Professional Documents

Culture Documents

Trunnion load calcs

Uploaded by

Chirag ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trunnion load calcs

Uploaded by

Chirag ShahCopyright:

Available Formats

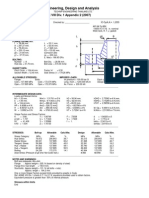

CALCULATIONS AND SKETCHES

JOB NO.

Southern Region Houston, Texas BY DATE:

CHKD. DATE:

PAGE REV.

CLIENT AND LOCATION

UNIT

ITEM

Longitudinal Bending Circumferential Bending Axial Load

Header Pipe: Reinforcing Pad:

8.625 0

0.322 Note 3

0 Note 4 0.322

Trunnion:

6.625 Notes:

0.28 1. All stress values below are given in lbs/in

2.

22.4 Note 5 2. All load values below are given in lbs.

0.148 3. If line is existing, check against actual wall thickness

as reported by plant inspection.

Applied Loads (lbs) and Moments (in-lbs): 4. If line is existing, use corrosion allowance as reported by

plant inspection, or use original corrosion allowance as

0 reported in original pipe specification, whichever is greater.

0 5. Length of trunnion determined from outside wall of run pipe to

2525 to contact with grade or centerline of support beam.

64

200

Allowable Stresses:

16700

16700

Longitudinal Circumfrential Axial

Atofina, Beaumont, Texas

Sulfox

Trunnion loads on base ell at node 425. Ceasar calculation 25-007

TRUNNION OR OTHER CYLINDRICAL ATTACHMENTS TO PIPE

8" Sch 40s elbow with type 7 trunnion.

SUSTAINED INPUT

Corrosion Allowance (in.) Wall Thickness + Pad Thk - Corrosion t (in.)

Axial Force on Trunnion W (lbs)

Design Pressure P (psi)

Longitudinal Moment M

L

(in - lbs)

Circumfrential Moment M

c

(in - lbs)

Outside Diameter d (in.)

Wall Thickness (in.)

Length of Trunnion L (in.)

Design Temperature (F)

Hot Allowable Stress (psi)

Cold Allowable Stress (psi)

EQUATIONS

Outside Diameter D (in.) Reinforcing Pad thickness (in.)

Wall Thickness (in.)

Weld Size (in)

2

) 4 / ( d

M

f

L

L

t

=

t

D P

t

D f

S

L

2

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

2

) 4 / ( d

M

f

c

c

t

=

t

D P

t

D f

S

c

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

t

D P

t

D f

S

A

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

) 2 / ( 2 d

W

f

a

t

=

Rev.6

Longitudinal Evalvuation

f

L

=

0 Note 2 (typ)

S

L

=

429 25,050 Note 1 (typ) PASS

f

1

=

182

S

L2

=

2,848 25,050 PASS

Note: Expansion Load case gives the same result as Sustained Case. No evaluation is necessary.

Circumferential Evaluation

f

cs

=

0

f

2s

=

0

S

c2s

=

857 25,050 PASS

Localized Load f

2

=1.5( fc + f

a

) f

2Ma

=

182

S

c2Ma

=

3,277 25,050 PASS

Combined Resultant Load Evaluation

fr = 0

Localized Load f

3s

=1.5(fr + f

a

) f

3s

=

182

S

c3s

=

3,277 25,050 PASS

Axial Evaluation

f

a

=

121

S

as

=

2,470 25,050 PASS

Global Stress Evaluation

Bending Stress in Trunnion Bending Stress

f

s

=

0

S

b

=

0 < Sh = 16,700 PASS

Trunnion Section Modulus

Weld Resulant Force

Z

t

=

8.5

f

F

=

121

Weld Shear Stress

Shear Stress in Fillet Weld

S

w

=

55.71

< S

sa

=

13,360 PASS

Weld Area (in

2

) 2

Sustained Load Case (Mc+W)

< 1.5 S

h

=

Sustained Load Case (ML)

Sustained Load Case (Mc)

Localized Load f

2

= 1.5(f

cs

) < 1.5 S

h

=

< 1.5 S

h

=

Sustained Load Case (ML+W)

SUSTAINED CALCULATIONS

NOTE: IF ANY FAILURES RESULT BELOW, THE PIPING LOADS MUST BE ADJUSTED AND THEN RE-CALCULATED

< 1.5 S

h

=

Localized Load f

1

= f

L

+ 1.5f

a

< 1.5Sh =

< 1.5Sh =

Sustained Loading (ML+Mc+W)

Sustained Loading (W)

|

|

.

|

\

|

=

D

d D

Z

t

4 4

32

t

2 2

c L s

f f f + =

t

s

b

Z

L f

S

=

2 2 2

a c L F

f f f f + + =

W

F

W

A

f

S =

2 2

C L r

f f f + =

Rev.6

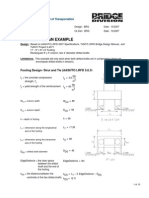

CALCULATIONS AND SKETCHES

JOB NO. 0

Southern Region Houston, Texas BY 0 DATE: 1/0/1900

CHKD. DATE:

PAGE REV.

