Professional Documents

Culture Documents

Adirondack Plans

Uploaded by

Debbie MackOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adirondack Plans

Uploaded by

Debbie MackCopyright:

Available Formats

Workshop

b y v e r n g r a s s e l i P H O T O S BY D a n C a r y

Contemporary Adirondack Chair

A sleek, comfortable update of a classic design

Because I grew up in upstate New York, Ive always been a big fan of the Adirondack chair. I appreciated the wide armrests, contoured seat and curved back, but I didnt like the bulky appearance and the low seat that made getting up difficult. So when I was asked to build a modern version of this

American classic, I was thrilled to be able to make some changes. My goal was to come up with a sleek, stylized outdoor chair that still had the look, feel and comfort of a traditional Adirondack. After you build the version shown in the plans on p. 7, grab a cold lemonade and have a seat

Larry okrend

I think youll agree that the mission was a success. Instead of using one of the common types of exterior-rated boards, such as cedar or pressure treated pine, I built these chairs using a new product called Perennial Wood. These boards are Southern pine that has gone through an interesting new treatment process (see First Impressions, p. 8). The boards measured 7/8 in. thick x 5-3/8 in. if you prefer, you can substitute other types of wood deck boards and the cutting dimensions will remain the same.

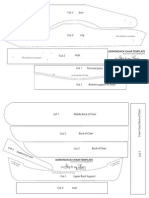

Cutting List

KEY A B C D E F G H I J K L M N O NO. DESCRIPTION 2 Front legs 2 Back legs 2 Front leg brackets 2 Armrest supports 2 Seat supports 1 Seat front 7 Seat slats 1 Back seat slat 2 Armrests 1 Lower back rail 1 Middle back rail 1 Upper back rail 1 Middle back slat 2 Inside back slats 2 Outside back slats SIZE 7/8 x 3 x 25-1/4 in. 7/8 x 5-3/8 x 34 in. 7/8 x 2-3/8 x 25-1/4 in. 7/8 x 2 x 21-3/8 in. 7/8 x 5-3/8 x 23-1/2 in. 7/8 x 2-3/4 x 22 in. 7/8 x 2-1/4 x 22 in. 7/8 x 3-7/8 x 22 in. 7/8 x 5-3/8 x 25-3/4 in. 7/8 x 4 x 22 in. 7/8 x 5-3/8 x 25-3/4 in. 7/8 x 3-3/4 x 22 in. 7/8 x 5-3/8 x 33-3/4 in. 7/8 x 5-3/8 x 32-1/4 in. 7/8 x 5-3/8 x 30-3/4 in

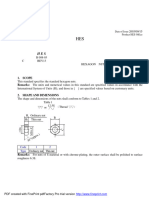

Build the leg assemblies

Whenever I build a piece of furniture that has a lot of curved profiles, I make full-size templates of all of the curved parts. This approach is especially useful for building multiple pieces. (It will come in handy in the future, when your neighbor sits in your chair and asks you to build one for him.) I draw the shape on 1/4-in. plywood or hardboard, cut it out and then trace the template on the actual parts (photo 1, below). Once youve made the templates, cut the four legs to the rough sizes stated in the cutting list (above) before cutting them to their final shapes. Use a miter saw to cut the ends of the back legs (B) at 35 degrees; then use a jigsaw or a

