Professional Documents

Culture Documents

2012 - TRAN1001 HETR210D - Heat Transfer Dec 2012 PDF

Uploaded by

Travis LegairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2012 - TRAN1001 HETR210D - Heat Transfer Dec 2012 PDF

Uploaded by

Travis LegairCopyright:

Available Formats

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 1

THE UNIVERSITY OF TRINIDAD & TOBAGO

FINAL ASSESSMENT/EXAMINATIONS DECEMBER 2012

Course Code and Title: TRAN1001, HETR210D, Heat Transfer

Programme: NETD in Chemical Engineering

Date and Time: Tuesday 11

th

December, 2012 1:00pm-4:00pm

Duration: 3 hours

PLEASE READ ALL INSTRUCTIONS CAREFULLY BEFORE YOU BEGIN THIS

EXAMINATION

Instructions to Candidates

1. This paper has _8_ pages and _4_questions, page 1 is the cover, questions are on page 2-3,

and data and formulae are on page 4 - 8.

2. You are required to answer ALL _4_ questions.

The question paper must be returned with the Answer script.

Key Examination Protocol

1. Students please note that academic dishonesty (or cheating) includes but is not limited to

plagiarism, collusion, falsification, replication, taking unauthorised notes or devices into an

examination, obtaining an unauthorised copy of the examination paper, communicating or

trying to communicate with another candidate during the examination, and being a party to

impersonation in relation to an examination.

2. The above mentioned and any other actions which compromise the integrity of the academic

evaluation process will be fully investigated and addressed in accordance with UTTs

academic regulations.

3. Please be reminded that speaking without the Invigilators permission is NOT allowed.

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 2

ANSWER ALL QUESTIONS

1. Answer the following.

a. A furnace wall consists of 0.25 mof fireclay brick (k =1.64 W/m-K), and 0.12 m

outer layer masonry brick (k =0.6 W/m-K). It is exposed to furnace gas at 1400 K

with ambient air at 310 K adjacent to the outside wall.

i. If the outside and inside convective heat transfer coefficients are considered as

115 W/m

2

-K and 23 W/m

2

-K respectively. Calculate the heat transferred per

m

2

per second. [9 marks]

ii. Also calculate the actual surface temperatures and all the interface

temperatures in the case above. [6 marks]

b. In a 1-2 exchanger (counter current) the values of the temperatures are cold water in =

72

o

C; cold water out = 135

o

C; hot water in = 248

o

C; hot water out = 124

o

C. Make a

sketch showing all the temperatures clearly. Then calculate the corrected log mean

temperature drop in this exchanger?

[10 marks]

2. Answer the following:

a. An insulated steam pipe has an internal diameter of 0.06 mand an external diameter

of 0.0725 m. The outside diameter of the asbestos insulation is 0.145 m. It is located

where the ambient temperature is 32

o

C. The steam in the pipe is at a temperature of

160C. If thermal conductivities are 45 W/m

o

C and 0.014 W/m

o

C for steel and

asbestos respectively, calculate the heat loss in 12 mof pipe per second. Only

consider the outside convective heat transfer coefficient which is 8.5 W/m

2

-K.

Neglect the effects of radiation. [15 marks]

b. Steam at 135

o

C condenses on the outside of a tube at 345 kPa gauge. The tube has

outer diameter 33.4 mmand inside diameter 26.6 mm. Oil at 38

o

C is flowing inside

the tube. Take h

o

= 7420W/m

2

K and h

i

= 690W/m

2

K. Find the tube wall temperature

neglecting wall resistance. [10 marks]

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 3

3. Answer the following:

a. Carbon tetrachloride (specific heat capacity = 920 J /kg-

o

C) flowing at 19,000 kg/h is

to be cooled from 85

o

C to 40

o

C using 15,500 kg/h of cooling water (specific heat

capacity = 4200 J /kg-

o

C) entering at 20

o

C. Given that the overall heat transfer

coefficient is 350 W/m

2

- K what will the area of a counter current exchanger be. If a

parallel exchanger is used over a counter flow exchanger what will be the increase in

area. Ignore any correction factor of LMTD . [15 marks]

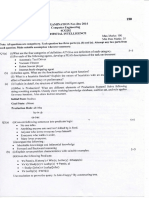

b. Use figure 1 below, the data for film thickness and local heat transfer coefficients for

methanol to answer the following. Condensation is taking place on a tube 8 feet high.

