Professional Documents

Culture Documents

Best Irrigation Water Pumping Manual

Uploaded by

MisgatesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Best Irrigation Water Pumping Manual

Uploaded by

MisgatesCopyright:

Available Formats

Small-scale pumped irrigation - energy and cost

iii

PREFACE

This manual is about reducing the costs involved in small-scale pumped irrigation schemes. Too often, schemes are designed and constructed with thought given only to the immediate cost of constructing the scheme and of buying and installing equipment. Little or no attention is given to operating costs, with the result that some schemes may well be cheap to install but very costly to run. When water is pumped, every litre has a real cost because of the energy needed. If more water is pumped than is needed or is pumped inefficiently, then operating costs can rise significantly because of the additional energy which is wasted. Ways of approaching scheme design and equipment selection are described so as to take account of the operating costs. Simple examples are used to show how this can be done, and how true comparisons can be made between different designs. Guidelines are given, based on experience in many developing countries, so that sound practical choices can be made. The manual is not just for those starting a new scheme. It is also for those who wish to evaluate and improve existing schemes, and practical ways of reducing operating costs by improving the efficiency of water use and pumping are described. The readership envisioned is that group of people with some practical experience in small-scale irrigation but who have little or no technical or engineering knowledge and wish to be able to advise farmers on appropriate equipment selection and its proper and efficient use. Although not numbered in the same series as the FAO/ILRI Irrigation Water Management Training Manuals, this particular publication is seen as being complementary to that series, and, as a consequence, numerous cross-references are made in the text to the various volumes of the Training Manuals series. The text is substantially the work of Dr Melvyn Kay, of Silsoe College, UK, with additional technical input from N. Hatcho of the Land and Water Development Division, FAO, Rome. The text was edited and prepared by Thorgeir Lawrence for publication by FAO. Any comments on the text as it stands and any suggestions for potential improvements that could be included in subsequent editions are welcomed, and should be addressed to: Water Resources, Development and Management Service , AGLW FAO Viale delle Terme di Caracalla I-00100 ROMA, Italy

iv

Small-scale pumped irrigation - energy and cost

CONTENTS

1. INTRODUCTION 1.1 Small-scale irrigation 1.2 Problems 1.3 Solutions 1.4 Making choices 2. SOME BASIC CONCEPTS 2.1 Introduction 2.2 Pressure 2.3 Discharge 2.4 Energy 2.5 Power11 2.6 Efficiency 3. CHOOSING A NEW IRRIGATION SYSTEM 3.1 Introduction 3.2 Water sources 3.3 Pumps and power units 3.3.1 Pump types 3.3.2 Pump Characteristics 3.3.3 Pump selection 3.3.4 Power units 3.3.5 Efficiency 3.4 Distribution systems 3.4.1 Open channels 3.4.2 Pipelines 3.4.3 Distribution efficiency 3.5 Methods of irrigation 3.5.1 Surface irrigation 3.5.2 Sprinkler irrigation 3.5.3 Trickle irrigation 3.5.4 Selecting an irrigation method 3.6 System capacity 3.6.1 Crop water requirements 3.6.2 Peak scheme water demand 3.6.3 Seasonal scheme water demand 3.7 Peak power and energy demand 3.8 Costs 3.8.1 Capital cost 3.8.2 Operating cost 3.8.3 Overall cost 3.8.4 Effects of changes 3.8.5 Some general conclusions 3.8.6 Some practical considerations Page 1 1 1 2 2 5 5 5 7 9 13 15 15 18 18 18 22 23 24 26 29 29 31 35 37 37 39 40 40 41 42 44 45 45 46 47 47 49 52 53 54

vi

4. CASE STUDY - 1 Introduction 4.1 Options available 4.2 Scheme water demand 4.3 Peak power and energy demand 4.4 Overall costs 4.5 Conclusions 4.6 Guidelines 5. CASE STUDY - 2 5.1 Options available 5.2 Scheme water demand 5.3 Overall power and energy demand 5.4 Overall costs 5.5 Conclusions 5.6 Guidelines 6. IMPROVING EXISTING SCHEMES 6.1 Introduction 6.2 Inefficient water use 6.3 Inefficient equipment 6.4 Effect of inefficiency 6.5 Evaluating a scheme 6.6 Obtaining data 6.6.1Observing and questioning 6.6.2Some basic data ANNEX 79

55 55 55 56 57 59 59 62 63 63 63 64 65 67 70 71 71 72 73 74 74 76 76 76

Small-scale pumped irrigation - energy and cost

vii

TABLES

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. Energy content of fuels and foods A guide to selecting centrifugal pumps Pump selection for small-scale schemes Indicative values of distribution efficiency (%) Typical field application efficiencies for irrigation methods Typical sprinkler data Factors affecting selection of irrigation method Indicative values for crop water needs and growing periods Useful life of irrigation system components Indicative maintenance and repair costs Capital recovery factors (CRF) EAC values for pumps at various discount rates EAC values for pumps for different life expectancies Changing the distribution system and its effects on energy and cost Calculating scheme water demand Overall power and energy demands Overall cost comparisons Calculating scheme water demand Overall power and energy demands Overall cost comparisons Efficiency of surface irrigation methods Page 10 21 23 35 37 39 41 43 47 48 50 51 51 52 56 57 58 64 64 65 73

viii

FIGURES

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. Making choices , the design process Relationship between force and pressure Measuring pressure in a pipe Calculating discharge Measuring discharge Energy conversion - analagous systems in people and machines Illustration of the problem considered in Example 3 Relationship between rate of energy use and power Graph relating flow, static head and power Choosing irrigation system components Components of a typical irrigation scheme Typical axial flow pump The radial flow (centrifugal) pump Typical mixed flow pump Pump characteristics of the three pump types Pump selection based on head and discharge parameters Manufacturer s data for a centrifugal pump Efficiency of components of pumping plant Suction lift limitations Energy demand for open channel distribution Channel design: dimensions and drop structures Pipe system and its energy demand Hydraulic gradient Nomograph relating pipe diameter, discharge, head loss and velocity Basin, border and furrow irrigation Sprinkler irrigation Hose-pull sprinkler system Trickle irrigation Peak and seasonal scheme water demands The concept of water requirements in mm Relationship between pipe size and seasonal energy cost Effect on EAC values of reducing pump efficiency Effect on EAC values of changing interest rate Effect on EAC values of a greater depth to the groundwater table Effect of reducing pumping efficiency on EAC values Effect of greater depth to groundwater on EAC values Effect of increasing scheme size on capital and operating costs Evaluating irrigation scheme performance System efficiency value ranges The relationship between efficiency and seasonal operating costs Page 4 5 6 7 8 10 11 12 13 15 16 19 20 21 22 24 25 26 28 29 30 32 33 34 36 38 39 40 42 43 53 60 60 61 66 66 68 71 74 75

Small-scale pumped irrigation - energy and cost

Chapter 1 Introduction

1.1 SMALL-SCALE IRRIGATION

Small-scale irrigation is an important aspect of irrigation development in many countries. Approximately half of the irrigated area in Sub-Saharan Africa, for example, is irrigated in this way. It involves individual or small groups of farms, organized and managed by farmers, usually independent of government resources. This type of development has often proved successful in places where the larger-scale, primarily government controlled, projects have not. This is not to say that small-scale is therefore better than large-scale farming, or indeed that small-scale is more simple to develop. It is a different approach to irrigated farming, with its own challenges. Irigation development requires careful design, construction and management to be successful. It is, perhaps, in the management element that the key difference lies. In a small system there are no tiers of management, as in the large-scale schemes. Farmers alone decide when to irrigate and how much water to apply; start and stop the pumps; and generally run the entire scheme with the help of the family or local community. Small-scale farming can be highly productive in terms of yield per hectare of land. The energy input into large-scale schemes can be up to 15 times greater than that required for smallscale farming for the same output of crops produced. This is in sharp contrast to large-scale schemes where the ratio is normally less than 4. Thus, on a national or regional scale, when considering the use of commercial fuel in agriculture, which in many countries is both scarce and expensive, the small-scale approach can be an attractive one. 1.2 PROBLEMS

Despite their apparent attractiveness in terms of potential productivity, small-scale schemes are, however, not always as efficiently run as they could be. Most schemes rely on pumping to supply their water needs and are often designed on the basis of minimum investment cost, with little or no thought given to the effect that this might have on operating costs over many years. For example, a farmer may purchase a cheap pump which runs at a very low level of efficiency. The energy cost may be considerable and it may require much servicing and spare parts. If the farmer were to purchase a better and more appropriate pump then more money might be spent initially but there should be much more money saved over the years through reduced fuel (energy) costs and maintenance. Similar issues arise when selecting other components of an irrigation system. An equally important issue to consider is how well the scheme is managed once it is operating. The most appropriate system design and selection will be of little use in the hands of an inexperienced or unskilled irrigator. Good equipment is no substitute for good management and, here too, considerable savings in energy and operating costs can be made by ensuring good equipment and water management practices.

