Professional Documents

Culture Documents

General CheckList

Uploaded by

kasandra010 ratings0% found this document useful (0 votes)

60 views3 pagesCheck the condition of the heating and cooling coils and the AHU filters. If the coils are dirty or the filters are clogged, change out the filters and clean the coils.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCheck the condition of the heating and cooling coils and the AHU filters. If the coils are dirty or the filters are clogged, change out the filters and clean the coils.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views3 pagesGeneral CheckList

Uploaded by

kasandra01Check the condition of the heating and cooling coils and the AHU filters. If the coils are dirty or the filters are clogged, change out the filters and clean the coils.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

SAVING ENERGY IN COMMERCIAL BUILDINGS

General Air Handling Unit Checklist

Verify Proper Operation of Air Dampers Confirm that all AHU dampers are operating correctly. Have an operator send a control signal to open and close all dampers and visually confirm that they are fully opening and closing. Also have the operator open the dampers to about 50% to make sure they are modulating correctly. Repair any actuators or damper banks that are not functioning correctly. In some cases modulating damper actuators will need to be installed to allow for changes in outside airflow rates if the current dampers are open/closed. Verify Proper Operation of Air-side Economizer Check the DDC system control sequence to see if the current control system is using an air-side economizer. Make sure the economizer is working correctly by viewing damper positions and outside airflow rates at different outside air temperatures. If no air-side economizer function is currently used, determine the applicability of enabling one. Outside air temperature sensors are required for dry bulb based economizers and an additional outside air relative humidity sensor is needed for enthalpy-based economizers. Both of these sensors need to be working correctly for the system to operate as designed. Verify Proper Operation of Heating and Cooling Valves Check all heating and cooling valves for proper operation. Check the heating valve in the winter by shutting off the valve and checking the air handler mixed air and discharge temperatures. If the valve is closed and supply is still heated by the coil, the valve isnt seating correctly and is causing unnecessary simultaneous heating and cooling. The same procedure should be followed for cooling coil analysis. Check the Condition of Heating and Cooling Coils and AHU Filters Visually inspect the condition of the heating and cooling coils and the AHU filters. If the coils are dirty or the filters are clogged, change out the filters and clean the coils. If the current maintenance schedule isnt sufficient, revise the schedule accordingly. If static pressure sensors are used to determine filter dirt loading, make sure the sensors are working correctly. Dirty filters and coils will increase the static pressure across the coil, increasing fan system energy use in addition to reducing the heat transfer coefficient of the coil, forcing the system to move more air over the coil for the same heating/cooling effects. Eliminate Duct Leakage Periodically trace the main heating, ventilating, and air conditioning (HVAC) duct runs and listen for air leaks in the duct system. Confirm that the duct static pressure setpoint is within the pressure class of the installed ductwork before repairing any leaks. If the distribution system is really leaky, consider replacing the ductwork or using a duct sealant system to seal the leaks. Eliminate 100% of Outside Air Systems if Practicable One of the largest energy-wasting systems is 100% outside air ventilation in areas that dont require it. Common areas that require 100% outside air are operating rooms (ORs) and labs. If 100% outside air AHUs are being used for differing space types that dont require outside air, modulating outside air dampers and return air systems should be installed to reduce outside air.

