Professional Documents

Culture Documents

Cream Ale

Uploaded by

Elijah LewisOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cream Ale

Uploaded by

Elijah LewisCopyright:

Available Formats

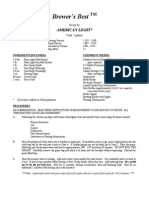

CREAM ALE

Official NORTHERN BREWER Instructional Document

PROCEDURE

An ale version of the light, fizzy American lager style, cream ale is a specialty of the eastern US. Our Cream Ale is medium-bodied and smooth, gold in color and low in bitterness; the specialty grain blend adds some complexity with a clean, sweet malt profile and a hint of buttered toast in the aroma and flavor. A homebrewed lawnmower beer is pretty hard to beat as a summertime thirst-quencher. O.G: 1.040 READY: 4 WEEKS 2 weeks primary, 2 weeks bottle conditioning

A FEW DAYS BEFORE BREWING DAY

1. Remove the liquid Wyeast pack from the refrigerator, and smack as shown on the back of the yeast package. Leave it in a warm place (7080 F) to incubate until the pack begins to inflate. Allow at least 3 hours for inflation; some packs may take up to several days to show inflation. Do not brew with inactive yeast we can replace the yeast, but not a batch that fails to ferment properly. If you are using dry yeast, no action is needed.

BEYOND BREWING DAY, WEEKS 12

15. Active fermentation begins. Within approximately 48 hours of Brewing Day, active fermentation will begin there will be a cap of foam on the surface of the beer, and you may see bubbles come through the fermentation lock. 16. Active fermentation ends. Approximately 12 weeks after brewing day, active fermentation will end: the cap of foam falls back into the new beer, bubbling in the fermentation lock slows down or stops.

ON BREWING DAY

2. Collect and heat 2.5 gallons of water. 3. For mail-order customers grains for extract kits come crushed by default, but if you requested uncrushed grains, crush them now. Pour crushed grain into supplied mesh bag and tie the open end in a knot. Steep for 20 minutes or until water reaches 170F. Remove bag and discard. 4. Bring to a boil and add the 6 lbs Pilsen malt syrup. Remove the kettle from the burner and stir in the Pilsen malt syrup. 5. Return wort to boil. The mixture is now called wort, the brewers term for unfermented beer.

-- Add 1 oz Cluster hops and boil for 60 minutes.

KIT INVENTORY:

SPECIALTY GRAIN

-- 0.75 lbs Gambrinus Honey Malt -- 0.25 lbs Belgian Biscuit

BOTTLING DAYABOUT 2 WEEKS AFTER BREWING DAY

17. Sanitize siphoning and bottling equipment. 18. Mix a priming solution (a measured amount of sugar dissolved in water to carbonate the bottled beer) of 2/3 cup priming sugar in 16 oz water. Bring the solution to a boil and pour into the bottling bucket. 19. Siphon beer into bottling bucket and mix with priming solution. Stir gently to mixdont splash. 20. Fill and cap bottles.

FERMENTABLES

-- 6 lbs Pilsen malt syrup

HOPS & FLAVORINGS

-- 1 oz Cluster (60 min)

YEAST

-- DRY YEAST (DEFAULT): Safale US-05 Ale Yeast. Optimum temp: 59-75F -- LIQUID YEAST OPTION: Wyeast 1056 American Ale. Apparent attenuation: 7377%. Flocculation: lowmedium. Optimum temp: 60-72 F.

2 WEEKS AFTER BOTTLING DAY

21. Condition bottles at room temperature for 2 weeks. After this point, the bottles can be stored cool or cold. 22. Serving. Pour into a clean glass, being careful to leave the layer of sediment at the bottom of the bottle. Cheers!

6. Cool the wort. When the 60-minute boil is finished, cool the wort to approximately 100 F as rapidly as possible. Use a wort chiller, or put the kettle in an ice bath in your sink. 7. Sanitize fermenting equipment and yeast pack. While the wort cools, sanitize the fermenting equipment fermenter, lid or stopper, fermentation lock, funnel, etc along with the yeast pack and a pair of scissors. 8. Fill primary fermenter with 2 gallons of cold water, then pour in the cooled wort. Leave any thick sludge in the bottom of the kettle. 9. Add more cold water as needed to bring the volume to 5 gallons. 10. Aerate the wort. Seal the fermenter and rock back and forth to splash for a few minutes, or use an aeration system and diffusion stone. 11. OPTIONAL: if you have our Mad Brewer Upgrade or Gravity Testing kits, measure specific gravity of the wort with a hydrometer and record. 12. Add yeast once the temperature of the wort is 78F or lower (not warm to the touch). Use the sanitized scissors to cut off a corner of the yeast pack, and carefully pour the yeast into the primary fermenter. 13. Seal the fermenter. Add approximately 1 tablespoon of water to the sanitized fermentation lock. Insert the lock into rubber stopper or lid, and seal the fermenter. 14. Move the fermenter to a warm, dark, quiet spot until fermentation begins.