Introduction

1.3

SOLUTIONS

This manual describes ways of approaching scheme design and equipment selection which take account of both investment and operating costs, and, in particular, emphasise the significance of energy costs. Some basic concepts need to be understood about water flow, energy and power, and, for those who have little or no knowledge of these, they are described in Chapter 2. In Chapter 3 the basic components of an irrigation scheme are described together with ways of choosing between different pumps, distribution systems and methods of irrigation. There may be many different ways of irrigating a farm and a basis for comparison and selection is needed. Cost is often the dominant factor. Thus the idea of cost effectiveness is introduced, showing that both capital costs and operating costs must be considered when selecting equipment, and that the one affects the other. This is demonstrated in Chapters 4 and 5, where two contrasting case studies show how the principles and practices of Chapter 3 can be applied. Many small-scale irrigation schemes are already in operation, and one question here might be how to get the best results from what is already there. Chapter 6 examines ways of looking at existing schemes to determine energy use and operating costs, and to find ways of reducing them through improved efficiency of equipment and water use. 1.4 MAKING CHOICES

Much of this manual is about the process of design the process of making logical choices between systems of irrigation and equipment (Figure 1). It is important to realize at the outset that there is unlikely to be just one ideal choice; there may be many alternatives, any one of which might be quite appropriate. The job of the designer is to present the options available in relation to good irrigation practice, water availability, equipment, its reliability and cost. The farmer can then choose the system which he or she feels is most appropriate. The design process A preliminary design is usually done first. This is often done quickly in order to establish the options available. Once a choice has been made, work then proceeds to a detailed design which details every nut and bolt to be purchased and every canal and structure to be constructed. To undertake a preliminary design, basic information is needed about the land and crops to be irrigated. However, accurate details about land areas and crops may not be necessary at this stage. To understand this it is important to realize what preliminary design is about. It is to establish the maximum capacity or size of the system to be constructed and the choices available to the farmer. The system capacity must be enough to satisfy the maximum amount of water needed by the crops, and there are simple ways of assessing this without detailed knowledge of the cropping. Clearly the answer will not be exact but great accuracy is not needed at this stage. Remember that when a scheme is operating it will run for most of the time at well below its maximum capacity. It may only run at full capacity for a very short period when the crops are maturing and need most water. It is very much like designing and using a car. It may be designed to operate at a maximum speed of 150 km/h, but most drivers would travel well below this speed and only use the maximum speed occasionally. Thus whether the maximum speed is 150 or 160 km/h is not really very critical to the overall use of the car if it otherwise meets all the demands made upon it by the driver. If the actual maximum performance is less than

Small-scale pumped irrigation - energy and cost

150 km/h, then the car will still get there it will just take a little longer. In the same way the capacity of an irrigation system need not be determined with great accuracy as long as the capacity will meet most, if not all, of the operating demands that the farmer will make. If the capacity falls a little short of demand then the difference can be made up by running the system for a longer period. A further aspect of design is considering How will the final cost of the scheme be affected by the decisions made during the design process?. If, for example, the crop water requirement is changed by 10%, or a channel is increased in size by 20%, does this significantly affect the overall cost of the scheme? If it does, then this figure needs to be chosen with considerable care. If it does not, then such accuracy is not needed. A good designer will concentrate on the important factors which will have significant effects on the outcome. The inexperienced designer will need to experiment a little to determine which are the critical factors in the design process. A final aspect of design, which the inexperienced designer may not realize at first, is that there are no formulae which can help with the initial decision making. For example, there is no formula which would show that a pipe should be used instead of an open channel. This is a matter of choice, which may eventually be decided by cost or some other constraint. The designer would thus consider both options, prepare a preliminary design for each one, and then see which was best. Several designs may be done in this way before the best one can be chosen. In other words, the designer will often choose what seems to be appropriate and then set about proving that the choices made are indeed the best. This is where an experienced designer can be invaluable. On the basis of past experience of similar situations the designer may well be able to greatly simplify the design process because he or she may have a very good idea of what will be the best solution. Unfortunately, the inexperienced designer must go through a more rigorous process to arrive at the best solution. This manual is to help the inexperienced designer, and to try and pass on some of the experience of others in order to shorten and simplify the design process. Cost Cost will be an important factor when making choices. In this manual typical costs are used to demonstrate the selection process, but the reader must take great care when using conclusions drawn from this because local costs may vary considerably from those shown. The reader is thus encouraged to go through the design process using local costs and to make judgements based on local solutions. Throughout the text the unit of currency used is the United States dollar ($US).

Introduction

FIGURE 1 Making choices - the design process

Small-scale pumped irrigation - energy and cost

Chapter 2 Some basic concepts

2.1 INTRODUCTION

This chapter provides a guide to some of the basic principles which affect energy needs in small-scale irrigation. SI units the International Metric System are used throughout the text. Reference is made to other units where appropriate, because it is an unfortunate fact of life that many different systems are in use in irrigation, and sometimes it can be confusing and lead to serious mistakes. The fundamental units in the SI systems are: Measurement Length Volume Mass Force 2.2 PRESSURE Unit metre cubic metre kilogramme newton Symbol m m3 kg N

Pressure is a commonly used term, but it does have a special meaning in hydraulics. It describes the force exerted by water on each square metre of some object submerged in water. It may be the bottom of a tank, the side of a dam, or a pipeline. Pressure is normally measured in kilonewtons per square metre (kN/m2). An alternative to this in irrigation is the bar , where 1 bar is equal to 100 kN/m2. Pressure is calculated by:

force (kN) area (m2)

Pressure (kN/m2) =

Thus pressure is force per unit area (Figure 2).

FIGURE 2 Relationship between force and pressure

Some basic concepts

EXAMPLE 1 Calculate the pressure when a force of 10 kN is applied to an area of 2 m2. - We know that Pressure = force / area, so P = 10 / 2 = 5 kN/m2. If the area is increased to 4 m2, what will be the nre pressure? - P = 10 / 4 = 2.5 kN/m2. Thus the force has remained the same but the pressure is reduced by spreading the force over

A typical operating pressure for a sprinkler system is 3 bar pressure, or 300 kN/m2. This means that every square metre of the inside of the pipes and pump has a uniform force of 300 kN acting on it. Other common units of pressure are kilogrammes-force per square centimetre (kgf/cm2) and pounds-force per square inch (lbf/in2). For conversion from one unit to another:

1 bar = 14.7 lbf/in2 = 1 kgf/cm2 = 100 kN/m2

Pressure measurement Pressure in pipes can be measured using a bourdon gauge (Figure 3). Inside the gauge is a curved tube of oval section, which tries to straighten out when the system is under pressure. The tube is linked to a pointer which moves across a graduated scale and indicates pressure. Irrigators normally measure pressure in the field using these gauges as they are robust and simple to use. However, engineers often refer to pressure as a head of water in metres (m) rather than a pressure in kN/m2. If the bourdon gauge was replaced with a long vertical tube, the water pressure in the pipe would cause water to rise up the tube. The height of this water column is a measure of the pressure in the pipe. For example, a pressure of 3 bar in the pipe would result in water rising to a height of 30 m in the tube. Thus, engineers may refer to the pressure as 3 bar or 30 m head of water. It is simple to change from pressure to head of water:

Head of water in metres (m) = 0.1 x pressure (kN/m2) = 10 x pressure (bar) FIGURE 3 Measuring pressure in a pipe

In this manual both the terms pressure and head are used to mean the same thing.