SAVING ENERGY IN COMMERCIAL BUILDINGS | Air Handling Unit Checklists

Reduce Outside Airflow Rates to ASHRAE 62.1-2010 Most buildings are bringing in more outside air than they are required to per ASHRAE 62.1-2010. Outside airflow rates should be reduced to the minimum allowed by ASHRAE for each space. Consider installing CO2 sensors in return air ductwork and maintaining interior CO2 levels at <700 ppm above outside air CO2 levels during occupied hours. Also consider implementing an outside air damper reset schedule based on time of day and occupancy patterns within the building. During unoccupied hours and during morning warm-up cycles, all outside air dampers should be 100% closed. Implement an HVAC System Night Setback Schedule For all HVAC systems that serve non 24/7 areas, make sure that night setback controls have been implemented. Work with site staff to identify operational hours of HVAC equipment. Some areas may contain equipment that have acceptable temperature limits, thus it is important that unoccupied setpoints are not outside the acceptable limits of the equipment in the space. Track HVAC Setback Set up trend logs of your HVAC systems to collect data on whether your systems are actually going into night setback mode. If your system is coming on during the night to either warm up or cool down spaces, look at the unoccupied temperature range of the space to see if it can be adjusted. Also check to see if there is something going on in the space causing the temperature to go out of range. In addition, the site can implement an optimum start/stop sequence through the building automation system or advanced programmable thermostat. Monitor Exhaust Fan Controls For HVAC zones that are utilizing night setbacks, make sure the exhaust fans serving that zone are shutting down on a similar schedule. If exhaust fans are left on 24/7 a negative pressure will form within the building that will draw in unconditioned outside air, increasing the amount of time and energy it will take the HVAC system to bring the space temperature back to the occupied setpoints. This will also use additional electrical energy at night to power the fans, which can be reduced or eliminated by turning the fans off or installing variable frequency drives (VFDs) to set back the flow rate at night. Slow Down Systems During Unoccupied Hours If certain parts of the building are occupied after hours, implement the following measures: - Reset outside air intake to a lower level (outside air damper 0-5% open) - Reset minimum airflow to a lower value (typically 33% to 50% of current flow) - Reset supply air static to a lower level or set supply air fan speed to a lower value

SAVING ENERGY IN COMMERCIAL BUILDINGS | Air Handling Unit Checklists

Constant Volume Air Handling Unit Checklist

Adjust Total Airflow and Head Airflow rates are often significantly higher than required in buildings primarily due to system oversizing. In some large systems, an oversized fan causes over-pressurization in terminal boxes. The excessive airflow can often cause excessive fan energy consumption, excessive heating and cooling energy consumption, humidity control problems, and excessive noise in terminal boxes. Calculate the required airflow rate in heating and cooling mode to determine the correct flow rates. If the airflow rate can be reduced, install a VFD and slow the fan down to the required flow rates. The VFD can also be used to slow down the fan during unoccupied hours if the AHU has to stay on at night. In addition, make sure outside air is reduced accordingly. Convert the Constant Volume System to a VAV System A VAV system can significantly reduce HVAC system energy use. All constant volume AHUs should be identified and considered for retrofit to a VAV system. Implement a Supply Air Temperature Reset Schedule The goal of a supply air temperature reset schedule is to minimize combined fan power and thermal energy consumption or cost. For single duct constant volume systems, maintain the supply air temperature no higher than 57F if the outside air humidity ratio is higher than 0.009 or the dew point is higher than 55F. When the outside air humidity ratio is lower than 0.009, the supply air temperature can be reset to a higher temperature over the temperature range of 55F to 65F.

Variable Air Volume Air Handling Unit Energy Conservation Measures

Investigate Duct Static Pressure For VAV systems, review your duct static pressure setpoints and adjust them as low as possible while keeping all VAV dampers below 90% open. If VAV dampers are 100% open during periods, identify the reasons the space is calling for additional air flow and adjust system loads (i.e., relocate certain internal loads). Reset the Supply Air Temperature Maintain the air temperature no higher than 57F if the outside air humidity ratio is higher than 0.009 or the dew point is higher than 55F. Both humidity ratio and dew point can be determined using dry bulb temperature and relative humidity data. Maintain the supply air temperature no higher than 57F if the fan air flow is higher than 70% of the air flow under the maximum load conditions. This is often significantly smaller than 70% of the design air flow. When the air flow is higher than 70%, increased air flow has a significant impact on fan power. For example, resetting the supply air temperature from 55F to 57F can potentially increase the air flow by 10%. This will increase fan power from 34% to 51% of the maximum value. When the outside air humidity ratio is lower than 0.009 and the air flow is lower than 50%, the supply air temperature can be modulated to maintain total airflow at 50% or lower. If the air flow is lower than 50%, the supply air temperature can be increased. However, the supply air temperature must be lower than a high limit, which can be set to 65F.

