Professional Documents

Culture Documents

Method Statement Steel Structure 1 4 Meg

Uploaded by

Nick LawOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement Steel Structure 1 4 Meg

Uploaded by

Nick LawCopyright:

Available Formats

JABALI PROJECT

METHOD STATEMENT FOR MINE ADMIN OFFICE AND WORKSHOP STEEL STRUCTURE

Owner Contractor : : Jabal Salab Company (Yemen) Limited Nabil Salah for Trading and Contracting

Prepared by : Mohammed AL-Fareh Email : bridger@ymail.com Website : www.alfareh.webs.com

Mine Admin. Offices & Workshop Method Statement

Page 2 of 26

TABLE OF CONTENTS

Purpose Scope Responsibilities Resources to be deployed Erection Methodology Quality Control Safety Precautions Attachments

2 2 2 3 10 19 20 21

1.

PURPOSE

Mine Admin. Offices & Workshop Method Statement

Page 3 of 26

The purpose of this document is to provide a detailed Method Statement indicating the work procedures for erecting the steel structure to be carried for the Mine Admin Office and Workshop. 2. SCOPE

The scope of work covered by this Method Statement is as follows: Lean concrete Reinforced concrete for the foundation ( anchor bolts and pedestal) Erection of steel structure Frames with Sheeting. Masonry Works

3.

RESPONSIBILITIES

Project Manager shall be responsible for the overall organization, progress and safe execution of the works. Assistant Project Manager has all responsibilities with Project Manger. Resident Engineer shall be responsible for ensuring the works are carried out in accordance with the construction drawings and specifications and shall report to the Project Manager. He is also in charge of the day to day organization, execution and safe execution of the works. He shall also be responsible for monitoring and assuring the quality of the works. Surveyor shall be responsible for setting out of the works and shall report to the Project manager.

Mine Admin. Offices & Workshop Method Statement

Page 4 of 26

Resource to be Deployed

Mobile Crane

Guy Wires

Clamps

Ratchet Puller

Mine Admin. Offices & Workshop Method Statement

Page 5 of 26

Light Duty Scaffolding

Ladders

Generators

Screw Gun

Mine Admin. Offices & Workshop Method Statement

Page 6 of 26

Pop Rivet Puller Grinder

10 mm Drill Vice Grips

Aviation snips

Mine Admin. Offices & Workshop Method Statement

Page 7 of 26

Ratchet Spanner

Utility Knife

Hacksaw

Mastic Gun

Spud wrench

Miscellaneous Tools

Mine Admin. Offices & Workshop Method Statement

Page 8 of 26

Tool Belt and Bolt Bag

Plumb bob

Total Station

Spirit

Level Measuring Tape

Mine Admin. Offices & Workshop Method Statement

Page 9 of 26

Goggles Welding Hood

Gloves Safety Harness

Safety Shoes

Helmet

Mine Admin. Offices & Workshop Method Statement

Page 10 of 26

First Aid Kit Portable Fire Extinguisher Welding Machine

5.2 Manpower to be deployed. a) Project Manager b) Assistant project Manger c) Resident Engineer/Safety Officer d) Surveyor e) Foreman / Supervisor f) Erection Crew g) Carpenter with Assistants h) Bar bender with Assistants i) Operator j) Concrete Labors k) Mason l) General Workers

Mine Admin. Offices & Workshop Method Statement

Page 11 of 26

Erection Methodology

Lean Concrete After the ground have been leveled by a grader and compacted with a roller, the lean concrete can be pour. After lean concrete is poured, it should be cured by water for a minimum of one week. Reinforced concrete for the foundation The day after lean concrete is poured, formworks fabrication along with rebar cutting and bending will commence as per approved drawings.

Mine Admin. Offices & Workshop Method Statement

Page 12 of 26

After all rebar are set in place, anchor bolts should be put in accurate place with the help of steel plate to keep anchor bolts in position during the pouring of the foundation. After the anchor bolts and rebar are in their final position, the foundation will be ready for pouring. Curing for the foundation will be for not less than a week for the concrete to gain the required strength of 30 Mpa.

