Professional Documents

Culture Documents

Coupling Moisture Transport in Air Flows and Porous Materials Using CFD

Uploaded by

getsweetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coupling Moisture Transport in Air Flows and Porous Materials Using CFD

Uploaded by

getsweetCopyright:

Available Formats

Coupling moisture transport in air flows and porous materials using CFD

Hendrik-Jan Steeman, Department of Flow, Heat and Combustion Mechanics, Ghent University-UGent, Sint-Pietersnieuwstraat 41 9000 Gent, Belgium; Hendrikjan.Steeman@ugent.be, www.floheacom.ugent.be Arnold Janssens, PhD, Department of Architecture and Urban Planning, Ghent University-UGent, Jozef Plateaustraat 22, 9000 Gent, Belgium; Arnold.Janssens@ugent.be, www.architectuur.ugent.be Michel De Paepe, PhD, Department of Flow, Heat and Combustion Mechanics, Ghent University-UGent, Sint-Pietersnieuwstraat 41 9000 Gent, Belgium; Michel.Depaepe@ugent.be, www.floheacom.ugent.be KEYWORDS: HAM, CFD, model, porous material. SUMMARY: Modelling local moisture content in objects and walls inside buildings requires the knowledge of the interaction of the material with the local indoor climate. Computational Fluid Dynamics (CFD) can be used to model the local climate and is currently already used to model heat exchange at the interface of air and porous materials. In this paper a coupled CFD-material model is presented which is capable of modelling non-isothermal transient moisture exchange between air and porous materials. The coupled model integrates a 2 or 3D heat and moisture transport model for porous materials in a commercial CFD solver. A verification and validation study of the new model results in an excellent agreement between simulations on the one hand and analytical reference solutions and experiments on the other hand.

1. Introduction

The use of numerical models for heat and moisture transfer in building components is becoming increasingly popular. Numerical simulation allows for an accurate analysis of the hygric and thermal performance of building components. Yet to obtain realistic results it is eminent that realistic boundary conditions are provided to the model. In a recent paper Janssen et al. describe the integration of atmospheric boundary conditions in a numerical heat and moisture model (Janssen, 2007). As boundary conditions such as wind driven rain are highly variable in space and time Computational Fluid Dynamics (CFD) is used in the latter paper to simulate the outdoor environment and generate (part of) the boundary conditions. If the interest of a study lies in simulating the local hygrothermal response of building components or objects facing the indoor air, a strong coupling between the air and the porous materials can occur. Unlike the outdoor environment, which is independent of the situation in the building component, the temperature and relative humidity of the indoor air are influenced by the interaction with the building components. Hence in this situation it is no longer sufficient to pass information from the CFD model to the hygrothermal model, but a two-way coupling between both models is necessary. Recently several models which feature a two way coupling between CFD and a hygrothermal material model have been developed. These models can be divided in two categories: the directly coupled models and the indirectly coupled models. Directly coupled models are those models which solve both the fluid domain as the porous material domain with one solver. Models which use an indirect coupling solve the fluid and the porous domain with a different solver and exchange information between both solvers. Examples of indirectly coupled models can be found in (Amissah, 2005) and (Erriguible, 2006). In (Amissah, 2005) a 3D CFD model is coupled to a 1D hygrothermal material model, while in (Erriguible, 2006) a 2D CFD and a 2D hygrothermal material model are coupled. Both these indirectly coupled models use explicit time stepping to link the CFD solver and

the hygrothermal solver as information between the solvers is exchanged once each time step. An example of a direct coupled model can be found in (Mortensen, 2007). In this model a 3D steady state CFD solver was adapted to include the governing equations for heat and moisture transfer in porous materials. The transport equations in the air and the porous material were separated and an algorithm was developed that predicts the moisture flux at the air-material interface and reconciles the water vapour content at both sides of this interface. In this paper a coupled 3D CFD hygrothermal material model is developed that is capable of performing transient simulations. The governing equations in the porous material and the fluid are written in function of the same variables and are solved with the CFD solver. This implies that the continuity at the fluid-material interface will be automatically fulfilled. As the new model is directly coupled and continuous at the material interface no time consuming iteration between two codes is needed. Also the coupling between the fluid and the material is no longer explicit, which allows for larger time steps in the simulation. A detailed verification and validation study of the newly developed model is performed in the second part of the paper.

2. Coupled CFD-material model

The strategy followed here to develop a directly coupled CFD-material model is integrating the governing equations for heat and moisture transport in hygroscopic porous media into the commercial CFD solver Fluent (Fluent Inc., 2006). The advantage of using a commercial CFD solver is that new advances in fluid modelling are integrated in the CFD solver with every new release. In the CFD solver transport equations for heat and moisture transfer in fluids are available. By writing the governing equations for heat and moisture transport in porous media as function of the same transported variables as those used in the CFD solver, source terms, diffusion terms and unsteady terms are obtained to convert the standard CFD heat and moisture transport equations. The CFD solver is used to solve the transport equations in the entire domain (fluid and porous zones) taking into account the changed source terms in the porous zone.