NREL/FS-7A20-50134 June 2011

You might also like

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Thermodynamics ChapterDocument42 pagesThermodynamics ChapterBuild AteddyNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- VRV SystemDocument152 pagesVRV SystemKHA120096 StudentNo ratings yet

- Selecting the Right AHUDocument24 pagesSelecting the Right AHUrahulNo ratings yet

- Daikin VRV IV CatalogueDocument46 pagesDaikin VRV IV CatalogueNathan Vo100% (5)

- Daikin VRV III (Selection Installation Proceedure) Technical Data Book PDFDocument56 pagesDaikin VRV III (Selection Installation Proceedure) Technical Data Book PDFHarveen Singh100% (1)

- Heat Wheel: Mohammad Yusuf 13PKB380Document10 pagesHeat Wheel: Mohammad Yusuf 13PKB380Haider Ali100% (1)

- ASHRAE62.1 and FAQsDocument18 pagesASHRAE62.1 and FAQsols3dNo ratings yet

- Ahu & Chiller OkDocument40 pagesAhu & Chiller OkAndy DwiNo ratings yet

- Chiller Vs VRF PDFDocument26 pagesChiller Vs VRF PDFHenry San PedroNo ratings yet

- PIBCV-40Document2 pagesPIBCV-40James ChanNo ratings yet

- HVACDocument17 pagesHVACGladdelyn PiencenavesNo ratings yet

- Installation Instruction of The Verano-Convector Trench HeatersDocument2 pagesInstallation Instruction of The Verano-Convector Trench HeatersPaul KwongNo ratings yet

- HvacDocument24 pagesHvacNeal JohnsonNo ratings yet

- VRV CatalogueDocument164 pagesVRV CatalogueJie JinNo ratings yet

- Commissioning of Cooling TowersDocument4 pagesCommissioning of Cooling TowersSiva KulanjiNo ratings yet

- Code of Practice For Ventillation and Air Conditioning Duct WorkDocument31 pagesCode of Practice For Ventillation and Air Conditioning Duct WorkpastorgeeNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- 2016 NEBB Official Formula & Psychrometric Chart DocumentDocument8 pages2016 NEBB Official Formula & Psychrometric Chart DocumentRamadan RashadNo ratings yet

- Lecture 6 Zoning in HvacDocument32 pagesLecture 6 Zoning in HvacBhaskar BhatiaNo ratings yet

- Method of Statement - R1 PDFDocument49 pagesMethod of Statement - R1 PDFMohamed YoussifNo ratings yet

- VAV Terminal UnitsDocument15 pagesVAV Terminal Unitsckyee88No ratings yet

- Building HVAC Requirements: 4.1 OverviewDocument55 pagesBuilding HVAC Requirements: 4.1 OverviewHaroon GhaniNo ratings yet

- Central Air Conditioning Systems ReviewDocument23 pagesCentral Air Conditioning Systems ReviewlalaNo ratings yet

- Variable Speed Chillers With PicvDocument1 pageVariable Speed Chillers With PicvPradeep SukumaranNo ratings yet

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- Control Valves For Ahu Chilled WaterDocument4 pagesControl Valves For Ahu Chilled WaterHussein Akil100% (1)

- Biddle - VRVDocument31 pagesBiddle - VRVutzu_yooNo ratings yet

- 2018 Multi V 5Document72 pages2018 Multi V 5Vo DungNo ratings yet

- BSE 3712 HVAC System Design for Commercial BuildingDocument19 pagesBSE 3712 HVAC System Design for Commercial BuildingChan Tsz HimNo ratings yet