Mine Admin. Offices & Workshop Method Statement

Page 13 of 26

Erection of steel structure

General Although several methods are used to erect general steel rigid frames, it has been found most satisfactory to erect the columns first, tie them together with the girts and tighten the anchor bolts. After the columns have been erected, the ground assembled rafter is hoisted into place and connected to the columns. Generally, the rafter will be connected on ground and then lifted to its final position. The intermediate or interior frames nearest the end wall are usually erected first. This bay usually contains the optional diagonal bracing. Erection Procedure

Step 1 : Stand main frame Columns and turn nuts on anchor bolts.

Mine Admin. Offices & Workshop Method Statement

Page 14 of 26

Step 2 : Add wall girts

Step 3 : Add main frame rafter and secure with rope, tighten connection bolts snug, using crane.

Mine Admin. Offices & Workshop Method Statement

Page 15 of 26

Step 4 : Add another main Frame rafter and several roof purlins to stabilize frame

First Frame of braced bay

Second Frame of braced bay

Roof Purlins

Mine Admin. Offices & Workshop Method Statement

Page 16 of 26

Step 5 : Add cable bracing. Snug tighten only. Remove rope ties and repeat the previous steps with other main frames.

Step 6 : Add corner columns, sidewall girts and eave struts. Then proceed with endwall columns, rafters, remaining roof purlins and flange braces.

When the frame work is standing, the structure should be plumbed and

squared. Use a level as shown for wall columns. Square the roof with the use of the cable braces as shown. Taking diagonal measurements and

Mine Admin. Offices & Workshop Method Statement

Page 17 of 26

adjusting the tension of the xbracing will square the roof and aid in plumbing the structure endwalls.

Roof bracing

Erect next bay

Erect remaining bays

Mine Admin. Offices & Workshop Method Statement

Page 18 of 26

Step 7 : Plumbing and squaring the framework .

Mine Admin. Offices & Workshop Method Statement

Page 19 of 26

Block Works After columns are set and their alignment is checked, block work will commence with the use of simple equipment and scaffolding when needed The mezzanine floor will be erected with main frames generally prior to sheeting and then casting the mezzanine floor. The sheeting for the workshop will be installed using scaffolding.

Mine Admin. Offices & Workshop Method Statement

Page 20 of 26

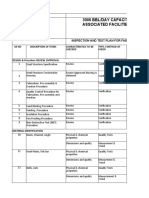

Quality Control

The safety and quality of erection will be ensured by engaging qualified supervisor and technicians on the job. The quality plan as a minimum should contain the following : a. b. c. d. Erection Inspection Check List EICL ( Attachment I) Method Statement. Risk Assessment. Bolt Tighten Procedure ( Attachment II)

Mine Admin. Offices & Workshop Method Statement

Page 21 of 26

Safety Precautions

For safety reasons there are precautions that need to be taken during erection. 8.1 8.2 Make daily check on all lifting equipment. Make daily checks on all lifting slings. 8.9 Ensure that erection always starts at a braced bay. 8.10 Ensure permanent bracing and flange stays are installed as work proceeds. 8.11 Ensure that high strength bolts are used where indicated. 8.12 maintain a clean and tidy site. Thus avoid material loss or accident. 8.13 Tie down Sheeting Once the bundle is opend. 8.14 Ensure that high strength bolts are correctly tightened. 8.15 when walking on the roof, step in the valley of the panels, not the ribs.