Small-scale pumped irrigation - energy and cost

Importance of Pressure Pressure is important to the successful operation of both sprinkler and trickle irrigation. Sprinklers must be operated at the right pressure so that the water jet breaks up properly and a uniform water application is achieved (Section 3.5.2.). The right pressure is also required in trickle systems so that each emitter gives the same discharge throughout the scheme (Section 3.5.3). Atmospheric pressure Atmospheric pressure is the pressure of the atmosphere around us, pressing down on our bodies and the surface of the earth. Although air seems very light, when there is a large depth, as at the earth s surface, it creates a pressure of approximately 100 kN/m2. This is equivalent to l bar or 10 m head of water.

Atmospheric pressure = 100 kN/m2 = 1 bar = 10 m head of water

Atmospheric pressure is important to the understanding of suction when pumping water (Section 3.3.3) and particularly its effects on the efficiency of pumping (Section 3.3.5). 2.3 DISCHARGE

The speed at which water flows in a pipe or channel is called the velocity and is measured in metres per second (m/s). The discharge is the volume of water flowing along the pipe or channel each second, and is measured in cubic metres per second (m3/s). To understand this, consider the case of water flowing in a 100 mm diameter pipe at a velocity of 1.5 m/s (Figure 4). In one second the quantity of water moving past some point in the pipe will be equal to the shaded volume shown. This volume is numerically equal to the water velocity multiplied by the cross-sectional area of the pipe, i.e., 1.5 0.008 = 0.012 m3/s.

FIGURE 4 Calculating discharge

In general terms:

Discharge (m3/s) = cross-sectional area of pipe (m2) x velocity of water (m/s)

Some basic concepts

FIGURE 5 Measuring discharge

Figure 5-A

Figure 5-C

Figure 5-B

For most small irrigation systems the unit of discharge (m3/s) is much too large and so litres per second (l/s) is very often used. The conversion is made by multiplying by 1000.

Discharge (l/s) = discharge (m3/s) x 1000

Small-scale pumped irrigation - energy and cost

Discharge measurement Discharge in a pipeline can be measured using a flow meter (Figure 5-A). The meter indicates the volume of water passing through the pipeline. By noting the time for a given volume of water to pass the discharge can be determined using the formula:

Discharge (m3/s) = volume of water (m3) / time (s)

A simple way of measuring discharge from a pipe or sprinkler is to catch the flow in a bucket of known volume, measuring how long it takes to fill (Figure 5-C). The discharge is calculated using the above formula. See Example 2. Discharge in open channels can be measured using a weir or flume measuring structure (Figure 5-B). If no measuring structure is available, a rough guide can be obtained by estimating the velocity of flow using a float; measuring the cross-sectional area of the channel; and multiplying the velocity and the area together. (See Training Manual 7: Canals)

EXAMPLE 2 A small plastic tube is connected to a sprinkler nozzle to collect water in a bucket. If the bucket holds 5 litres and it takes 15 seconds to fill, calculate the sprinkler discharge. Discharge = volume / time = 5 / 15 = 0.33 l/s

2.4

ENERGY

Energy is another word commonly used in everyday language, but in hydraulics and irrigation it has a very specific meaning: Energy enables useful work to be done People and animals require energy to do work. This is obtained by eating food and converting it into useful energy for work through the muscles of the body. In irrigation, energy is needed to lift or pump water. Water energy is supplied by a pumping device driven by human or animal power, or a motor using solar, wind or fossil fuel energy. Energy measurement Energy is normally measured in units of watt-hours. One watt-hour is a very small amount of energy and so engineers tend to use a larger unit, the kilowatt-hour (kWh) instead, where 1 kilowatt-hour = 1000 watt-hours. Here are some examples of energy use which may be familiar to the reader and which will provide some practical indication of energy use: A farmer working in the field uses 0.2 - 0.3 kWh every day. An electric desk fan uses 0.3 kWh every hour. An air-conditioner uses 1 kWh every hour. Notice how a time period (e.g., every hour, every day) is always given when describing the amount of energy needed. The farmer using 0.2 kWh every day, for example, indicates that this energy must be supplied from food each day otherwise he or she would not be able to work properly. In irrigation, energy requirements may be determined on a daily, monthly or seasonal basis.

10

Some basic concepts

Energy sources Energy comes from food, in the case of animals and people, and from fossil fuel, wind and sunshine in the case of engines and motors. Foods have energy values which our bodies convert into useful energy so that we can do useful work. In the same way fossil fuels, wind and sunshine have energy which can be converted into useful energy to pump water. Table 1 gives some indication of energy values for typical foods, fossil fuels and energy sources.

TABLE 1 Energy content of fuels and foods

Fuel or food Maize Wood Diesel Petrol Wind Solar

Energy

Indicative efficiency (1) 10% 10% 20% 10% 20% 5%

Comment

1 kWh/kg 4 kWh/kg 11 kWh/l 9 kWh/l 0.01-41 kWh/m2 1 kWh/m2

As animal and human consumption Sometimes also expressed as fuel consumption (0.09 l/kWh for diesel and 0.11 l/kWh for petrol) For wind speeds from 2.5 to 40 m/s respectively Maximum solar energy at sea level

Note: 1. Approximate efficiency when converted to mechanical power. FIGURE 6 Energy conversion - analogous systems in people (top) and machines (bottom)

Changing energy An important aspect of energy is that it can be changed from one form of energy to another. People and animals can convert food into useful energy to drive their muscles (Figure 6). In a typical pumping system powered by a diesel engine, the energy is changed several times before it is usefully used by the water. Chemical energy contained within the fuel (diesel oil in this case) is burnt in a diesel engine to produce mechanical energy. This is passed to the pump via

Small-scale pumped irrigation - energy and cost

11

a drive shaft, and finally to the water. Thus the discharge, pressure or both can be increased. A pump can be thought of as a device for putting additional energy into a water system. The system of energy transfer is not perfect and energy losses occur through friction between the moving parts and are usually lost as heat energy (the human body temperature rises when work hard; an engine heats as fuel is burnt to provide power). Energy losses can be significant in pumping systems, and so can be costly in terms of fuel use. This concept is discussed further in Section 2.6. Calculating energy requirement The amount of energy needed to pump water depends on the volume of water to be pumped and the head required and can be calculated using the formula:

volume of water (m3) x head (m) 367

Water energy (kWh) =

Increasing either the volume of water or the head will directly increase the energy required for pumping.

EXAMPLE 3 600 m3 of water is pumped each day to a tank 10 m above ground (Figure 7). Calculate the amount of energy reguired to do this. Water energy (kWh) = (600 x 10) / 367 = 16.3 kWh. This is the energy required each day.

FIGURE 7 Illustration of the problem considered in Example 3

2.5

POWER

Power is often confused with the term energy. They are related, but they have different meanings. Energy is the capacity to do useful work whereas power is the rate at which the energy is used.

12

Some basic concepts

Power is the rate of using energy and is commonly measured in kilowatts (kW). The power needed to pump water is called water power.

Power (kW) = energy (kWh) time (h)

Another commonly used measure of power is horse power (HP). As it is not part of the metric units system it will not be used in this manual. However, if comparison is needed the relationship is 1 kW = 1.36 HP.

EXAMPLE 4 In Example 3 it was calculated that the water energy required each day to lift 600 m3 of water through 10 m was 16.3 kWh. Calculate the water power needed to do this. To calculate water power from water energy it is necessary to know the time over which pumping takes place. If pumping continues for 24 hours per day: Water power (kW) = energy used per day (kWh) / time (h) = 16.3 / 24 = 0.68 kW. If the pump operates only 12 h/day: Water power = 16.3 / 12 = 1.35 kW. If pumping is only 6 h/day: Water power = 16.3 / 6 = 2.7 kW. Note that the water energy is the same in each case, but that the rate of using the energy - the power - changes with the time period. More power is needed when less time is available for pumping the same volume of water.