CLIENT AND LOCATION

UNIT

ITEM

Longitudinal Bending Circumferential Bending Axial Load

Header Pipe: Reinforcing Pad:

Outside Diameter D (in.) 8.625 Reinforcing Pad thickness (in.) 0

Wall Thickness (in.) 0.322 Note 3

Wall Thickness + Pad Thk t (in.) 0.322

Trunnion:

Outside Diameter d (in.) 6.625 Notes:

Wall Thickness (in.) 0.28 1. All stress values below are given in lbs/in

2.

Length of Trunnion L (in.) 22.4 Note 5 2. All load values below are given in lbs.

Weld Size (in) 0.148 3. If line is existing, check against actual wall thickness

as reported by plant inspection.

Applied Loads (lbs) and Moments (in-lbs): 4. If line is existing, use corrosion allowance as reported by

plant inspection, or use original corrosion allowance as

Longitudinal Moment M

L

(in - lbs) 16970 reported in original pipe specification, whichever is greater.

Circumfrential Moment M

c

(in - lbs) 16970 5. Length of trunnion determined from outside wall of run pipe to

Axial Force on Trunnion W (lbs) 340 to contact with grade or centerline of support beam.

Design Pressure P (psi) 64

Design Temperature (F) 200

Allowable Stresses:

Hot Allowable Stress (psi) 16700

Cold Allowable Stress (psi) 16700

Longitudinal Circumfrential Axial

Atofina, Beaumont, Texas

Sulfox

Trunnion loads on base ell at node 425. Ceasar calculation 25-007

8" Sch 40s elbow with type 7 trunnion.

TRUNNION OR OTHER CYLINDRICAL ATTACHMENTS TO PIPE

EQUATIONS

EXPANSION INPUT

2

) 4 / ( d

M

f

L

L

t

=

t

D P

t

D f

S

L

2

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

2

) 4 / ( d

M

f

c

c

t

=

t

D P

t

D f

S

c

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

t

D P

t

D f

S

A

) 2 / ( ) 2 / ( 17 . 1

5 . 1

+ =

) 2 / ( 2 d

W

f

a

t

=

Rev.6

Longitudinal Evalvuation

f

L

= 492

S

L

= 6,975 25,050 Note 1 (typ) PASS

f

1

= 517 Note 2 (typ)

S

L2

= 7,301 25,050 PASS

Note: Expansion Load case gives the same result as Sustained Case.

Circumferential Evaluation

f

cE

= 492

Localized Load fcE = fc

S

cE

= 7,403 25,050 PASS

Localized Load f

2E

= fc + 1.5f

a

f

2E

= 517

S

c2E

= 7,729 25,050 PASS

Combined Resultant Load Evaluation

fr = 696

Localized Load f

3E

=fr + 1.5f

a

f

3E

= 721

S

c3E

= 10,441 25,050 PASS

Axial Evaluation

f

a

= 16

S

a

= 1,074 25,050 PASS

Global Stress Evaluation

Bending Stress in Trunnion Bending Stress

f

s

= 696 S

b

= 1,836 < Sh = 16,700 PASS

Trunnion Section Modulus

Weld Resulant Force

Z

t

= 8.5 f

F

= 696

Weld Shear Stress

Shear Stress in Fillet Weld

S

w

= 319.77 < S

sa

= 13,360 PASS

Weld Area (in

2

) 2

EXPANSION CALCULATIONS

< 1.5Sh =

< 1.5Sh =

Expansion Load Case (ML+W)

Expansion Load Case (Mc)

Expansion Load Case (Mc+W)

Expansion Load Case (ML+Mc+W)

< 1.5 S

h

=

< 1.5 S

h

=

< 1.5 S

h

=

< 1.5 S

h

=

Localized Load f

1

= f

L

+ 1.5f

a

Expansion Load Case (ML)

NOTE: IF ANY FAILURES RESULT BELOW, THE PIPING LOADS MUST BE ADJUSTED AND THEN RE-CALCULATED

|

|

.

