Professional Documents

Culture Documents

TDS - Glenium Sky 504

Uploaded by

Praveen K.RCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - Glenium Sky 504

Uploaded by

Praveen K.RCopyright:

Available Formats

GLENIUM SKY 504

New polycarboxylic ether superplasticizer for the production of high quality ready-mix concrete with low water cement ratio and exceptional workability Description GLENIUM SKY 504 is an innovative second generation superplasticizer based on polycarboxylic ether (PCE) polymers. It is derived directly from the Total Performance ControlTM concept. GLENIUM SKY 504 is specially engineered for ready-mix concrete. Its particular configuration allows its delayed adsorption onto the cement particles and disperses them efficiently. As compared with other PCE superplasticizers, it is possible to obtain a high quality concrete mix with accelerated strength development and extended workability without delayed setting characteristics. The Total Performance ControlTM concept ensures that ready-mix producers, contractors and engineers get a concrete that is of the same high quality as originally specified; starting from production at the batching plant, to the delivery and application into place, and followed by its hardening process. Utilizing Smart Dynamic Concrete (SDC) technology it provides a concrete mix with exceptional placing characteristics and accelerated cement hydration for early strength development and high quality concrete. GLENIUM SKY 504 may be used in combination with RheoMATRIX for producing Smart Dynamic Concrete (SDC). The technology produces advanced self compacting concrete, without the aid of vibration. For economic, ecological and ergonomic ready-mix / precast concrete production.

Features and Benefits GLENIUM SKY 504 offers the following benefits for: The ready-mix producer: Capability of delivering high performance concrete at any time to the job site in place Production of a concrete with low water cement ratios without loss of workability Single product for many application needs The contractor / applicator: Easier placing and development

faster

strength

Improved concrete surfaces Guarantee to place the same concrete as specified and ordered from ready-mix plant

The engineer: Insurance that concrete meets original specification High quality durable concrete

Packaging GLENIUM SKY 504 is supplied in 210 litre drums, 1,000 litre containers or in bulk. *Typical properties

Appearance Specific gravity Chloride content Whitish to straw coloured liquid 1.115 at 25C chloride-free to EN 934-2

GLENIUM SKY 504

Standards EN 934-2 Tables 3.1, 3.2, 11.1 and 11.2 ASTM C-494 Type F&G ASTM C-1017 Type I & II Application procedure Dosage The normally recommended dosage rate of GLENIUM SKY 504 is 0.8 to 1.5 litre per 100kg of total cementitious material. Other dosages may be recommended in special cases according to the specific site conditions. In this case please consult our Technical Services Department for advice. Mixing GLENIUM SKY 504 is a ready-to-use admixture to be added to the concrete as a separate component. Optimal result is obtained if GLENIUM SKY 504 is poured into the concrete mix right after the addition of the first 80% of the mixing water, i.e. when all solids are wetted. Avoid adding the admixture to the dry aggregates. Compatibility GLENIUM SKY 504 is not compatible with RHEOBUILD superplasticizers. In order to optimize special requirements the use of the following complementary additives is suggested: Air entraining agent MICRO-AIR to improve frost/thaw resistance Storage GLENIUM SKY 504 should be stored out of direct sunlight and protected from extremes of temperature. The shelf life is 9 months when stored as above. Handling and transportation No special requirements must be observed during use. Protection gloves and glasses are however recommended. GLENIUM SKY 504 is nonflammable, non-toxic or irritant and is not subject to special transport requirements. Safety precautions GLENIUM SKY 504 contains no hazardous substances requiring labelling. For further information refer to the Material Safety Data Sheet. Note Field service, where provided, does not constitute supervisory responsibility. For additional information contact your local BASF representative. BASF reserves the right to have the true cause of any difficulty determined by accepted test methods. Quality and care All products originating from BASFs Dubai, UAE facility are manufactured under a management system independently certified to conform to the requirements of the quality, environmental and occupational health & safety standards ISO 9001, ISO 14001 and OHSAS 18001.

01/2005 BASF_CC-UAE revised 11/2010

* Properties listed are based on laboratory controlled tests.