An air conditioner may have a power rating of 3 kW. This means that it uses 3 kWh of energy every hour. In 24 hours it will consume 72 kWh (3 kW 24 h) of energy at the rate of 3 kW every hour. Thus, power is describing the rate at which the energy is used. The greater the energy use rate the greater is the power need (Figure 8).

FIGURE 8 Relationship between rate of energy use and power

Another way of calculating power and energy is to use the pump discharge rather than the volume of water to be pumped.

Water power (kW) = 9.81 x discharge (m3/s) x head (m)

In this case the water power required can be calculated by first using the formula: Figure 9 is a graph of this formula and from which water power can be obtained. Energy can then be calculated from power. It is the amount of power used in a given time period and so:

Small-scale pumped irrigation - energy and cost

13

FIGURE 9 Graph relating flow, static head and power

Water energy (kWh) = water power (kW) x operating time (h)

Example 5 demonstrates this approach and shows that the results are the same whichever method is used to calculate power and energy.

EXAMPLE 5 Referring to Example 4, if 600 m3 of water is pumped 10 m each day, calculate the water power and energy required, using the pump discharge approach if pumping is for only 6 h/day. Discharge (m3/s) = volume (m3) / time (s) = 600 / (6 x 3600) = 0.028 m3/s. Using the above equations: Water power (kW) = 9.81 x discharge (m3/s) x head (m) = 9.81 x 0.028 x 10 = 2.7 kW. Water energy (kWh) = water power (kW) x operating time (h) = 2.7 x 6 = 16.3 kWh. These answers are the same as those obtained in the previous example, thus demonstrating that water power and energy can be calculated using either approach.

2.6

EFFICIENCY

When pumping irrigation water it is not enough just to meet the water power and energy requirements. Additional energy and power must be provided because losses occur in transferring fuel energy to water energy via the power unit and pump. The losses in the system are caused by friction and water turbulence and are usually expressed as efficiency. This can be expressed both in terms of energy use and of power use.

14

Some basic concepts

Energy use efficiency

Pumping plant efficiency (%) = (water energy / actual energy) x 100

This provides an overall indication of the way energy is used. It would usually be assessed on a seasonal or annual basis. Power use efficiency

Pumping plant power efficiency (%) = (water power / power input) x 100

This provides an assessment of the efficiency with which power is converted from the fuel to the water, but only at the moment of measurement. The efficiency may vary over time, particularly if there is wear in the engine and pump. A system with no friction would have an efficiency of 100% and all the energy and power input would be transferred to the water. However, this is not the case in real life and there are always friction losses in all the components of the power unit and pump. This is discussed more fully in Section 3.3.5. Sometimes efficiencies can be very low without pump users being aware of the problem. This can result in excessive energy use and high pumping costs. This is an important aspect of pumping and is discussed more fully in Chapter 5. For the purposes of this manual, the efficiencies of energy and power use are assumed to be the same. In practice this may not be the case. A seasonal assessment of energy use efficiency may not always give the same value as power use efficiency measured only once or twice during the season. Note that, in calculations using efficiencies, we always use the decimal form [(efficiency in %) / 100] of the value.

Small-scale pumped irrigation - energy and cost

15

Chapter 3 Choosing a new irrigation system

3.1 INTRODUCTION

Choosing a new irrigation system is about choosing the various components which make up the system. In this chapter the main components are listed, and guidance is given in how to choose, for preliminary design purposes, between the various options and component configurations available. Figure 10 illustrates the process of preliminary design and the decisions to be made. Each part of the process is described in this chapter.

FIGURE 10 Choosing irrigation system components

Small-scale pumped irrigation systems are made up of the following components (Figure 11):

Water source; Pump and power unit; Distribution system; and Method of irrigation.

16

Choosing a new irrigation system

FIGURE 11 Components of a typical irrigation scheme

Small-scale pumped irrigation - energy and cost

17

The water source, the distribution system and the method of irrigation determine the energy demand. The pump and power unit provide the energy supply. Water source The water source may be a river or lake (surface water) or a shallow well or borehole (groundwater). In some cases, water can be abstracted from rivers by gravity, but in many cases pumping will be needed. In the case of groundwater abstraction, pumping is essential. (See also Training Manual 6: Scheme irrigation water needs and supply.) The amount of water abstracted and the height through which it must be lifted from the river or borehole add to the energy demand. Pump and power unit The pump may be driven by a power unit such as a diesel or petrol engine, or an electric motor. In some special cases solar or wind power, or even hand or animal power, may be used to provide the power source for the pump, but they are not so common and are generally limited to very small irrigated plots. In this manual the primary concern is with the use of pumps driven by diesel or petrol engines, as these are usually the main sources of energy supply available to most small-scale farmers. Distribution system The distribution system conveys water from the pump to the fields and may consist of pipes or open channels. Some systems are a combination of both. The choice of distribution system has a significant effect on the energy demand. Method of irrigation The method of irrigation may be surface, sprinkler or trickle irrigation. This may also affect the choice of distribution system and is also significant in determining the energy demand. Surface irrigation may be supplied by either pipe or open channel systems. Sprinkler and trickle irrigation systems would normally use piped distribution systems. (See also Training Manual 5: Irrigation Methods.) Typical systems The most common combinations of components for an irrigation system are:

Pump open channel Pump pipe supply Pump pipe supply

surface irrigation. surface irrigation. sprinkler or trickle irrigation.

The first system is the most common for small-scale irrigation, although the advantages of the second are now being more fully realized. Sprinkle, and especially trickle, irrigation are growing in importance in some areas where soils are very sandy and water is scarce, or energy costs are high, or both, but surface irrigation is the dominant method and is likely to remain so in many countries for the foreseeable future.

18

Choosing a new irrigation system

3.2

WATER SOURCES

Rivers and lakes Many small irrigation schemes are located close to natural river channels and lakes and obtain water by pumping from these sources. They provide a supply which can be seen by the farmer and be judged whether sufficient or not for the seasonal needs of the farm. Usually, the pumping pressures , and hence energy requirements, needed to use such sources are small because the difference in elevation between the source water level and the level of the field are usually not large. Shallow groundwater This is an ideal source of supply for farms located some distance from a river or lake. Usually the groundwater table is fed by seepage from a river or lake and may be only a few meters below ground level. This source may be less reliable than surface water because except through pumping experience there is no easy way of assessing whether there is a sufficient reserve of water to ensure adequate irrigation. However, the farmer can save the cost of an expensive canal or pipe system to bring water from a more distant surface supply. As with surface supplies, the energy costs involved in pumping are relatively low. Deep groundwater This may be water which has permeated through the ground from a surface source many kilometres away or water which has been trapped in the ground by impermeable soils for many thousands of years (fossil water). Pumping deep groundwater which may be 20 - 100 m or more below ground level can be expensive in terms of energy use, as well as in the cost of drilling the borehole, and requires special, deep borehole, pumping equipment, which may also be expensive to buy. 3.3 PUMPS AND POWER UNITS

A pump is a machine which changes fuel energy into useful water energy and needs a petrol or diesel engine or an electric motor to drive it. In special circumstances it may also be possible to use wind or solar energy. For surface irrigation the pump lifts water from a river or groundwater into a channel or pipe system. For sprinkler and trickle irrigation the pump provides the energy for the pressure and discharge needed to distribute water in the pipes to the sprinklers and emitters, in addition to the energy needed to lift water from the source. 3.3.1 Pump types Although there are many types of pumps and water lifting devices, many are unsuited to irrigation use. The most commonly used types are the axial flow (or propeller) pump, the radial flow (or centrifugal) pump, and the mixed flow pump. These are looked at in detail below. Axial flow pump An axial flow pump consists of a propeller hence its alternative name housed inside a tube which is located below the water level (Figure 12). The tube acts as the discharge pipe, and the power unit turns the propeller by means of a long shaft running down the middle of the

