relays ELRM44V30-2-ADocument1 pageEarth Leakage Relays ELRM44V30-2-ABrian BurchNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- VMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsDocument6 pagesVMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsjjcanoolivaresNo ratings yet

- PTS HIPOT INSTRUMENTS OPERATOR MANUALDocument34 pagesPTS HIPOT INSTRUMENTS OPERATOR MANUALOmar Marquez BonillaNo ratings yet

- Earth Leakage Relay P-373-ELRDocument2 pagesEarth Leakage Relay P-373-ELRIsmet KoracNo ratings yet

- A Isometer IR420 D6Document6 pagesA Isometer IR420 D6Ursula JohnsonNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- 100AE MK3 Manual v9Document36 pages100AE MK3 Manual v9vjNo ratings yet

- IRDH265Document4 pagesIRDH265pukyssNo ratings yet

- 7sg118 Argus 8 Catalogue SheetDocument12 pages7sg118 Argus 8 Catalogue SheetCristi GrosuNo ratings yet

- EL Meaure MeterDocument40 pagesEL Meaure MeterRangasamyNo ratings yet

- Digital Multimeter DT830 Series ManualDocument12 pagesDigital Multimeter DT830 Series ManualJohn G.75% (4)

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

- Model Ut51-55: Operating ManualDocument20 pagesModel Ut51-55: Operating ManualAdv Faizan GorayaNo ratings yet

- A Isometer IR475LYDocument3 pagesA Isometer IR475LYUrsula JohnsonNo ratings yet

- Wireless TRMS Multimeter: User's GuideDocument17 pagesWireless TRMS Multimeter: User's Guidespock_65No ratings yet

- Adr 132 BDocument5 pagesAdr 132 Btandin tshewangNo ratings yet

- TMP 35 GDocument16 pagesTMP 35 GWeslley FariaNo ratings yet

- Multifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationDocument9 pagesMultifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationtonielhageNo ratings yet

- Em266 enDocument17 pagesEm266 enगणेश पराजुलीNo ratings yet

- EARTH LEAKAGE RELAYS & CORE BALANCE CTsDocument2 pagesEARTH LEAKAGE RELAYS & CORE BALANCE CTsDEADMANNo ratings yet

- Wireless TRMS Multimeter: User's GuideDocument19 pagesWireless TRMS Multimeter: User's GuideAdam SonenshineNo ratings yet

- Syl 2372Document8 pagesSyl 2372Ismael 8877No ratings yet

- Bender Rcm470lyDocument3 pagesBender Rcm470lyRobert Arias TabrajNo ratings yet

- Eld E08405Document2 pagesEld E08405AndrewcaesarNo ratings yet

- A5E02261863A_02_201210291111411944Document7 pagesA5E02261863A_02_201210291111411944Lucas Fuzeto VizoniNo ratings yet

- 1735A ManualDocument58 pages1735A ManualLilia MijangosNo ratings yet

- Fuente Goldstar PDFDocument11 pagesFuente Goldstar PDFdirectNo ratings yet

- Magnetrol 48-635Document36 pagesMagnetrol 48-635João LuizNo ratings yet

- Zeeta308d PDFDocument25 pagesZeeta308d PDFGeorcchi CheeckNo ratings yet

- 832 Series ManualDocument10 pages832 Series ManualBECHER CAPCHANo ratings yet

- XGen Xcite 400W 700W 1000W 1200W ACDC Power SupplyDocument4 pagesXGen Xcite 400W 700W 1000W 1200W ACDC Power SupplyBerlian AkbarNo ratings yet

- Manual Multimeter Uni-T UT890DDocument5 pagesManual Multimeter Uni-T UT890DConsumerNo ratings yet

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Document71 pages1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- MEG1000 ManualDocument17 pagesMEG1000 ManualKostas TressosNo ratings yet

- 7SG117 Argus 7: Answers For EnergyDocument10 pages7SG117 Argus 7: Answers For EnergygovindarulNo ratings yet

- Velleman Ps3010 3020 Power Supply UmDocument23 pagesVelleman Ps3010 3020 Power Supply UmFernando VidalNo ratings yet

- TM-6001 (20181025) (1)Document34 pagesTM-6001 (20181025) (1)vũ trầnNo ratings yet

- Overload and Short Circuit Relay: Eocr-3Dis-AuDocument2 pagesOverload and Short Circuit Relay: Eocr-3Dis-AuAngelo Michael ClementeNo ratings yet

- Users Manual: MultimeterDocument20 pagesUsers Manual: MultimeterchepebotellaNo ratings yet