At 7 feet from the base find the following.

i. The film thickness in feet. [2 marks]

ii. The local heat transfer coefficient in Btu/h-ft

2

-

o

F. [2 marks]

iii. The thermal conductivity in W/m-K. [6 marks]

4. A 2-4 heat exchanger has shell diameter, D

s

, 667 mmand baffle cut 25%. The tubes are on a

triangular pitch equal to 1.25 d

o

. The outer diameter of the tubes, d

o

are 20 mmand the baffle

spacing, l

B

or baffle pitch is to be 1/5 the shell diameter. Gas oil at the rate of 22,500 kg/h is

to be cooled on the shell side from 200

o

C to 40

o

C. There are 4 tube passes and 2 shell

passes so the area for cross flow, A

s

, will be half that given by the regular equation. The

physical properties at the bulk average temperature are given below.

Specific heat capacity, c

p

, 2280 J/kg

o

C Viscosity, , 0.00017 Pa-s

Thermal conductivity, k, 0.125 W/m

o

C Density, , 850 kg/m

3

Neglecting the correction factor for wall temperature, calculate the following:

a. The area for cross flow, A

s

for this 2-4 exchanger. [5 marks]

b. The flow rate of gas oil in kg/s. [1 mark]

c. The shell side mass velocity, G

s

in kg/s-m

2

. [2 marks]

d. The shell side equivalent diameter, d

e

. [5 marks]

e. The shell side Reynolds number, Re. [3 marks]

f. The Kerns shell side heat transfer factor j

H

. [2 marks]

g. Prandtl number, Pr [3 marks]

h. The shell side heat transfer coefficient, h

s

. [4 marks]

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 4

DATA AND FORMULAE

Figure 1.

0 1 2 3 4

0

0.5

1

1.5

2

2.5

3

0

0.5

1

1.5

2

2.5

3

0 400 800 1200 1600 2000

Film Thickness, x 10

-4

ft

D

i

s

t

a

n

c

e

f

r

o

m

T

o

p

o

f

T

u

b

e

,

f

t

Coefficient, Btu/h-ft

2

-

o

F

Heat Transfer

coefficient

Film

Thickness

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 5

Figure 2.

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 6

Figure 3.

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 7

Flat Surface-Composite:

o i

h k

s

k

s

h

T At

Q

1

...

1

2

2

1

1

+ + + +

A

=

Cylindrical-Composite:

( )

o o n

n i o

n

n

i i

h r k

r r n l

h r

T t L

Q

1

/

1

2

1

+ +

A

=

=

t

Log Mean Temperature Difference, LMTD. Correction factor Z and

H

.

) / (

2 1

2 1

u u

u u

n l

LMTD

=

cold

hot

i c co

ho hi

T

T

T T

T T

Z

A

A

=

=

possible

cold

ci hi

ci co

H

T

T

T T

T T

max

A

A

=

= q

ESTIMATION OF WALL TEMPERATURE (neglecting wall resistance):

) / 1 ( ) / ( / 1

) / 1 (

o o i i

i

i

h D D h

T h

T

+

A

= A

Descending film (vertical tubes or plates),

o

f

x

k

h =

where h

x

, is the local coefficient of

heat transfer, k

f

is thermal conductivity of the film, and , local film thickness.

A

s,

:The area for cross-flow in between the baffles (at shell equator)

For a 2-4 exchanger For a 1-2 exchanger

t

B s o t

s

p

l D d p

A

) (

5 . 0

=

t

B s o t

s

p

l D d p

A

) (

=

Where p

t

= tube pitch

d

o

= tube outside diameter

D

s

= shell inside diameter, m

l

B

(P)

= baffle spacing, m (same as baffle pitch, P)

G

s

: The shell side mass velocity in kg/s-m

2

G

s

=W

s

/A

s

Where W

s

(

m ) = fluid flow rate on the shell side, kg/s

The University of Trinidad and Tobago

December 2012 Final Examinations

(TRAN1001 Heat Transfer) Page 8

d

e

: The shell side equivalent diameter or hydraulic diameter, m

SQUARE PI TCH EQUI LATERAL TRI ANGULAR PI TCH

) 785 . 0 (

27 . 1

2 2

o t

o

e

d p

d

d =

) 917 . 0 (

10 . 1

2 2

o t

o

e

d p

d

d =

Re : The shell side Reynolds number Re =G

s

d

e

/ = u

s

d

e

/

h

s

:The shell side heat transfer coefficient using

Nu =h

s

d

e

/ k

f

=j

h

Re Pr

0.33

(/

w

)

0.14

14 . 0

33 . 0

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

=

w f

p

e s

h

f

e s

k

c

d G

j

k

d h

where

k

f

= thermal conductivity of shell fluid or outside fluid

CONVERSI ON FACTORS:

To convert from: To: Multiply by:

