Professional Documents

Culture Documents

Mahindra Deming Award

Uploaded by

Harshi AggarwalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mahindra Deming Award

Uploaded by

Harshi AggarwalCopyright:

Available Formats

About The company:

Farm Equipment Sector (FES) is one of the six sectors in which Mahindra and Mahindra Ltd (M&M) operates. Mahindra and Mahindra Ltd (M&M) is the flagship company of the US$ 1.96 billion Mahindra Group. The Sector is involved in designing, manufacturing and marketing agricultural tractors since 1963. For the last 21 years, Mahindra and Mahindra Ltd (M&M) has been the market leader in the highly competitive Indian tractor market. The Sector manufactures 15 major models of tractors at four manufacturing plants located in Mumbai, Nagpur, Jaipur and Rudrapur, with a total employee strength of over 4000. Over 400 suppliers and 450 dealers are also a part of the extended Mahindra family. About 15 per cent of the FES production is exported to various countries, with the USA being the largest importer, where the tractors are sold and serviced by its subsidiary, Mahindra USA (MUSA), since almost a decade.

Awards:

Mahindra and Mahindra Ltd (M&M) was awarded the Deming Prize by JUSE in 2003. With this, Mahindra and Mahindra Ltd (M&M) achieved the distinction of becoming the first tractor manufacturer in the world to win this coveted prize. Prior to this, two of M&M's tractor plants at Mumbai and Nagpur located in western India were certified to International Quality Standards ISO 9000, QS 9000 and ISO 14001 by the German Certification Agency RWTUV.

Success factors leading to recognition:

Evolution of Total Quality Management (TQM) System The TQM journey at FES started in 1985. It can be broadly divided into four phases till 2003, when the company won the Deming Prize. a) Orientation Phase - 1985 to 1989 b) Introduction Phase - 1990 to 1994 c) Promotion Phase - 1995 to 1999 d) Development Phase - 2000 to 2003 a) Orientation Phase - The focus was on Quality Circle movement for employees staff and workmen during this phase. The movement started on a pilot basis in Mumbai in 1985, subsequently spread to Nagpur and substantially increased in scale over the next decade, with about 50 per cent of the employees being involved. The Quality Circles solved hundreds of problems in operational areas to improve quality, housekeeping, and safety and reduce wastage and cost. b) Introduction Phase - During this phase, FES focused on solving major cross-functional quality problems through involvement of managers as well as enhanced product quality by improving quality of manufactured and bought out components. This phase was marked by the use of Dr Juran's process of quality improvement for problem solving, use of Statistical Process Control (SPC) for all critical machining processes and systematic support to all suppliers to improve their processes and product quality.

c) Promotion Phase - The focus during this phase was on improvement through implementation of robust systems. Accordingly, both the Mumbai and Nagpur plants were certified, first to ISO 9000 and subsequently to QS 9000. Business Process Re-engineering (BPR) was implemented in the manufacturing areas, with substantial improvement in employee involvement and productivity. During the same phase, the Global Leadership Vision to become the largest tractor manufacturer in the world was conceived and the application of Deming Prize guidelines, under the guidance of Dr Y Washio, an eminent TQM expert from Japan, was initiated. d) Development Phase - This stage focused on improving at a rapid pace, to progress towards the Vision of Global Leadership and challenging the Deming Prize before 2004. The New Product Development process was improved and brought to international standards under the guidance of Dr Washio. His inputs enabled substantial improvement in manufacturing and supplier support processes. Sales, dealer support and customer operations were systematised under the umbrella of Mahindra Sales System (MSS). Leadership and employee participation Commitment of leadership was fundamental for TQM implementation, and even moreso in challenging the Deming Prize. The Deming Prize Examiners evaluated this through Schedule A presentations that were made by the Chief Executive Officer and other senior managers, and additionally through a special Executive Session. The 'energetic efforts for practising TQM to realise the Business Strategy' under active top management leadership was highlighted in the Deming Prize Committee report. Employee Involvement was another feature of TQM and the DemingPrize. Introduction of Continuous Improvement Teams (CIT) for workmen, Officers' Improvement Teams (OIT) and need-based Cross Functional Teams (CFTs) for officers ensured 100 per cent employee involvement over the last three years. The total 100 per cent employee involvement and improved labour-management relationship was another aspect appreciated by the Deming Examiners. Regular improvements in business processes Due to implementation of TQM, marked improvements were perceptible in all key business processes: a) Manufacturing Due to Standardisation, effective usage of SPC and practice of Daily Work Management (DWM), rework and rejection (Quality) came down to less than 1000 PPM levels. For the same reason, the Field Quality measured by number of complaints in first 250 and 500 hours of operations, improved substantially. Productivity improved considerably on account of implementation of Business Process Reengineering (BPR). b) Supplier Management The quality of outsourced components improved substantially owing to the support to suppliers. Similarly a marked improvement in Supplier Schedule Adherence was achieved.