SHOPPING List

7/8 x 5-3/8 x 96-in. deck boards (7) 1/4 x 2-1/2-in. stainless steel carriage bolts, washers and nuts (6) 1-5/8-in. deck screws (1 box) 2-1/2-in. deck screws (6) Semitransparent stain or paint (1 quart) band saw to cut the curves (photo 2, p. 9), and clean them up with a sander. Cut the armrest supports (D) to size and then drill four pilot holes for the screws that will attach the supports to the armrest. These holes should be slightly oversize (roughly 3/16 in. dia.) to allow the shank of the 2-1/2-in. screws to slide freely in the countersunk holes. This will allow you to easily draw the armrest tight and avoid splitting the supports. Next, use a router equipped with a 1/8-in.-radius roundover bit to ease the edges. If you dont have a 1/8-in.-dia. bit, you can use a slightly larger roundover bit, such as a 1/4-in.-radius bit, and set the router height so that the bit is not cutting at its full cutting depth. To build each leg assembly, fasten the front leg (A) and back leg (B) to the armrest support (D). Do not attach the front leg brackets (C) at this time. Follow the spacing in the drawing, and clamp the pieces in place to keep the assembly square. Drill pilot holes and countersinks; then fasten the legs with 1-5/8-in. deck screws (photo 3).

1

1/4-in. plywood pattern

35-degree angles

Make the seat

Rip a 35-degree bevel along the top edge of the seat front (F); then mark and cut an arched profile (with a rise of about 1 in.) in the bottom edge. Next, make a template for the seat supports (E). Trace the template on each seat

Make full-size templates for the curved pieces so you can trace the contours on the actual parts.

WORKshop

contemporary adirondack chair

7" 1/4 x 2-1/2" STAINLESS-STEEL CARRIAGE BOLT

J

5-1/2" 4"

M L

I D B K J A

20 BEVEL

C 13-3/4" 29" G G G G E 35 BEVEL 1-3/4" E K H 11-3/8" 24 BEVEL A

1-1/2"

1 SQUARE = 1"

F

2-3/4"

1-1/8"

PILOT HOLES

I

B

4" A C 3/8"

B L

ARMREST DETAIL

illustration by michael anderson

support and cut the shape. Then cut the seat slats (G) to size and ease the top edges with a router and a 1/8-in.radius roundover bit. Attach the seat front to the seat supports, lining up the top edge of the seat fronts bevel with the top edge of the seat supports (E) . Position the front seat slat (G) so that it overhangs about 1/2 in., and attach it to the seat supports with a single 1-5/8-in. screw centered in each end. Attach the rest of the slats, working your way to the back of the seat and leaving a 1/4-in. gap between slats. Do not attach the back seat slat (H) yet; youll do that after youve assembled the back.

Cut close to the line and then sand up to the line to create a smooth, refined curve. With the leg assembly on its side, use a temporary spacer to raise the bottoms of the legs so they are level and use a square to keep t h e l e g a s s e m b ly square while screwing the legs into the armrest support.

Assemble the chair bottom

Lay one of the leg assemblies on its side and position the seat assembly on the legs. The bottom edge of the front of the seat support should be 11-3/4 in. above the bottom of the front leg, and the bottom edge of the back of the seat support should measure 10 in. from the floor. Attach the seat assembly with a single 1-5/8-in. screw driven into each leg (photo 4, p. 9). Offset these screws to allow for the bolt hole that you will later drill into the center of each leg connection. Flip the chair over and attach the other leg assembly.

3

Temporary spacer Framing square

FIRST IMPRESSIONS

This is the first time Ive used Perennial Lumber, Southern yellow pine treated with heat, pressure and an organic compound to make it much more resistant to water absorption. When the lumber was delivered, the first thing I noticed was its strong vinegar odor (which eventually fades away). The next thing I observed was that the straight-grain boards were free of knots and completely flat and straight. The wood machined well and was a pleasure to work with. The downside is that the treatment process left the boards harder and heavier, and they had a tendency to split if I overtightened the screws or didnt drill pilot holes. For more information on this relatively new lumber option, visit PerennialWood.com. VG

Holes in armrest support for attaching armrest

20-degree bevel

Attach the seat assembly to the two leg assemblies with 1-5/8-in. screws.

Angle the jigsaw base and cut the beveled curves in one pass. Move slowly around the faceted corners.

Workshop

With the chair bottom upright and the four legs firmly on level ground, the middle back rail is ready to be fastened to the armrests with bolts.

1/8-in. spacers

When assembling the back, work from the center out and from the top down.

