Professional Documents

Culture Documents

4 - Offshore Gas Well Deliquification in Southern North Sea

Uploaded by

Juan I. SánchezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 - Offshore Gas Well Deliquification in Southern North Sea

Uploaded by

Juan I. SánchezCopyright:

Available Formats

Shell Exploration & Production

Offshore GWD in Southern North Sea

3rd European Conference on Gas Well Deliquification - 16 September 2008

Copyright: Shell Exploration & Production Ltd.

Kees Veeken*, Charles Mombo, Majeed Yousif, Peter de Boer, Bert Lugtmeier, Al Zanimonsky, Ewout Biezen Danial Leybourne*, Gert de Vries and Matthias Verstraeten (NAM-EPE, Assen)

File Title: PTPC2007 Gas Well Deliquification Strategy in EPE

Shell Exploration & Production

Contents

Southern North Sea gas asset Benefit of deliquification Offshore deliquification

Comparing options Retrofitting foam Mobile compression

Production chemistry aspects of applying foam offshore

UK & NL, 60 platforms, 300 gas wells, vintage 1968-2008

Shell Exploration & Production

2008 production 35 106 sm3/d (1250 MMscf/d)

30% liquid loading 3.5 106 sm3/d at stake (10%)

ONEgas West (UK)

ONEgas East (NL)

Shell Exploration & Production

Benefit of Deliquification

Incremental recovery 1%-10% 20-200 106 m3 per well

Determine incremental reserves based on reduction of minimum stable rate (Qmin) in Decline Curve Analysis (DCA)

1.20

Gas Production Rate (e6 m /d)

1.00

Qmin=0.05 mln m3/d UR=1.65 Bcm (RF +4%) Qmin=0.1 mln m3/d UR=1.58 Bcm

0.80

0.60

0.40

0.20

0.00 0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

3

1.60

1.80

2.00

Cumulative Gas Production (e9 m )

Shell Exploration & Production

Benefit of Deliquification

All wells potential candidates 5-25 109 m3

Determine incremental reserves based on reduction of abandonment pressure (Pab) in Material Balance (MB)

350 P/Z (bara @ datum level) 300 250 200 150 100 50 0 0.0 0.5 1.0 1.5 2.0

3

Qmin=0.3 mln m3/d (P/Z)ab=34 bar UR=1.62 Bcm

K7-FB-101 K7-11 Material Balance

Qmin=0.15 mln m3/d (P/Z)ab=28 bar UR=1.66 Bcm (RF +2%)

2.5

3.0

Gas Produced (mrd m )

Shell Exploration & Production

Determine Abandonment Point [Qmin,Pab]

Quick & dirty: ignore holdup use Turner Qmin & AFBC Pab

Pab = [B*FTHP2+A*Qmin+(C+F)*Qmin2]0.5 where FBHP2 = B*FTHP2+C*Qmin2 and Pres2-FBHP2 = A*Q+F*Q2

Prosper modelling: include holdup use Modified Gray Deliquification

Compression: reduce FTHP

BHP

Stimulation: reduce A (and F) Velocity string: reduce ID Foam: WGR=0 Downhole pump: WGR=CGR=0

Holdup

Wet gas WGR=0 WGR=CGR=0 6 Qgas

Shell Exploration & Production

Deliquification Scenarios

BC ID=0.0635 200 180 160 140 Gas Rate (e3m3/d) 120 100 80 60 40 20 0 20 30 40 50 60 FTHP=10 WGR=0 A=0.01 WGR=CGR=0

Scenario Base Case Compression Stimulation Foam Velocity string Downhole pump

Qmin (103 m3/d) Turner 79 56 79 38 27 0 Prosper 78 55 82 56 30 0

Pab (bara) AFBC 47 36 38 37 33 24 Prosper 51 38 43 42 41 25

Base Case: ID=0.109 m (5" tubing) A=20 bar2/e3m3/d THP=20 bar WGR=89e-6 m3/m3 CGR=10e-6 m3/m3 Abandonment Point [Qmin,Pab]

Reservoir Pressure (bara)

Shell Exploration & Production

Minimum & Optimum ID

Minimum ID = ID for minimum Pab Minimum ID decreases with A Minimum ID results in initial capacity ~10% of inflow constraint Optimum ID depends on connected volume, typically 1x-4x Minimum ID