C) New Product Development With the usage of tools like Quality Function Deployment products meeting more exact customer requirements could be developed and marketed. Use of tools like Failure Mode Effect Analysis (FMEA) helped reduce quality problems at the Product Development stage itself. Development Cycle Time was reduced substantially. Due to this initiative, the company could produce 15 new models, including some specifically for export, over the last three years. This led to a sharp rise in export figures. d) Sales and Customer Operations Following application of various innovative service initiatives like Mobile Service Van, Single-Window concept for spares procured from Original Equipment Manufacturers, the Overall Customer Satisfaction Index improved. Standardised Sales process introduced in the form of Mahindra Sales System (MSS) and support offered to dealers in various forms contributed to increase Market Share, widening the gap between Farm Equipment Sector (FES) and the next best competition. Strength as an organisation to attract overseas attention FES could attract overseas attention on account of following strengths: Global vision backed by long term strategy, with specific focus on exports Capability displayed in developing new products required for the export market World-class manufacturing quality Low costs due to improved productivity and various cost re-engineering efforts Skilled and motivated workforce Capability to develop sales and service network, as demonstrated in the US markets Sustained market leadership in the Indian tractor market, the largest in the world Rapidly increasing exports World-class Quality and Management systems certified first through ISO/QS 9000, and subsequently recognised with the Deming Prize Technological edge FES' technological edge lies basically in three areas: a) World-class Product Development and R&D facilities manned by over 300 well-qualified engineers and equipped with world-class design and testing facilities. These have contributed to the development of new and attractive product offerings for export and domestic markets. b) Manufacturing facilities complete with world-class engine assembly plant, CED Paint Shop and resourced by a skilled work force. c) Constant exposure to the sophisticated US market through subsidiary-MUSA.

Business excellence model

FES' model of Excellence, which was in general based on the Deming Model, can be summarised as follows: a) Foundation comprised the following: Company core purpose and core values. Top management leadership, Vision (of Global Leadership) and Strategy. b) The main pillars of their model of TQM comprised:

Quality Assurance systems (based on standards) in New Product Development Manufacturing Supplier Management Sales and Customer Operations Policy Deployment - A top management led process/system of setting and deploying longterm targets that were effectively pursued with employees integrating them into their annual targets. Their achievement was assured through the effective practice of Daily Work management. Continuous improvement with 100 per cent employee involvement, using scientific problem solving tools and quality information data. Standardised Support Services like IT, Cost Management, Delivery Management and Human Resource Management. c) On the top of this structure/model stood the Purpose: Satisfaction of all stakeholders, employees, customers, suppliers and society. Excellent business results.

The Deming Prize recognition

Specific comments from the auditors during evaluation and specific points mentioned during the investiture ceremony The Deming Prize Examiners pointed out, There are several excellent features in the company-wide energetic efforts for practising TQM to realise the business strategy under the leadership of the President. They further added that, The results of Top Management driven TQM activities had shown remarkable improvement in the last few years as follows In a short span of time, entry in the American market was successfully achieved and the turnover in the new market was being continuously improved. Various management systems, not only within FES, but even involving Suppliers and Dealers had been inducted and deployed. Large scale BPR aimed at improving profitability and productivity was put in practice. Improvement in labour-management relationship was achieved. The Deming Prize Examiners additionally appreciated the following: Ambitious and attractive Global Vision and road map Deployment of Policy to divisional and further levels Mature New Product Development system using various tools Correct use of SPC giving process capabilities of over 1.33 in all important processes Drastic reduction in rejection and rework and improvement in Field Quality Kaizen activity with 100 per cent involvement of employees Supplier Support resulting in drastic reduction in receipt rejection Support provided to dealers in Sales and Service events Systematic Training and Education system On November 11, 2003, Dr Hitoshi Kume, Chairman, Deming Prize Sub-committee handed over the Deming Prize Medal and Certificate to the FES President, Mr K J Davasia, at Tokyo. At the time, Dr Kume read the following from the Certificate: Mahindra and Mahindra Ltd, Farm Equipment Sector, India has achieved outstanding performance by practising Total Quality