8.3 Check that all access equipment is in good condition, including scaffolding and ladders. 8.4 Check weather conditions, strong winds are dangerous during erection and sheeting. 8.5 Check for overhead electric lines before moving in with a crane. 8.6 check that all erectors have the correct personal safety equipment, helmet, safety shoes, safety harness etc. 8.7 ensure that there are sufficient guy wires on site for temporary bracing 8.8 Check electric cables for hand tools, discard frayed or split cables

Mine Admin. Offices & Workshop Method Statement

Page 22 of 26

Mine Admin. Offices & Workshop Method Statement

Page 23 of 26

Mine Admin. Offices & Workshop Method Statement

Page 24 of 26

Mine Admin. Offices & Workshop Method Statement

Page 25 of 26

Mine Admin. Offices & Workshop Method Statement

Page 26 of 26

You might also like

- Anchor Bolt MSDocument7 pagesAnchor Bolt MSGaneshNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Document9 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepNo ratings yet

- Steel Structures Erection Method Statement-DraftDocument43 pagesSteel Structures Erection Method Statement-DraftMahmoud Fakhereddin100% (1)

- Fabrication Procedure Steel Structure TSEDocument21 pagesFabrication Procedure Steel Structure TSEspazzbgt67% (6)

- Method Statement of Steel FabricationDocument15 pagesMethod Statement of Steel Fabricationjohney291% (11)

- Method Statement For Safety and Maintenance Steel Grating WalkwayDocument10 pagesMethod Statement For Safety and Maintenance Steel Grating WalkwayEnviron SupportNo ratings yet

- Method Statement For Fabrication Works Structural SteelDocument13 pagesMethod Statement For Fabrication Works Structural SteelRohit SharmaNo ratings yet

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYDocument39 pagesMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonNo ratings yet

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- Steel Structure Fabric & Installation - Doc Rev01Document7 pagesSteel Structure Fabric & Installation - Doc Rev01whah11No ratings yet

- Method Statement of Steel FabricationDocument14 pagesMethod Statement of Steel FabricationKhyle Laurenz Duro100% (4)

- 8.steel Structure WorkDocument15 pages8.steel Structure Workibal_farhan100% (4)

- Steel Structure ErectionDocument33 pagesSteel Structure ErectionAhmed ImranNo ratings yet

- Erection of Steel Structures PDFDocument76 pagesErection of Steel Structures PDFUmar MohammadNo ratings yet

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- Structural Steel ErectionDocument8 pagesStructural Steel Erectionbratishkaity100% (1)

- Chain-Link Fence and Gate WorksDocument8 pagesChain-Link Fence and Gate WorksIrene Ionie Rarangol - TengcoNo ratings yet

- Fabrication Method StatmentDocument11 pagesFabrication Method StatmentAkhilesh KumarNo ratings yet

- Method Statement For Setting Up Anchor Bolts in Steel StructureDocument3 pagesMethod Statement For Setting Up Anchor Bolts in Steel StructureIbrahim AlrabibNo ratings yet

- Method Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Document9 pagesMethod Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Azel Bumagat94% (18)

- Method Statement For Steel ErectionDocument15 pagesMethod Statement For Steel Erectionstrikersam95% (21)

- Steel Structures Installation Procedure and Method StatementDocument6 pagesSteel Structures Installation Procedure and Method StatementOussama Sissaoui100% (1)

- Method of Statement For HDPE Pipe InstallationDocument2 pagesMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Anchor Bolt ProcedureDocument7 pagesAnchor Bolt ProcedureAthanasius Kurniawan Prasetyo Adi100% (1)

- Steel Erection MethodologyDocument26 pagesSteel Erection MethodologyLiniel de JesusNo ratings yet

- Structural Steel Erection Method Statement .Document6 pagesStructural Steel Erection Method Statement .Mohamed Elarabi0% (1)

- Method of Statement Plumbing WorksDocument3 pagesMethod of Statement Plumbing Workshasan_6764896160% (1)

- Method Statement For Rigging System Rev-01Document13 pagesMethod Statement For Rigging System Rev-01Anwar Mohiuddin50% (2)

- Fabrication of Structural Steel WorkDocument16 pagesFabrication of Structural Steel WorkyogeswaranNo ratings yet