Whilst any information contained herein is true, accurate and represents our best knowledge and experience, no warranty is given or implied with any recommendations made by us, our representatives or distributors, as the conditions of use and the competence of any labour involved in the application are beyond our control. As all BASF technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

BASF Construction Chemicals UAE LLC P.O. Box 37127, Dubai, UAE Tel: +971 4 8090800 www.basf-cc.ae Fax: +971 4 8851002

You might also like

- Masterglenium Sky 504 TdsDocument2 pagesMasterglenium Sky 504 TdsaliNo ratings yet

- Masterglenium Sky 504: Description Features and BenefitsDocument2 pagesMasterglenium Sky 504: Description Features and BenefitsvikasNo ratings yet

- MasterGlenium Sky 504S Technical Data SheetDocument3 pagesMasterGlenium Sky 504S Technical Data Sheetabukayes.abdinNo ratings yet

- TDS - Glenium 119MDocument2 pagesTDS - Glenium 119MgalgiodesNo ratings yet

- TDS - Glenium 114Document2 pagesTDS - Glenium 114Alexi ALfred H. TagoNo ratings yet

- TDS - Glenium Ace 456Document3 pagesTDS - Glenium Ace 456vasantsunerkarNo ratings yet

- TDS - Glenium Ace 415Document3 pagesTDS - Glenium Ace 415Alexi ALfred H. TagoNo ratings yet

- TDS Conmix P5 000 Feb13Document1 pageTDS Conmix P5 000 Feb13Vipas MankosolNo ratings yet

- Glenium Sky 777 v4Document2 pagesGlenium Sky 777 v4babu_ssrNo ratings yet

- TDS - Glenium Ace 340Document3 pagesTDS - Glenium Ace 340Alexi ALfred H. TagoNo ratings yet

- Glenium 105 Suretec TdsDocument2 pagesGlenium 105 Suretec TdsGabriel LimNo ratings yet

- Basf Masterpolyheed 3532ae TdsDocument2 pagesBasf Masterpolyheed 3532ae TdsVisJadNo ratings yet

- Mastercrete 1000 TdsDocument2 pagesMastercrete 1000 Tdsaruncg2No ratings yet

- Master Glenium SKY 8777 v1Document3 pagesMaster Glenium SKY 8777 v1Yati AggarwalNo ratings yet

- Admix Sec eDocument2 pagesAdmix Sec eDamodharNo ratings yet

- Ment He 510Document2 pagesMent He 510Fenil JoseNo ratings yet

- MasterGlenium ACE 575 Technical Data SheetDocument3 pagesMasterGlenium ACE 575 Technical Data Sheetabukayes.abdinNo ratings yet

- PolybitpolyprimeDocument2 pagesPolybitpolyprimerazeeth1212No ratings yet

- TDS - Glenium Ace 30Document2 pagesTDS - Glenium Ace 30Alexi ALfred H. TagoNo ratings yet

- TDS - Glenium Ace 30 PDFDocument2 pagesTDS - Glenium Ace 30 PDFAlexi ALfred H. TagoNo ratings yet

- Rheo FibreDocument2 pagesRheo FibreBinoy Sankar SarkerNo ratings yet

- Master Kure 181Document2 pagesMaster Kure 181aahtagoNo ratings yet

- Chrysofluid Optima 222 PDFDocument2 pagesChrysofluid Optima 222 PDFmanil_5No ratings yet

- Rheobuild 890Document2 pagesRheobuild 890Ahmed ZidanNo ratings yet

- Sikament® NNSDocument3 pagesSikament® NNStalonflame24100% (1)

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- Basf Masterrheobuild 858 TdsDocument2 pagesBasf Masterrheobuild 858 TdsHassan SyedNo ratings yet

- Sikament - 2004 NsDocument2 pagesSikament - 2004 NsJerry TomNo ratings yet

- TDS - Rheobuild 850Document2 pagesTDS - Rheobuild 850nischal_babuNo ratings yet

- Sikament - 600: High Range Water-Reducing Concrete AdmixtureDocument3 pagesSikament - 600: High Range Water-Reducing Concrete Admixturedeboline mitraNo ratings yet

- Admix CF 555Document2 pagesAdmix CF 555melvinkorahNo ratings yet

- Construction Material - Degussa AdmixtureDocument2 pagesConstruction Material - Degussa AdmixturecivilproNo ratings yet

- Plastiment® 100Document3 pagesPlastiment® 100Troy AustinNo ratings yet

- Glenium 51 TDSDocument2 pagesGlenium 51 TDSTooma DavidNo ratings yet

- Super Conmix 999 Concrete AdmixturesDocument2 pagesSuper Conmix 999 Concrete AdmixturesparulhariyaNo ratings yet

