Professional Documents

Culture Documents

TTTTTTTTTTTTTTTTTTTTTTTTTTKUKU

Uploaded by

Juan Ramón RincónOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TTTTTTTTTTTTTTTTTTTTTTTTTTKUKU

Uploaded by

Juan Ramón RincónCopyright:

Available Formats

Fuel Processing Technology 88 (2007) 73 76 www.elsevier.

com/locate/fuproc

The influence of Cu, Fe, Ni, Pb and Zn on gum formation in the Brazilian automotive gasoline

Leonardo S.G. Teixeira a,, Jurema C. Souza a,b , Hilda C. dos Santos c , Luiz A.M. Pontes a , Paulo R.B. Guimares a , Eledir V. Sobrinho a , Regina F. Vianna d

a

Departamento de Engenharia e Arquitetura, Universidade Salvador, UNIFACS, Av. Cardeal da Silva 132, 40.220141, Salvador-BA, Brazil b Instituto de Qumica, Universidade Federal da Bahia, Campus Universitrio de Ondina, 40.170-280, Salvador-BA, Brazil c Servio Nacional de Aprendizagem Industrial, Centro de Tecnologia Industrial Pedro Ribeiro, Av. Lus Tarqunio Pontes 938, 42.700-000, Lauro de Freitas-BA, Brazil d Agncia Nacional do Petrleo, Gs Natural e Biocombustveis, Av. Tancredo Neves 450, Sala 1401, 41820-020, Salvador-BA, Brazil Received 2 May 2006; received in revised form 29 August 2006; accepted 30 August 2006

Abstract In this research work, the effect of different concentrations of copper, iron, lead, zinc and nickel ions on the tendency for gum formation in gasohol fuel is investigated. For that purpose, a gasohol sample has been doped with these five metals ions at concentration levels of 0.25, 1.0, 2.0 and 3.0 g ml 1. Washed gum content tests have been carried out using ASTM D 381 on samples stored for 7, 14, and 28 days. The results show that gum formation is strongly affected by Cu and Fe, with a much weaker effect from Ni and Zn, and an almost negligible effect from Pb. A variance analysis (ANOVA) of the experimental results shows that an increase in metal concentration strongly increases the rate of gum formation for all metal ions investigated, particularly Cu and Fe, while an increase in storage time has only a much weaker effect, being negligible for Zn. 2006 Elsevier B.V. All rights reserved.

Keywords: Metal ions; Gasoline; Gum; Variance analysis

1. Introduction Automotive gasoline is a complex mixture of olefinic, paraffinic, naphthenic and aromatic hydrocarbons, with a carbon content in the C4C12 range and boiling points between 30 C and 220 C, approximately, plus small amounts of sulfur, oxygen, and, to a lesser degree, nitrogen compounds [1,2]. The combination of these hydrocarbons with the oxygenate compounds present determines the physico-chemical properties of the fuel and has a great influence on engine performance. These combination effects are even greater for the gasoline used as automotive fuel in Brazil, that contains between 20% and 25% v/v of ethanol, being referred to as gasohol. Some classes of hydrocarbons, particularly olefins and diolefins, are able to slowly react, at ambient temperatures,

Corresponding author. Tel.: +55 71 32032594; fax: +55 71 32032712. E-mail address: leonardoteixeira@unifacs.br (L.S.G. Teixeira). 0378-3820/$ - see front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.fuproc.2006.08.008

with the oxygen in the air [3]. The oxidation of these hydrocarbons is responsible for the formation of an insoluble solid, commonly called deposits or gum, which sticks to the metal surfaces of internal combustion engines. Accumulation of these products can cause engine wear and can have adverse effects on engine efficiency, performance, and durability [46]. The washed gum content of a gasoline stands for the nonvolatile residue which will remain after evaporation of gasoline and it is one of the most important parameters for evaluation of its quality. Brazilian legislation regarding gasoline quality standards establishes that the maximum gum content should be 5.0 mg per 100 ml of gasoline [7]. Several factors contribute to accelerate gum formation, such as increases in temperature and storage time, as well as the presence of metal ions. Trace amounts of certain dissolved metals can promote fuel degradation by oxidation of organic compounds, that often leads to gum formation. Moreover, the presence of metallic species in automotive fuels is generally undesirable since it is associated with corrosion, metal