- Air Handling Units (AHU) Pre-Commissioning TestsDocument2 pagesAir Handling Units (AHU) Pre-Commissioning TestsJaya PrathabNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Small Absorption Chillers Process ApplicationsDocument2 pagesSmall Absorption Chillers Process ApplicationsAdil AbdoNo ratings yet

- Fan Coil UnitDocument99 pagesFan Coil UnitUmer FarooqNo ratings yet

- VRF SpecsDocument6 pagesVRF SpecsAshar HassanNo ratings yet

- Description of Useful HVAC TermsDocument64 pagesDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- Boq Hvac Works: Item RefDocument7 pagesBoq Hvac Works: Item RefMohamed TallyNo ratings yet

- Free Cooling Types and ControlsDocument2 pagesFree Cooling Types and ControlsHnin PwintNo ratings yet

- Air WashersDocument7 pagesAir WashersimshubhamlackNo ratings yet

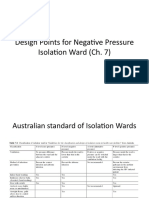

- Design Points For Negative PressureDocument23 pagesDesign Points For Negative PressureShohei Namjoon LetoNo ratings yet

- FI NotesDocument1,069 pagesFI NotesparadoxendazzlingNo ratings yet

- Coldstoragepptpragati 150509061348 Lva1 App6891 PDFDocument39 pagesColdstoragepptpragati 150509061348 Lva1 App6891 PDFmahesh bandaraNo ratings yet

- System Design Manual-DPCVDocument29 pagesSystem Design Manual-DPCVrama_easNo ratings yet

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- AhuDocument1 pageAhusiruslara6491No ratings yet

- Hospital Operating Theatre AHU CoilsDocument56 pagesHospital Operating Theatre AHU CoilsfisplNo ratings yet

- Vav BoxDocument20 pagesVav BoxCsiszer RobertNo ratings yet

- Constant vs Variable flow systemsDocument2 pagesConstant vs Variable flow systemsbatazivoNo ratings yet

- Combined Sprinkler and Standpipe AssemblyDocument1 pageCombined Sprinkler and Standpipe Assemblydesign sseNo ratings yet

- Zoning Reference GuideDocument20 pagesZoning Reference GuideqwincyNo ratings yet

- UH Master Construction Spec Specifications Mechanical ScopeDocument352 pagesUH Master Construction Spec Specifications Mechanical ScopeCarl CrowNo ratings yet

- Water Heater Sizing GuidelinesDocument8 pagesWater Heater Sizing GuidelinesMac ShaikNo ratings yet

- Clion-Marine Chiller Specs 2017Document1 pageClion-Marine Chiller Specs 2017Sandy NugrahaNo ratings yet

- Reverse vs Direct Piping DesignDocument2 pagesReverse vs Direct Piping Designmaddy_giftNo ratings yet

- Duct Leakage TesterDocument8 pagesDuct Leakage TesterJay PresleyNo ratings yet

- Upvc Pipes and FittingsDocument40 pagesUpvc Pipes and Fittingshammad21No ratings yet

- 2009 UPC PresentationDocument81 pages2009 UPC PresentationFarhsa Dhom Eemihahs DhomNo ratings yet

- Air Handler Check ListDocument3 pagesAir Handler Check Listmnt6176100% (1)

- ManualDocument8 pagesManualkasandra01No ratings yet

- Flow CharacteristicsDocument17 pagesFlow CharacteristicsRajeesh DamodaranNo ratings yet

- Taylor Rules and Monetary PolicyDocument13 pagesTaylor Rules and Monetary Policykasandra01No ratings yet

- Virgil StairExercisesDocument16 pagesVirgil StairExerciseskasandra01No ratings yet

- 2012 08 24 Plumbing DrawingsDocument6 pages2012 08 24 Plumbing DrawingsAnonymous 0ZNZuCEf5No ratings yet