2.1 Heat and moisture transfer in air

In Fluent, the CFD solver used in this paper, heat and moisture transfer in the air can be simulated using the energy and the species transport equations. The air can be modelled as an incompressible fluid in which case the energy and species transport equations can be simplified to:

C p

= . k (T ) cvapT + Lvap g (T ) + v. (T ) t

) )

(1)

= . ( D ( ) ) ( ) + v . ( ) t

(2)

where is the air density, Cp the air thermal capacity, k the thermal conductivity, cvap the thermal capacity of the water vapour, Lvap the latent heat of vaporization, g the water vapour diffusion flux and D the diffusion coefficient of water vapour in air. The transported variables are the temperature T and the mass fraction of water vapour in the air, .

2.2 Heat and moisture transfer in porous materials

2.2.1 Governing equations In the porous material only moisture transport due to water vapour diffusion is considered. The modelled materials are capillary active and are characterized by a sorption curve giving the moisture content w (kg/m) as function of the relative humidity. Heat and moisture transfer is modelled under the assumptions that: No air transfer, no liquid transfer and no radiation heat transfer occurs Moisture storage is independent of temperature The temperature remains below the boiling point

Under these assumptions the moisture transport equation and the heat transport equation can be written in function of and T (Eq. 3-4).

D dw w RH w RH T = .g + = . ( ) dt RH t RH T t

(3)

dh = . kmat (T ) cvapT + Lvap g dt wliq wvap T mat c + cliqT + cvapT + Lvap = . ( kmat (T ) ) cvapT + Lvap .g t t t

) ) )

(4)

with

h = mat cmat T + cliq wliqT + cvapT + Lvap wvap c = cmat + cliq wliq + cvap wvap

(5) (6)

mat

w

mat

wliq = 1

vap

1

(7)

liq

vap

1

(8)

w wvap =

liq

1

liq

vap

where is the vapour resistance factor, the subscript mat refers to dry material conditions and is the porosity of the material. In the right hand side of Eq. (4) the assumption is made that the energy associated with the water vapour flux is quite constant and can be brought outside the divergence operator. 2.2.2 Conservative implementation Because of the non-linear nature of the transport equations (3) and (4) mass and energy conservation is not guaranteed: e.g. the storage term w RH . RH varies with and is not constant during a time step. To solve this problem Janssen proposed an iterative solution procedure in which the property that has to be conserved is estimated by a truncated Taylor series (Janssen, 2007; Janssen, 2002) This approach proved to be very effective and is implemented here. This approach, together with the segregated solution procedure of the CFD solver, leads to the following discretization of equations (3) and (4):

D w RH t + t , m +1 t +t , m wt +t , m wt + = . ( ) RH t t

(9)

mat c

T t + t , m +1 T t +t , m ht +t , m ht + = . ( kmat (T ) ) + cvapT + Lvap t t

D ) . ( )

(10)

Note that the equations (9) and (10) are written in function of T and .

2.3 Practical implementation in Fluent

In the previous section the differences between the transport equations in the fluid and the porous zone are discussed. In Fluent it is not possible to transform the standard energy and species transport equations into equations (9) and (10). It is however possible to use empty transport equations, so called UDS transport, which can be altered at will. For this reason the standard energy and species transport equations are not used, instead equations (1-2) and (9-10) are implemented in the UDS transport equations.

7.00E-04

6.00E-04

Water vapour density rise (kg/m)

5.00E-04

4.00E-04

3.00E-04

2.00E-04

1.00E-04

0.00E+00 0 0.01 0.02 0.03 0.04 0.05 x (m) 0.06 0.07 0.08 0.09 0.1

FIG. 1: Comparison between the increase in water vapour density predicted by the numerical model ( __ ) and the analytical model ( 500s ( ), 5000s (), 20000s (), 200000s () and 500000s ())

5.00E-03 4.50E-03 4.00E-03 3.50E-03 Temperature rise ( C) 3.00E-03 2.50E-03 2.00E-03 1.50E-03 1.00E-03 5.00E-04 0.00E+00 0 0.01 0.02 0.03 0.04 0.05 x (m) 0.06 0.07 0.08 0.09 0.1

FIG. 2: Comparison between the increase in temperature predicted by the numerical model ( __ ) and the analytical model ( 500s ( ), 5000s (), 20000s (), 200000s () and 500000s ())

