Professional Documents

Culture Documents

Piping 2

Uploaded by

Jeffrey SsalonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping 2

Uploaded by

Jeffrey SsalonCopyright:

Available Formats

Piping

Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.[1][2] Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of Piping Design (or Piping Engineering). Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process. "Piping" sometimes refers to Piping Design, the detailed specification of the physical piping layout within a process plant or commercial building. In earlier days, this was sometimes called Drafting, Technical drawing, Engineering Drawing, and Design but is today commonly performed by Designers who have learned to use automated Computer Aided Drawing / Computer Aided Design (CAD) software. Plumbing is a piping system that most people are familiar with, as it constitutes the form of fluid transportation that is used to provide potable water and fuels to their homes and business. Plumbing pipes also remove waste in the form of sewage, and allow venting of sewage gases to the outdoors. Fire sprinkler systems also use piping, and may transport nonpotable or potable water, or other fire-suppression fluids. Piping also has many other industrial applications, which are crucial for moving raw and semi-processed fluids for refining into more useful products. Some of the more exotic materials of construction are Inconel, titanium, chrome-moly and various other steel alloys.

Piping engineering

Generally, industrial piping engineering has three major subfields:

piping material Piping design Stress analysis

Piping material

The material with which a pipe is manufactured often forms as the basis for choosing any pipe. Materials that are used for manufacturing pipes include:

Carbon Steel (CS) Low Temperature Service Carbon Steel (LTCS)

Stainless Steel (SS) Non Ferrous Metals (Inconel, Incoloy, Cupro-nickel, etc.) Non Metallic (GRE, PVC,CPVC, HDPE, tempered glass, etc.)

Wooden piping Early wooden pipes were constructed out of logs that had a large hole bored lengthwise through the center. Later wooden pipes were constructed with staves and hoops similar to wooden barrel construction. Stave pipes have the advantage that they are easily transported as a compact pile of parts on a wagon and then assembled as a hollow structure at the job site. Wooden pipes were especially popular in mountain regions where transport of heavy iron or concrete pipes would have been difficult. Wooden pipes were easier to maintain than metal, because the wood did not expand or contract with temperature changes as much as metal and so consequently expansion joints and bends were not required. The thickness of wood afforded some insulating properties to the pipes which helped prevent freezing as compared to metal pipes. Wood used for water pipes also does not rot very easily.Electrolysis, that bugbear of many iron pipe systems, doesn't affect wood pipes at all, since wood is a much better electrical insulator. In the Western United States where redwood was used for pipe construction, it was found that redwood had "peculiar properties" that protected it from weathering, acids, insects, and fungus growths. Redwood pipes stayed smooth and clean indefinitely while iron pipe by comparison would rapidly begin to scale and corrode and could eventually plug itself up with the corrosion. [3]

Stress analysis

Process piping and power piping are typically checked by Pipe Stress Engineers to verify that the routing, nozzle loads, hangers, and supports are properly placed and selected such that allowable pipe stress is not exceeded under different situations such as sustained, operating, pressure testing etc., as per the ASME B31, EN 13480 or any other applicable codes and standards. It is necessary to evaluate the mechanical behaviour of the piping under regular loads (internal pressure and thermal stresses) as well under occasional and intermittent loading cases such as earthquake, high wind or special vibration, and water hammer. [4][5] This evaluation is usually performed with the assistance of a specialized (finite element or beam theory) pipe stress analysis computer program such asCAESAR II, Triflex, ROHR2, CAEPIPE and AUTOPIPE. In cryogenic pipe supports, most steel become more brittle as the temperature decreases from normal operating conditions, so it is necessary to know the temperature distribution for cryogenic conditions. Steel structures will have areas of high stress that may be caused by sharp corners in the design, or inclusions in the material.[6]

Standards

There are certain standard codes that need to be followed while designing or manufacturing any piping system. Organizations that promulgate piping standards include:

ASME - The American Society of Mechanical Engineers - B31 series

ASME B31.1 Power piping (steam piping etc.) ASME B31.3 Process piping ASME B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids ASME B31.5 Refrigeration piping and heat transfer components ASME B31.8 Gas transmission and distribution piping systems ASME B31.9 Building services piping ASME B31.11 Slurry Transportation Piping Systems ASME B31.12 Hydrogen Piping and Pipelines

ASTM - American Society for Testing and Materials API - American Petroleum Institute

API 570 "Piping Inspection Code - Inspection, Repair, Alteration, and Rerating of In-service Piping Systems"