- Leg Cblman 11 090Document1 pageLeg Cblman 11 090starykltNo ratings yet

- Stair ConfigDocument4 pagesStair Configkasandra01No ratings yet

- Stair WorkoutsDocument10 pagesStair Workoutskasandra01No ratings yet

- Commisioning Guidelines EPADocument29 pagesCommisioning Guidelines EPAAndy MoviemakersNo ratings yet

- The Role of Financial Factors in The Trade Collapse - A Skeptic's ViewDocument13 pagesThe Role of Financial Factors in The Trade Collapse - A Skeptic's Viewkasandra01No ratings yet

- Designing Beams for Shear ResistanceDocument7 pagesDesigning Beams for Shear ResistancestarykltNo ratings yet

- Indirect Waste DrainageDocument1 pageIndirect Waste Drainagekasandra01No ratings yet

- BCC P21plumbing SymbolsDocument1 pageBCC P21plumbing Symbolskasandra01No ratings yet

- Heaters SizingSelectionDocument2 pagesHeaters SizingSelectionkasandra01No ratings yet

- @general Sizing Formula For Potable Watwer Supply@Document14 pages@general Sizing Formula For Potable Watwer Supply@kasandra01No ratings yet

- Realistic Domestic Hot-Water ProfilesDocument18 pagesRealistic Domestic Hot-Water Profileskasandra01No ratings yet

- Pump Selection Guide Criteria PDFDocument7 pagesPump Selection Guide Criteria PDFrodriguez.gaytanNo ratings yet

- Hourly Hot Water Demand Calculation TableDocument2 pagesHourly Hot Water Demand Calculation Tablekasandra01No ratings yet

- Guidelines For Sizing Water HeatersDocument8 pagesGuidelines For Sizing Water Heaterskasandra01No ratings yet

- Learning Imbalanced Data With Random ForestsDocument18 pagesLearning Imbalanced Data With Random Forestskasandra01No ratings yet

- Heaters SizingSelectionDocument2 pagesHeaters SizingSelectionkasandra01No ratings yet

- Dusek - Chapter 2Document2 pagesDusek - Chapter 2Alvaro Perez Lopez0% (1)

- PrinciplesDocument33 pagesPrinciplesVinay GuptaNo ratings yet

- Homeowners InstructionDocument6 pagesHomeowners Instructionkasandra01No ratings yet

- 16-p3.1 Plumbing Riser Diagrams Security ResidenceDocument1 page16-p3.1 Plumbing Riser Diagrams Security Residencekasandra01No ratings yet

- Guidelines SanitaryFacilitiesDocument16 pagesGuidelines SanitaryFacilitieskasandra01No ratings yet

- DPW Guide for Architects on Drainage, Water Supply & Storm WaterDocument28 pagesDPW Guide for Architects on Drainage, Water Supply & Storm Waterkasandra01No ratings yet

- Builder's Guide To GeoThermalDocument6 pagesBuilder's Guide To GeoThermaltagriloNo ratings yet

- DAIKIN - Manejadoras DAR de 7.5 y 10 TR PDFDocument12 pagesDAIKIN - Manejadoras DAR de 7.5 y 10 TR PDFIsmael Pachas RoncerosNo ratings yet

- List of Software Available For Energy Audit and Other Relative Jobs. SR No Software Make/Type RemarksDocument4 pagesList of Software Available For Energy Audit and Other Relative Jobs. SR No Software Make/Type RemarksNeeraj GuptaNo ratings yet

- Izolatie SpiroDocument2 pagesIzolatie SpiroMariIacomiNo ratings yet

- An Overview Of: Plant Layout AND PipingDocument21 pagesAn Overview Of: Plant Layout AND Pipingmurali100% (1)

- Alfa Laval - Emd00308en - EhDocument4 pagesAlfa Laval - Emd00308en - EhEnder ZenginobuzNo ratings yet