- MasterRheobuild 859 Technical Data SheetDocument3 pagesMasterRheobuild 859 Technical Data Sheetabukayes.abdinNo ratings yet

- Rheobuild 850Document2 pagesRheobuild 850Haresh BhavnaniNo ratings yet

- MasterGlenium SKY 8522 v1Document3 pagesMasterGlenium SKY 8522 v1Jaga NathNo ratings yet

- Sika® Viscocrete®-180 G: Product Data SheetDocument3 pagesSika® Viscocrete®-180 G: Product Data SheetRyan PradanaNo ratings yet

- Construction Chemicals for Concrete WorkabilityDocument2 pagesConstruction Chemicals for Concrete WorkabilityShaik Qutubuddin100% (1)

- Dow Corning® 993 Structural Glazing Sealant: Product InformationDocument4 pagesDow Corning® 993 Structural Glazing Sealant: Product InformationMohammad ALTAKINo ratings yet

- Glenium Ace 309 Suretec - PDSDocument2 pagesGlenium Ace 309 Suretec - PDSmcwong_98No ratings yet

- Basf Masterrheobuild 1000 TdsDocument3 pagesBasf Masterrheobuild 1000 TdsDevendraNo ratings yet

- Plastiment P 121 R Pds enDocument2 pagesPlastiment P 121 R Pds enparanrengi agusNo ratings yet

- Molykote GreaseDocument2 pagesMolykote GreasenooraniaNo ratings yet

- Eng Masterrheobuild 850 TdsDocument4 pagesEng Masterrheobuild 850 TdsaghamshahidNo ratings yet

- PDS Pilogel PDSDocument1 pagePDS Pilogel PDSEzekiel PatawaranNo ratings yet

- Sikafume - Technical Data SheetDocument2 pagesSikafume - Technical Data SheetSigit PurwandiNo ratings yet

- Pdsgleniumc317 171211141713 PDFDocument2 pagesPdsgleniumc317 171211141713 PDFRavi AyyavuNo ratings yet

- Pds - Glenium C 317Document2 pagesPds - Glenium C 317Doby YuniardiNo ratings yet

- RHEOBUILD 623 v1Document2 pagesRHEOBUILD 623 v1Shoyeeb AhmedNo ratings yet

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 pagesPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-No ratings yet

- TDS - Glenium 110 UN PDFDocument3 pagesTDS - Glenium 110 UN PDFAlexi ALfred H. TagoNo ratings yet

- Sika ViscoCrete-225 SDocument2 pagesSika ViscoCrete-225 SMajid AlzubadyNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- Knowledge Tree July 2012Document11 pagesKnowledge Tree July 2012Praveen K.RNo ratings yet

- Examples For Ductile Detailing RCC BuildingsDocument72 pagesExamples For Ductile Detailing RCC BuildingsVaidyanathan SivasubramanianNo ratings yet

- How To Execute A Post-Fire Rebuild PDFDocument2 pagesHow To Execute A Post-Fire Rebuild PDFPraveen K.RNo ratings yet

- Aniket Bhondve: ObjectiveDocument2 pagesAniket Bhondve: ObjectivePraveen K.RNo ratings yet

- C 5Document17 pagesC 5jjrelucio3748No ratings yet

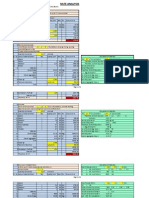

- Rate AnalysisDocument6 pagesRate AnalysisKrunal Joshi100% (1)

- Fly Ash Silica Fume in ConcreteDocument16 pagesFly Ash Silica Fume in ConcreteMax KopNo ratings yet

- Aniket Bhondve: ObjectiveDocument2 pagesAniket Bhondve: ObjectivePraveen K.RNo ratings yet

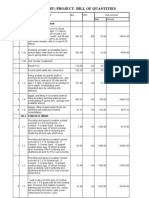

- Rate Analysis and Abstract BOQDocument37 pagesRate Analysis and Abstract BOQThota Revanth78% (41)

- Hiranandani Hill Crest Project Rebar Delivery RecordsDocument1 pageHiranandani Hill Crest Project Rebar Delivery RecordsPraveen K.RNo ratings yet