API RP 2201 "Safe Hot Tapping Practices in the Petroleum & Petrochemical Industries"

EN 13480 - European metallic industrial piping code

EN 13480-1 Metallic industrial piping - Part 1: General EN 13480-2 Metallic industrial piping - Part 2: Materials EN 13480-3 Metallic industrial piping - Part 3: Design and calculation EN 13480-4 Metallic industrial piping - Part 4: Fabrication and installation EN 13480-5 Metallic industrial piping - Part 5: Inspection and testing EN 13480-6 Metallic industrial piping - Part 6: Additional requirements for buried piping PD TR 13480-7 Metallic industrial piping - Part 7: Guidance on the use of conformity assessment procedures

EN 13480-8 Metallic industrial piping - Part 8: Additional requirements for aluminium and aluminium alloy piping

EN 1993-4-3 Eurocode 3 Design of steel structures - Part 4-3: Pipelines AWS - American Welding Society AWWA - American Water Works Association MSS Manufacturers' Standardization Society ANSI - American National Standards Institute NFPA - National Fire Protection Association

EJMA - Expansion Joint Manufacturers Association

Pipe is measured by the nominal size, 1/2", 3/4" 1", 1-1/2", 2", 3" 4" etc. Then a pipe schedule is given with that size (Sch 40, Sch 80, etc). Example 4" Schedule 40 pipe. =Pipe is not measure by outside or inside diamter. A 4" pipe has an outside diameter of 4.5" This inside diamter of a 4" pipe can range from about 4.26" to 3.44" Tubing you have to give the outside diamter and then the inside diameter or wall thickness or pressure rating. In the real world, not in class, when you order pipe from a supplier, you give the person nominal pipe size, schedule and material. If you tell him the OD and then ID, he will put you on hold, laugh, then tell all his co workers about what an engineer asked for, they will all laugh, and he might be done laughing when he gets back on a phone to try to figure out what you want. =Outside Diameter, Wall Thickness ( BWG fraction or decimal inches), Inside Diameter and Weight-per-Foot. =Keep in mind that pipe size refers to a nominal - not actual - inside pipe diameter. Schedule refers to the pipe's wall thickness. The actual physical OD is larger than it's nominal OD. =Pipes are used to transport something, and tubes to construct something; hence, tubes are defined by the outside diameter and wall thickness (for construction stability), and pipes are measured by inside diameter to allow a calculation for transportation viz., speed, volumes etc. (OD = ID + 2 WT) COUPLING A coupling (or coupler) (used in piping or plumbing) is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazedor soldered (copper, brass etc.) together. f the two ends of a coupling are different (e.g. one BSP threaded and one NPT threaded), then it is usually referred to as an adapter. Another variation is one plain socket and one threaded socket. Yet another variation would be 3/4" NPT to 1/2" NPT. When the two ends use the same connection method but are of a different size, the terms reducing coupling or reducer are used. Reducer =is the component in a pipeline that reduces the pipe size from a larger to a smaller bore (inner diameter).

Steel pipe

Steel pipe (or black iron pipe) was once the most popular choice for supply of water and flammable gases. Steel pipe is still used in many homes and businesses to convey natural gas or propane fuel, and is a popular choice in fire sprinkler systems due to its high heat resistance. In commercial buildings, steel pipe is used to convey heating or cooling water to heat exchangers, air handlers,variable air volume (VAV) devices, or other HVAC equipment.

Copper pipe

Copper tubing is most often used for supply of hot and cold water, and as refrigerant line in HVAC systems. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, or solder. Copper offers a high level of resistance to corrosion, but is becoming very costly.

Aluminum pipe

Aluminium is sometimes used due to its low cost, resistance to corrosion and solvents, and its ductility. Aluminium tube is more desirable than steel for the conveyance of flammable solvents, since it cannot create sparks when manipulated. Aluminium tubing can be connected by flare or compression fittings, or it can be welded by the TIG or heliarc processes.

Glass pipe

Tempered glass pipes are used for specialized applications, such as corrosive liquids, medical or laboratory wastes, or pharmaceuticalmanufacturing. Connections are generally made using specialized gasket or O-ring fittings.

NOZZLE A nozzle is a device designed to control the direction or characteristics of a fluid flow (especially to increase velocity) as it exits (or enters) an enclosed chamber or pipe. A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. VALVE A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically valves fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure = by a handle, lever, pedal or wheel.