|

\

|

=

D

d D

Z

t

4 4

32

t

2 2

c L s

f f f + =

t

s

b

Z

L f

S

=

2 2 2

a c L F

f f f f + + =

W

F

W

A

f

S =

2 2

C L r

f f f + =

Rev.6

You might also like

- Operating Case Trunnion Calculation Sheet: Input DataDocument1 pageOperating Case Trunnion Calculation Sheet: Input DataJagadish JasNo ratings yet

- DummyDocument1 pageDummythopa_nath100% (2)

- Trunnion CalculationDocument8 pagesTrunnion CalculationPrashant ChauhanNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Pipe SupportDocument11 pagesPipe SupportAditya Bagus M100% (3)

- CALCULATION SHEETSDocument27 pagesCALCULATION SHEETSBharat Bellad100% (1)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDocument10 pagesGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaNo ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Flange Leakage CheckDocument1 pageFlange Leakage CheckPhornlert WanaNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- TRUNNION CALCULATION SHEETDocument1 pageTRUNNION CALCULATION SHEETAtty Atty100% (1)

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakellyNo ratings yet

- Nozzle Loads WRC 107 Ver 1.1Document5 pagesNozzle Loads WRC 107 Ver 1.1Honey Tiwari75% (4)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Expansion Loop CalculationDocument2 pagesExpansion Loop Calculationsk130986100% (1)

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan PanchalNo ratings yet

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Asme Viii D Table 2aDocument16 pagesAsme Viii D Table 2aJohakim974100% (1)

- N-318-5 Lug Local StressDocument3 pagesN-318-5 Lug Local StresscohenfuNo ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- PVElite Course by Mr. AsgarzadeganDocument79 pagesPVElite Course by Mr. AsgarzadeganSaam Sasanian33% (3)

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- 16147-Shoe With Gusset No RepadDocument5 pages16147-Shoe With Gusset No RepadRamesh Krishnan100% (1)

- Standard Shoe Verification Rev - ADocument19 pagesStandard Shoe Verification Rev - AballisnothingNo ratings yet

- Pipe Span Without Point LoadsDocument36 pagesPipe Span Without Point Loadsbakelly100% (4)

- Lifting Lug TutorialDocument20 pagesLifting Lug Tutorialmontie3No ratings yet

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)amaNo ratings yet

- Pipe Support ManualDocument5 pagesPipe Support Manualzytyrant33% (3)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Pipe Pressure RatingDocument1 pagePipe Pressure RatingbakellyNo ratings yet

- Member Check 60x60x5 RSA (Top & Bottom Boom)Document10 pagesMember Check 60x60x5 RSA (Top & Bottom Boom)Bobor Emmanuel OfovweNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Penstock Design CalculationsDocument26 pagesPenstock Design CalculationsRoland TagufaNo ratings yet

- 3 Analysis and Design of Deck SlabDocument14 pages3 Analysis and Design of Deck SlabAshish BhoiNo ratings yet

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- 200-Foot Simple Span Bridge Girder Design Using NU2000 V1Document50 pages200-Foot Simple Span Bridge Girder Design Using NU2000 V1Anthony GravagneNo ratings yet

- LOAD CALCULATIONSDocument19 pagesLOAD CALCULATIONSSudathipTangwongchaiNo ratings yet

- HDD Pipeline Design OptimizationDocument15 pagesHDD Pipeline Design Optimizationoconnorr8133% (3)

- Transmission Tower Foundation DesignDocument26 pagesTransmission Tower Foundation DesignSara Nuon86% (7)

- Spreader Bar Plus Free BodyDocument17 pagesSpreader Bar Plus Free BodyMichael HaiseNo ratings yet

- Design of Pipe Rack StructureDocument23 pagesDesign of Pipe Rack Structureibson045001256No ratings yet

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Design Examples: Concentrically Loaded Lipped Channel ColumnDocument25 pagesDesign Examples: Concentrically Loaded Lipped Channel ColumnmrnaeemNo ratings yet

- Shaft Footing ExampleDocument10 pagesShaft Footing Exampleอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Busbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605Document45 pagesBusbar Current Rating and BPI Cantilever Calculation(Equation No. 30, IEEE 605annuvyas100% (1)

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Stress Analysis of Piping Systems with Caesar II ProgramDocument22 pagesStress Analysis of Piping Systems with Caesar II ProgramDaniel FullerNo ratings yet