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- Method of StatementDocument23 pagesMethod of StatementDeepan TravellerNo ratings yet

- Erection Steel Structure ProcedureDocument15 pagesErection Steel Structure ProcedureOussama Sissaoui100% (1)

- ERECTION METHOD STATEMENT Part 1Document8 pagesERECTION METHOD STATEMENT Part 1joseph chewNo ratings yet

- Method Statement For Structural ErectionDocument15 pagesMethod Statement For Structural Erectionchallam4239100% (11)

- Method Statement For Roof Covering of Three Clear Water Storage TanksDocument11 pagesMethod Statement For Roof Covering of Three Clear Water Storage TanksMhando Ignas50% (2)

- Structural Steel Inspection ReportDocument2 pagesStructural Steel Inspection ReportAnnaNo ratings yet

- Structure Method StatementDocument8 pagesStructure Method StatementIrfanadi PratomoNo ratings yet

- Method Statement For Steel Structure & Erection PDFDocument16 pagesMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pages3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatNo ratings yet

- MOS - Concrete Works 07.18 R-0Document9 pagesMOS - Concrete Works 07.18 R-0RABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- Method of Statement Structural SteelDocument45 pagesMethod of Statement Structural SteelMahmoud Moustafa Elnegihi100% (3)

- S86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Document47 pagesS86088-LKA-C07CE-MS-004 - Sub & Superstructure (Rev0)Stephen David Gozun100% (1)

- Erection Method StatementDocument32 pagesErection Method StatementDilxan Fdo100% (4)

- MS008 Steel Tank MSDocument9 pagesMS008 Steel Tank MSMhando IgnasNo ratings yet

- Method Statement For Installation of Anchor BoltsDocument4 pagesMethod Statement For Installation of Anchor BoltsSiegfred RaccaNo ratings yet

- Attachment 1 - SOW For Port-O-CabinsDocument8 pagesAttachment 1 - SOW For Port-O-CabinsZafar BakhshNo ratings yet

- Site Erection ManualDocument11 pagesSite Erection Manualjohney2No ratings yet

- Safety Plan For Erection Steel BuildingDocument8 pagesSafety Plan For Erection Steel Buildingari_prasNo ratings yet

- MS For Slab On GradeDocument9 pagesMS For Slab On GradeJoe PSNo ratings yet

- Method Statement For Peat Shed ErectionDocument2 pagesMethod Statement For Peat Shed ErectionWASIM MAKANDARNo ratings yet

- Concretingofsuperstructure 141120013141 Conversion Gate01Document11 pagesConcretingofsuperstructure 141120013141 Conversion Gate01Zitheeq UmarNo ratings yet

- Written Work Instruction (Sheet Piles Installation)Document14 pagesWritten Work Instruction (Sheet Piles Installation)cynthia100% (1)

- Screen Wall at PBP SiteDocument33 pagesScreen Wall at PBP SiteressurrectedNo ratings yet

- Practical Training: B. Tech. Semester VIIDocument53 pagesPractical Training: B. Tech. Semester VIIRakshit Gp Goyal100% (1)

- C4M Mivan FormworkDocument3 pagesC4M Mivan Formworkmanohar reddyNo ratings yet

- Diaphargm Wall Construction DetailsDocument48 pagesDiaphargm Wall Construction DetailsAkshay Joshi100% (1)

- Fencin Method StatementDocument7 pagesFencin Method StatementNdaba Zams100% (2)

- Method Statment CEB BUILDINGDocument7 pagesMethod Statment CEB BUILDINGUpali KarunarathneNo ratings yet

- Duncan Vs GlaxoDocument8 pagesDuncan Vs GlaxoJoshua L. De JesusNo ratings yet

- Accra Business School: MSC Human Resource ManagementDocument9 pagesAccra Business School: MSC Human Resource ManagementBenjamin OpokuNo ratings yet