3. Verification and validation study

3.1 Verification

The aim of the verification study is to check the correct implementation of the equations given in the previous chapter. A test case for which the analytical solution is available, is simulated using the numerical model. Comparison of the analytical and numerical results allow for the assessment of the accuracy of the numerical model. 3.1.1 Test case The considered test case was designed by (Milly, 1982) and represents the one dimensional, coupled diffusion of heat and water vapour in a 10 cm high porous material. Initially the temperature in the material is 20C and the relative humidity is 23.45%. A step change is imposed at the top of the material: the relative humidity changes to 27.11% while the temperature at the top is maintained at 20C. This causes water vapour to diffuse into the porous material and leads to a varying temperature inside the material (due to latent heat release). The bottom of the material is considered to be vapour tight and adiabatic. To obtain an analytical solution for this test case the following assumptions have to be made: (1) the transfer of sensible heat by vapour diffusion and the storage of sensible heat in the liquid water and the water vapour are negligible, (2) the perturbations in temperature and vapour density are so small that the relation between the moisture content w and the relative humidity can be considered linear around the initial state with all other material properties considered constant. If these assumptions are valid the analytical solution developed by (Crank, 1989) can be used to describe the coupled heat and water vapour diffusion. The following material properties are used: w = 4.615RH + 74.261 kg/m; D = 4.37E-6 m/s ; c = 2E6 J/kgK ; kmat = 1.5 W/mK. Note that an extremely high heat capacity c is chosen to guarantee small changes in temperature and hence assure the linear nature of the transport equations. 3.1.2 Results Figure 1 and Figure 2 respectively give the increase of the vapour density and the temperature inside the porous material, as predicted by the analytical and numerical model. Figure 2 shows how the water vapour diffusion into the material triggers a temperature increase which levels out in time under influence of the heat conduction to the surface. The excellent agreement between both models shows that the equations in the numerical model have been correctly implemented and that the interaction between heat and water vapour transport is accurately represented.

3.2 Validation

In the validation study it is checked whether the hygric interaction between the air flow and the porous material simulated with the newly developed model agrees with reality. To this end an experiment for the benchmarking of 1D transient heat and moisture models of hygroscopic materials (Talukdar, 2007; Talukdar, 2008) is simulated. This particular benchmark experiment is well suited for the validation of the new model as the temperature, humidity and velocity of the airflow above the material are accurately controlled. This makes it possible to model the heat and moisture transport in both the air flow and the porous material. 3.2.1 Experiment The experimental set up is elaborately described in (Talukdar, 2007). The test case simulated in this paper is not the case discussed in (Talukdar, 2008), but is a test case developed within the frame of IEA Annex 41(IEA Annex 41, 2008). The most important characteristics of the set up and test case are briefly discussed here. During the experiment conditioned air is sucked through a duct which passes over a porous specimen. This test specimen is placed in an impermeable container with adiabatic walls. A step change in the humidity of the conditioned air is imposed and the resulting temperature and relative humidity change in the porous specimen are measured. The cross section of the duct has a height of 20.5mm. The porous specimen has a height of 37.5mm and a length of 498mm. Temperature and relative humidity sensors are placed inside the porous specimen at a depth of 12.5mm and 25mm.

The porous material used in the validation experiment is gypsum board. Three different experiments were carried out: the response of uncoated gypsum board (Test1), gypsum board coated with 0.1mm acrylic paint (Test2) and gypsum board coated with 0.1mm latex paint (Test3) were measured in the test set up. The material properties (sorption isotherm and vapour resistance factor) of the gypsum board, acrylic paint and latex paint were measured in (IEA Annex 41, 2008) and were used as input for the numerical model. The average velocity of the airflow in the duct is 0.82m/s which corresponds with a Re number of 2000. The test conditions for the three different validation cases are given in Table 1. In all three tests the relative humidity of the air flow is high during the first 24 hours. Next a step change is imposed to the air relative humidity resulting in a low relative humidity. TABLE. 1: Test conditions for the three validation cases Test Used material Initial conditions T (C) 1 uncoated gypsum 23.3 RH (%) 30 Airflow conditions T(C) 23.8 22.5 2 acrylic coated gypsum 24 34.6 23.2 23.2 3 latex coated gypsum 24.1 31.4 23.4 23.4 3.2.2 Model settings The simulations are performed under the assumption of isothermal water vapour transfer: a constant temperature is imposed to the air and the porous material. To model the material properties as accurately as possible 5th order polynomial functions are used for the sorption isotherm and the vapour resistance factor of the gypsum board, acrylic paint and latex paint. The air flow in the duct is assumed to be laminar and to have a hydrodynamically fully developed profile. This is in agreement with measurements performed by (Iskra, 2007). The time step used in the transient simulation is 60s. 3.2.3 Results Figure 3 shows the distribution of the relative humidity in the porous material and the air. In this figure the developing boundary layer for moisture transfer and its effect on the distribution of the relative humidity in the material is clearly visible. RH(%) 71.9 29.6 72.2 30.8 70.9 31.2