- Circular Water Tank-DeSIGNDocument3 pagesCircular Water Tank-DeSIGNMarianne Aravilla Dela CruzNo ratings yet

- HDD Calculation (Template)Document4 pagesHDD Calculation (Template)bebas_amarah87% (15)

- Amp CoidDocument1 pageAmp CoidChirag ShahNo ratings yet

- Appendix H Alignment Sheet ExampleDocument2 pagesAppendix H Alignment Sheet ExampleFaizal KhanNo ratings yet

- Relief Valve - Convential Liquid ASME Code, Find AreaDocument2 pagesRelief Valve - Convential Liquid ASME Code, Find AreaChirag ShahNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument16 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Ph4-Si-1011-Var-r0 Nozzle Check X 1310 Nozzle C NP 2090Document11 pagesPh4-Si-1011-Var-r0 Nozzle Check X 1310 Nozzle C NP 2090Chirag ShahNo ratings yet

- FCU 500 RPT Reliability - 10152020Document6 pagesFCU 500 RPT Reliability - 10152020Chirag ShahNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument16 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Relief Valve - Convential Liquid ASME Code, Find AreaDocument2 pagesRelief Valve - Convential Liquid ASME Code, Find AreaChirag ShahNo ratings yet

- Experience Sharing LNG Storage Tan: K Execution Vijay Tanks & Vessels (VTV)Document8 pagesExperience Sharing LNG Storage Tan: K Execution Vijay Tanks & Vessels (VTV)Chirag ShahNo ratings yet

- ANNEX 1 SOW Assumptions XXXXXXXXXXXXXXXXXX Piping EngineeringDocument1 pageANNEX 1 SOW Assumptions XXXXXXXXXXXXXXXXXX Piping EngineeringChirag ShahNo ratings yet

- Ph4-Si-1011-Var-r0 Nozzle Check X 1310 Nozzle C NP 2090Document11 pagesPh4-Si-1011-Var-r0 Nozzle Check X 1310 Nozzle C NP 2090Chirag ShahNo ratings yet

- D - Caesar - Nu 06 - p0523 - 02-Latest Caesar File - Fired Heater CalcDocument1 pageD - Caesar - Nu 06 - p0523 - 02-Latest Caesar File - Fired Heater CalcChirag ShahNo ratings yet

- 60% LDTDocument63 pages60% LDTChirag ShahNo ratings yet

- Ph4-Si-1011-Var-r0 Nozzle Flexibility X 1310 NP 2090Document9 pagesPh4-Si-1011-Var-r0 Nozzle Flexibility X 1310 NP 2090Chirag ShahNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument15 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- 000 V1a MBHC 00065Document1 page000 V1a MBHC 00065Chirag ShahNo ratings yet

- Global Chemicals-Plot PlanDocument1 pageGlobal Chemicals-Plot PlanChirag ShahNo ratings yet

- 000 V1a MBHC 00078Document1 page000 V1a MBHC 00078Chirag ShahNo ratings yet

- 000 V1a MBHC 00063Document1 page000 V1a MBHC 00063Chirag ShahNo ratings yet

- SRR Phase 3 HP RD Reaction ForceDocument9 pagesSRR Phase 3 HP RD Reaction ForceChirag ShahNo ratings yet

- Employee Share Plan Site Terms and ConditionsDocument2 pagesEmployee Share Plan Site Terms and ConditionsChirag ShahNo ratings yet

- Ejma Expansion Joint RatingDocument2 pagesEjma Expansion Joint RatingChirag ShahNo ratings yet

- DCL For Work Share GIDIK Rev BDocument24 pagesDCL For Work Share GIDIK Rev BChirag ShahNo ratings yet

- Computershare Plan Managers Pty LTD Abn 56 084 591 131 and Cpu Share Plans Pty LTD Abn 20 081 600 875 Financial Services GuideDocument6 pagesComputershare Plan Managers Pty LTD Abn 56 084 591 131 and Cpu Share Plans Pty LTD Abn 20 081 600 875 Financial Services GuideChirag ShahNo ratings yet

- Wall Thickness Calculation-12 InchDocument23 pagesWall Thickness Calculation-12 InchChirag ShahNo ratings yet

- Public Review Draft 2404Document115 pagesPublic Review Draft 2404Said100% (1)

- Unlocked - Wall Thickness Calculation-12 InchDocument17 pagesUnlocked - Wall Thickness Calculation-12 InchChirag ShahNo ratings yet