Inf

low

Outflow constrained

co ns tra ine d

1000 100,000 10,000 KH (mD.m) 100 10

Shell Exploration & Production

Offshore Deliquification - Boundary Conditions

Installation = Costly [cost offshore = 5x cost onshore]

Workover typically not justified Need retrofit solution(s)

Subsurface safety valve required Completion types of varying vintage, generally not monobore Enable future application of new technology

Operation = Infrequent & Costly [no crane, no helideck]

Assume 1 maintenance visit per 2+ yrs using work platform Need low maintenance / high reliability solutions

Automation (SCADA) is key

Shell Exploration & Production

Slam Dunk Probable Win Possible Win

Benefit 4 3 2 2 2 3 5 4 4 5 4 1 Capex 5 5 3 4 4 3 1 2 1 0 0 3 Opex 4 4 5 4 3 3 3 2 2 2 2 5

5 Highest Score 0 Lowest Score

Offshore Ranking

Technique Stimulation Water shut-off Velocity string Automated intermittent Automated batch foam Continuous foam Mobile compression Plunger Downhole pump Wellhead compression Gas lift Insulated tubing

Uptime 5 5 5 4 4 3 4 2 2 3 3 5

10

Shell Exploration & Production

Offshore Reliability is Key

Critically compare batch Vs continuous

Field trials

SV KW

Control line fluid and Surfactant

Actuated

Manual

Surfactant

SV KW

Surfactant

Retrofit capillary foam injection

Use SSSV control line Utilise LMGV cavity Integral deployment using Torus

Control line fluid

SSSV

SSSV

Control line fluid

FWV UMGV=SSV LMGV

FWV UMGV=SSV LMGV

KW

SV=SSV FWV=SSV UMGV LMGV

SSSV

11

Reduce future cost of continuous foam, velocity string,

Shell Exploration & Production

gas lift, plunger, contingency control line etc.

Utility Tree Prepares Gas Well for Rainy Day

Asleep

Continuous Foam

Pressure Foam Electrical Hydraulic Gas Injection

Pressure Foam Electrical

Hydraulic Gas Injection

12

Shell Exploration & Production

X-FA Batch Foam Trial

X-FA-101 "

Dead well 65 m3 slug of water produced after batch (2x) Too much water to handle, wait for continuous foam trial

X-FA-106 !

Dead well Batch job: 25 L surfactant + 200 L 3% KCl, 1x per 1-2 days Gain: 60 103 m3/d (2 MMscf/d), uptime 50%, defoamer at startup

X-FA-107 "

Stable well Foam impaired near-wellbore (2x), cleaned up

13

K14-FA-106 0.33 80 80 50

Shell Exploration & Production

0.28

K14FA1P.FPTR-815F.U 0.128 Mm3/d K14FA1P.TT-60.U 27.6 barg K14FA1P.TT-10.U 19.4 barg K14FA1P.PT-62.U 13.4 barg

0.23

106 THP

0.18

Qmin~70

0.13

103

m3/d

106 THT Ambient THT 106 Qg

8.E-02 -20 -20 -50 10/08/2008 07:33:22.548

25.00 days

04/09/2008 07:33:22.548

14

Shell Exploration & Production

Mobile Compression Offshore

Cost of wellhead compression generally prohibitive

Power supply, space and weight restrictions, logistics and interfacing

Install compression package on mobile jackup

Allows cost sharing and production of all platform wells instead of single well

MOAB at Trent 15

Shell Exploration & Production

Summary

Large scope exists for offshore deliquification (5-25 109 m3)

Determine deliquification benefit via decline curve analysis and/or material balance using abandonment point [Qmin,Pab] Best determine abandonment point via outflow model (e.g. Prosper) Turner Qmin and AFBC Pab provide reasonable approximation, however ignore holdup and mislead velocity string selection

Offshore deliquification challenges are related to high cost and low frequency of offshore installation and intervention

Improve reliability of continuous foam by optimising hardware, fluid access and deployment [environmental aspects covered in 2nd part] Tailor plunger lift based on onshore experience

Evaluate offshore application of mobile compression

16

Shell Exploration & Production

Production Chemistry Challenges Applying Foam Offshore

3rd European Conference on Gas Well Deliquification - 16 September 2008 Danial Leybourne, Gert De Vries and Matthias Verstraeten

File Title: PTPC2007 Gas Well Deliquification Strategy in EPE

Copyright: Shell Exploration & Production Ltd.

