Professional Documents

Culture Documents

D NV Webpage

Uploaded by

Hooman TakhtechianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D NV Webpage

Uploaded by

Hooman TakhtechianCopyright:

Available Formats

Today, there are no recognised specifications or recommended practices available for Subsea Pipeline Integrity Management Systems.

DNV is currently launching two Joint Industry Projects (JIP) covering these aspects.

ThefirstJIP,managedbyDNVHvik,invitesoilandgascompanies,surveycompaniesandauthoritiesworldwideto participate in developing a DNV Recommended Practice - (RP)-F116 Subsea Pipeline System Integrity Management. The second JIP, leading to a Guideline for the development of a Subsea Pipeline Integrity Management Program for the Gulf of Mexico , will be managed by DNV Houston and funded by pipeline owners and operators in the Gulf of Mexico. Due to current industry practices, a significant percentage of unpiggable pipelines, local regulatory requirements and Gulf of Mexico reporting requirements, a local guideline is required for pipelines in this area. The outcome of this JIP will be referred to, or incorporated into the DNV RP -F116. In addition, the DNV OS -F101 is being updated and the 2007 revision will introduce a requirement of a Pipeline Integrity Management system within the oil and gas operator s organisations. The currently launched JIP project will provide details regarding the content of this required PIM system. Will solve integrity challenges Bente H. Leinum, the project manager for the DNV RP -F116, points out: Today, there are no recognised specifications or recommended practices available for Subsea Pipeline Integrity Management Systems. Onshore standards, such as API1160 Managing System Integrity for Hazardous Liquid Pipelines and ASME B31.8S Managing System Integrity of Gas Pipelines , are currently used for subsea pipelines together with the oil and gas companies own systems, which are often project -specific PIM -documentation. The RP and guideline are being prepared in response to the pipeline industry s recognition of the need for such documents as a result of: Aging pipeline system The lifetime extension and requalification of existing pipelines n Optimised design, which implies a stricter need for monitoring n Novel design producing new challenges n The introduction of PIM for onshore pipelines (API1160, ASME31.8S).

n n

The output from both JIPs will address in -service issues of concern, from the early design phase through to the operational phase. They aim to be state -ofthe-art documents, developed in close cooperation with the industry and reflecting industry practices and sound engineering practices for establishing and maintaining the integrity of subsea pipeline systems. The development and utilisation of the DNV RP -F116 and the guideline for the Gulf of Mexico will put more focus on the operational phase from the early design phase, allowing a more optimised inspection and maintenance regime, and hence provide a reduction in operational costs. In addition, the establishment of a more uniform PIM system within and across operator organisations will be promoted. The operators may also use the RP to document compliance to the authorities, explains Bente H Leinum. Dan Powell, the project manager for the Gulf of Mexico guideline, points out: It will identify the components of a subsea pipeline integrity management programme and provide a highly detailed framework that producers or pipeline operators can utilise when preparing the integrity management programmes for their own pipeline systems. The guideline will also include a detailed framework for a direct assessment methodology, which would be applicable to the unpiggable subsea pipelines and will be submitted to the National Association of Corrosion Engineers, International (NACE) for review and approval. This work will be referred to in the DNV RP -F116. Ultimately, both the DNV RP -F116 and the Gulf of Mexico guideline aim to ensure that each subsea pipeline is managed in a cost -effective manner, with a focus on maintaining safety and protecting the environment throughout its operational lifetime. The documents are intended to be applicable to subsea pipelines, both piggable and unpiggable, which transport natural gas or hydrocarbon liquids, and will address integrity management relating to both internal and external corrosion as well as other relevant threats to the system, such as free span and third party damage. Date: 04 May 2007 Author: Svein Inge Leirgulen

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

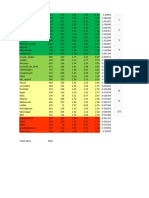

- Ansi Color CodingDocument2 pagesAnsi Color CodingHESuarez100% (1)

- Relief Well Planning ChecklistDocument9 pagesRelief Well Planning Checklistbyed100% (2)

- Chamber PopDocument7 pagesChamber PopHooman TakhtechianNo ratings yet

- Material SelectionDocument34 pagesMaterial SelectionmatsuruNo ratings yet

- Aberdeen MPTC Car Route 1-5Document5 pagesAberdeen MPTC Car Route 1-5Hooman TakhtechianNo ratings yet

- CPD Recording TemplateDocument3 pagesCPD Recording TemplateHooman TakhtechianNo ratings yet

- ReadmeDocument1 pageReadmeHooman TakhtechianNo ratings yet

- Reference ListDocument3 pagesReference ListHooman TakhtechianNo ratings yet

- RYMDocument33 pagesRYMHooman TakhtechianNo ratings yet

- Exam Study PlanDocument1 pageExam Study PlanHooman TakhtechianNo ratings yet

- RYM SaraDocument5 pagesRYM SaraHooman TakhtechianNo ratings yet

- Asset Integrity Engineer - JDDocument2 pagesAsset Integrity Engineer - JDHooman TakhtechianNo ratings yet