- Precautions For Installation and Safe Use: Da-0101 / Da-0103 Digital Ammeters 72x72 & 96x48mm SIZESDocument2 pagesPrecautions For Installation and Safe Use: Da-0101 / Da-0103 Digital Ammeters 72x72 & 96x48mm SIZESKhaleel KhanNo ratings yet

- RMC 131d Data Sheet 4921240104 UkDocument8 pagesRMC 131d Data Sheet 4921240104 UkAilton NevesNo ratings yet

- DLRO200 115EDataSheet PDFDocument2 pagesDLRO200 115EDataSheet PDFShadab WaseemNo ratings yet

- Ramde RelayDocument8 pagesRamde RelayculwavesNo ratings yet

- ADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualDocument6 pagesADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualMahendraLiyanage0% (1)

- Zelio Control - Measurement and Control Relays: FunctionsDocument4 pagesZelio Control - Measurement and Control Relays: Functionsnacho_romero_18No ratings yet

- Ut33a Palm Size Multimeter ManualDocument13 pagesUt33a Palm Size Multimeter ManualTheo SopranoNo ratings yet

- DataKom 409 - INSTEDocument7 pagesDataKom 409 - INSTEKhaleel KhanNo ratings yet

- Manual Multimetro HPDocument2 pagesManual Multimetro HPMauricioNo ratings yet

- .J N I - .J N - P U1 0 S : 0Document15 pages.J N I - .J N - P U1 0 S : 0Montse TovarNo ratings yet

- VME421HDocument4 pagesVME421HJoao SantosNo ratings yet

- 1550 ManualDocument8 pages1550 ManualSIPI SAPO0% (1)

- General Specifications: EJX510A and EJX530A Absolute and Gauge Pressure TransmitterDocument10 pagesGeneral Specifications: EJX510A and EJX530A Absolute and Gauge Pressure TransmitterapisituNo ratings yet

- Transformer Oil TestingDocument29 pagesTransformer Oil TestingDEADMAN100% (1)

- Simple Methods For Calculating Short Circuit Current Without A ComputerDocument4 pagesSimple Methods For Calculating Short Circuit Current Without A ComputerDEADMANNo ratings yet

- Transformer Name Plate Details: Short Circuit Current Calculation For Transformer (Short Cicuit Test)Document1 pageTransformer Name Plate Details: Short Circuit Current Calculation For Transformer (Short Cicuit Test)DEADMANNo ratings yet

- Basic Nec Code Rules and Design PracticeDocument13 pagesBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- Thirukural (TamilEnglish)Document167 pagesThirukural (TamilEnglish)arunprasad.vit100% (5)

- Uyir Yethu TamilDocument1 pageUyir Yethu TamilDEADMANNo ratings yet

- 110V DC Station Battery and Charger Sizing CalculationDocument2 pages110V DC Station Battery and Charger Sizing CalculationDEADMAN100% (1)

- Short Circuit Calculation GuideDocument5 pagesShort Circuit Calculation Guideashok203No ratings yet

- Thevaram 7.039 Thiru Thonda ThogaiDocument18 pagesThevaram 7.039 Thiru Thonda ThogaiShanmuga Sundaram100% (2)

- As BuiltDocument1 pageAs BuiltDEADMANNo ratings yet

- LVAC Operation PhilosophyDocument1 pageLVAC Operation PhilosophyDEADMANNo ratings yet

- KT Factor CalculationDocument1 pageKT Factor CalculationDEADMANNo ratings yet

- Trip UnitDocument2 pagesTrip UnitDEADMANNo ratings yet

- SPD Design StepDocument1 pageSPD Design StepDEADMANNo ratings yet

- Delta REFDocument1 pageDelta REFDEADMAN100% (1)

- SPD Design StepDocument1 pageSPD Design StepDEADMANNo ratings yet

- Thiruvasagam Sila SinthanaigalIiDocument409 pagesThiruvasagam Sila SinthanaigalIiDEADMANNo ratings yet

- SPD Design StepDocument1 pageSPD Design StepDEADMANNo ratings yet

- Tamil QuranDocument810 pagesTamil QuranDEADMAN100% (1)

- Earth Fault Protection Part 2Document5 pagesEarth Fault Protection Part 2DEADMAN100% (1)

- Cable Impedance CalculationDocument1 pageCable Impedance CalculationDEADMANNo ratings yet

- Earth Fault Protection Explained in 40 CharactersDocument9 pagesEarth Fault Protection Explained in 40 CharactersDEADMAN100% (1)

- EarthingDocument40 pagesEarthingmamoun_hammad7917No ratings yet

- Busbar Protection SlidesDocument2 pagesBusbar Protection SlidesDEADMANNo ratings yet