- MAN B&W 98-50 MC/MC C-TII Type Engines Engine Selection GuideDocument369 pagesMAN B&W 98-50 MC/MC C-TII Type Engines Engine Selection GuideSuperhypoNo ratings yet

- 07 Opportunities For PoA in Energy Efficiency by Konrad Von RitterDocument11 pages07 Opportunities For PoA in Energy Efficiency by Konrad Von RitterThe Outer MarkerNo ratings yet

- Steam Power PlantsDocument73 pagesSteam Power PlantsManvendra Pratap Singh Bisht95% (20)

- NPE Commercial Application Guide FLIP 1805 PDFDocument13 pagesNPE Commercial Application Guide FLIP 1805 PDFranga lakminiNo ratings yet

- Optimax ManualDocument38 pagesOptimax Manualspaske_No ratings yet

- ENG Quantum FolderDocument9 pagesENG Quantum FolderAnonymous TThmYKFpNo ratings yet

- Npbc-V3m-E Um enDocument24 pagesNpbc-V3m-E Um enMilovan StaničićNo ratings yet

- HOVAL Dati Tecnici Caldaie IngleseDocument57 pagesHOVAL Dati Tecnici Caldaie Ingleseosama alabsiNo ratings yet

- Hot Oil Systems Explained: Key Components and OperationDocument14 pagesHot Oil Systems Explained: Key Components and OperationHuzefa ArsiwalaNo ratings yet

- DentaireDocument21 pagesDentaireZiani100% (3)

- Gog-Gazette-Gdcr 2011Document55 pagesGog-Gazette-Gdcr 2011Bharat BlueNo ratings yet

- Ecological Home Heating with the Alfa 90 Pellet StoveDocument33 pagesEcological Home Heating with the Alfa 90 Pellet StoveKushtrim MalaNo ratings yet

- Leaflet - BRC1E71 - Daikin ACDocument2 pagesLeaflet - BRC1E71 - Daikin ACDaviah MaziyaNo ratings yet

- M1 MP-7 and MP-8 OverhaulDocument116 pagesM1 MP-7 and MP-8 OverhaulHEY86% (7)

- Wall-mounted boiler with storage tank technical documentationDocument52 pagesWall-mounted boiler with storage tank technical documentationscostelNo ratings yet

- Case Study - Airborne Tea Tree Oil Used For Treatment of Air Quality Aboard A Large Passenger ShipDocument2 pagesCase Study - Airborne Tea Tree Oil Used For Treatment of Air Quality Aboard A Large Passenger ShipVic RollinsNo ratings yet

- Recommended Practices For Storage and Transport of Edible Oils and FatsDocument13 pagesRecommended Practices For Storage and Transport of Edible Oils and FatsM Alim Ur RahmanNo ratings yet

- Boiler Working PrincipleDocument1 pageBoiler Working PrincipleSabrinaNo ratings yet

- EE1451 RES 2 Mark Q & ADocument8 pagesEE1451 RES 2 Mark Q & AparameshNo ratings yet

- The Role of Natural Gas Today and TomorrowDocument14 pagesThe Role of Natural Gas Today and TomorrowCanadianNaturalGasNo ratings yet

- Preliminary Master Plan Design for Sur Office BlockDocument20 pagesPreliminary Master Plan Design for Sur Office BlockPradeep SukumaranNo ratings yet

- 11-3457 WPDocument10 pages11-3457 WPacarrenoNo ratings yet

- Cleanroom Design in 10 Easy StepsDocument10 pagesCleanroom Design in 10 Easy StepsNEDALNo ratings yet

- Topsoe Hydrocracking Processes 2011Document17 pagesTopsoe Hydrocracking Processes 2011Trần Văn TìnhNo ratings yet

- RX25GV1NB RX35GV1NB FTX25GV1NB FTX35GV1NB PDFDocument174 pagesRX25GV1NB RX35GV1NB FTX25GV1NB FTX35GV1NB PDFMalay K GhoshNo ratings yet