Set the chair-bottom assembly upright on a level surface and attach the front leg brackets (C) with three 1-5/8-in. screws. Next, cut the middle back rail (K) that will be attached to the back of the armrest supports and armrests. Tilt the jigsaw base to cut a 20-degree bevel; then cut the inside curve profile of the middle back rail (photo 5, p. 9). Note that the back rails curve profile and the back seat slat are faceted to fit the back slats. Set the jigsaw base at 90 degrees to cut the back edge of the middle back rail. Place the middle back rail on the notched ends of the armrest supports and attach it with 1-5/8-in. screws. Next, place the armrests (I) on the armrest supports, clamp the parts in place and drive 2-1/2-in. screws up through the holes in the bottom of the armrest supports. Drill a 1/4-in. bolt hole through each armrest and the middle back rail (photo 6, top, left). Fasten the parts with 1/4- x 2-1/2-in. stainless steel carriage bolts, washers and nuts. Next, drill the bolt holes through the legs and seat supports. Make sure that all four legs are sitting flat and level when you drill the holes and tighten the bolts.

Add the back

Lay out and cut the back slats (M, N, O) to shape. I used a jigsaw to cut close to the line on the long tapers and then sanded up to the line with a belt sander. You could also cut the long tapers on the three inside slats using a band saw or a table saw with Center the back a s s e m b ly o n t h e middle back rail and screw it in place before attaching the back seat slat (H).

a tapering jig. Ease the edges with a router and roundover bit. Attach the back slats to the upper and lower back rails, starting with the middle back slat (M). Center the upper back rail (L) on the back of the middle slat and 7 in. below the top. Attach the slat with a 1-5/8-in. screw. Use a 1/8-in. spacer to align the two inside back slats (N) on either side of the middle slat. Position the upper back rail 5-1/2 in. below the top edge of each inside slat. I found it easier to attach the three inside slats (M and N) to the lower back rail (J) before adding the two outside back slats (O). Center the lower back rail 3/8 in. above (and parallel to) the bottom of the middle back slat and screw it in place. Use the 1/8-in. spacers and screw the inside back slats in place. Next, attach the outside back slats (O) to the upper and lower back rails (photo 7, p. 10). Position the top of the upper back rail 4 in. below the top of the outside slats. Note: The bottom of the back slats will extend past the lower back rail at different lengths because of the curve. I left them long because they are hidden by the back seat slat, and the extra length helps to strengthen the screw joint. Set the lower back rail (J) in the seat-support notches and screw it in place. Center the back assembly on the middle back rail and fasten with a 1-5/8-in. screw in the center of each slat (photo 8). Tilt the jigsaw base to cut roughly a 24-degree bevel, and cut the back seat slat (H) . Adjust the fit as necessary; then attach the slat to the seat supports with 1-5/8-in. screws. I finished the chairs with gray semitransparent deck stain for a natural weathered look. Of course, you can apply the stain or paint of your choice to achieve the look you desire. Once the finish cures, pour yourself some lemonade and sit awhile.

Handyman Club life member Vern Grassel is a custom furniture builder, cabinetmaker and woodworking designer in Elk River, Minnesota.

You might also like

- Chair 8Document18 pagesChair 8Naga Raj100% (2)

- Handy Screen HouseDocument4 pagesHandy Screen HouseMiguel Angel Rodríguez ZentenoNo ratings yet

- Easy DIY Garden Shed Plans - 1Document4 pagesEasy DIY Garden Shed Plans - 1Fred Mirtz100% (1)

- Modern Planter Box Plans, Copyright Crafted Workshop 2018Document11 pagesModern Planter Box Plans, Copyright Crafted Workshop 2018robins115350100% (2)

- Work Bench 3Document4 pagesWork Bench 3- yAy3e -100% (1)

- Bench - Classic Cedar Garden PDFDocument11 pagesBench - Classic Cedar Garden PDFmarianrkwNo ratings yet