Small-scale pumped irrigation - energy and cost

19

FIGURE 12 Typical axial flow pump

pipe and this lifts the water up the pipe. This pump is very efficient for lifting large volumes of water at low pressure and is ideally suited to lifting water from a river or lake to provide surface irrigation water to a farm with open channel distribution. However, these pumps tend to be very expensive because of the high cost of materials, particularly the drive shaft and bearings to support the shafted propeller. For this reason there are no small axial flow pumps manufactured of a size suitable for the small farm of 1 - 2 ha. They tend only to be used on larger farms and for communal schemes, where several small farms are irrigated from the same pump. They are particularly suited to paddy rice schemes because of the large volumes of water usually needed for this crop. Radial flow (centrifugal) pump Centrifugal pumps are the most common type of pump used on small schemes because they are much cheaper than axial pumps to buy and maintain. Small pump sets are often readily available in most developing countries (Figure 13). They are best suited to sprinkler and trickle irrigation, where a higher pressure is needed than for surface irrigation. To understand how a centrifugal pump works, consider first how centrifugal forces occur. Most readers will at some time have spun a bucket of water around at arm s length and observed that no water falls from the bucket even when it is upside down (Figure 13). Water is held in the bucket by the centrifugal forces created by spinning the bucket. A centrifugal pump makes use of this idea and can be thought of as many buckets all spinning around together. The buckets are replaced by an impeller with blades or vanes which spin at high speed inside the pump casing (Figure 13). Water is drawn into the pump from the source of supply through a

20

Choosing a new irrigation system

FIGURE 13 Radial flow (centrifugal) pump

Small-scale pumped irrigation - energy and cost

21

short length of inlet pipe called the suction pipe. As the impeller spins, water is thrown outwards and is collected by the pump casing and guided towards the outlet. This is called the delivery. Some pumps have very simple impellers with straight vanes. These tend to be inefficient because TABLE 2 they create a lot of turbulence in the flow and hence A guide to selecting centrifugal pumps energy losses. However they are cheap to make and are used in cases where efficiency is not important. Pump size (mm) Discharge (l/s) Most irrigation pumps have curved vanes so that the 0-5 25 water enters and leaves the impeller smoothly. This 5 - 15 50 means lower energy losses and higher energy use 15 - 25 75 efficiency. Some impellers have side plates and are 25 - 35 100 called closed impellers. When there is debris in the 35 - 50 125 water open impellers are used to reduce the risk of blockage. Centrifugal pumps can be classified into two types: volute pumps, and turbine (diffuser) pumps. The main difference between them is that the turbine type has diffuser vanes, which provide diverging passages to direct the water flow. Centrifugal pumps are often described by the diameter of the delivery connection pipe, e.g., a 50 mm pump . Table 2 is a guide to selecting centrifugal pump sizes for different flow ranges.

FIGURE 14 Typical mixed flow pump

Mixed flow This pump is a mixture of the axial flow and the centrifugal pump and has the advantage of combining the best features of both pump types (Figure 14). Mixed flow pumps are more efficient at pumping larger quantities of water than centrifugal pumps and are more efficient at pumping to higher pressures than axial flow pumps. They can also operate as submersible pumps, i.e., being completely below the source water surface.

22

Choosing a new irrigation system

FIGURE 15-A Pump characteristics: discharge - head

FIGURE 15-B Pump characteristics: discharge - power

3.3.2 Pump Characteristics Axial flow, centrifugal and mixed flow pumps are designed to run at a constant speed and their performances are described by the following characteristics:

FIGURE 15-C Pump characteristics: discharge - efficiency

Head and discharge; Power requirements; and Efficiency of operation.

Typical characteristics for operating head and discharge for the three pump types appear as Figures 15-A, 15-B and 15-C. They show how head, power and efficiency vary as the discharge changes. For example, when the head requirement is 120% of the design head value, discharge is reduced to 60%, 80% and 90% of design discharge for centrifugal, mixed flow and axial flow pumps respectively. Head and discharge Pumps can deliver a wide range of discharges depending on the pressure required and the speed at which the pump is operated. However, there is a trade off between head and discharge. If more discharge is needed the head drops, and if less discharge is needed, then the head rises. A different set of curves would be obtained if the pump was running at a different speed. The faster it runs the greater the head and the discharge.

Small-scale pumped irrigation - energy and cost

23

Power All pumps need power to rotate the impeller. The amount of power needed depends on the speed of the pump and the discharge that is required. The faster the pump rotates, the more power is needed. For axial flow pumps there is a very large power demand as the pump is starting because there is a lot of water and a heavy pump impeller to get moving. Once the pump is under way the power demand drops to its normal running level. Centrifugal pumps behave quite differently. The power demand is very low when starting, but as the discharge increases the power also gradually increases. Mixed flow pumps operate in between these two contrasting conditions and have a more uniform power demand over the discharge range. Efficiency The concept of efficiency was first developed in Section 2.6. It measures how well the mechanical energy and power from the power unit is converted into water energy and power in the pump. The pump power efficiency is calculated by:

Pump power efficiency (%) = (water power output / actual power output) x 100

The efficiency generally increases to some maximum value and then falls again over the discharge range. The maximum efficiency is usually between 30 - 80% and there is only a limited range of discharges and heads over which the pumps operate at maximum efficiency. Outside this range the pump will be less efficient and so more power and energy will be needed to operate the system. Smaller pumps tend to operate at lower efficiencies than larger ones because they have more friction to overcome relative to their size. 3.3.3 Pump selection There are many pumps on the market and the designer must try to select a pump which will provide the discharge and head needed for the scheme while the pump is operating within its maximum efficiency range. Table 3 indicates the range of good operating conditions for different pump types.

TABLE 3 Pump selection for small-scale schemes

Irrigation system Surface irrigation - open channel distribution - pipe distribution - deep tube well Sprinkler system Trickle system

Pressure or Head (bar) (m) 0.5 1.0 >2.0 2-6 1-2 5 10 >20 2 - 60 10 - 20

Discharge (l/s) any any any any any discharge discharge discharge discharge discharge

Pump type

axial1 or mixed axial1 or mixed mixed or centrifugal centrifugal centrifugal

Note: 1. The ideal pump type, but not usually available for small-scale farming.

A large number of irrigation schemes use surface irrigation and open channel distribution pumping from shallow water supplies. This situation is ideal for axial flow pumps but unfortunately few, if any, pumps are available at a reasonable price for the small discharges

24

Choosing a new irrigation system

FIGURE 16 Pump selection based on head and discharge parameters

required on many farms. The only alternative is to use centrifugal pumps instead and accept that they will run at well below their peak efficiency (Figure 16). For sprinkler and trickle irrigation much higher pressures are needed and so centrifugal pumps are ideally suited to this use and will operate more efficiently. A typical example of pump selection using the data supplied by a manufacturer would be as follows:

EXAMPLE 6 A centrifugal pump is required for a small sprinkler irrigation system. The discharge required is 12 l/s, at a pressure of 2 bar. Using the information supplied by the manufacturer (see Figure 17), determine the pump efficiency. If the same pump was to be used to pump water into an open channel and the pressure needed for this was only 1 bar, show what effect this would have on the pump discharge and the efficiency. From Figure 17, the efficiency of the pump at a discharge of 12 l/s and pressure of 2 bar (20 m of head) is 52%. This is within the high efficiency zone of the pump. If the pressure required was only 1 bar (10 m of head) the discharge would increase to 18 l/s, but at the much reduced efficiency of only 12%. Thus, using an inappropriate pump for the surface irrigation option has a significant effect on the efficiency of pumping.

3.3.4 Power units There are two main types of power unit: internal combustion engines, and electric motors. Internal combustion engines Many small irrigation schemes do not have access to electricity and so rely on petrol (spark ignition) engines or diesel (compression ignition) engines to drive the pumps. These engines have a good weight:power output ratio, and are compact in size and relatively cheap due to mass production techniques.