Management, utilising statistical concepts and methodology based on company's excellent business philosophy and leadership as demonstrated by the senior management. In recognition thereof, the Deming Prize committee hereby presents the Deming Application Prize to them.

Contribution to further growth/business and international recognition

The journey undertaken for challenging the Deming Prize gave FES many benefits, which could be divided into two categories, namely: Culture-related Business result-related Culture related The whole organisation was steered in one direction, due to effective implementation of policy deployment. Involvement of all three major stakeholders, namely, employees, suppliers and dealers, in working together improved tremendously Business result related Product Quality improved substantially. Fifteen new models could be developed over 2000-03 Customer satisfaction and domestic market share improved Export volume increased substantially

Future Plans

FES has set its next target to challenge the Japan Quality Medal before 2007, which is also awarded by JUSE. Only the Deming Prize winning companies are eligible for challenging this award. Till date only 10 per cent Deming Prize-winners have progressed and won this award. This award will require FES to benchmark itself with the best in the world and improve its core processes substantially, to achieve improved results. Dr Washio has agreed to guide the company in this journey. Inspired by his encouragement as well as continued commitment by the firm's top management, FES has decided to accept this challenge. FES is certain that the next established target would help realise its dream of Global Leadership with substantial international presence.

You might also like

- Mahindra and Mahindra LimitedDocument8 pagesMahindra and Mahindra LimitedRothin ShawNo ratings yet

- Six Sigma's Role in Motorola's SuccessDocument9 pagesSix Sigma's Role in Motorola's SuccessnidhiNo ratings yet

- Sundaram Clayton - Winning The Deming PrizeDocument24 pagesSundaram Clayton - Winning The Deming PrizeApoorv Jhudeley100% (3)

- Profiting Through Quality Improving 'Right First Time' PDFDocument40 pagesProfiting Through Quality Improving 'Right First Time' PDFVishal kumarNo ratings yet

- Lean-Implementation A25 MakrandDocument12 pagesLean-Implementation A25 MakrandKolekarMakrandMahadeoNo ratings yet

- Kano Model PDFDocument5 pagesKano Model PDFdanielmugaboNo ratings yet

- Lean and Green: Profit for Your Workplace and the EnvironmentFrom EverandLean and Green: Profit for Your Workplace and the EnvironmentRating: 3 out of 5 stars3/5 (1)

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- SubhikshaDocument22 pagesSubhikshaUshaman SarkarNo ratings yet

- Times of Change Offer The Biggest Opportunities!Document6 pagesTimes of Change Offer The Biggest Opportunities!Oscar OrtizNo ratings yet

- SCL - Winning The Deming Prize - Case StudyDocument17 pagesSCL - Winning The Deming Prize - Case StudyspantdurNo ratings yet

- Construction of a Pasig Riverside Green Building condominiumDocument38 pagesConstruction of a Pasig Riverside Green Building condominiumMehrad SarabandiNo ratings yet

- Brand ArchitectureDocument3 pagesBrand ArchitectureSuvid SharmaNo ratings yet

- Toyota Success RecipeDocument7 pagesToyota Success Recipeapi-3740973No ratings yet

- TQM Versus Six SigmaDocument16 pagesTQM Versus Six Sigmaapi-3751356No ratings yet

- Six SigmaDocument27 pagesSix SigmaagarwalsaurabhhNo ratings yet

- Ocm India Private LimitedDocument16 pagesOcm India Private LimitedMudit SharmaNo ratings yet

- Automotive Quality Management Systems A Complete Guide - 2020 EditionFrom EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionNo ratings yet

- Lean Manufacturing: Competitiveness ProgrammeDocument10 pagesLean Manufacturing: Competitiveness ProgrammeDhaval SharmaNo ratings yet

- Objective Tree MethodDocument13 pagesObjective Tree MethodGrk GuptaNo ratings yet