Shell Exploration & Production

Challenges Applying Foam Offshore

Product specifications

Stability (winterized, non-viscous) Non-corrosive Compatible (i.e. solids, emulsion) Does it foam? Is there an anti-foamer? Minimal impact on quality Water Overboard (WOB) Minimal impact on quality condensate

Registration/Permits

CEFAS/MSDS Location specific

18

Shell Exploration & Production

Compatibility

Compatible with produced fluids no solid / emulsion generation

Compatible with system

chemical compatibility

19

Shell Exploration & Production

Foam Performance

Low salinity Salinity Product A Product B Product C Product D Product E < 5.000 mg/L ClGood Good Moderate Moderate Moderate Poor Poor Poor High salinity > 100.000 mg/L ClGood Good Good Moderate Poor Poor

Foam build up time (s) < 80 80 < x < 120 >120

Result Good Moderate Poor

20

10

Shell Exploration & Production

Performance with Condensate

Product A

250 Build up time of foam 200 Half-life time of foam Time (s) 150 100

increasing condensate vol%

Performance vs condensate %

50 0 5 40 60 90 95 100 Condensate %

21

Shell Exploration & Production

Anti-Foam Performance

Anti-foam collapses foam & stops re-foaming

Anti-foamer Foamer Product A Product B Product C Product D Product E Product 1 Moderate Good Moderate Moderate Poor Product 2 Poor Poor Poor Poor Poor

% Performance <30 >30 < x < 50 >50

Indicator Good Moderate Poor

Product 3 Poor Poor Poor Poor Poor

Product 4 Good Poor Poor Poor Poor

Product 5 Moderate Poor Poor

22

11

Shell Exploration & Production

Oil in Water

Hydrocarbon content X-FA

80000 70000 60000 50000 40000 30000 20000 10000 0 1 2 3 4

Foam / anti-foam does have an impact on oil in water Package to mitigate against Increase in oil in water De-oilers clarifiers Foam / anti-foam including demulsifier blended in

Hydrocarbon content (ppm)

Batch

Daily legal limit = 30 mg/L Max. daily discharge = 100 mg/L (~0.01 vol%)

23

Shell Exploration & Production

Summary

Specifications for foam & anti-foam products are key in avoiding operational problems and ensuring success Performance tests

Lab tests are representative in screening products for field trials Test foam products on produced fluids from candidate well to ensure maximum success in field trials (salinity, hydrocarbon tolerance) Foam / anti-foam compatibility

Foam has shown to affect the oil in water content Steer to the chemical service industry from Shell

More products which meet requirements Products (or package of products) which do not damage the water quality and meet the legal requirements for offshore

24

12

Shell Exploration & Production

Many thanks to:

Foam team

Gert De Vries Jeltje Schouwstra Jeroen Fijn Ewout Biezen Majeed Yousif Peter De Boer Erik van der Vegt Matthias Verstraeten Well services Operations

25

13

You might also like

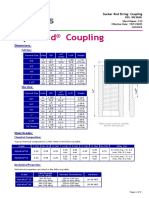

- Alpharod Coupling: DimensionsDocument2 pagesAlpharod Coupling: DimensionsJuan I. SánchezNo ratings yet

- Offshore Oil and Gas Industry - Abbreviations and AcronymsDocument40 pagesOffshore Oil and Gas Industry - Abbreviations and Acronymsmadonnite3781No ratings yet

- Características de Software para Bombeo MecánicoDocument2 pagesCaracterísticas de Software para Bombeo MecánicoPierina Jaimes PirelaNo ratings yet

- AmocoDocument16 pagesAmocoJuan I. SánchezNo ratings yet

- Tri CoilDocument1 pageTri CoilJuan I. SánchezNo ratings yet

- PCS Marathon PresentationDocument18 pagesPCS Marathon PresentationJuan I. SánchezNo ratings yet

- PCS GasLiftCatalogDocument20 pagesPCS GasLiftCatalogJuan I. SánchezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Centrifugal CompressorsDocument6 pagesCentrifugal CompressorsGokulAgNo ratings yet

- Clinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistryDocument43 pagesClinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistrySergioPachecoSerranoNo ratings yet

- Welding Purge Panel WPP Series: Features and BenefitsDocument2 pagesWelding Purge Panel WPP Series: Features and BenefitsAlexNo ratings yet

- Process UtilityDocument13 pagesProcess UtilityAnupam Manoj100% (1)

- NTK O2 Sensor HistoryDocument9 pagesNTK O2 Sensor Historyonukvedat7219No ratings yet

- Adva PII PDFDocument19 pagesAdva PII PDFAhskNo ratings yet

- Chapter 13 - Normalization Tutorial: Branchno Branchaddress TelnosDocument2 pagesChapter 13 - Normalization Tutorial: Branchno Branchaddress TelnosMoms Diva Diva DivaNo ratings yet

- CBLM SampleDocument26 pagesCBLM SampleMaryjane Binag Gumiran100% (1)

- Nadcap 2020Document4 pagesNadcap 2020amirkhakzad498No ratings yet

- Service Manual CSCU-RE12GKE PDFDocument16 pagesService Manual CSCU-RE12GKE PDFJose Vicente Ausina100% (1)

- Axis TurbineDocument7 pagesAxis TurbineBhertrand GomesNo ratings yet

- Her DrearyDocument3 pagesHer DrearyMiera Yushira Yusoff67% (6)

- MSDS KCL Pupuk - 1 LBRDocument1 pageMSDS KCL Pupuk - 1 LBRQuality AssuranceNo ratings yet

- Laboratory Activity # 1 MICROBIOLOGYDocument4 pagesLaboratory Activity # 1 MICROBIOLOGYatvillasNo ratings yet

- TSS-TI-021-02 Chalking of Epoxy Surfaces PDFDocument2 pagesTSS-TI-021-02 Chalking of Epoxy Surfaces PDFYeoh chun yenNo ratings yet

- Rapid Fire NewDocument85 pagesRapid Fire NewvarunsanghiNo ratings yet

- Recrystallization: Activity No. 6Document6 pagesRecrystallization: Activity No. 6Mary Jean SteffenNo ratings yet

- Catalogue DM AhuDocument54 pagesCatalogue DM AhurianaNo ratings yet

- Lied Mann 2017Document8 pagesLied Mann 2017Chandra SekarNo ratings yet

- Risk Management PlanDocument2 pagesRisk Management PlanRoxanneGailBigcasGoleroNo ratings yet

- Chlorine Dioxide: Chlorophenol Red Method Method 8065 0.01 To 1.00 MG/L Clo (LR)Document6 pagesChlorine Dioxide: Chlorophenol Red Method Method 8065 0.01 To 1.00 MG/L Clo (LR)Oudah AliNo ratings yet

- 5 OzoneDocument14 pages5 OzoneParakram KharelNo ratings yet

- Comparative of Basement Waterproofing SODDocument2 pagesComparative of Basement Waterproofing SODManoj BhonsleNo ratings yet

- MS DirectPhD Sample PDFDocument4 pagesMS DirectPhD Sample PDFArunKumarNo ratings yet

- Selective Oxidation of Secondary AlcoholsDocument24 pagesSelective Oxidation of Secondary AlcoholsFernando Silva BetimNo ratings yet

- NEW Sonotech UT-X Powder PDFDocument2 pagesNEW Sonotech UT-X Powder PDFanmosNo ratings yet

- Faizal Bux, Yusuf Chisti Eds. Algae Biotechnology Products and ProcessesDocument344 pagesFaizal Bux, Yusuf Chisti Eds. Algae Biotechnology Products and ProcessesHAMED100% (4)

- Saic Q 1048Document1 pageSaic Q 1048Gian Carlo100% (1)

- Soft Offer Sugar Ic45-Jun10Document3 pagesSoft Offer Sugar Ic45-Jun10davidarcosfuentesNo ratings yet

- Arthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020Document36 pagesArthrex Starfish ™ Scope Rotation Attachment Insert Manual: 950-0036-01 Revision 0 08/2020eliaNo ratings yet