- Minwax Advanced Project Adirondack ChairDocument9 pagesMinwax Advanced Project Adirondack ChairPetrus Cassu Menck100% (1)

- Intermediate Project Storage BinsDocument10 pagesIntermediate Project Storage BinsTyler BassNo ratings yet

- Adirondack Chair: Woodworks: Intermediate ProjectDocument8 pagesAdirondack Chair: Woodworks: Intermediate ProjectEucap MdzNo ratings yet

- 10 06 WorkshopDocument5 pages10 06 WorkshopMiguel Angel Rodríguez Zenteno100% (2)

- Birdhouse PlansDocument8 pagesBirdhouse Plansroose1No ratings yet

- Build An Adjustable Sawhorse Under $60 In 3 HoursDocument15 pagesBuild An Adjustable Sawhorse Under $60 In 3 HoursMad Cow100% (1)

- Building The SGN-22 (Single-Shot Rifle Build)Document25 pagesBuilding The SGN-22 (Single-Shot Rifle Build)blowmeasshole191167% (6)

- Banco Escalera PDFDocument3 pagesBanco Escalera PDFluanbagonNo ratings yet

- Dancing ClockDocument8 pagesDancing Clockbehnamin_rahmani100% (2)

- Planos Casa de JuegosDocument47 pagesPlanos Casa de Juegosdaniel estrada0% (1)

- Small Parts SledDocument3 pagesSmall Parts Sledricheklund100% (3)

- Box Joint Jig PlanDocument8 pagesBox Joint Jig PlanLarry MullinsNo ratings yet

- Ultimate Router Table PlansDocument59 pagesUltimate Router Table Plansiacob_gilberto6473100% (6)

- WoodDocument92 pagesWooda silva100% (3)

- 8A Thickness SanderDocument15 pages8A Thickness SanderAulia Haq Aqoby100% (1)

- Woodwork Projects for Your Garden and Porch: Simple, Functional, and Rustic Décor You Can Build YourselfFrom EverandWoodwork Projects for Your Garden and Porch: Simple, Functional, and Rustic Décor You Can Build YourselfRating: 3 out of 5 stars3/5 (2)

- Vintage Playground Plans 1950s PDFDocument39 pagesVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- Tilting Mirror Stand - FH96DJADocument7 pagesTilting Mirror Stand - FH96DJAJvlValenzuelaNo ratings yet

- Bench - Langcrest - LoveseatDocument5 pagesBench - Langcrest - LoveseatvdbrogerNo ratings yet

- Milling Table: Illustration by James ProvostDocument4 pagesMilling Table: Illustration by James ProvostrhinorodNo ratings yet

- From MagazineDocument5 pagesFrom Magazine- yAy3e -No ratings yet

- Adirondack Chair Plans 10pagesDocument10 pagesAdirondack Chair Plans 10pagesNilton100% (2)

- WOOD Store: Thank You!Document12 pagesWOOD Store: Thank You!lacroitoruNo ratings yet

- Make Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenFrom EverandMake Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenRating: 5 out of 5 stars5/5 (1)

- Papa's Wood Shop: Simple Woodworking How-To and Project Plans for BeginnersFrom EverandPapa's Wood Shop: Simple Woodworking How-To and Project Plans for BeginnersNo ratings yet

- Folding chair planDocument16 pagesFolding chair planOswal OsunaNo ratings yet

- WOOD Monthly DownloadDocument9 pagesWOOD Monthly DownloadRoomel UrbinaNo ratings yet

- WS23342 - Welcoming Hall Bench PDFDocument12 pagesWS23342 - Welcoming Hall Bench PDFMarianoNo ratings yet

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- Build Adirondack Chair & TableDocument7 pagesBuild Adirondack Chair & Tablenevadablue67% (3)

- Adjustable Shop Stool: © 2017 Cruz Bay Publishing, IncDocument8 pagesAdjustable Shop Stool: © 2017 Cruz Bay Publishing, IncAdam Mikitzel100% (2)