FIG. 3:Relative humidity in the porous material (Y<0) and air (Y>0) after 24 hours for Test case1

75 70 65 60 55 50 45 40 35 30 0 20 40

a)

RH (%)

75 70 65 60 55 50 45 40 35 30 0 20 40

b)

RH (%)

60

60

time (h)

time (h)

FIG. 4: Comparison of the measured (__) and simulated (_ _) evolution of the average relative humidity for Test1 at a depth of a) 12.5mm b) 25mm

70 65 60

70

a)

RH (%)

65 60 55 50 45 40 35 30

b)

RH (%)

55 50 45 40 35 30 0 10 20 30 40 50 60

10

20

30

40

50

60

time (h)

time (h)

FIG. 5: Comparison of the measured (__) and simulated (_ _) evolution of the average relative humidity for Test2 at a depth of a) 12.5mm b) 25mm

44 42 40

44

a)

RH (%)

42 40 38 36 34 32 30

b)

RH (%)

38 36 34 32 30 0 10 20 30 40 50 60

10

20

30

40

50

60

time (h)

time (h)

FIG. 6: Comparison of the measured (__) and simulated (_ _) evolution of the average relative humidity for Test3 at a depth of a) 12.5mm b) 25mm

In Figure 4, Figure 5 and Figure 6 the evolution of the average relative humidity at a given depth inside the porous material is compared for the numerical model and the experiments. A good agreement is found, especially during the absorption phase. The larger deviations during desorption might be caused by hysteresis in the material. By comparing the latter figures it can be seen that the humidity increase in the gypsum board decreases as the coating becomes more vapour tight (uncoated acrylic paint latex paint). This phenomenon was accurately predicted by the numerical model. The validation cases show that the new model is capable of simulating the hygric response of a porous material to a change in the properties of the air flowing over it.

4. Conclusion

In this paper a coupled CFD - hygrothermal material model is presented. A mass and energy conservative formulation of the heat and moisture transport equations in porous materials is implemented in the commercial CFD solver Fluent, hence assuring a direct coupling between the fluid and the porous zone. A verification of the newly developed model was performed by comparing the model with the analytical solution for a simplified test case. Next experiments for the benchmarking of one dimensional heat and moisture transfer model were simulated. The good agreement between the simulation and the experiment proves the capability of the new model to accurately predict the hygrothermal interaction at the air-material interface.

5. References

Amissah P. K. (2005). Indoor Air Quality - Combining air humidity with construction moisture. Department of Mechanical Engineering. University of Strathclyde, Glasgow. Crank J. (1989). The mathematics of diffusion. Oxford Science Publications, Oxford. Erriguible A., Bernada F., Couture F. and Roques M. (2006). Simulation of Convective Drying of a Porous Medium with Boundary Conditions provided by CFD, Chemical Engineering research and design, Vol 85(A2), p.113-123. Fluent Inc. (2006). Fluent userss guide. Version 6.3. Lebanon, NH, USA I.E.A. Annex 41 (2008), Whole building heat, air and moisture response Iskra C. R. and Simonson C.J. (2007). Convective mass transfer coefficient for a hydrodynamically developed airflow in a short rectangular duct, International Journal of Heat and Mass Transfer, Vol 50 (11-12), p. 2376-2393. Janssen H. (2002). The influence of soil moisture transfer on building heat loss via the ground. Department of Civil Engineering. Katholieke Universiteit Leuven, Leuven. Janssen H., Blocken B. and Carmeliet J. (2007). Conservative modelling of the moisture and heat transfer in building components under atmospheric excitation. International Journal of Heat and Mass Transfer, Vol 50(5-6), p. 1128-1140. Milly P. C. D. (1982). Moisture and heat transport in hysteretic, inhomogeneous porous media: a matric headbased formulation and a numerical model. Water Resources Research , Vol 18, p. 498-498. Mortensen L. H., Woloszyn M., Rode C. and Peuhkuri R. (2007). Investigation of microclimate by CFD modeling of moisture interactions between air and constructions. Journal of Building Physics , Vol 30(4), p. 279-315. Talukdar P., Olutmayin S. O., Osanyintola A. F., Simonson C. J. (2007). An experimental data set for benchmarking 1-D, transient heat and moisture transfer models of hygroscopic building materials. Part I: Experimental facility and material property data. International Journal of Heat and Mass Transfer , Vol 50(23-24), p.4527-4539. Talukdar P., Olutmayin S. O., Osanyintola A. F., Simonson C. J. (2008) . An experimental data set for benchmarking 1-D, transient heat and moisture transfer models of hygroscopic building materials. Part II: Experimental, numerical and analytical data. to be published in: International Journal of Heat and Mass Transfer