PRIMING SUGAR

-- 5 oz Priming Sugar (save for Bottling Day)

These simple instructions are basic brewing procedures for this Northern Brewer extract beer kit; please refer to your starter kit instructions for specific instructions on use of equipment and common procedures such as siphoning, sanitizing, bottling, etc. For more detailed extract brewing instructions, please visit www.northernbrewer.com

BEFORE YOU BEGIN ...

MINIMUM REQUIREMENTS

-- Homebrewing starter kit for brewing 5 gallon batches -- Boiling kettle of at least 3.5 gallons capacity -- Approximately two cases of either 12 oz or 22 oz pry-off style beer bottles

UNPACK THE KIT

-- Refrigerate the yeast upon arrival -- Locate the Kit Inventory (above) this is the recipe for your beer, so keep it handy -- Doublecheck the box contents vs. the Kit Inventory -- Contact us immediately if you have any questions or concerns!

You might also like

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsFrom EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNo ratings yet

- QL BaldrgaxDocument1 pageQL BaldrgaxwackorobieNo ratings yet

- Northern Brewer Classic Dry Mead Kit: ProcedureDocument1 pageNorthern Brewer Classic Dry Mead Kit: ProcedureYNOT4No ratings yet

- Hank'S Hefeweizen: Read All Instructions Before StartingDocument2 pagesHank'S Hefeweizen: Read All Instructions Before StartingBhagavanNo ratings yet

- Mangrove Jack's Brewer's Series Kit InstructionsDocument2 pagesMangrove Jack's Brewer's Series Kit InstructionsEsteban Iturra CerónNo ratings yet

- Killians RED Beer Reciepe 03638Document2 pagesKillians RED Beer Reciepe 03638Joe MoldovanNo ratings yet

- Dogfish Head 60 Minute IPA CloneDocument2 pagesDogfish Head 60 Minute IPA CloneJdca DallNo ratings yet

- 1 Gallon of BeerDocument1 page1 Gallon of Beergo1iathNo ratings yet

- Austin Homebrew Supply: 15112 N IH-35, Austin TX 78728 (512) 300-BREW or (800) 890-BREWDocument2 pagesAustin Homebrew Supply: 15112 N IH-35, Austin TX 78728 (512) 300-BREW or (800) 890-BREWEric SteenNo ratings yet

- Mangrove Jack's Craft Series Beer Pouch InstructionsDocument2 pagesMangrove Jack's Craft Series Beer Pouch InstructionsJoao MoreiraNo ratings yet

- Negra Modelo All Grain RecipeDocument2 pagesNegra Modelo All Grain RecipeKevin van HollandNo ratings yet

- Sierra Nevada Pale Ale CloneDocument2 pagesSierra Nevada Pale Ale Cloneantonio alberto gutierrez suarezNo ratings yet

- AG INS PlinyTheElderDoubleIPACloneDocument2 pagesAG INS PlinyTheElderDoubleIPACloneMario JammaersNo ratings yet

- American Pale AleDocument2 pagesAmerican Pale AleJustin GarciaNo ratings yet

- Kit Inventory: Maillard MaltsDocument3 pagesKit Inventory: Maillard Maltsapi-262611537No ratings yet

- GaardenHoe 1526777293495Document1 pageGaardenHoe 1526777293495viniciusprussNo ratings yet

- Mangrove Jack's Craft Series Cider Pouch InstructionsDocument2 pagesMangrove Jack's Craft Series Cider Pouch InstructionsCsillag DávidNo ratings yet

- DunkelDocument1 pageDunkelGlenda LaunNo ratings yet

- AG INS BlazingSaizonDocument2 pagesAG INS BlazingSaizonMario JammaersNo ratings yet

- 1018 American LightDocument2 pages1018 American LightAhmet MetinNo ratings yet

- AG FruitStandWheat 1658856498745Document2 pagesAG FruitStandWheat 1658856498745jv7jfc2qwnNo ratings yet

- Dry Irish Stout RecipeDocument1 pageDry Irish Stout RecipewtshankNo ratings yet

- Extract Brewing Instructions: Necessary Equipment and SuppliesDocument2 pagesExtract Brewing Instructions: Necessary Equipment and SuppliesHenry Clark TravagliniNo ratings yet