- Incra P TDocument90 pagesIncra P T100taxidriver75% (4)

- Airbus Seal Installation ManualDocument9 pagesAirbus Seal Installation ManualJivendra KumarNo ratings yet

- Adirondack Chair: ModerateDocument15 pagesAdirondack Chair: ModeratealexnmNo ratings yet

- 09 08 Workshop Summer SwingDocument3 pages09 08 Workshop Summer SwingpatriciachaquilaNo ratings yet

- WJ088 Garden BenchDocument13 pagesWJ088 Garden BenchOsvaldo Moraes100% (1)

- American Woodworker: OCTOBER 2002Document9 pagesAmerican Woodworker: OCTOBER 2002JvlValenzuelaNo ratings yet

- Ladder ShelvesDocument1 pageLadder ShelvesGigi Franco100% (1)

- Build Classic Cedar Garden Bench Under 40 CharactersDocument11 pagesBuild Classic Cedar Garden Bench Under 40 Charactersvdbroger100% (1)

- 0906workshop DoubleAdirondackDocument3 pages0906workshop DoubleAdirondackkacey001No ratings yet

- Runners and GatesDocument35 pagesRunners and Gatesbjdavies2010100% (2)

- Portable Dovetail Jig WorkcenterDocument8 pagesPortable Dovetail Jig Workcentergmand6850% (2)

- 2.2.2 Technical Requirements For Weld Overlay, Cladding & HardfacingDocument6 pages2.2.2 Technical Requirements For Weld Overlay, Cladding & Hardfacingim4uim4uim4u100% (4)

- 20-Minute Scroll Saw Puzzles: 56 Easy Animal Designs for BeginnersFrom Everand20-Minute Scroll Saw Puzzles: 56 Easy Animal Designs for BeginnersRating: 5 out of 5 stars5/5 (1)

- Patio Chair - FH01SEPDocument6 pagesPatio Chair - FH01SEPTikarko Nakama100% (1)

- Adirondack ChairDocument5 pagesAdirondack ChairCristian Liviu CiovicaNo ratings yet

- Olde Forge Adirondack Chair PLANS PDFDocument49 pagesOlde Forge Adirondack Chair PLANS PDFjlct2009No ratings yet

- Asme B18.13-2017Document30 pagesAsme B18.13-2017윤규섭100% (1)

- WB31238 Diy-WorkbenchDocument8 pagesWB31238 Diy-WorkbenchFrancois VaaltynNo ratings yet

- Silla MaderaDocument12 pagesSilla Maderagmo2189No ratings yet

- A Book of Vintage Designs and Instructions for Outdoor Children's Toys - A Guide to Making Wooden Toys at HomeFrom EverandA Book of Vintage Designs and Instructions for Outdoor Children's Toys - A Guide to Making Wooden Toys at HomeRating: 3 out of 5 stars3/5 (2)

- Cutting With BroachDocument5 pagesCutting With BroachJori Kristian RidayatNo ratings yet

- Fine BlankingDocument26 pagesFine BlankingHarish Ks100% (1)

- Router Table - Projects - American WoodworkerDocument12 pagesRouter Table - Projects - American Woodworkermarcoskelpen100% (1)

- Adriondack Chair Template 2012Document2 pagesAdriondack Chair Template 2012pocetnikNo ratings yet

- Adirondack Chair TemplatesDocument7 pagesAdirondack Chair TemplatesDebbie MackNo ratings yet

- Mantel Clock: © 2012 August Home Publishing CoDocument9 pagesMantel Clock: © 2012 August Home Publishing CoEsequiel Yakueczik100% (1)

- Lista de verbos irregulares en españolDocument5 pagesLista de verbos irregulares en españolMonserrath :p100% (1)

- Welding Guide Cast Lip 2019 PDFDocument38 pagesWelding Guide Cast Lip 2019 PDFRodolfoMarínNo ratings yet