You might also like

- UG Oct 2007 Paper A41-T2-B-07-6Document2 pagesUG Oct 2007 Paper A41-T2-B-07-6Ermias AbelnehNo ratings yet

- Water: CFD Simulations of Multiphase Flows: Interaction of Miscible Liquids With DiDocument18 pagesWater: CFD Simulations of Multiphase Flows: Interaction of Miscible Liquids With DiSaswataChakrabortyNo ratings yet

- Simulation of conjugate heat transfer with OpenFOAMDocument17 pagesSimulation of conjugate heat transfer with OpenFOAMkkkkNo ratings yet

- Simulation of Two-Phase Flows in Vertical Tubes With The CFDDocument12 pagesSimulation of Two-Phase Flows in Vertical Tubes With The CFDdigecaNo ratings yet

- Implementation and Benchmarking of A 3D Hygrothermal Model in The COMSOL Multiphysics SoftwareDocument6 pagesImplementation and Benchmarking of A 3D Hygrothermal Model in The COMSOL Multiphysics SoftwareNouha JhiderNo ratings yet

- Modeling of Heat and Mass Transfer PDFDocument32 pagesModeling of Heat and Mass Transfer PDFAnonymous AW5jFq9SNo ratings yet

- On The Validity of The Boussinesq Approximation in A Tall Differentially Heated Cavity With WaterDocument7 pagesOn The Validity of The Boussinesq Approximation in A Tall Differentially Heated Cavity With WatercrazzyrajNo ratings yet

- Efficiency and Optimization of Straight Fins With Combinate Heat and Mass TransferDocument10 pagesEfficiency and Optimization of Straight Fins With Combinate Heat and Mass TransferMauro De La RosaNo ratings yet

- 3.2 - Baxter - Char Bed ModelDocument15 pages3.2 - Baxter - Char Bed ModelHuy NguyenNo ratings yet

- Heat and Mass Transfer in An Indirect Contact Cooling Tower: CFD Simulation and Experiment Jorge Faca o and Armando C. OliveiraDocument12 pagesHeat and Mass Transfer in An Indirect Contact Cooling Tower: CFD Simulation and Experiment Jorge Faca o and Armando C. OliveiraAkinNo ratings yet

- Laminar Forced Convection Heat and Mass Transfer of Humid Air Across A Vertical Plate With CondensationDocument11 pagesLaminar Forced Convection Heat and Mass Transfer of Humid Air Across A Vertical Plate With Condensationait hssainNo ratings yet

- Heat and Mass Transfer Through A Thick Bed of Cocoa Beans During DryingDocument9 pagesHeat and Mass Transfer Through A Thick Bed of Cocoa Beans During DryingFadli Ryan ArikundoNo ratings yet

- Revised ManuscriptDocument23 pagesRevised Manuscriptapi-3728640No ratings yet

- Batch Drying of Banana: Modelling and ExperimentsDocument6 pagesBatch Drying of Banana: Modelling and ExperimentsDaniel David ArangurenNo ratings yet

- Determination of Surface Convective Transfer Coefficients by CFD - Adamneale PDFDocument12 pagesDetermination of Surface Convective Transfer Coefficients by CFD - Adamneale PDFMustafa YılmazNo ratings yet

- Annular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsDocument9 pagesAnnular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsRashed KaiserNo ratings yet

- Numerical Analysis of Suction MufflersDocument11 pagesNumerical Analysis of Suction MufflersJose PradoNo ratings yet

- CI - Calculating Drying Shrinkage StressesDocument5 pagesCI - Calculating Drying Shrinkage StressesdavidchansmNo ratings yet

- Vacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsDocument6 pagesVacuum Contact Drying of Crystals: Multi-Scale Modelling and ExperimentsNishant Kumar GuptaNo ratings yet

- Simulation of Oil Tank FiresDocument12 pagesSimulation of Oil Tank Firesengtrader100% (1)

- Two-D modeling of energy and mass transfer in porous building componentsDocument10 pagesTwo-D modeling of energy and mass transfer in porous building componentsmanigandanNo ratings yet

- Czech Technical University in Prague, Faculty of Civil Engineering Thákurova 7, 16629 Prague 6, Czech RepublicDocument11 pagesCzech Technical University in Prague, Faculty of Civil Engineering Thákurova 7, 16629 Prague 6, Czech RepublicJaleel ClaasenNo ratings yet

- Numerical Model for Direct Evaporative CoolerDocument12 pagesNumerical Model for Direct Evaporative CoolerumairismailNo ratings yet