- MARSDocument15 pagesMARSChirag ShahNo ratings yet

- DiplomaDocument1 pageDiplomaChirag ShahNo ratings yet

- MS em STD 0011Document3 pagesMS em STD 0011Chirag ShahNo ratings yet

- Merdeka Copper GoldDocument5 pagesMerdeka Copper GoldChrisna Anggara PutraNo ratings yet

- C5-2015-03-24T22 29 11Document2 pagesC5-2015-03-24T22 29 11BekNo ratings yet

- Reading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelDocument2 pagesReading Process Theories: Bottom-Up Model Interactive Model Top-Down ModelBeverly Panganiban CadacioNo ratings yet

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplNo ratings yet

- Positronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColeDocument1 pagePositronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColekamaveriyanNo ratings yet

- Linux - Notes by Jitendra SirDocument125 pagesLinux - Notes by Jitendra SirgoyaltarunNo ratings yet

- Analysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck ConverterDocument12 pagesAnalysis, Design and Implementation of Zero-Current-Switching Resonant Converter DC-DC Buck Converterdaber_huny20No ratings yet

- Drawing and Sketching Portraits: How To Draw Realistic Portraits For Beginners by Jacquelyn DescansoDocument3 pagesDrawing and Sketching Portraits: How To Draw Realistic Portraits For Beginners by Jacquelyn DescansoSent Mail0% (1)

- Reportte Cambios CPC 2a1Document1 pageReportte Cambios CPC 2a1FERNANDO FERRUSCANo ratings yet

- Ebook Childhood and Adolescence Voyages in Development 6Th Edition Rathus Test Bank Full Chapter PDFDocument64 pagesEbook Childhood and Adolescence Voyages in Development 6Th Edition Rathus Test Bank Full Chapter PDFolwennathan731y100% (8)

- DEA462F - EntelliGuard G Circuit Breakers - Lo-ResDocument8 pagesDEA462F - EntelliGuard G Circuit Breakers - Lo-Resyasser foudaNo ratings yet

- Sustainable Urban Transport Index for Bhopal, IndiaDocument43 pagesSustainable Urban Transport Index for Bhopal, IndiaSayani MandalNo ratings yet

- Introduction To Critical Reading SkillsDocument4 pagesIntroduction To Critical Reading SkillsParlindungan PardedeNo ratings yet

- 1-Evidence Plan HilotDocument5 pages1-Evidence Plan HilotJeanette Magno100% (2)

- GeneralMusic synthesizer service manual section titlesDocument16 pagesGeneralMusic synthesizer service manual section titlesAnonymous Syjpyt4Mo100% (1)

- Installing A Konica Minolta C220, C280, C360, C452, C652Document3 pagesInstalling A Konica Minolta C220, C280, C360, C452, C652nazerrulNo ratings yet

- Origin and Meaninng of Little P in PH PDFDocument2 pagesOrigin and Meaninng of Little P in PH PDFlNo ratings yet

- SC1000 60HZ Cummins GeneratorDocument4 pagesSC1000 60HZ Cummins GeneratorChen CarolineNo ratings yet

- SH BSC Hons Pre Registration Nursing PDFDocument104 pagesSH BSC Hons Pre Registration Nursing PDFJogendra Singh PatelNo ratings yet

- Xtract V 3 0 8Document72 pagesXtract V 3 0 8Don Ing Marcos LeónNo ratings yet

- Arduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFDocument33 pagesArduino The Ultimate Beginners Guide To Arduino Learn How To Get Started With Arduino Programming Projects and More PDFefrain100% (1)

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDocument5 pagesGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Muhammad Usama: Internship at Ibrahim Fibres Limited, Polyester PlantDocument20 pagesMuhammad Usama: Internship at Ibrahim Fibres Limited, Polyester PlantUsamaNo ratings yet

- Cambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Document11 pagesCambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Ms jennyNo ratings yet

- WorkshopDocument4 pagesWorkshopAmit GuptaNo ratings yet

- Build Ubuntu for Ultra-96 FPGA DevelopmentDocument5 pagesBuild Ubuntu for Ultra-96 FPGA Developmentksajj0% (1)

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDocument186 pagesAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNo ratings yet

- Nist Technical Note 1297 SDocument25 pagesNist Technical Note 1297 SRonny Andalas100% (1)

- Energy Landscapes: Applications To Clusters, Biomolecules and Glasses (Cambridge Molecular Science)Document6 pagesEnergy Landscapes: Applications To Clusters, Biomolecules and Glasses (Cambridge Molecular Science)darlyNo ratings yet

- Pipelining VerilogDocument26 pagesPipelining VerilogThineshNo ratings yet