- Hexalubulour BoltDocument20 pagesHexalubulour BoltMitesh MakvanaNo ratings yet

- Easy DIY Adirondack Chair and Table PlansDocument11 pagesEasy DIY Adirondack Chair and Table PlansMoises Martins RochaNo ratings yet

- 2014-4800-0L-0008 Rev B Welding Procedures & Performance Qualification Spec - ApprovedDocument19 pages2014-4800-0L-0008 Rev B Welding Procedures & Performance Qualification Spec - ApprovedfiniteinjusticeNo ratings yet

- bi/ /wɒz /w3 ʳ/ /bi:n/: Infinitive Fonética Past Simple Fonética Past Participle Fonética TraducciónDocument8 pagesbi/ /wɒz /w3 ʳ/ /bi:n/: Infinitive Fonética Past Simple Fonética Past Participle Fonética TraducciónDebbie MackNo ratings yet

- PDF Verbos IrregularesDocument4 pagesPDF Verbos Irregularesjose garciaNo ratings yet

- Print On Cardstock: Print 2 Sheets Corners RailingsDocument4 pagesPrint On Cardstock: Print 2 Sheets Corners RailingsPaúl SocasiNo ratings yet

- Common Irregular Verb ListDocument4 pagesCommon Irregular Verb Listapi-27488371100% (1)

- Roland JWX-30 Set UpDocument62 pagesRoland JWX-30 Set UpDragos Manzateanu0% (1)

- Unit VDocument26 pagesUnit VSabik NainarNo ratings yet

- Bolting and Welding PDFDocument25 pagesBolting and Welding PDFDennis RangwetsiNo ratings yet

- The Different Metal Cutting Forms and Processes ExplainedDocument8 pagesThe Different Metal Cutting Forms and Processes Explainedmiguel100% (2)

- CNC Definitive GuideDocument36 pagesCNC Definitive GuidePhucNo ratings yet

- Screw Thread TolerancingDocument4 pagesScrew Thread TolerancinguttamkboseNo ratings yet

- 1113984-23 Touch Probes en PDFDocument64 pages1113984-23 Touch Probes en PDFNjaziZollumiNo ratings yet

- Secoroc Rock Drilling Tools Grinding Equipment Product CatalogueDocument3 pagesSecoroc Rock Drilling Tools Grinding Equipment Product CatalogueMarcio Herbert Vilcapoma BravoNo ratings yet

- Wurth HelicoilDocument32 pagesWurth HelicoilstaedtlerpNo ratings yet

- Unit 3. Components and AssembliesDocument10 pagesUnit 3. Components and AssembliesFiqhi Fahrizal HaffidNo ratings yet

- Is 3601.2006Document21 pagesIs 3601.2006kprasad_56900No ratings yet

- Pt. Bina Megah IndowoodDocument7 pagesPt. Bina Megah IndowoodAndrianes TeguhNo ratings yet

- Effect of Cooling Rate on MicrostructureDocument7 pagesEffect of Cooling Rate on MicrostructuresivaNo ratings yet

- Avesta 2205 VDX Ac DCDocument1 pageAvesta 2205 VDX Ac DCpipedown456No ratings yet

- Tech Uddeholm Ramax HH ENDocument8 pagesTech Uddeholm Ramax HH ENwrh9rqr22vNo ratings yet

- Aadhira ProfileDocument11 pagesAadhira ProfileBatsha PonnusamyNo ratings yet

- Single Station Manufacturing (CH.13 & 14 of Groover Book)Document70 pagesSingle Station Manufacturing (CH.13 & 14 of Groover Book)Khurram ShahzadNo ratings yet

- Welding Procedure Specification GuideDocument4 pagesWelding Procedure Specification GuideAndhira FarizkiNo ratings yet

- Inlab MC X5 Accessories: Order FormDocument1 pageInlab MC X5 Accessories: Order FormCiprian SarivanNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet