Professional Documents

Culture Documents

SAIC-L-2060 Rev 0

Uploaded by

philipyapOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-L-2060 Rev 0

Uploaded by

philipyapCopyright:

Available Formats

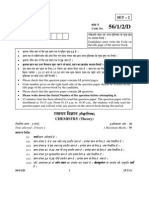

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Final Inspection of Fire Water Distribution System

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2060

WBS / BI / JO NUMBER

25-May-05

PIPING-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

Instructions on use of this checklist: 1. Any Item marked as "Fail" requires to be identified with the specific description and location of the descripancy/violation and shall be listed in the Contractor's Re-Instatement Punchlist Form, SATR- A-2011. 2. Column "Y/N" is used to pre-determine each respective item as required for start-up ( Y), or not required for start-up (N). 3. This Checklist along with the Re-Instatement Punchlist, with or with out cleared items, shall be submitted to Saudi Aramco on or before the requested time for Mechanical Completion Punchlisting. ITEM No. A

ACCEPTANCE CRITERIA Equipment Documentation Test and Inspection Plan (SATIPs) and Inspection Checklists for field installation as detailed in SATIP-L-350-05 were verified to be complete and accepted. All non-conformance reports and worksheets have been resolved to the satisfaction of Inspection Department. All log book entries have been resolved to the satisfaction of Inspection Department. All equipment fabrication documents and inspection record books are available for review. P&ID Check / Walkthrough All fire water piping components are installed in their respective locations as shown in the P&ID. All in-line equipment & Instruments are installed in their respective locations as shown in the P&ID. (i.e: Pressure Indicators, Temperature, temperature indicators, sample probes, etc) Pressure gages installed are of the same range as shown in the P&ID. Pressure gages are installed with block and bleed valves. (The bleed valve shall be plugged.) Temperature Gages installed are of the same range as shown in the P&ID. Thermowells are provided with chained plug and plug installed where temperature indicators are not provided. (Refer to Std.Dwg. AB-36019)

REFERENCE

PASS

FAIL

N/A

Y/N

RE-INSP DATE

A4

GI-2.710 Para. 4.1.1.2 GI-2.710 Para. 4.1.1.4 GI-2.710 Para. 4.1.1.4 GI-2.710 Para. 4.1.1.6

A5

A6

Y/N

A7 B B1

P&ID # ____________ P&ID # ____________ P&ID # ____________ SAES-J-200, Para. 6.1 & 6.4 P&ID #

B2

B3

B4

B5

Y ____________ SAES-J-400, Para. 5.2.5 N

B6

Page 1 of 4

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Final Inspection of Fire Water Distribution System

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2060

WBS / BI / JO NUMBER

25-May-05

PIPING-

CONTRACTOR / SUBCONTRACTOR

ITEM No. B7

ACCEPTANCE CRITERIA Thermowells are provided with chained plug and plug installed where temperature indicators are not provided. (Refer to Std.Dwg. AB-36019) Mechanical Works All nuts and bolts flange connections are fully engaged.

REFERENCE SAES-J-400, Para. 5.2.5

PASS

FAIL

N/A

Y/N

RE-INSP DATE

C C1

GI-2.710-06, Item 1j

C2

Hydrants, Monitors and hose reels are instaled in the designated locations as shown in the approved construction drawings. Installed Relief Valves were verified to conform with the P&ID and the corresponding Form 3099A signed. (NOTE: Verification & inspection is done using inspection Checklist, SAIC-J-2009) Jack screw bolts installed in flanges with spectacle plates. Atmospheric drain and vent valves are provided with a plug or blind on the discharge side. Flange joints were verified to be tightened using the applicable Torque procedure. Pipe spools removed during pressure test are re-installed. Strainers, both temporary and permanent, spectacle blinds and temporary blinds were installed as required by commissioning and as called for on the P&ID.. All tempoary blanks, plugs, caps spectacle plates and temporary spools installed for the hydrotest have been removed. Loose flanges are tightened using new gaskets. In- line check valves and control valves were installed in their correct direction. Supports, guides and anchors are installed and shims installed where required. Restraints of spring supports removed and spring supports set. In- line instruments as per P&ID are installed, ie; corrosion probes, thermowells, orifice plates, venturi Pre-test punch list "B" items are corrected and completed. (NOTE: Outstanding items shall be listed in the FEIL.) Structural Items: All access areas including platforms, walkways, stairs, ladders are free of debris, tools and extraneous materials which would impede operation or cause an unsafe condition. Edges of all tightly contacting surfaces of steel structures are seal welded.