Heat or Energy Btu J 1054.4

h,U (surface/overall coeff) Btu/hr-ft

2

-

o

F W/m

2

-

o

C 5. 3

Heat flux Btu/hr-ft

2

W/m

2

3.1546

Heat capacity, c

p

Btu/lb

m

-

o

F J/kg-

o

C 4186.8

Pound mass lb

m

kg 0.45366783

k, (thermal conductivity) Btu/hr-ft-

o

F W/m-

o

C 1.7307

Pound force lb

f

N 4.4482

Inches in mm 25.4

Viscosity, in ccentipoise cP kg/m-s (Pa-s) 0.001

THE END

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Libros de Estructuras MetalicasDocument8 pagesLibros de Estructuras MetalicasNata277No ratings yet

- FM TransmitterDocument38 pagesFM TransmitterTushar Goel100% (1)

- BCA Self Assessment English and TagalogDocument3 pagesBCA Self Assessment English and TagalogReymundo Pantonial Tugbong JrNo ratings yet

- Internal Floating Roof DesignDocument38 pagesInternal Floating Roof DesigncrnewsomNo ratings yet

- A30050-X6026-X-4-7618-rectifier GR60Document17 pagesA30050-X6026-X-4-7618-rectifier GR60baothienbinhNo ratings yet

- PROBLEM 6.14: SolutionDocument9 pagesPROBLEM 6.14: SolutionWilliam HendersonNo ratings yet

- Datasheet Solis 110K 5GDocument2 pagesDatasheet Solis 110K 5GAneeq TahirNo ratings yet

- Tactical Missile Design Presentation FleemanDocument422 pagesTactical Missile Design Presentation Fleemanfarhadi100% (16)

- 18 DiplexorDocument3 pages18 DiplexorFernando GutiérrezNo ratings yet

- Re - Rockspace.local - Ap - SetupDocument6 pagesRe - Rockspace.local - Ap - SetuptrujillobresslerNo ratings yet

- Parametric Modeling A Simple ToolDocument6 pagesParametric Modeling A Simple ToolFatimeh ShahinNo ratings yet

- Sample LT1 AnsDocument2 pagesSample LT1 AnsEirik LawNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- US6362718 Meg Tom Bearden 1Document15 pagesUS6362718 Meg Tom Bearden 1Mihai DanielNo ratings yet

- D-Intro To Programming With RAPTORDocument13 pagesD-Intro To Programming With RAPTORmarkecbNo ratings yet

- Manual Xtable EXCEL LinkDocument7 pagesManual Xtable EXCEL LinkElena Alexandra BeladanNo ratings yet

- Delta ASDA B User ManualDocument321 pagesDelta ASDA B User ManualRichard ThainkhaNo ratings yet

- Simplex 4098+seriesDocument4 pagesSimplex 4098+seriesCode JonNo ratings yet

- Experimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustDocument13 pagesExperimental Study On Partial Replacement of Fine Aggregate With Quarry Dust and Saw DustPerarasan MNo ratings yet

- Madanapalle Institute of Technology & ScienceDocument40 pagesMadanapalle Institute of Technology & ScienceRavikanth NssNo ratings yet

- Modbus RegisterDocument7 pagesModbus RegisterZuniiga AndersonNo ratings yet

- I Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofDocument30 pagesI Twin Technology: Submitted in Partial Fulfillment of The Requirements For The Award of The Degree ofBarma RajkumarNo ratings yet

- Reasoning Calendar Questions Finding Day or Date, Concepts, Shortcuts ExplainedDocument8 pagesReasoning Calendar Questions Finding Day or Date, Concepts, Shortcuts ExplainedManish KumarNo ratings yet

- Assign N LabDocument4 pagesAssign N LabMtende MosesNo ratings yet

- Wordpress The Right WayDocument62 pagesWordpress The Right WayAdela CCNo ratings yet

- Physical and Chemical Properties of Crude Oil and Oil ProductsDocument10 pagesPhysical and Chemical Properties of Crude Oil and Oil ProductsEnegineer HusseinNo ratings yet

- Validation of The Perceived Chinese Overparenting Scale in Emerging Adults in Hong KongDocument16 pagesValidation of The Perceived Chinese Overparenting Scale in Emerging Adults in Hong KongNeha JhingonNo ratings yet

- Code Reason Effect: Step 1. Step 1ADocument2 pagesCode Reason Effect: Step 1. Step 1AAhmedmahNo ratings yet

- IET DAVV 2014 Com2Document12 pagesIET DAVV 2014 Com2jainam dudeNo ratings yet

- CERNCourier2021JanFeb DigitaleditionDocument33 pagesCERNCourier2021JanFeb DigitaleditionBhakti rautNo ratings yet