Small-scale pumped irrigation - energy and cost

25

FIGURE 17 Manufacturer s data for a centrifugal pump

Diesel engines tend to be heavier and more robust than petrol engines and are more expensive to buy. However, they are also more efficient to run and if operated and maintained properly they have a longer working life and are more reliable than petrol. In some countries petrol-driven pumps have needed replacing after only 3 years of operation. Diesel pumps operating in similar conditions could be expected to last at least 6 years. However, it must not be forgotten that engine life is not just measured in years, it is measured in hours of operation and its useful life depends on how well it is operated and serviced. There are cases in developing countries where diesel pumps have been in continual use for 30 years and more. A diesel-engined pump can be up to four times as heavy as a petrol-engined pump of equivalent power, and so if portability is important a petrol pump may be the answer. Electric motors Electric motors are very efficient in energy use (75 - 85%) and can be used to drive all sizes and types of pumps. The main drawback is the reliance on a power supply which is beyond the control of the farmer, and which in many places is unreliable. Inevitably electrical power supplies usually fail when they are most needed. Heavy demands occur when crops are needing most water and so a power failure over several days can have disastrous consequences for a crop. When using trickle irrigation on light sandy soils, serious crop losses may well occur after only a few days without power.

26

Choosing a new irrigation system

3.3.5 Efficiency The efficiency of power units and pumps is very variable, and few data are available on actual field performance of small-scale irrigation pumping installations. The data that are available indicate that efficiencies are very low, in the range 0.5 to 8%, and that such poor levels are quite common. Many of the common causes of low efficiency can be corrected at little cost once the problem is identified, but unfortunately it is easy to run an inefficient pumping system without even realizing it. Any shortfall in output is simply made up by running the system for longer than would otherwise be necessary. Pumping efficiencies are likely to be much higher for sprinkler and trickle systems as the head needs of these systems are more favourable to the hydraulic characteristics of centrifugal pumps. Figure 18 shows the main components of a small pumping system and the poor efficiencies that can commonly occur. The main reasons for inefficiency are listed below. Note that improved efficiency can be achieved by rectifying the common faults.

FIGURE 18 Efficiency of components of pumping plant

Fuel efficiency 90-100%. Fuel is often spilt or leaks from tanks, or from joints in the

fuel pipeline.

Power unit efficiency

Small petrol engines (1 kW) 10%. Small diesel engines (1.5 - 2 kW) 15-35%. Large diesel engines 30-40%. (Text books normally quote 30-40% for engines but these are optimistic. Ageing of engine, poor quality maintenance, excessive power consumed by cooling fans, injectors, etc., all bring down efficiency.) Electric motors have much higher efficiencies 75-85% but a reliable electricity supply may be difficult to obtain in many locations.

Small-scale pumped irrigation - energy and cost

27

Power unit to pump transmission If the engine and pump are direct coupled, then

transmission efficiency nears 100%.

Pump efficiency A pump running at optimum head and speed has an efficiency of between

40% and 80%. Many pumps are not run at optimum head and speed, and so their efficiency could be much lower. This is particularly true for small pumps where the frictional losses are a higher proportion of the total power requirement. The overall efficiency of the pumping system can be found by multiplying together the efficiencies of each component:

Pumping plant efficiency (%) = fuel efficiency x power unit efficiency x transmission efficiency x pump efficiency x 100

Note that in any calculation of this type the decimal equivalent of the percentage is used, i.e., an efficiency of 10% becomes 0.1 in the calculation, 20% becomes 0.2, and so on. Taking the worst and best possible combinations of all the above efficiencies provides some indication of the most likely range of overall efficiencies:

EXAMPLE 7 Worst condition = 0.9 x 0.1 x 0.9 x 0.4 x 100 = 3% Best condition = 1.0 x 0.35 x 1.0 x 0.8 x 100 = 28%

This implies that the worst likely efficiency is around 3%. Even this seems good when compared to the actual field measurements of 0.5% referred to earlier in this section! Although an efficiency of 30% might be expected from a centrifugal pump operating a sprinkler or trickle system, it is unlikely to reach this level of efficiency for surface irrigation. The best that can be achieved would be around 10%. Peak power demand The water power and overall efficiency of the pumping plant are used to calculate the overall power demand.

Overall power demand = water power (kW) / pumping plant efficiency

Developing the formula from Section 2.5:

Overall power demand (kW) =

3 9.81 x discharge (m /s) x head (m) pumping plant efficiency

EXAMPLE 8 A small diesel-driven pump delivers a discharge of 2 l/s when lifting water 3 m from a river. Calculate the peak power demand when the overall efficiency of pump and power unit is 10%. Peak power demand = (9.81 x 0.002 x 3) / 0.1 = 0.59 kW Note that the discharge of 2 l/s must be divided by 1000 to convert it into 3 m /s.

28

Choosing a new irrigation system

FIGURE 19 Suction lift limitations

Pump suction An aspect of using centrifugal and mixed flow pumps which is not always fully understood, and which can seriously impair efficiency, is the suction side of the pump. In cases of shallow groundwater or surface water pumping, the pump is located above the water surface and water has to be sucked up a short length of pipe into the pump, as shown in Figure 19. The difference in height between the water surface and the pump is called the suction lift. When a pump is operating it draws in water in much the same way as a person sucks water up through a drinking straw. There is a limit to how high water can be lifted in this way and it depends on atmospheric pressure (Section 2.2). At sea level this is approximately 10 m head of water. Sucking creates a low pressure in the drinking straw and the outside pressure of the atmosphere pushes down on the water surface and forces water up the straw. As atmospheric pressure is the driving force, this puts a practical limit on the height to which water can be lifted in this way. Ideally it should be possible to lift water 10 m, but because of friction losses in the pipe and pump a practical limit is 7 m. Even at this level many pumps will have difficulty sucking water. Considerable energy will be needed to suck the water and the pump operator may have difficulty keeping the pump primed (i.e., keeping the pump and suction pipes full of water when starting the pump). For this reason, pumps should be located so that the suction lift is less than 3 m if possible. If the depth to the water is greater than 3 m, then a small shelf can be excavated and the pump located nearer to the water surface (Figure 19). Note that these rules only apply when operating in areas close to sea level. Here the atmospheric pressure is approximately 10 m head of water. For schemes operating at higher altitudes in mountainous regions the atmospheric pressure may be much lower than 10 m and so the suction lift will need to be reduced well below 3 m to ensure proper pump operation. However, not all pumps suffer from suction lift limitations. Pumps designed to work below the water surface submersible pumps have no such problems. An example of the effects of variations in suction lift on pump discharge is given by the case of a small centrifugal pump, which delivered 6.5 l/s when operating at 3 m suction. When the suction lift was increased to 8 m the discharge dropped to 1.2 l/s a loss in flow of 5.3 l/

Small-scale pumped irrigation - energy and cost

29

s, or a loss of 85% of the original discharge! Thus, at the greater suction lift the pump would have to be operated considerably longer to meet water demand, and at such a low flow rate the pump may be well away from its best operating efficiency. This example was cited by Wagner and Lanoix1 (1969). 3.4 DISTRIBUTION SYSTEMS

The distribution system conveys water from the pump to the fields. This may be by open channels or through pipes. The choice of distribution system affects both the power and energy requirements. 3.4.1 Open channels The most common method of distribution is through open channels, which may be lined or unlined. Channel design affects the energy demand of the system in three ways:

by determining the energy requirement to lift water from its source into the channels; by influencing energy losses resulting from friction between the water and the canal; and by influencing the extent of any additional energy required to pump water which is lost

through seepage, canal breaches and misuse. Water will only flow downhill in open channels and so the layout of canals should ensure that the highest point in the canal system is near to the pump and water source. In this way water will then flow downhill under the force of gravity and out onto the fields. Sufficient power must be provided in this case to lift water from its source into the channels (Figure 20). The head required is determined by the difference in level between the water source and the water level in the channel. The water level in the channel at the source must be high enough to ensure an adequate flow of water to the field, and must include adequate head to allow effective flow from the channel to the field.