- Xplore-Tech Services Private Limited: Plot Y9, Block-EP, Sector-V, Salt Lake City, Kolkata-700091Document8 pagesXplore-Tech Services Private Limited: Plot Y9, Block-EP, Sector-V, Salt Lake City, Kolkata-700091Kushal GuptaNo ratings yet

- 7c OSH Practices Policies and Programs of Selected BPOs Hotels and Construction Companies in 3 Major Cities of The PhilsDocument23 pages7c OSH Practices Policies and Programs of Selected BPOs Hotels and Construction Companies in 3 Major Cities of The PhilsAnonymous 11sRVcSCNo ratings yet

- Fonterra Brands v. Largado & EstrelladoDocument4 pagesFonterra Brands v. Largado & EstrelladoBananaNo ratings yet

- John Paul B. ManaloDocument3 pagesJohn Paul B. ManaloJohn Paul B. ManaloNo ratings yet

- Project On Employee SatisfactionDocument71 pagesProject On Employee SatisfactionvinaykulagodNo ratings yet

- What Is The Difference Between TstiDocument4 pagesWhat Is The Difference Between TstiFortuna HunilaNo ratings yet

- Holiday Vs NLRCDocument1 pageHoliday Vs NLRCKling KingNo ratings yet

- Questions PsoDocument3 pagesQuestions PsoIshaan HarshNo ratings yet

- Graduate School Tips - Donald Asher PresentationDocument11 pagesGraduate School Tips - Donald Asher Presentationadityaferrarif1No ratings yet

- TrashOut Cash. Property Preservation Training LLCDocument78 pagesTrashOut Cash. Property Preservation Training LLCJhnsn H.100% (2)

- Colin MacKenzie's Harding LectureDocument28 pagesColin MacKenzie's Harding LecturerasanavaneethanNo ratings yet

- Drawing Drafting Cost Hour Ratr - Google SearchDocument1 pageDrawing Drafting Cost Hour Ratr - Google Searchamirul rofiqNo ratings yet

- F2 Sec1 A Day in The Life of Alex SanderDocument9 pagesF2 Sec1 A Day in The Life of Alex SanderRobert MillerNo ratings yet

- Sap Infor TypeDocument12 pagesSap Infor TypeDEEP KHATINo ratings yet

- Impact of Unethical Behavior at Workplace PPT - FinalDocument11 pagesImpact of Unethical Behavior at Workplace PPT - Finalrahila ak0% (1)

- Bus Math-M6Document3 pagesBus Math-M6Caslenia IvyNo ratings yet

- HR Policies PresentationDocument34 pagesHR Policies PresentationHaresh Patel100% (2)

- n362 Professional Dev PlanDocument4 pagesn362 Professional Dev Planapi-302732994No ratings yet

- Havells FinalDocument59 pagesHavells FinalprateekNo ratings yet

- Malabar Cements Project ReportDocument74 pagesMalabar Cements Project ReportPrem Lal100% (2)

- Career Interests Guide Final 092010Document6 pagesCareer Interests Guide Final 092010naba1577No ratings yet

- Gratuity Law in PakistanDocument7 pagesGratuity Law in PakistanWaseem HyderNo ratings yet

- Ra 8042 AmendedDocument18 pagesRa 8042 AmendedYsabel PadillaNo ratings yet

- Payment of Wages Act, 1936-Object, Scope and Application-Labour AwDocument5 pagesPayment of Wages Act, 1936-Object, Scope and Application-Labour Awadv_animeshkumar63% (8)

- HBO Lesson 4 - Values, Attitude, and Job SatisfactionDocument9 pagesHBO Lesson 4 - Values, Attitude, and Job SatisfactionJoe P PokaranNo ratings yet

- ITIL ServiceDocument6 pagesITIL ServiceDSunte WilsonNo ratings yet

- Case DigestDocument15 pagesCase DigestEd Ech100% (1)

- Classy Glass Inc Policy Package HighlightedDocument90 pagesClassy Glass Inc Policy Package HighlightedTMJ4 NewsNo ratings yet