Types

be classified by how they are actuated:

Hydraulic Pneumatic Manual Solenoid

Motor Anactuator is a mechanism or device to automatically or remotely control a valve from outside the body. Some valves have neither handle nor actuator because they automatically control themselves from inside; for example, check valves and relief valves may have neither.

Gaskets

Gaskets are the mechanical seals, or packings, used to prevent the leakage of a gas or fluids from valves.

PRESSURE VESSEL

A pressure vessel is a closed container designed to hold gases or liquids at a pressuresubstantially different from the ambient pressure. shapes made of sections of spheres, cylinders, and cones are usually employed. A common design is a cylinder with end caps called heads. Are made of steel. a pressure vessel is considered to be thin-walled if its

radius is larger than 5 times its wall thickness

Safety Valves

As the pressure vessel is designed to a pressure, there is typically a safety valve or relief valve to ensure that this pressure is not exceeded in operation. A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action. FLANGE A flange is an external or internal ridge, or rim (lip), for strength, as the flange of an ironbeam such as an I-beam or a T-beam; or for attachment to another object, as the flange on the end of a pipe, steam cylinder, etc., or on the lens mount of a camera; or for a flange of arail car or tram wheel. a plate or ring to form a rim at the end of a pipe when fastened to the pipe (for example, a closet flange). A blind flange is a plate for covering or closing the end of a pipe. A flange joint is a connection of pipes, where the connecting pieces have flanges by which the parts are bolted together.

INSULATION-- thermal or acoustic insulation used on pipework. Condensation control, Pipe freezing, Energy saving, Protection against extreme temperatures, Control of noise MATERIALS USED Mineral wool, Glass wool, Flexible elastomeric foams, Rigid foam, Polyethylene, Cellular Glass, Aerogel, Polystyrene, Polyurethane,

Fiberglass,

Gas compressor

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas. Liquids are relatively incompressible; while some can be compressed, the main action of a pump is to pressurize and transport liquids. Baffles are flow-directing or obstructing vanes or panels used in some industrial process vessels (tanks), such as shell and tube heat exchangers, chemical reactors, and static mixers. Baffles are an integral part of the shell and tube heat exchanger design. A baffle is designed to support tube bundles and direct the flow offluids for maximum efficiency

Fitting A fitting is used in pipe plumbing systems to connect straight pipe or tubing sections, to adapt to different sizes or shapes, and for other purposes, such as regulating or measuring fluid flow.

You might also like

- Piping DesignDocument9 pagesPiping Designjmclaug502No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Piping Design (Revised)Document22 pagesPiping Design (Revised)Yash PatelNo ratings yet

- Piping Engineering.nDocument6 pagesPiping Engineering.nAjay KumarNo ratings yet

- Is 4310 Spec Weldeable Steel Pipe Fittings For Marine PurposesDocument12 pagesIs 4310 Spec Weldeable Steel Pipe Fittings For Marine Purposesnarasimhareddy415No ratings yet

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocument21 pagesChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNo ratings yet

- Piping BasicsDocument10 pagesPiping Basicstulasirao.nammiNo ratings yet

- 1 PipelineDocument69 pages1 PipelineEhab MohammedNo ratings yet

- Piping Interview Questionnaire 5Document2 pagesPiping Interview Questionnaire 5Valli RajuNo ratings yet

- Piping QuizDocument20 pagesPiping QuizAlex CarreraNo ratings yet

- Why Insulate Pipes: 3 Key Benefits of InsulationDocument13 pagesWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenNo ratings yet

- Basics of Pipe For Oil & Gas EngineerDocument12 pagesBasics of Pipe For Oil & Gas EngineerMannuddin KhanNo ratings yet

- Pipe rack structure and designDocument11 pagesPipe rack structure and designpuru55980No ratings yet

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- 436 Piping Course DescriptionDocument2 pages436 Piping Course DescriptionAnonymous q9eCZHMuS100% (1)

- Flare Line Stress AnalysisDocument7 pagesFlare Line Stress AnalysisdhurjatibhuteshNo ratings yet

- Expansion Loop DesignDocument61 pagesExpansion Loop DesignTauqueerAhmadNo ratings yet

- General Q and ADocument10 pagesGeneral Q and AmohamedqcNo ratings yet

- Piping Questionnaire - Piping Study-NDocument14 pagesPiping Questionnaire - Piping Study-NBhanu Prakash100% (1)

- Implementation of Expansion LoopsDocument13 pagesImplementation of Expansion LoopsSSSNo ratings yet

- Pipe Fittings and Piping AuxiliariesDocument38 pagesPipe Fittings and Piping Auxiliariesmsaad2No ratings yet

- Reflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightDocument3 pagesReflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightAnonymous DMdGdsOENo ratings yet

- Pipeline Support1Document18 pagesPipeline Support1Mohamed RishaNo ratings yet

- Asme 16.5Document2 pagesAsme 16.5Norman MoralesNo ratings yet

- History b16 34Document5 pagesHistory b16 34qazi12100% (1)

- 1Document156 pages1Abhijeet DarvekarNo ratings yet

- PTC Cacls Asme b31.3Document1 pagePTC Cacls Asme b31.3MamacintNo ratings yet

- Guideline On Installation of ThermowellDocument7 pagesGuideline On Installation of Thermowell이가람No ratings yet

- Decibel Nde Training Institute Offers NDT CoursesDocument1 pageDecibel Nde Training Institute Offers NDT CoursesSangeeth.KpNo ratings yet

- 11/20/2018 /conversion/tmp/scratch/402494814Document13 pages11/20/2018 /conversion/tmp/scratch/402494814Anonymous NR3qZ30No ratings yet

- Buttweld Fittings Accesorios SoldadosDocument5 pagesButtweld Fittings Accesorios SoldadosJuan CadenaNo ratings yet

- Why use Pipe Supports: Types of Pipe Hangers and SupportsDocument25 pagesWhy use Pipe Supports: Types of Pipe Hangers and SupportsmurugesanNo ratings yet

- Presentation On: Internal Attachments - ABSORBERDocument14 pagesPresentation On: Internal Attachments - ABSORBERmuraliNo ratings yet

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Piping Engineering Course OverviewDocument2 pagesPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Distillation Column Nozzle Location Guidelines PDFDocument21 pagesDistillation Column Nozzle Location Guidelines PDFShyam MurugesanNo ratings yet

- Basics of Piping Engineering - Online Certificate CourseDocument2 pagesBasics of Piping Engineering - Online Certificate CourseSharjeel Aslam FaizNo ratings yet

- Piping Interview QuestionnaireDocument26 pagesPiping Interview QuestionnaireSARA VijayNo ratings yet

- Project Standard Specification: Hydronic Piping 15181 - Page 1/12Document12 pagesProject Standard Specification: Hydronic Piping 15181 - Page 1/12adel rihanaNo ratings yet

- Piping IsometricDocument4 pagesPiping IsometricShyam MurugesanNo ratings yet

- Piping Overview 01Document18 pagesPiping Overview 01Rajkumar ANo ratings yet

- GE Weldstar PDFDocument4 pagesGE Weldstar PDFJamesNo ratings yet

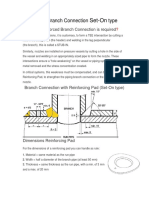

- Reinforced Branch Connection Set-On TypeDocument3 pagesReinforced Branch Connection Set-On Typeedgar paglinawanNo ratings yet

- Mechanical Engineering Drawing: SR KaleDocument22 pagesMechanical Engineering Drawing: SR KaleAdnan RanaNo ratings yet

- Piping Design Training - Piping Codes and Standards - OilandgasclubDocument4 pagesPiping Design Training - Piping Codes and Standards - Oilandgasclubchandramohan murugan100% (2)

- Ipebs 31 CourseDocument9 pagesIpebs 31 Coursevenky2hemaNo ratings yet

- Piping IsometricDocument19 pagesPiping IsometricdeepakNo ratings yet

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- WPS SummaryDocument33 pagesWPS SummaryMidhun K ChandraboseNo ratings yet

- PIPING CODES AND STANDARDS GUIDEDocument299 pagesPIPING CODES AND STANDARDS GUIDENaresh Sharma0% (1)

- Piping ClassDocument2 pagesPiping ClassDylan RamasamyNo ratings yet

- Pipe ThicknessDocument33 pagesPipe ThicknessMukesh GuptaNo ratings yet

- Piping QA Quiz Answers for Fluor Daniel ProjectsDocument13 pagesPiping QA Quiz Answers for Fluor Daniel Projectssairam2234100% (1)

- Codes and Standards: ASME B31 Piping CodesDocument44 pagesCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNo ratings yet

- Welding Electrodes - Understanding The SMAW Electrode SymbolsDocument5 pagesWelding Electrodes - Understanding The SMAW Electrode SymbolsRobert DelafosseNo ratings yet

- PipingDocument4 pagesPipingzidaaanNo ratings yet

- Piping Stress 123Document8 pagesPiping Stress 123Arun NambiarNo ratings yet

- Piping - WikipediaDocument6 pagesPiping - Wikipediaramthecharm_46098467No ratings yet