FIGURE 20 Energy demand for open channel distribution

Large water losses can easily occur in open channels. This may be due to seepage through the bed and sides of a channel. However, open channels, particularly unlined ones, are prone to breaching, whereupon considerable amounts of water can be lost. They are also easily

1 Wagner, E.G. & Lanoix, J.N. 1969. Water Supply for Rural Areas and Small Communities. Geneva: World Health Organization.

30

Choosing a new irrigation system

misused. Channels may be left open, particularly when control gates are not working properly, and water runs to waste. These features of open channels mean that considerable amounts of water may be pumped which are wasted, using additional energy and fuel for which there is no benefit in terms of additional crops. Of course channels can be lined to reduce seepage, but this requires additional capital expenditure. A choice must then be made between the additional cost of lining and the cost of pumping the water which would be lost through seepage. This involves a comparison between capital expenditure and operating costs, which is discussed later in Section 3.8.3. Lining canals can often seem an attractive way of reducing seepage losses. It can also reduce maintenance costs and improve irrigation system distribution efficiency. However, if linings are to be successful they must be constructed with great care. A concrete lining, for example, needs to be well vibrated as it is poured so as to be impermeable, and must be placed on channel beds and banks that have been well compacted. If settlement occurs after construction and the lining cracks, then not only will seepage losses be high but the cost of the specialist repairs will also be significant. Water losses in channels for typical irrigation schemes expressed in terms of efficiency are shown in Table 4.

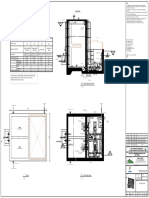

FIGURE 21 Channel design: dimensions and drop structures

Channel hydraulics Most irrigation channels excavated in the natural soil are trapezoidal in shape and slope downhill away from the water source. Channels usually follow the natural ground slope but if the land is steep, then drop (or fall) structures may be needed to avoid serious erosion problems (Figure 21). Channels with longitudinal bed slopes of less than 1:1000 will usually avoid serious erosion problems, but a minimum slope of greater than 1:5000 is needed to discourage siltation and plant growth problems. Channels which are lined may be trapezoidal but can also be rectangular or semi-circular. The main aspect of channel design is choosing the bed width and depth of flow. This can present some difficulties because choosing a value for one affects the other. Thus channel design is a little more complicated than pipe design because pipes are always circular and so only one value is chosen the pipe diameter. The reader must look to other texts for the detailed design of channels, but as guidelines:

Small-scale pumped irrigation - energy and cost

31

Unlined channels are designed so that the velocity is low and the bed and sides are not

eroded by the water. For this reason, unlined channels tend to be wide and shallow, spreading the flow over a large area to reduce the erosive power of the water.

Lined channels are expensive to construct. For this reason they tend to be narrow and deep

which ensures the minimum area of lining for a given channel carrying capacity. The velocity also tends to be high, but this is not usually a problem as the channel is protected from erosion by the lining. 3.4.2 Pipelines Pipelines are often thought to be too expensive for many small irrigation schemes except when sprinkler or trickle irrigation is used, as then the use of pipes is essential. However, expensive is a relative word and does not convey a specific meaning. It may well be that when the full operating advantages of pipes are considered they may be a viable alternative to open channels. For small-scale surface irrigation schemes, recent research has shown many advantages for piped distribution systems:

Very low distribution losses even less than lined channels, as it is much easier to close off the flow in a pipe than in an open channel (See Table 4 for water losses in pipelines expressed as an efficiency). Less land area is taken up by buried pipes. Channels can take up 0.5-2% of the command area. Pipes can often be installed at lower cost than lined canals. Pipe systems can provide a more flexible and reliable system of supply. Reduced contact with water has potential health benefits.

Pipelines for surface irrigation usually operate at low pressures, typically around 0.5 bar (5 m of head). Pipelines are essential for the use of sprinkler and trickle irrigation, and they need to operate at much higher pressures (typically 2 - 6 bar for sprinkler and 1 - 2 bar for trickle systems) and need to be strong enough to withstand up to twice the working pressure. The reason for this is that pressure surges which are much greater than the normal working pressure can occur in pipes, and can cause bursts. It is thus important to install a pipe with the correct pressure rating to avoid the expense of repair or even replacement of a complete system. Energy is needed in pipe systems not only to pump water from the source to the pipe but also to overcome the energy losses due to friction as water flows down the pipe (Figure 22). If surface irrigation is used, then water can flow freely from the pipe into the field. If sprinkler or trickle irrigation is used, then additional energy is needed to ensure the water sprays or drips properly. Predicting head losses in pipes is not an exact science, and it easy to make mistakes when calculating them. In addition, losses can increase as the pipe ages and becomes rougher inside through continued use. For these reasons the losses in the distribution system should be kept low at the design stage by choosing pipe diameters that are large enough for friction to not dominate the operation of the system at some later date. As a guideline, energy losses in the pipes should be less than 30% of the total pumping head.

32

Choosing a new irrigation system

FIGURE 22 Pipe system and its energy demand

energy needed to pressurize sprinklers

Pipeline hydraulics Energy is lost when water flows along a pipe. This is due to friction between the flowing water and the pipe wall. This energy loss means that the pressure near the pump will always be greater than at the far end of the pipe. The change in pressure is called the hydraulic gradient (Figure 23). Additional power and energy must be supplied by the pump to overcome that friction so that sufficient water is still delivered to the scheme at the right pressures. Energy loss in pipelines can be measured as a head loss in metres (m). It depends on the following factors:

Discharge small changes in discharge can cause very large changes in head loss. Pipe diameter small changes in pipe diameter can cause very large changes in head loss. Pipe length changes in pipe length cause similar changes in head loss. Increasing a pipe

length from 100 m to 200 m will double the head loss.

Pipe layout the kinds and numbers of bends and junctions.

Small-scale pumped irrigation - energy and cost

33

FIGURE 23 Hydraulic gradient

Pipe material it determines frictional resistance by its smoothness or otherwise.

Energy loss in pipes can be determined from information supplied by pipe manufacturers. A typical nomograph for PVC pipes is shown in Figure 24. The following examples will demonstrate effects of discharge, pipe diameter and pipe length on the head loss. A good guide to selecting the right pipe diameter is to keep the velocity below 1.6 m/s. This is good engineering practice. It ensures that head losses are low and it will help to avoid the surge and water hammer (sudden oscillations in water pressure) problems which can cause pipes to burst. Practical considerations

Different pipe materials have different friction characteristics. The example used in this

text is PVC. If other pipes are used, then values for friction head losses must be obtained from the supplier.

The smallest diameter pipe may be the cheapest, but it is not always the best choice. Pressure

losses can be very high and so can the cost of providing the extra energy to overcome the losses. It may be cheaper in the long term to use a larger pipe size, which may have a higher capital cost but requires less energy in use and so has a much lower operating cost. This issue is discussed in detail in Section 3.8.5.

Think long term when selecting pipes. Will more water be needed in the future? Will the

system be extended? If so, investment now in a larger pipe size may save high energy costs later when trying to pump an increased discharge down a pipe which is too small. A common problem across the world is that farmers install pipelines which are too small. Many regret the decision later when they see the potential for irrigation and wish to expand their system.

It is not necessary to use a pipe size which is the same diameter as the pump delivery pipe.

For example, a 50 mm diameter pump does not mean the farmer must use a 50 mm diameter

34

Choosing a new irrigation system

FIGURE 24 Nomograph relating pipe diameter, discharge, head loss and velocity

pipe. The diameter is selected according to the above guidelines and if it is different from the pump diameter then a special section of pipe with a varying diameter (a reducer) is simply used to connect the pump to the pipeline.

It is important to see what pipe sizes and pumps are available in the local market and to

design around this equipment. This may not always give the most efficient system from an energy use point of view but it will mean that local support for servicing, maintenance and repair will be available. Such an advantage may far outweigh any fuel efficiency use issues.