- SoCo Almond Coconut Stout All Grain Recipe InstructionsDocument2 pagesSoCo Almond Coconut Stout All Grain Recipe InstructionsJavier OrozcoNo ratings yet

- Coopers Yeast CulturingDocument4 pagesCoopers Yeast Culturingmatthendry100% (1)

- Brewing: A Brief Guide To Get You Started Making Your Own Home BrewDocument1 pageBrewing: A Brief Guide To Get You Started Making Your Own Home Brewbathtub2025No ratings yet

- Apple Cider InstructDocument2 pagesApple Cider InstructlegionsixNo ratings yet

- Instructions On How To Make Hard CiderDocument3 pagesInstructions On How To Make Hard CiderkarnizsdjuroNo ratings yet

- Midwest Honeybee AleDocument2 pagesMidwest Honeybee AleJesso GeorgeNo ratings yet

- The Key IngredientsDocument4 pagesThe Key Ingredientsk_168911826No ratings yet

- Fantome Saison-Style Ale (16C) - All GrainDocument2 pagesFantome Saison-Style Ale (16C) - All GrainMonitoreo SPERNo ratings yet

- DIY Apple CiderDocument3 pagesDIY Apple CiderGeorge LeongNo ratings yet

- Beginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.NzDocument6 pagesBeginners Guide To Brewing in A Bag, or Biab: WWW - Biabrewer.Info WWW - Forum.Realbeer - Co.Nzerickscribduy321No ratings yet

- Rice BeerDocument8 pagesRice BeerPied7PiperNo ratings yet

- How To Brew - by John PalmerDocument4 pagesHow To Brew - by John Palmerzaratustra210% (1)

- 1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiDocument5 pages1 Gallon Mead Recipe For Beginners - Easy Mead Recipe & KiRyanNo ratings yet

- A Water Tublng Capper: OftubingDocument1 pageA Water Tublng Capper: OftubingAhmet MetinNo ratings yet

- Brewers Friend Checklist ExtractDocument2 pagesBrewers Friend Checklist ExtractGanges LimNo ratings yet

- PumpkinAle 2Document2 pagesPumpkinAle 2Adrián LampazziNo ratings yet

- Beer Brewing For BeginnersDocument5 pagesBeer Brewing For BeginnerspauloadrianoNo ratings yet

- Blackberry Wine: IngredientsDocument2 pagesBlackberry Wine: IngredientssergeiivanNo ratings yet

- JB's Best India AleDocument2 pagesJB's Best India AleJesso GeorgeNo ratings yet

- Wildgrapewine PDFDocument2 pagesWildgrapewine PDFcacaolesNo ratings yet

- CzechPilsner 1526677404803Document1 pageCzechPilsner 1526677404803jdryden95No ratings yet

- Snickerdoodle Latte Holiday AleDocument2 pagesSnickerdoodle Latte Holiday Alejeju121212No ratings yet

- How To Brew Beer at HomeDocument5 pagesHow To Brew Beer at Homelucas.siqueiraNo ratings yet

- Pineapplewine PDFDocument2 pagesPineapplewine PDFAdrian Ellarma RamosNo ratings yet

- Mangrove Jacks CatalogoDocument13 pagesMangrove Jacks CatalogolhcorreaNo ratings yet

- Julner Instructions ENGDocument2 pagesJulner Instructions ENGmintursingolloNo ratings yet

- Brooklyn Brew Shop - Everyday IPA InstructionsDocument3 pagesBrooklyn Brew Shop - Everyday IPA Instructionstecleador10% (1)

- Receta Casera de Vino de PlátanDocument3 pagesReceta Casera de Vino de PlátanAtencio MacrofNo ratings yet

- Bananawine PDFDocument2 pagesBananawine PDFJerico D. CamposNo ratings yet

- Basic Homebrewed Lambic: in The Loft at Cantillon. You Can (Barely) See Bales of Hops Aging in The Back LeftDocument5 pagesBasic Homebrewed Lambic: in The Loft at Cantillon. You Can (Barely) See Bales of Hops Aging in The Back LeftBruno MelloNo ratings yet

- Simple Home Brewing Spice Beer Recipes - John AndersonDocument76 pagesSimple Home Brewing Spice Beer Recipes - John Andersonseagypsy0475% (4)

- Kraeusening Your BeerDocument1 pageKraeusening Your BeerJesso GeorgeNo ratings yet

- KK Beer Guide Booklet 091522 Print Ready - Small-MinDocument12 pagesKK Beer Guide Booklet 091522 Print Ready - Small-MinClifton SutherlandNo ratings yet

- PumpkinAle 1Document2 pagesPumpkinAle 1Adrián LampazziNo ratings yet

- Home Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You Want (With Recipe Journal)From EverandHome Brewing: 70 Top Secrets & Tricks To Beer Brewing Right The First Time: A Guide To Home Brew Any Beer You Want (With Recipe Journal)No ratings yet