- Revised ManuscriptDocument23 pagesRevised Manuscriptapi-3728640No ratings yet

- Dahmani PortugalDocument11 pagesDahmani PortugalhiimrujuNo ratings yet

- The University of Bradford Institutional RepositoryDocument27 pagesThe University of Bradford Institutional Repositorymuhammad aliNo ratings yet

- CFD Simulation of Boiling Flows Using The Volume-Of-Fluid Method Within OpenFOAM Sir PaperDocument17 pagesCFD Simulation of Boiling Flows Using The Volume-Of-Fluid Method Within OpenFOAM Sir PaperedNo ratings yet

- HVAC Coil Design Software for Wet and Dry CoilsDocument5 pagesHVAC Coil Design Software for Wet and Dry CoilsgaryckfanNo ratings yet

- Soils modelling using Boltzmann equation in Lagrangian descriptionDocument21 pagesSoils modelling using Boltzmann equation in Lagrangian descriptionAndres PuertaNo ratings yet

- Finite Element Toolbox Simulates Solid-Liquid Phase ChangesDocument42 pagesFinite Element Toolbox Simulates Solid-Liquid Phase Changesmanoj srinivasNo ratings yet

- Modeling A Composition PDF TransportDocument22 pagesModeling A Composition PDF TransportMohamad PoortoosiNo ratings yet

- A New Mathematical Method To Solve Highly Coupled Equations of Heat and Mass Transfer in Porous MediaDocument10 pagesA New Mathematical Method To Solve Highly Coupled Equations of Heat and Mass Transfer in Porous MediabrunoNo ratings yet

- Modelling evaporation from a capillaryDocument36 pagesModelling evaporation from a capillaryDiego JesusNo ratings yet

- Mathematical Modeling, CFD Simulation, and ECT Measurement for Batch Fluidized-Bed DryingDocument18 pagesMathematical Modeling, CFD Simulation, and ECT Measurement for Batch Fluidized-Bed DryinghaftomNo ratings yet

- Runge Kutta MethodsDocument19 pagesRunge Kutta Methodssiva_ksrNo ratings yet

- Theoretical and Experimental Investigation of A Single-Stage Posi PDFDocument17 pagesTheoretical and Experimental Investigation of A Single-Stage Posi PDFAngel OfrenNo ratings yet

- Modelling The Arctic Convective Boundary-Layer With Different Turbulence ParameterizationsDocument24 pagesModelling The Arctic Convective Boundary-Layer With Different Turbulence ParameterizationsWenbo TANNo ratings yet

- DNS of Gas Solid ReactionsDocument25 pagesDNS of Gas Solid ReactionsShuiquan LanNo ratings yet

- International Journal of Heat and Mass Transfer: M. Khayet, A.O. Imdakm, T. MatsuuraDocument11 pagesInternational Journal of Heat and Mass Transfer: M. Khayet, A.O. Imdakm, T. MatsuuraIbrahim Al-MutazNo ratings yet

- 2005 - Theoretical Analysis of Dehumidification Process in A Desiccant WheelDocument10 pages2005 - Theoretical Analysis of Dehumidification Process in A Desiccant WheelzebrazerozeroNo ratings yet

- Comparing Homogeneous and Heterogeneous Models for Heat Transfer in Enclosures with Solid MaterialDocument18 pagesComparing Homogeneous and Heterogeneous Models for Heat Transfer in Enclosures with Solid MaterialGabriel SaavedraNo ratings yet

- Vdocuments - MX - Conduction and Convection Phenomena Through A Conduction and Convection PhenomenaDocument16 pagesVdocuments - MX - Conduction and Convection Phenomena Through A Conduction and Convection PhenomenaAndrew RichardsonNo ratings yet

- A Mathematical Model of Drying ProcessesDocument14 pagesA Mathematical Model of Drying ProcessesAlexander VovaNo ratings yet

- Chandramohan Numerical IjhmtDocument13 pagesChandramohan Numerical IjhmtNimish JainNo ratings yet

- NASA - Convective Heat Transfer in The Reusable Solid Rocket Motor of The Space Transportation SystemDocument39 pagesNASA - Convective Heat Transfer in The Reusable Solid Rocket Motor of The Space Transportation SystemUdil BalmogimNo ratings yet

- A Model To Simulate Chopped Alfalfa Drying in Fixed Deep-BedDocument9 pagesA Model To Simulate Chopped Alfalfa Drying in Fixed Deep-BedobajemarthaNo ratings yet

- Modeling of Steam Water Direct Contact Condensation Using Volume of Fluid ApproachDocument18 pagesModeling of Steam Water Direct Contact Condensation Using Volume of Fluid ApproachMustafa DemircioğluNo ratings yet