Small-scale pumped irrigation - energy and cost

35

EXAMPLE 9 An irrigation scheme uses a 100 mm diameter pipeline, 130 m long, to deliver a discharge of 8 l/s. Determine the head loss. From Figure 24: When discharge is 8 l/s through a pipe of 100 mm , head loss is 10 m/km. Therefore, over 130 m [= 0.13 km] head loss will be 10 x 0.13 = 1.3 m. What will be the increase in head loss is the discharge is increased to 16 l/s? From Figure 24: When discharge is 16 l/s through a pipe of 100 mm , head loss is 37 m/km. Therefore, over 130 m [= 0.13 km] head loss will be 37 x 0.13 = 4.8 m. The increase in head loss is 4.8 - 1.3 = 3.5 m. Increasing discharge causes a large increase in head loss. Determine the change in head loss if a pipe of 80 mm is used to deliver the same discharge [8 l/s] over the same distance [130 m]. FromFigure 24: When discharge is 8 l/s through a pipe of 80 mm , head loss is 29 m/km. Therefore, over 130 m [= 0.13 km] head loss will be 29 x 0.13 = 3.8 m. Difference is 3.8 - 1.3 = 2.5 m, i.e. anincrease in head loss. A decrease in pipe diameter causes an increase head loss. Determine the change in head loss if the 100 mm pipe is used to deliver the same discharge [8 l/ s] over twice the distance [260 m]. FromFigure 24: When discharge is 8 l/s through a pipe of 100 mm , head loss is 10 m/km. Therefore, over 260 m [= 0.26 km] head loss will be 10 x 0.26 = 2.6 m. Difference is 2.6 - 1.3 = 1.3 m, anincrease in head loss. An increase in pipe length causes a corresponding increase in head loss.

3.4.3 Distribution efficiency Water is not always distributed efficiently, and losses may occur from channels through seepage, evaporation and mismanagement of the system. In the case of open channels this may involve gates being left open when no one is irrigating, and canal banks breaching through poor maintenance. For pipe systems, there may be leakage from the joints because of poor sealing and, again, valves may not always be closed properly. However, it is likely that pipelines have a potentially higher efficiency than open channels. For design purposes, Table 4 indicates typical values of distribution efficiency.

TABLE 4 Indicative values of distribution efficiency (%)

Earth canals Scheme size (ha) Large: >2 000 ha Medium: 200 - 2 000 ha Small: <200 ha sand 60 70 80 loam 70 75 85 clay 80 85 90

Lined canals

Pipes

95 95 95

95 95 95

36

Choosing a new irrigation system

FIGURE 25 Basin, forder and furrow irrigation

Small-scale pumped irrigation - energy and cost

37

3.5

METHODS OF IRRIGATION

There are three methods of irrigation commonly used on small schemes (See also Training Manual 5: Irrigation Methods):

Surface irrigation Sprinkler irrigation Trickle irrigation

The main objectives of these methods are to:

Apply an adequate amount of water to meet crop needs Apply water uniformly across the field Ensure there are no long-term problems (e.g., soil erosion, salinization).

3.5.1 Surface irrigation This is the most common method used on small schemes and involves flooding water across the soil surface so that it can infiltrate into the root zone and be used by the crop. Basin irrigation, border irrigation and furrow irrigation are all surface methods (Figure 25). The choice of surface method depends on the crop, cultivation practices, soils and topography, and farmer preferences. Surface irrigation is a labour-intensive method but generally requires less energy than other methods because of the low head required for distribution. Although surface irrigation is considered to be a simple method of irrigation this can be very misleading. Surface irrigation design and construction is relatively simple and little or no imported specialist materials are needed. However, the proper management of the method is very complex. The efficient use of irrigation water all depends on the skill of the farmer, who must decide when to irrigate and how much to apply, and then provide the right discharge into the field so that water infiltrates adequately and uniformly into the root zone. This is not an easy task, as the soil and topographic conditions can be very variable and the farmer may not have the necessary degree of control over the discharge and timing of the application Potentially, surface irrigation can be very efficient if all the factors involved are under the careful control of an experienced irrigator. More often however, the water management skills are lacking and efficiency tends to be low. As the designer will not know the level of field application efficiency that the farmer will achieve once the scheme is built, a typical value is used for design purposes (Table 5). If the actual efficiency is less than the typical value once the scheme is operating, then the farmer will need to operate the system for longer each day, or to reduce the cropped area to compensate. This fall in efficiency will increase the energy demand (Section 5.2).

TABLE 5 Typical field application efficiencies for irrigation methods

Irrigation method Surface Sprinkler Trickle

Efficiency (%) 60 75 90

For additional information on surface irrigation see Kay (1986)1.

1. Kay, M. 1986. Surface Irrigation: Systems and Practice. Cranfield, UK: Cranfield Press.

38

Choosing a new irrigation system

3.5.2 Sprinkler irrigation Sprinkler irrigation involves distributing water in pipes under pressure and spraying it into the air so that it breaks up into small droplets and falls to the ground like natural rainfall. Sprinkler systems are generally more efficient and use less labour than surface irrigation and can be adapted more easily to sandy and erodible soils on undulating ground. There are many types of sprinkler system available, but the most common is a system using portable pipes (aluminium or plastic) supplying rotary impact sprinklers (Figure 26).

FIGURE 26 Sprinkler irrigation

An individual rotary impact sprinkler produces a circular wetting pattern with poor uniformity. To obtain good uniformity, several sprinklers are always operated close together so that the patterns overlap. Pressure is an important factor in successful sprinkler operation. Typical operating pressures range from 2 to 6 bar, and so energy requirements can be much greater than for surface irrigation. If sprinklers are working at the pressure recommended by the manufacturer then the distribution will be good. If the pressure is above or below this value then the distribution will be adversely affected. The most common problem is when pressure is too low and this happens when pump and pipes wear, increasing friction and so reducing pressure. Typical data for rotary impact sprinklers are shown in Table 6. It is usually assumed that sprinkler irrigation is more efficient than surface irrigation. Potentially this is the case, but it largely depends on how well the system is operated and maintained. If pipe seals leak or burst, and if sprinklers are left running for longer than necessary, then wastage is inevitable. For design purposes, a field application efficiency of 75% is generally used. Traditional sprinkler irrigation is not so well suited to small farms. Typical spacings for sprinklers are 18 m 18 m, and so they are not so flexible and adaptable to the multitude of small plots usually found on many farms. An alternative which may be more applicable to

Small-scale pumped irrigation - energy and cost

39

TABLE 6 Typical sprinkler data

Nozzle diameter (mm)

Pressure (bar)

Diameter of wetted circle (m)

Flow (m3/h)

Application rate (mm/h) for spacings:

18 x 18 m 4 5 6 8 10 3.0 3.0 3.0 4.0 4.5 29 32 35 43 48 1.02 1.67 2.44 4.96 8.13 3.2 5.2 7.5 15.3 25.1

18 x 24 m .. 3.8 5.7 11.4 18.9

24 x 24 m .. .. 4.2 8.6 14.0

small farms is the use of smaller sprinklers connected to the mainline by flexible hoses (Figure 27). This is often called a hose-pull system. These sprinklers have great flexibility in operation and are easily re-located around the farm. For fuller details of the methods, their design and management the reader should refer to standard text books and other publications3.

FIGURE 27 Hose-pull sprinkler system

3.5.3 Trickle irrigation Trickle irrigation involves dripping water onto the soil at very low flow rates (2-20 l/h) from a system of small diameter plastic pipes fitted with outlets called emitters. Water is applied close to the plants so that only the part of the soil volume in which the roots develop is wetted. Applications are usually frequent (every 2-3 days) and this can provide a favourable high moisture level condition in which the plants can flourish. Many other claims are made about the method, including increased crop yields, greater efficiency of water use, possible use of saline water, reduced labour requirements and its adaptability to poor soils. An important advantage is the ease with which nutrients can be applied with the irrigation water. The relative importance of each of these attributes will vary depending on the situation. A typical trickle irrigation system is shown in Figure 28.

1. Two publications for further reading are: FAO/ILRI. [1988]. Irrigation methods. Irrigation Water Management Training Manual 5. Kay, M. 1983. Sprinkler Irrigation: Equipment and Practice. London: Batsford.

40

Choosing a new irrigation system

FIGURE 28 Trickle irrigation