- Value Stream MappingDocument5 pagesValue Stream Mappingrizwan ziaNo ratings yet

- Process Improvement Simplified: A How-to-Book for Success in any OrganizationFrom EverandProcess Improvement Simplified: A How-to-Book for Success in any OrganizationNo ratings yet

- KCCQC-2015 Quality Circles ConventionDocument7 pagesKCCQC-2015 Quality Circles Conventionvij2009No ratings yet

- Asian Paints FinalDocument28 pagesAsian Paints FinalBhavya Mittal100% (2)

- Aerospace Lean Six Sigma NadeemDocument4 pagesAerospace Lean Six Sigma NadeemSyedNadeemAhmedNo ratings yet

- Quality Circles & Total Quality ManagementDocument10 pagesQuality Circles & Total Quality ManagementSunilNo ratings yet

- 7 Steps Problem Solving N 7 QC ToolsDocument2 pages7 Steps Problem Solving N 7 QC ToolsSUSHANT JAINNo ratings yet

- Six Sigma Black Belt Project On: Reduction in Breakage in BiscuitsDocument42 pagesSix Sigma Black Belt Project On: Reduction in Breakage in BiscuitsHombing Haryanto100% (1)

- Kaizen, 6 Sigma, 7 WastesDocument36 pagesKaizen, 6 Sigma, 7 WastesKoustav GhoshNo ratings yet

- Loyal Customer Base and Growth of Shoppers StopDocument1 pageLoyal Customer Base and Growth of Shoppers Stopaliakhtar9No ratings yet

- Six SigmaDocument23 pagesSix Sigmashubham shindeNo ratings yet

- Decoding The DNA of The Toyota Production System - Case StudyDocument10 pagesDecoding The DNA of The Toyota Production System - Case StudyCH NAIRNo ratings yet

- World Cls MFGDocument40 pagesWorld Cls MFGHarshad SawantNo ratings yet

- A.introduction of Low Cost AutomationDocument5 pagesA.introduction of Low Cost AutomationssrgmanNo ratings yet

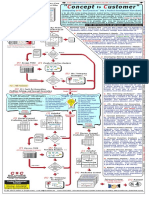

- " Oncept Ustomer": SolutionsDocument1 page" Oncept Ustomer": SolutionsJac DNo ratings yet

- Qcfi Durgapur Chapter: Question & Answers BankDocument13 pagesQcfi Durgapur Chapter: Question & Answers Bankdeepakhishikar24No ratings yet

- Case Study - Lucas TVSDocument19 pagesCase Study - Lucas TVSMangesh GhandatNo ratings yet

- Multivari CHARTSDocument16 pagesMultivari CHARTSanujkumartyagi9275No ratings yet

- Deming PrizeDocument22 pagesDeming PrizeGaurav Kumar100% (1)

- Problem Solving & 7qc Tools (Compatibility Mode)Document42 pagesProblem Solving & 7qc Tools (Compatibility Mode)Krunal PandyaNo ratings yet

- Beyond World ClassDocument26 pagesBeyond World ClassvidhishNo ratings yet

- Customer Satisfaction Levels A Complete Guide - 2020 EditionFrom EverandCustomer Satisfaction Levels A Complete Guide - 2020 EditionRating: 1 out of 5 stars1/5 (1)

- TQMDocument46 pagesTQMjillmehta14No ratings yet

- Improving 3D Printing Laboratory Operations: A Case Study of Lean Six Sigma ImplementationDocument10 pagesImproving 3D Printing Laboratory Operations: A Case Study of Lean Six Sigma ImplementationBOHR International Journal of Operations Management Research and Practices (BIJOMRP)No ratings yet

- Dfss Watermark 1Document124 pagesDfss Watermark 1sanx2014No ratings yet

- The Notes of Deming AwardDocument13 pagesThe Notes of Deming AwardbardarsandyNo ratings yet

- KaizenDocument10 pagesKaizenSiddharth KarakotiNo ratings yet

- Manufacturing Process of 450LBS Belly Wash MachineDocument52 pagesManufacturing Process of 450LBS Belly Wash Machinemorshed neazNo ratings yet

- Worldwide Operations of ToyotaDocument42 pagesWorldwide Operations of Toyotaniom0250% (2)