- El Hammami 2010Document24 pagesEl Hammami 2010ait hssainNo ratings yet

- A Three-Dimensional Simulation of Mine Ventilation Using Computational Fluid DynamicsDocument3 pagesA Three-Dimensional Simulation of Mine Ventilation Using Computational Fluid DynamicsTariq FerozeNo ratings yet

- The Effect of Tray Geometry On The Sieve Tray EfficiencyDocument9 pagesThe Effect of Tray Geometry On The Sieve Tray EfficiencyDr Mohammed AzharNo ratings yet

- 1 s2.0 S1877705817350543 Main PDFDocument7 pages1 s2.0 S1877705817350543 Main PDFRafi Bachtiar SaputraNo ratings yet

- tmp4B41 TMPDocument7 pagestmp4B41 TMPFrontiersNo ratings yet

- Numerical Simulation of Turbulent Flow and Heat Transfer in A Three-Dimensional Channel Coupled With Flow Through Porous StructuresDocument23 pagesNumerical Simulation of Turbulent Flow and Heat Transfer in A Three-Dimensional Channel Coupled With Flow Through Porous Structuresbouziane boudraaNo ratings yet

- Boundary Element Technique in Petroleum Reservoir SimulationDocument8 pagesBoundary Element Technique in Petroleum Reservoir Simulationiky77No ratings yet

- Computational Fluid Dynamics (CFD) Analysis of Cyclone Separators Connected in SeriesDocument9 pagesComputational Fluid Dynamics (CFD) Analysis of Cyclone Separators Connected in Seriesrajish1No ratings yet

- CFD Based Heat TransferDocument20 pagesCFD Based Heat Transfersujayan2005No ratings yet

- Dynamic Modelling of Refrigerated Truck Chambers: R.A.Pitarma, P.D.Gaspar & M.G.CarvalhoDocument8 pagesDynamic Modelling of Refrigerated Truck Chambers: R.A.Pitarma, P.D.Gaspar & M.G.CarvalhoRodrigo GonçalvesNo ratings yet

- Hydrothermal Analysis in Engineering Using Control Volume Finite Element MethodFrom EverandHydrothermal Analysis in Engineering Using Control Volume Finite Element MethodNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- Renewable Theoretical Summary - Mona - MidtermDocument11 pagesRenewable Theoretical Summary - Mona - MidtermgetsweetNo ratings yet

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Solar 2 - Solar Power PlantsDocument60 pagesSolar 2 - Solar Power PlantsgetsweetNo ratings yet

- Sustainable BackgroundDocument111 pagesSustainable BackgroundgetsweetNo ratings yet

- ITEC Application Form 2014-15Document8 pagesITEC Application Form 2014-15Mangalah Gauari MahaletchnanNo ratings yet

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocument2 pagesHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

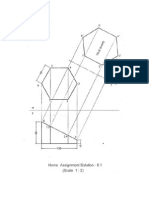

- Bearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°Document1 pageBearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°getsweetNo ratings yet

- Lesson 4 XPDocument30 pagesLesson 4 XPmaglalang_dexter_024No ratings yet

- Media Lecture Notes S5B1C6Document17 pagesMedia Lecture Notes S5B1C6getsweetNo ratings yet

- General Overview Boilers and FlowDocument22 pagesGeneral Overview Boilers and FlowLiam MoylanNo ratings yet

- CCAC Mechanical Drawing Worksheet 01 ProblemsDocument1 pageCCAC Mechanical Drawing Worksheet 01 ProblemsgetsweetNo ratings yet

- Multi-view drawing with dimensions of given objectDocument3 pagesMulti-view drawing with dimensions of given objectgetsweetNo ratings yet

- NEWChapter - 3-Mass Balance PDFDocument10 pagesNEWChapter - 3-Mass Balance PDFAbdelhaleem KhaderNo ratings yet

- Proposal Tips HintsDocument4 pagesProposal Tips HintsAravindan NatarajanNo ratings yet

- Create The Following Solid Models Using Solidworks.: ExerciseDocument1 pageCreate The Following Solid Models Using Solidworks.: ExercisegetsweetNo ratings yet

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- ST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- Air Pollution Examples Stability Classes ConcentrationsDocument50 pagesAir Pollution Examples Stability Classes ConcentrationsgetsweetNo ratings yet

- Oblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsDocument2 pagesOblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsgetsweetNo ratings yet

- Problem 01 Problem 02: Community College of Allegheny CountyDocument1 pageProblem 01 Problem 02: Community College of Allegheny CountygetsweetNo ratings yet

- U U U P T: Quick Visit To Bernoulli LandDocument9 pagesU U U P T: Quick Visit To Bernoulli LandAkash SodhaNo ratings yet