74

L.S.G. Teixeira et al. / Fuel Processing Technology 88 (2007) 7376

deposition on engine parts and poor fuel performance due to oxidative decomposition reactions [8,9]. In many countries, private and government programs have been established for the research and development of alternative, more ecologically friendly, fuels. Among these, ethanol is of increasing interest, both as an alternative fuel and/or an additive for gasoline. Brazil was the first country to attempt, and successfully implement, a large-scale program for the use of alcohol as an automotive fuel, either by the use of pure ethanol or ethanolgasoline blends gasohol, containing between 20 and 25% v/v of anhydrous ethanol [10,11]. Due to chemical differences between oil derived fuels and alcohols, corrosion problems are intrinsically more severe when alcohols are present in the fuel. Alcohols dissolve both water and inorganic salts and the water content of alcohol plays a significant role in metal corrosion when alcohol is used as fuel. Furthermore, the physical and chemical properties of alcohols influence corrosion [12]. Thus, metallic species may be introduced by corrosion of equipment during fuel production, processing and/or storage, promoting gum formation [13]. Other sources of metal contamination in gasoline may be the cracking process, fuel transportation, poor fuel storage conditions and fuel adulteration, as well as the use of ethanol as an octane booster additive. The influence of metal ions on gum formation in conventional gasoline, i.e. without the addition of ethanol, has been previously reported [14]. However, the large-scale use of gasohol and its contamination by metals, due to the presence of ethanol, has yet to be investigated with regard to the effect of the presence of different metals on gum formation. This research work intends to fill this gap by studying the effect of the presence of Zn, Fe, Ni, Pb and Cu with respect to metal ion concentration and fuel storage time.

2. Experimental 2.1. Procedure

The gum content of gasohol samples has been determined in accordance with ASTM D 381, Standard Test Method for Gum Content in Fuels by Jet Evaporation [15] using an evaporation bath equipped with a flowmeter (Walter Herzog GmbH, Lauda-Knigshofen). In this procedure, 50 ml of the sample is evaporated for 30.0 0.5 min under controlled conditions of temperature (160 165 C) and flow of filtered air at a pressure no higher than 35 kPa. The residue is weighed after extraction with n-heptane (99.7% minimum purity) and the results are reported as milligrams per 100 ml. This residue is called washed gum content.

2.2. Reagents and samples

All reagents used were of analytical grade. Methanol (99.8% min.) was used to prepare the metal solutions. These (1000 g ml 1 each) were prepared by accurately weighing copper, iron, zinc, nickel and lead nitrates (Merck) followed by dilution with methanol. These solutions were used to spike gasohol. A gasohol sample, previously analysed and found to be in accordance with Brazilian regulations, was used for doping with each of the five metals at concentration levels of 0.25, 1.0, 2.0 and 3.0 g ml 1. The tests were carried out by keeping 300 ml of each sample at 25 C for up to 28 days and measurement of the washed gum content, by evaporation in accordance with ASTM D 381, after 7, 14, and 28 days of sample storage. All the experiments were done in quadruplicate.

3. Results and discussion Metal ions, particularly those from transition metals (copper, nickel, lead, etc.), can have a profound effect on the rate of hydrocarbon oxidation [16]. Since, as previously shown by the work of de Campos et al. [17], Cu, Fe, Pb and Ni are frequently found in the gasohol fuel used in Brazil, and these metal ions,

Table 1 Washed gum content for uncontaminated and doped gasohol samples at different levels of metal contamination, and several storage periods (n = 4) Storage period Washed gum content (mg per 100 ml of gasohol) Uncontaminated sample 3.0 0.5 Sample doped with Cu Fe Ni Pb Zn Cu Fe Ni Pb Zn Cu Fe Ni Pb Zn Cu Fe Ni Pb Zn Contamination level, g ml 1 0.25 4.5 0.5 3.5 0.5 3.0 1.0 3.0 0.5 4.5 1.5 4.5 1.0 4.0 1.0 3.5 0.5 3.0 0.5 4.5 1.0 4.5 0.5 4.5 1.0 4.0 1.0 3.5 0.5 4.5 0.5 7.0 0.5 5.0 1.0 4.5 0.5 4.5 0.5 4.5 0.5 1.0 7.5 0.5 4.5 0.5 4.0 0.5 2.5 0.5 3.5 0.5 9.5 1.0 5.5 1.0 4.0 1.0 3.5 0.5 4.0 1.0 10.5 1.0 6.0 1.0 4.5 0.5 4.0 0.5 4.0 0.5 21.0 0.5 7.0 0.5 4.5 0.5 4.5 1.0 4.5 1.0 2.0 11.5 1.5 7.5 1.5 5.0 0.5 3.0 1.0 5.0 1.0 14.5 1.0 7.5 1.0 5.0 0.5 4.5 0.5 4.5 0.5 15.5 0.5 7.5 1.0 5.5 0.5 4.5 0.5 4.5 0.5 25.0 2.5 9.0 1.5 6.5 0.5 5.0 0.5 5.0 1.5 3.0 17.5 1.5 14.0 2.0 6.5 1.5 3.5 0.5 7.5 1.5 27.5 2.5 11.5 1.5 5.5 1.0 4.5 0.5 7.0 1.0 30.5 2.5 13.5 2.0 9.0 1.5 5.0 1.0 7.5 0.5 31.5 2.5 14.5 1.0 10.0 1.0 5.0 0.5 7.5 1.0