- Luyện Tập ReadingDocument29 pagesLuyện Tập ReadingTrần Hương ThảoNo ratings yet

- Cast Polypropylene Film Production ProcessDocument3 pagesCast Polypropylene Film Production Processrajput_ajay_mba6815100% (1)

- Marketing Mix by DjKatyDocument30 pagesMarketing Mix by DjKatykysecempeNo ratings yet

- Examples of Classical Conditioning 1Document2 pagesExamples of Classical Conditioning 1Kelsey ZammitNo ratings yet

- Analisis Dan Strategi Mitigasi Risiko Produksi Teh Botol Sosro Di PT. Sinar Sosro Pabrik BaliDocument10 pagesAnalisis Dan Strategi Mitigasi Risiko Produksi Teh Botol Sosro Di PT. Sinar Sosro Pabrik BaliFifi UmmahNo ratings yet

- TQ - Q3 - TLE - 6 - Jonalyn AmbronaDocument8 pagesTQ - Q3 - TLE - 6 - Jonalyn AmbronaJOY SHERYL PADIANGAN100% (1)

- Holy Grill (A Mobile - Based Ordering System) : STI College General SantosDocument41 pagesHoly Grill (A Mobile - Based Ordering System) : STI College General SantosCrisbel FlorinoNo ratings yet

- Nutrition Science and Applications 3rd Edition Smolin Test BankDocument21 pagesNutrition Science and Applications 3rd Edition Smolin Test Bankjonathoncameronpsndbwftca100% (11)

- Nypa FruticansDocument7 pagesNypa FruticansAnders Haagen100% (1)

- Ikigai Diet - The Secret of Japanese Diet To Health and LongevityDocument41 pagesIkigai Diet - The Secret of Japanese Diet To Health and LongevityArvind AhujaNo ratings yet

- Home ScienceDocument3 pagesHome ScienceAmoNo ratings yet

- New HSK 2 Word ListDocument39 pagesNew HSK 2 Word ListHà Lê100% (1)

- Cebu City Medical Center-College of Nursing: Classwork Format Level Ii CCMC-CN AY 2020-2021Document2 pagesCebu City Medical Center-College of Nursing: Classwork Format Level Ii CCMC-CN AY 2020-2021Carl Jayson LeysonNo ratings yet

- 100 Phrasal Verbs in EnglishDocument23 pages100 Phrasal Verbs in EnglishJorge RuizNo ratings yet

- HFN2 Textbook Assignment - Food SafetyDocument2 pagesHFN2 Textbook Assignment - Food SafetyValentino KIngNo ratings yet

- My Darkest Desires Telegram OSDocument13 pagesMy Darkest Desires Telegram OSsetyahangga3No ratings yet

- Picture DictionaryDocument48 pagesPicture DictionaryRicardo BolivarNo ratings yet

- Oktoberfest: Presented by Carol ParryDocument29 pagesOktoberfest: Presented by Carol ParryAParryNo ratings yet

- Lodging OperationsDocument23 pagesLodging OperationsJezzaJaneFrioNo ratings yet

- Pluto and PersephoneDocument2 pagesPluto and PersephoneBetsy D. SantiagoNo ratings yet

- ERT EMS2 - Final Summer Outing ProposalDocument10 pagesERT EMS2 - Final Summer Outing ProposalStacey LalatagNo ratings yet

- Grammar 1 Past Time PracticeDocument5 pagesGrammar 1 Past Time PracticeELENANo ratings yet

- Module in English 4Document46 pagesModule in English 4Bea Veronica BelardeNo ratings yet

- Food Magazine Philippines Issue 2 2017Document109 pagesFood Magazine Philippines Issue 2 2017lrt100% (2)

- Feasibility Study SAMPLEDocument38 pagesFeasibility Study SAMPLEashianna badeNo ratings yet

- CATALOGUE India Products 2018Document48 pagesCATALOGUE India Products 2018sagar chauhan0% (1)

- Fast Moving Consumer Goods: by Roshini MOP Vaishnav College For WomenDocument22 pagesFast Moving Consumer Goods: by Roshini MOP Vaishnav College For WomenroshmbaNo ratings yet

- Nutrition Case StudyDocument17 pagesNutrition Case Studymacedon14100% (18)

- Product Design & Quality ManagementDocument2 pagesProduct Design & Quality ManagementteahhhNo ratings yet

- CL 8 Engleza CorigentaDocument3 pagesCL 8 Engleza CorigentaMIHAELA RAMONA BURCUNo ratings yet