AFC Drawings

C3

SAES-J-600, Item 10

C4

SAES-L-350, Para. 10.5 SAES-L-108, Para. 7.7 GI-2.710-6, Item 1.j. G.I. 2.710-6 Item 4c G.I. 2.710-6 Item 4c G.I. 2.710-6 Item 4c G.I. 2.710-6 Item 4h G.I. 2.710-6 Item 4f G.I. 2.710-6 Item 4m G.I. 2.710-6 Item 4l P&ID # ___________ G.I. 2.710-6 Item 4-Piping

Y/N

C5

C6

C7

C8

C9

C10 C11 C12 C13 C15 C16 D

Y Y Y Y Y Y

D1

GI-2.710-06, Item 1e SAES-M-001, Para. 7.1.3.3

D2

Page 2 of 4

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Final Inspection of Fire Water Distribution System

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2060

WBS / BI / JO NUMBER

25-May-05

PIPING-

CONTRACTOR / SUBCONTRACTOR

ITEM No. D3

ACCEPTANCE CRITERIA Access platforms, ladders, stairs, walkways and handrails as per the scope of work and construction drawings are complete. Gratings are firmly anchored with a minimum of 2 fasteners at each support with a minimum of 4 fasteners per panel. (Note: Non-compliance shall be identified as "YES" item in the Facility Exception Item List for the MCC.) Painting Works Painting are complete. Pipes, vessels, valves, and related structural supports shall be painted a neutral background color such as aluminum, gray, or black per SAES-B067, Para.4.1.1) Identification of vessel stencilled and legible at a distance of 50 feet away. Safety yellow-and-black stripes are painted on obstructions that present bump hazards. (concrete supports at the base of stairways or ladders, passageway pinch points, unguarded edges, tripping hazards). Stripes shall be 100 mm wide. All exposed aboveground fire water piping and fittings shall be painted red. (NOTE: Exception: Runs of aboveground outdoor fire water piping longer than 65 meters may be painted an aluminum rather than a red color; however, all valves, tees, elbows, and connected piping within 3 meters of those valves and fittings shall be painted safety red. The piping shall have a safety red band at least every 30 m. Bands shall be 0.3 m (12 inches) long.) Sprinkler and deluge piping may be painted an aluminum color. However, in the header/riser piping all valves, tees, elbows, strainers, and their connected piping within 3 meters shall be painted red. Fire protection equipment: fire water pumps, fire water pump control panels, portable and fixed fire protection systems, the mounting background for fire extinguishers, portable fire-fighting equipment, and shelters for portable fire-fighting equipment shall be safety red. Insulation works/Fire Proofing Insulation is complete per applicable SATIP-N-001-01 or SATIP-N-00102 All fire proofing complete. All equipment, piping, instruments, instruments leads, etc. requiring insulation for heat conservation are complete. Insulation required for personnel protection are complete.

REFERENCE GI-2.710-06, Item 2c

PASS

FAIL

N/A

Y/N Y

RE-INSP DATE

D4

12-SAMSS-007, Para. 6.1.16

E E1

GI-2.710-06, Item 1d Scope of Work GI-2.710-06, Item 1a SAES-B-067, Para. 4.2.3 a

Y/N

E2

Y/N

E3

Y/N

E4

E5

SAES-B-067, Para. 4.2.1 a

E6

SAES-B-067, Para. 4.2.1 (a.2)

E7

SAES-B-067, Para. 4.2.1 b

F F1 F2 F3 F4

Scope of Work GI-2.710-06, Item 1c GI-2.710-06, Item 1c GI-2.710-06, Item 1c

Y Y Y Y

REMARKS:

REFERENCE DOCUMENTS: 1. G.I.-2.710, Mechanical Completion and Performance Acceptance of Facilities, (13 July, 2004)

Page 3 of 4

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Final Inspection of Fire Water Distribution System

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-L-2060

WBS / BI / JO NUMBER

25-May-05

PIPING-

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

Y/N

RE-INSP DATE

2. SAES-M-001, Structural Design Criteria for Non-Building Structures, (30 June, 2004) 3. SAES-J-200, Pressure, (31 May, 2003), 4. SAES-J-400, Temperature, (31 May, 2004) 5. SAES-J-600, Pressure Relief Devices, (31 March, 2003) 6. SAES-B-054, Access, Egress, and Materials Handling for Plant Facilities, (31 March, 2001) 7. SAES-B-067, Safety Identification and Safety Colors, (30 November, 2003)

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapNo ratings yet

- Resilent FlooringDocument7 pagesResilent FlooringphilipyapNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Panel BoardDocument7 pagesPanel BoardphilipyapNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- DuctworksDocument7 pagesDuctworksphilipyapNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Bazaar Tent StructureDocument5 pagesBazaar Tent StructurephilipyapNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Exterior LightingDocument8 pagesExterior LightingphilipyapNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Saudi Aramco Oil Company: SECTION 16110 RacewaysDocument10 pagesSaudi Aramco Oil Company: SECTION 16110 RacewaysphilipyapNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Wire, Cable and Low VotageDocument9 pagesWire, Cable and Low VotagephilipyapNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Finish CarpentryDocument17 pagesFinish CarpentryphilipyapNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Bazaar Tent StructureDocument5 pagesBazaar Tent StructurephilipyapNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Roof and Deck InsulationDocument3 pagesRoof and Deck InsulationphilipyapNo ratings yet

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Chilled Water PumpDocument6 pagesChilled Water PumpphilipyapNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- FanDocument7 pagesFanphilipyap100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Duct Works & AccessoriesDocument5 pagesDuct Works & AccessoriesphilipyapNo ratings yet

- DuctworksDocument7 pagesDuctworksphilipyapNo ratings yet

- SignageDocument4 pagesSignagephilipyapNo ratings yet

- Variable Air UnitDocument4 pagesVariable Air UnitphilipyapNo ratings yet

- Control SystemDocument21 pagesControl SystemphilipyapNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- G.furniture & FixturesDocument2 pagesG.furniture & FixturesphilipyapNo ratings yet

- Metal FramesDocument4 pagesMetal FramesphilipyapNo ratings yet

- Fan Coil UnitsDocument3 pagesFan Coil UnitsphilipyapNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Metal FramesDocument4 pagesMetal FramesphilipyapNo ratings yet

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapNo ratings yet

- 03210-Epoxy Coated Conc ReoDocument7 pages03210-Epoxy Coated Conc ReophilipyapNo ratings yet

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Floor MatsDocument3 pagesFloor MatsphilipyapNo ratings yet

- Swimming PoolDocument4 pagesSwimming PoolphilipyapNo ratings yet

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- Enhanced Tribological Properties of Wind Turbine Engine Oil Formulated With Flower-Shaped MoS2 Nano-AdditivesDocument10 pagesEnhanced Tribological Properties of Wind Turbine Engine Oil Formulated With Flower-Shaped MoS2 Nano-AdditivesZoubir SaidiNo ratings yet

- 620102/01 PN16/PN10: DESCRIPTION: Nodular Cast Iron Body Gate Standard & DesignDocument1 page620102/01 PN16/PN10: DESCRIPTION: Nodular Cast Iron Body Gate Standard & Designadvantage025No ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Determination of Volatile Fatty Acid in Enviromental Aqueos Samples PDFDocument6 pagesDetermination of Volatile Fatty Acid in Enviromental Aqueos Samples PDFNierza Alfiannur100% (1)

- Air Cooled Condensers Selection GuideDocument16 pagesAir Cooled Condensers Selection GuideelmerbayhonNo ratings yet