- Muda Mura Muri CompletoDocument9 pagesMuda Mura Muri CompletoXochiquetzal AstudilloNo ratings yet

- Toyota KaizenDocument11 pagesToyota KaizenSteve LeeNo ratings yet

- Product Life Cycle Stages and Cadbury's StrategiesDocument8 pagesProduct Life Cycle Stages and Cadbury's StrategiesranokshivaNo ratings yet

- TQM ProjectDocument37 pagesTQM ProjectMuddassir Hussain100% (1)

- Green Belt Class NotesDocument11 pagesGreen Belt Class NotesPankaj LodhiNo ratings yet

- Project Report On Communication Strategies in Rural MarketDocument53 pagesProject Report On Communication Strategies in Rural Marketzrd_1250% (2)

- What Is Motivation?: Key Elements AreDocument11 pagesWhat Is Motivation?: Key Elements AreHarshi AggarwalNo ratings yet

- Segmentation, Targeting and Positioning OF TitanDocument32 pagesSegmentation, Targeting and Positioning OF TitanHarshi Aggarwal100% (3)

- Indian housing finance industry outlook and trendsDocument13 pagesIndian housing finance industry outlook and trendsHarshi AggarwalNo ratings yet

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- Collegewise Cuttoff DetailDocument2 pagesCollegewise Cuttoff DetailHarshi AggarwalNo ratings yet

- AppexDocument1 pageAppexHarshi AggarwalNo ratings yet

- COS Paper-1Document5 pagesCOS Paper-1Harshi AggarwalNo ratings yet

- 10 1 1 199 5695Document43 pages10 1 1 199 5695Harshi AggarwalNo ratings yet

- WP Healthcare2Document10 pagesWP Healthcare2Harshi AggarwalNo ratings yet

- Ednhsp150413 PDFDocument9 pagesEdnhsp150413 PDFHarshi AggarwalNo ratings yet

- BBA Orientation 2013 Time TableDocument4 pagesBBA Orientation 2013 Time TableHarshi AggarwalNo ratings yet

- CHF Brochure 160910Document8 pagesCHF Brochure 160910Harshi AggarwalNo ratings yet

- Logistics and Supply Chain Management in The Hotel Industry - ImpaDocument48 pagesLogistics and Supply Chain Management in The Hotel Industry - ImpaSomnath MannaNo ratings yet

- The Service Concept The Missing Link in Service Design ResearchDocument14 pagesThe Service Concept The Missing Link in Service Design ResearchdarkennimbusNo ratings yet

- 86 Vissers LogrippoDocument16 pages86 Vissers LogrippoworldontopNo ratings yet

- SIDocument4 pagesSIHarshi AggarwalNo ratings yet

- The Service Concept The Missing Link in Service Design ResearchDocument14 pagesThe Service Concept The Missing Link in Service Design ResearchdarkennimbusNo ratings yet

- Case 3Document1 pageCase 3Harshi AggarwalNo ratings yet

- AdmmDocument5 pagesAdmmHarshi AggarwalNo ratings yet

- AdmDocument1 pageAdmHarshi AggarwalNo ratings yet

- AdmDocument1 pageAdmHarshi AggarwalNo ratings yet

- Impact of Liberalization, Privatization and Globalization On IndiaDocument1 pageImpact of Liberalization, Privatization and Globalization On IndiaHarshi AggarwalNo ratings yet

- Citizen of IndiaDocument2 pagesCitizen of Indiachaitu3996No ratings yet

- 20 Ratio Analysis3Document6 pages20 Ratio Analysis3Harshi AggarwalNo ratings yet

- Tomato KetchupDocument47 pagesTomato KetchupHarshi Aggarwal50% (2)

- Risk & ReturnDocument17 pagesRisk & ReturnHarshi AggarwalNo ratings yet

- Import and Export (Control) Act, 1947Document133 pagesImport and Export (Control) Act, 1947Subhakar AnandNo ratings yet

- Pricing ManagementDocument10 pagesPricing ManagementHarshi AggarwalNo ratings yet

- QuestionnaireDocument2 pagesQuestionnaireblazeweaverNo ratings yet

- Chapter 09Document33 pagesChapter 09Anonymous ed8Y8fCxkSNo ratings yet

- Glatt Plant EngineeringDocument12 pagesGlatt Plant Engineeringteatoom100% (3)