- Chapter 08 2Document64 pagesChapter 08 2Subhi MohamadNo ratings yet

- Worksheet Week7Document2 pagesWorksheet Week7getsweet0% (1)

- Home Soln 8Document4 pagesHome Soln 8getsweetNo ratings yet

- Roxul Cavityrock Application GuideDocument60 pagesRoxul Cavityrock Application GuidebobbobNo ratings yet

- Manual Particle Counter Pce RCM 10 en - 1163766Document9 pagesManual Particle Counter Pce RCM 10 en - 1163766Chan PhingNo ratings yet

- Ready-to-use Pigmented Surface ProtectionDocument2 pagesReady-to-use Pigmented Surface ProtectionZlatko KrsicNo ratings yet

- Improving Solar Food DryersDocument11 pagesImproving Solar Food Dryerspodbaydoor100% (1)

- FRENIC-Ace Instruction ManualDocument112 pagesFRENIC-Ace Instruction ManualGanesh YadavNo ratings yet

- FiberTec PPS Application v3 01Document7 pagesFiberTec PPS Application v3 01tsoheilNo ratings yet

- VVAA. Environment Policy V&A Museum. 1991Document7 pagesVVAA. Environment Policy V&A Museum. 1991Trinidad Pasíes Arqueología-Conservación100% (1)

- Modified Air Cooler With Split Cooling Unit (Original)Document41 pagesModified Air Cooler With Split Cooling Unit (Original)girish100% (4)

- Application Manual: Heat Insulation Glass Coating Material GLC - 1 Cool in Summer, Warm in WinterDocument20 pagesApplication Manual: Heat Insulation Glass Coating Material GLC - 1 Cool in Summer, Warm in WinterLollipopNo ratings yet

- Belzona 2211: Instructions For UseDocument2 pagesBelzona 2211: Instructions For UseMAMI RAKOTOMAHANINANo ratings yet

- Endos DC: Service ManualDocument114 pagesEndos DC: Service ManualJuan Carlos GoyzuetaNo ratings yet

- Tenability Criteria Practice Note 2 0Document22 pagesTenability Criteria Practice Note 2 0Mohammed TaherNo ratings yet

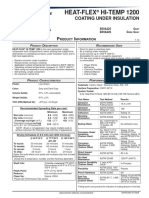

- Heat Flex Hi Temp 1200 CuiDocument4 pagesHeat Flex Hi Temp 1200 CuiVanner SalasNo ratings yet

- Test ExcelDocument30 pagesTest ExcelAnonymous sG3iVImJNo ratings yet

- ISO-7547-2002 IncompletoDocument9 pagesISO-7547-2002 Incompletopeter mayordNo ratings yet

- Thermal Univ QBDocument15 pagesThermal Univ QBrajapratyNo ratings yet

- Sam ReportDocument9 pagesSam ReportMahima mpNo ratings yet

- VITiny F300, Microscopio Digital Portátil, Manual EnglishDocument4 pagesVITiny F300, Microscopio Digital Portátil, Manual EnglishTICTRONICA Ltda.100% (2)

- Temal 400: Type Suitability Examples of USE Technical DataDocument2 pagesTemal 400: Type Suitability Examples of USE Technical Datammicu18No ratings yet

- Rezistenta Termica Perete Interior 15Document4 pagesRezistenta Termica Perete Interior 15Stelian BerceaNo ratings yet

- Water Contamination in Hydraulic and Lube SystemsDocument11 pagesWater Contamination in Hydraulic and Lube SystemsBrayan MejiaNo ratings yet

- User 'S Manual: QJ2000 Series Frequency Converter AC DriveDocument150 pagesUser 'S Manual: QJ2000 Series Frequency Converter AC DriveBRUNO GUIMARAESNo ratings yet

- Measuring Abiotic Factors in University of the East Manila CampusDocument9 pagesMeasuring Abiotic Factors in University of the East Manila CampusRACHELLE RAMOSNo ratings yet

- Carel DPPT0110000 ManualDocument4 pagesCarel DPPT0110000 ManualMd Abu BorhanNo ratings yet

- Biofix 2022 inDocument5 pagesBiofix 2022 inSahil KaliaNo ratings yet

- S1 Geography NotesDocument42 pagesS1 Geography NotesKurtis ChomiNo ratings yet

- SEM164 Humidity & Temperature Transmitters: 2.2 MechanicalDocument2 pagesSEM164 Humidity & Temperature Transmitters: 2.2 MechanicalElsad HasanliNo ratings yet

- Overall Assessment CHE 252 2020Document3 pagesOverall Assessment CHE 252 2020Enoch AffulNo ratings yet

- Be FR NLDocument198 pagesBe FR NLNaltu IonelNo ratings yet