- Piping: For Other Uses, See,, Bagpiping, Or, orDocument4 pagesPiping: For Other Uses, See,, Bagpiping, Or, orHarlon BartolomeNo ratings yet

- MSDS ScaleChem SI-7022Document5 pagesMSDS ScaleChem SI-7022Muaz Haziq MusaNo ratings yet

- Soundsafe Safety Data Sheet EnglishDocument5 pagesSoundsafe Safety Data Sheet Englishard127No ratings yet

- MSRR 6011Document14 pagesMSRR 6011pradellesNo ratings yet

- BC34.1 E9 Determination of Acid Value of FatsDocument3 pagesBC34.1 E9 Determination of Acid Value of FatsGlenn Vincent Tumimbang96% (26)

- IB Chemistry HL Summer AssignmentDocument4 pagesIB Chemistry HL Summer AssignmentVal B100% (1)

- Determination of HHV of Diesel FuelDocument7 pagesDetermination of HHV of Diesel FuelAdrian Soriaga LontocNo ratings yet

- OH&S Workplace Assessment ChecklistDocument9 pagesOH&S Workplace Assessment ChecklistAldrin ZlmdNo ratings yet

- Sensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Document7 pagesSensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Bagas Aryo SasongkoNo ratings yet

- Uniz Resin Spec PDFDocument11 pagesUniz Resin Spec PDFYerayNo ratings yet

- 1097 2301 Univar E Detergents Nordic Brochure 4Document12 pages1097 2301 Univar E Detergents Nordic Brochure 4troity100% (2)

- Cooling Towers: Key Design Factors and Operation PrinciplesDocument8 pagesCooling Towers: Key Design Factors and Operation PrinciplesMade PutraNo ratings yet

- Msds FFFP 3% UlDocument4 pagesMsds FFFP 3% UlOtto JamesNo ratings yet

- Chemical CarcinogenesisDocument24 pagesChemical CarcinogenesisKavitha S DineshNo ratings yet

- Zak SystemDocument10 pagesZak SystemSlavisa BjelicNo ratings yet

- Partial replacement of discarded rubber tyres with coarse aggregate in concreteDocument18 pagesPartial replacement of discarded rubber tyres with coarse aggregate in concretePrasanna Gayathri VinnakotaNo ratings yet

- ACROLEIN MSDSDocument6 pagesACROLEIN MSDSzaedmohd50% (2)

- Laboratory Corrosion Testing PDFDocument7 pagesLaboratory Corrosion Testing PDFeid elsayedNo ratings yet

- Peto MSDSDocument4 pagesPeto MSDSMenoddin shaikhNo ratings yet

- IJCSEIERDFEB20174Document10 pagesIJCSEIERDFEB20174TJPRC PublicationsNo ratings yet

- Odi Servinort SpaDocument5 pagesOdi Servinort SpayanmuyNo ratings yet

- X-ray Absorption Spectroscopy TechniqueDocument74 pagesX-ray Absorption Spectroscopy TechniqueAnonymous hz3n3HK1RNNo ratings yet

- Chapter 14Document11 pagesChapter 14Marco LuigiNo ratings yet

- Composite Fish Culture PDFDocument2 pagesComposite Fish Culture PDFHanumant JagtapNo ratings yet

- Fisa Tehnica ROBODURDocument1 pageFisa Tehnica ROBODURdneprmt1No ratings yet

- CamberDocument33 pagesCamberIES-GATEWizNo ratings yet

- Introduction To Drug Discovery & Development: Dr. Humair Bin MD OmerDocument9 pagesIntroduction To Drug Discovery & Development: Dr. Humair Bin MD OmerMD. RASEL MAHMUD MIMNo ratings yet

- Lesson 18 - Pricelist of MedicinesDocument4 pagesLesson 18 - Pricelist of MedicinesGrace RepolloNo ratings yet

- Essential Guide to Compressed Air SystemsDocument35 pagesEssential Guide to Compressed Air SystemsvmramakrishnanNo ratings yet

- Differential Thermal Analysis (Dta)Document21 pagesDifferential Thermal Analysis (Dta)Shaise Jacob100% (6)

- MATERIAL TAKE-OFF LIST FOR SAUDI ARABCO GAS PROJECTDocument12 pagesMATERIAL TAKE-OFF LIST FOR SAUDI ARABCO GAS PROJECTrajum465No ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)