- Reasons To Failures of Banking ProductsDocument10 pagesReasons To Failures of Banking ProductsLavkush TiwariNo ratings yet

- Global Product DevelopmentDocument16 pagesGlobal Product DevelopmentAman SachdevNo ratings yet

- 5 Product StrategyDocument40 pages5 Product StrategyAnirban Kundu50% (2)

- School of Fashion and JewelleryDocument35 pagesSchool of Fashion and JewelleryDavid BriggsNo ratings yet

- HRM Six SigmaDocument24 pagesHRM Six Sigmamalavika banukaNo ratings yet

- The Go-To-Market Playbook: Your Guide to a Successful Product LaunchDocument6 pagesThe Go-To-Market Playbook: Your Guide to a Successful Product LaunchBao NguyenNo ratings yet

- C8 - Building Customer ValueDocument20 pagesC8 - Building Customer ValueAndrei Claudiu MotocNo ratings yet

- CULTURE OF INNOVATION IN TRATOS FINAL SN 27 APRIL - WebDocument104 pagesCULTURE OF INNOVATION IN TRATOS FINAL SN 27 APRIL - WebSashank SwainNo ratings yet

- Cloud LogisticsDocument15 pagesCloud LogisticsJhon Arley Jimenez SierraNo ratings yet

- Personal Entrepreneurial Competencies and Environment MarketDocument8 pagesPersonal Entrepreneurial Competencies and Environment MarketPJ100% (2)

- A Framework Based On Fuzzy AHP-TOPSIS For Prioritizing Solutions To Overcome The Barriers in The Implementation of Ecodesign Practices in SmesDocument17 pagesA Framework Based On Fuzzy AHP-TOPSIS For Prioritizing Solutions To Overcome The Barriers in The Implementation of Ecodesign Practices in Smesnia divaNo ratings yet

- Design For Automatic Assembly PDFDocument190 pagesDesign For Automatic Assembly PDFAliSyarief100% (1)

- Strategy - Harley DavidsonDocument14 pagesStrategy - Harley DavidsonSamish Dhakal100% (2)

- Seismic Analysis at PRoSIMDocument2 pagesSeismic Analysis at PRoSIMgvsha88No ratings yet

- SMIT TEXTILE Awarded For Product InnovationDocument2 pagesSMIT TEXTILE Awarded For Product InnovationgomzielpNo ratings yet

- Marketing Plan For MagazinesDocument24 pagesMarketing Plan For MagazinesVarun Puri50% (4)

- Innovation Management PDFDocument180 pagesInnovation Management PDFjimmiNo ratings yet

- Mir Arge Company CatalogDocument128 pagesMir Arge Company CatalogVladimir VukovicNo ratings yet

- Technological Developments and Marketing OpportunitiesDocument13 pagesTechnological Developments and Marketing Opportunitiestamanna bavishiNo ratings yet

- Case 15 Rondell Data CorporationDocument5 pagesCase 15 Rondell Data CorporationSandeep Kuberkar100% (2)

- 8-step product development processDocument2 pages8-step product development processanuraj100% (1)

- COO Vice President Manufacturing in Cincinnati OH Resume Craig HoffheimerDocument1 pageCOO Vice President Manufacturing in Cincinnati OH Resume Craig HoffheimercraighoffheimerNo ratings yet

- Product Lifecycle Management - Driving The Next Generation of Lean ThinkingDocument3 pagesProduct Lifecycle Management - Driving The Next Generation of Lean ThinkingRana BakNo ratings yet

- Marketing Director Medical Device Healthcare in Jacksonville FL Resume Brian MillerDocument3 pagesMarketing Director Medical Device Healthcare in Jacksonville FL Resume Brian MillerBrianMillerNo ratings yet

- On MerchandisingDocument68 pagesOn Merchandisingsunilmehra2007100% (3)

- Emerging Market Entry Strategies of Multinational Corporations: The Intel Case StudyDocument20 pagesEmerging Market Entry Strategies of Multinational Corporations: The Intel Case StudyFranciane SilveiraNo ratings yet

- VDA 6.3audit GuidelinesDocument25 pagesVDA 6.3audit Guidelinesavinash_k007100% (4)

- EileenDocument82 pagesEileenBhawna KhoslaNo ratings yet