- Asset Integrity Engineer - JD - 2Document2 pagesAsset Integrity Engineer - JD - 2Hooman TakhtechianNo ratings yet

- RymDocument17 pagesRymHooman TakhtechianNo ratings yet

- Continuation of Bus Service Term 1 2013-2014Document1 pageContinuation of Bus Service Term 1 2013-2014Hooman TakhtechianNo ratings yet

- PTDF Exam TipDocument9 pagesPTDF Exam TipabusmohNo ratings yet

- API 570 Awareness Course PDFDocument63 pagesAPI 570 Awareness Course PDFRajesh Manoharan50% (4)

- Natural Gas in India: CGD Sector GrowthDocument19 pagesNatural Gas in India: CGD Sector GrowthAnkit PandeyNo ratings yet

- Key Renewables Trends: Excerpt From: Renewables InformationDocument12 pagesKey Renewables Trends: Excerpt From: Renewables InformationDhyogo WoskylevyNo ratings yet

- Method 3 Gas Analysis For Carbon Dioxide, Oxygen, Excess Air, and Dry Molecular WeightDocument17 pagesMethod 3 Gas Analysis For Carbon Dioxide, Oxygen, Excess Air, and Dry Molecular WeightAhmad RyderNo ratings yet

- DPT Well S & ADocument57 pagesDPT Well S & ABrahim Letaief100% (2)

- CO2 Huff N PuffDocument21 pagesCO2 Huff N PuffBen Azar100% (1)

- Pronunciation test with circle the wordDocument5 pagesPronunciation test with circle the wordĐỗ Cát TiênNo ratings yet

- Geothermal Plant SystemsDocument13 pagesGeothermal Plant SystemsKant KanyarusokeNo ratings yet

- Ammonia Energy Technologies: Ibrahim Dincer Dogan Erdemir Muhammed Iberia Aydin Huseyin Karasu Greg VezinaDocument368 pagesAmmonia Energy Technologies: Ibrahim Dincer Dogan Erdemir Muhammed Iberia Aydin Huseyin Karasu Greg VezinaatemtutemNo ratings yet

- The Tangguh LNG Project: Sjahrial Daud, PERTAMINA, IndonesiaDocument7 pagesThe Tangguh LNG Project: Sjahrial Daud, PERTAMINA, IndonesiaMarcelo Varejão CasarinNo ratings yet

- Polyurethane / Polyisocyanurate For: Cryogenic InsulationDocument28 pagesPolyurethane / Polyisocyanurate For: Cryogenic InsulationhacenescribdNo ratings yet

- Energy Resources Handout (C)Document3 pagesEnergy Resources Handout (C)PunchyDoodlesNo ratings yet

- 20160126Document47 pages20160126SATRIONo ratings yet

- Class10 Science Notes Chapter1 PDFDocument6 pagesClass10 Science Notes Chapter1 PDFdineshhissarNo ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Low Pressure LNG Sampling and SubcoolingDocument8 pagesLow Pressure LNG Sampling and SubcoolingOscarGomezMecanicoNo ratings yet

- Saunier Duval Thema Classic F24e Installation ManualDocument52 pagesSaunier Duval Thema Classic F24e Installation ManualProAndyNo ratings yet

- Geology From 1991Document45 pagesGeology From 1991api-3740563No ratings yet

- Envs Module - 2 MCQDocument4 pagesEnvs Module - 2 MCQsameershaik16797No ratings yet

- Generac Guardian Generator Installation ManualDocument12 pagesGenerac Guardian Generator Installation Manualrusten2No ratings yet

- PROJECT WORK PhysicsDocument9 pagesPROJECT WORK PhysicsFlame Gaming100% (1)

- Unit Unit Unit Unit Unit: I. Multiple Choice Questions (Type-I)Document12 pagesUnit Unit Unit Unit Unit: I. Multiple Choice Questions (Type-I)MantooKumarNo ratings yet

- SPE 164820 MS Probabilistic and Deterministic Methods Applicability in Unconventional Reservoirs PDFDocument12 pagesSPE 164820 MS Probabilistic and Deterministic Methods Applicability in Unconventional Reservoirs PDFNGT56No ratings yet

- Ansaldo Energia AE94 2 Upgrading Project PDFDocument20 pagesAnsaldo Energia AE94 2 Upgrading Project PDFRaden MasNo ratings yet

- M&e Tugasan 1Document7 pagesM&e Tugasan 1Shoby Kesavan PillaiNo ratings yet

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocument77 pagesAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- 5th Sem. B. Tech. - Power Station Practice - BEEE505T - 30 JuneDocument3 pages5th Sem. B. Tech. - Power Station Practice - BEEE505T - 30 Juneptarwatkar123No ratings yet