- SP-34-1987 Handbook On Reinforcement and DetailingDocument1 pageSP-34-1987 Handbook On Reinforcement and DetailingPraveen K.RNo ratings yet

- Concrete Mix DesignDocument10 pagesConcrete Mix Designkrishbist67% (3)

- Sikament NNG: Superplasticizer / High Range Water-ReducerDocument2 pagesSikament NNG: Superplasticizer / High Range Water-ReducerJean Marie NgaskaNo ratings yet

- Characteristics of Concrete With Admixtures PDFDocument6 pagesCharacteristics of Concrete With Admixtures PDFTran Huynh NamNo ratings yet

- The Effect of Isoprenyl Ether Polymer Molecular Structure On Cementitious CompositesDocument11 pagesThe Effect of Isoprenyl Ether Polymer Molecular Structure On Cementitious Compositessantosh mhetreNo ratings yet

- UHPFRC PortfolioDocument67 pagesUHPFRC Portfoliolanecastoldi100% (1)

- Types of ConcreteDocument38 pagesTypes of Concretesameer khanNo ratings yet

- JNT IncDocument35 pagesJNT IncMuhammad Farhan PutraNo ratings yet

- Compatibility Between Polycarboxylate-Based Admixtures and Blended Cement PasteDocument12 pagesCompatibility Between Polycarboxylate-Based Admixtures and Blended Cement Pasteshihab44No ratings yet

- Construction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghDocument7 pagesConstruction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghHasu MehtaNo ratings yet

- ProjectDocument13 pagesProjectFE3056 NAGARAJ.SNo ratings yet

- Precast Products - HandbookDocument10 pagesPrecast Products - HandbookkamakshiNo ratings yet

- SIKA Catalog 2020 - Infrastructure v20 December 17 PDFDocument60 pagesSIKA Catalog 2020 - Infrastructure v20 December 17 PDFMark anthony GauranoNo ratings yet

- Water-Reducing Admixtures for ConcreteDocument11 pagesWater-Reducing Admixtures for ConcreteSteven KuaNo ratings yet

- MasterGlenium SKY 8758 - MM v1 - 0119Document2 pagesMasterGlenium SKY 8758 - MM v1 - 0119Aung Naing Latt AungNo ratings yet

- Leta Hora Research PaperDocument101 pagesLeta Hora Research Papernetsanet shewaleuelNo ratings yet

- Additives For A Challenging Cement MarketDocument5 pagesAdditives For A Challenging Cement MarketkidcatNo ratings yet

- Water Reducing AdmixtureDocument2 pagesWater Reducing AdmixtureBryanMatthewLontokNo ratings yet

- SP 233 SymposiumDocument184 pagesSP 233 SymposiumCynti DZNo ratings yet

- Nano Concrete Report 2Document18 pagesNano Concrete Report 2Rahul Singh100% (1)

- Aggregates CharacteristicsDocument382 pagesAggregates Characteristicshusseinlakkis100% (1)

- Adv 21931Document7 pagesAdv 21931Giacomo AccomandoNo ratings yet

- Glo Concrete ViscoflowDocument3 pagesGlo Concrete ViscoflowarkarNo ratings yet

- Answers - Examination Paper For Concrete & AdmixturesDocument6 pagesAnswers - Examination Paper For Concrete & AdmixturesDileepa DissanayakeNo ratings yet

- Superplasticizers 2Document5 pagesSuperplasticizers 2brischikNo ratings yet

- Concrete Mix DesignDocument24 pagesConcrete Mix Designvishnumani3011No ratings yet

- Sika UCS Powder - Underwater ConcreteDocument2 pagesSika UCS Powder - Underwater ConcreteAnonymous uNhWGqNzNo ratings yet

- Effect of Superplasticizer Type on Properties of Fly Ash Blended CementDocument6 pagesEffect of Superplasticizer Type on Properties of Fly Ash Blended CementKaraline MarcesNo ratings yet

- Rheological Properties and Microstructure of Fresh Cement Pastes With Varied Dispersion Media and SuperplasticizersDocument9 pagesRheological Properties and Microstructure of Fresh Cement Pastes With Varied Dispersion Media and SuperplasticizersBattsengel NomindelgerNo ratings yet

- HSC ReportDocument53 pagesHSC ReportAless MarrticNo ratings yet

- Excel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)Document16 pagesExcel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)SOURAV RANJAN KHANRANo ratings yet