- Urinary Bladder Wall Repair What Suture To UseDocument3 pagesUrinary Bladder Wall Repair What Suture To UseRenan AreiasNo ratings yet

- 2016 ECI Catalogue RevE 03-2016 Section11 RO NPDocument13 pages2016 ECI Catalogue RevE 03-2016 Section11 RO NPAkuba AmanNo ratings yet

- RBSA Indian Steel Industry AnalysisDocument45 pagesRBSA Indian Steel Industry AnalysisVasiliy GuryevNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Brief Company Profile: Manuli Rubber Industries (MRI)Document36 pagesBrief Company Profile: Manuli Rubber Industries (MRI)Le Anh DangNo ratings yet

- BS 5950-1 1990Document126 pagesBS 5950-1 1990Anoy100% (4)

- 2008 Failure of Refurbished Turbine Blades in A Power Station by Improper Heat TreatmentDocument6 pages2008 Failure of Refurbished Turbine Blades in A Power Station by Improper Heat TreatmentArun KumarNo ratings yet

- Production and Characterization of Amorphous Al-Cu Alloy For Aerospace ApplicationsDocument9 pagesProduction and Characterization of Amorphous Al-Cu Alloy For Aerospace ApplicationsSamuel ArelianoNo ratings yet

- Exp. 4 Lipid Extraction and Lipid TestsDocument5 pagesExp. 4 Lipid Extraction and Lipid TestsEMELIE GRACE E CACHERONo ratings yet

- BS 434-2-1984 Code of Practice For Use of Bitumen Road EmulsiDocument22 pagesBS 434-2-1984 Code of Practice For Use of Bitumen Road EmulsianjanaNo ratings yet

- 12 Chemistry CBSE Exam Papers 2015 Delhi Set 2 PDFDocument12 pages12 Chemistry CBSE Exam Papers 2015 Delhi Set 2 PDFSatya KamNo ratings yet

- Pongkor Process Plant OverviewDocument17 pagesPongkor Process Plant OverviewImam SidikNo ratings yet

- LI-7200RS and SmartFlux 2 User CalibrationDocument1 pageLI-7200RS and SmartFlux 2 User CalibrationTomás Arturo Soto MurilloNo ratings yet

- Difcomanualofdeh 09 DigeDocument360 pagesDifcomanualofdeh 09 DigeDimas FirliantoroNo ratings yet

- Theory of Structures (CE4G) Direct and Bending StressesDocument22 pagesTheory of Structures (CE4G) Direct and Bending StressesDiptoNo ratings yet

- DactylosDocument50 pagesDactylosRed Snow75% (4)

- Lakshya JEE AIR Organic ChemistryDocument1 pageLakshya JEE AIR Organic ChemistryShardul DucheNo ratings yet

- Research Project For Cooperation Study: Fluidized-Bed Gasification PyrolysisDocument40 pagesResearch Project For Cooperation Study: Fluidized-Bed Gasification PyrolysisPattakon TaotiangNo ratings yet

- CES 6.0.0 Deck Management Oil TankerDocument13 pagesCES 6.0.0 Deck Management Oil Tankerboramir496793% (15)

- L10-Casting DesignDocument42 pagesL10-Casting DesignKhayrulIslam100% (2)

- Reliance - 10080-1-SS-PP-014 - REV2Document58 pagesReliance - 10080-1-SS-PP-014 - REV2Blain86% (7)

- Determining Formaldehyde Concentration in Air From Wood Products Using A Small Scale ChamberDocument9 pagesDetermining Formaldehyde Concentration in Air From Wood Products Using A Small Scale ChamberRubén Eduardo Galindo CarmonaNo ratings yet

- Astm D129 PDFDocument4 pagesAstm D129 PDFProkop100% (1)

- Unedited Version 193 RlsDocument167 pagesUnedited Version 193 RlsDavid LeNo ratings yet

- Shining A Light On High Volume Photocurable MaterialsDocument16 pagesShining A Light On High Volume Photocurable MaterialsDan MPNo ratings yet