- Network Feeder Source Impedance CalculationDocument1 pageNetwork Feeder Source Impedance CalculationDEADMANNo ratings yet

- FEWA LV Capacitor Bank SpecificationsDocument5 pagesFEWA LV Capacitor Bank SpecificationsDEADMANNo ratings yet

- Busbar ProtectionDocument16 pagesBusbar ProtectionDEADMANNo ratings yet

- Network Trafo. Impedance CalculationDocument1 pageNetwork Trafo. Impedance CalculationDEADMANNo ratings yet

- Battery SizingDocument9 pagesBattery SizingcharzreeNo ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- FI 48 Rigid Glasswool Sheets and Acoustic BlanketDocument2 pagesFI 48 Rigid Glasswool Sheets and Acoustic BlanketJimWest69No ratings yet

- 01 V5 X Series Engineering Data BookDocument212 pages01 V5 X Series Engineering Data Bookcalvin.bloodaxe4478No ratings yet

- Lessons Learned-Nuclear Gauge002Document66 pagesLessons Learned-Nuclear Gauge002Michael Murillo BaraquioNo ratings yet

- DENR HW Registration FormDocument5 pagesDENR HW Registration FormMeggy TayaoNo ratings yet

- Special Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)Document12 pagesSpecial Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)sahil4INDNo ratings yet

- Menard vertical drains consolidate soilsDocument3 pagesMenard vertical drains consolidate soilsSyed Shariq HassanNo ratings yet

- History of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Document584 pagesHistory of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Artisan Ideas75% (4)

- A Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFDocument12 pagesA Solar Power-Assisted Battery Balancing System For Electric Vehicles PDFCrispNo ratings yet

- Topic 2.4 - Momentum and ImpulseDocument38 pagesTopic 2.4 - Momentum and ImpulseKhánh NguyễnNo ratings yet

- Control Uniformity in Reactive Magnetron SputteringDocument4 pagesControl Uniformity in Reactive Magnetron SputteringmikecostantiniNo ratings yet

- LPG Parts Diagram BreakdownDocument43 pagesLPG Parts Diagram BreakdownناصرقوجيلNo ratings yet

- G20 Business Letter We Mean Business CoalitionDocument26 pagesG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoNo ratings yet

- 2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFDocument14 pages2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFCaio PaimNo ratings yet

- Lista Precios Ahu Mas Accesorios Sinclair 2020Document80 pagesLista Precios Ahu Mas Accesorios Sinclair 2020Jonathan ArboledaNo ratings yet

- RI Library Construction UpdateDocument1 pageRI Library Construction UpdaterooseveltislanderNo ratings yet

- Ecro RV: Technical ManualDocument21 pagesEcro RV: Technical ManualHyeong-Ho KimNo ratings yet

- Lorentz Ps ManualDocument72 pagesLorentz Ps ManualJohn KiokoNo ratings yet

- General CatalogueDocument26 pagesGeneral CatalogueKasturi LetchumananNo ratings yet

- Wuhuan - MR Pi JinlinDocument34 pagesWuhuan - MR Pi JinlinAmanNo ratings yet

- Offshore Wind PowerDocument22 pagesOffshore Wind PowerS. M. IsrafilNo ratings yet

- Complex Fluid For Olga 5Document10 pagesComplex Fluid For Olga 5angry_granNo ratings yet

- Single Split PAC R410A Non-Inverter CatalogDocument12 pagesSingle Split PAC R410A Non-Inverter CataloghuntsecondlifeNo ratings yet

- FIRST TERMINAL EVALUATION 2021-22 PHYSICS CLASS XDocument3 pagesFIRST TERMINAL EVALUATION 2021-22 PHYSICS CLASS XLahnNo ratings yet

- Ramgarh Gas Power Plant OverviewDocument31 pagesRamgarh Gas Power Plant Overviewswai singh100% (1)

- Liebert EXM 80-200 kVA PDFDocument123 pagesLiebert EXM 80-200 kVA PDFrogeriopaulaNo ratings yet

- ICOLD Review of WCD Report on Dams and DevelopmentDocument5 pagesICOLD Review of WCD Report on Dams and DevelopmentNazakat HussainNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- A4 G970 - G990 Product Brochure enDocument17 pagesA4 G970 - G990 Product Brochure endalibor_bogdan100% (3)

- SKF TIH 030M - 230V SpecificationDocument3 pagesSKF TIH 030M - 230V SpecificationÇAĞATAY ÇALIŞKANNo ratings yet

- Waterwell Catalog WebDocument96 pagesWaterwell Catalog WebJuan Carlos Sequeira RoblesNo ratings yet