7 days

14 days

3.5 0.5

21 days

3.5 0.5

28 days

4.0 0.5

L.S.G. Teixeira et al. / Fuel Processing Technology 88 (2007) 7376 Table 2 P-values obtained after applying ANOVA to washed gum contents Factor Copper Storage time Concentration 0.0077935 4.641 10 5 Iron 0.0240791 7.854 10 8 Metal studied Nickel 0.0329375 0.0003996 Lead 0.0001748 0.0038743 Zinc

75

0.3076462 1.052 10 7

plus Zn, were selected for use in this research work. Since the purpose of this research work has been to study fuel deterioration at adverse storage conditions and in order to account for a wide range of contamination, gasohol was doped with 0.25, 1.0, 2.0 and 3.0 g ml 1 of each of the selected metals. Automotive fuel is usually consumed shortly after production, in most cases within a week or two of purchase. However, there are occasions when fuel is kept for a longer period, such as when stored for usage on small-engine equipment or as a backup supply. In order to evaluate the effect of storage time on gum formation, a period of 4 weeks was selected for this study, and the washed gum content of the samples determined at the end of each week. The washed gum contents obtained for an uncontaminated and all doped gasohol samples after 7, 14, 21 and 28 days of storage are shown in Table 1. These indicate that, in the case of Cu and Fe, there is a marked increase in gum formation as the level of contamination increases. For the other metals studied (Ni, Pb and Zn) this effect depends on the level of contamination, being negligible up to 1.0 g ml 1 and very slight between 2.0 and 3.0 g ml 1. It also shows that for Ni, Pb and Zn, contaminations of up to 1.0 g ml 1 will not take the washed gum content over the limit set by Brazilian gasohol quality regulations, whereas the presence of 1.0 g ml 1 of Cu is enough to exceed that limit, by raising the washed gum content to a value of 7.5 g ml 1 after just 7 days of storage time. With regard to storage time, the results show that it increases gum formation for contaminations by Cu, Fe, Ni and Pb, being negligible for Zn. Moreover, for higher contamination levels of Fe and Ni time tends to be more important after 3 weeks of sample storage, while for Cu and Pb the effect of storage time is greater between 1 and 2 weeks of sample storage. In order to establish the significance of the effects of the level of metal contamination and of storage time on gum formation for each of the metals studied, a variance analysis (ANOVA) has been carried out. This analysis involved the evaluation of the P-value significance levels, which represents the probability of the effect of a factor being due solely to random error. Thus, if the P-value is less than 5%, the effect of the corresponding factor is significant [18]. In this research work, ANOVA has been applied to the data shown in Table 1 and the results obtained are shown in Table 2. These indicate that, for all metals studied, the contamination level is a major factor on the rate of gum formation. As previously observed this significance is much greater for Cu, Fe and Zn, than for Ni and Pb. ANOVA also shows that storage time is a factor much less significant than the metal contamination level. Nevertheless, it is more significant

for Cu and Pb than for the other metals studied, particularly Zn, for which it is a negligible factor. 4. Conclusions This research work has been aimed at giving some insight on the influence of different metals (zinc, nickel, copper, lead and iron) on gum formation in gasohol, with regard to metal contamination level and gasohol storage time. Results have shown that copper and iron, metals frequently present in the structure of piping, transportation vehicles and storage tanks, strongly increase the rate of gum formation, for any storage time, this influence increasing with the level of metal contamination. Nickel and zinc, on the other hand, exert a weaker influence on the rate of gum formation, the effect of zinc being independent of storage time, while the effect of lead is almost negligible. Acknowledgments The authors wish to acknowledge the financial support received from CNPq, FINEP/CTPETRO, Petrobras and FAPESB. References

[1] F.S. de Oliveira, L.S.G. Teixeira, M.C.U. Arajo, M. Korn, Screening analysis to detect adulterations in Brazilian gasoline samples using distillation curves, Fuel 83 (2004) 917923. [2] A. Zanier, Thermal-oxidative stability of motor gasolines by pressure d.s.c., Fuel 77 (1998) 865870. [3] J.M. Nagpal, G.C. Joshi, S.N. Rastogi, Stability of cracked naphthas from thermal and catalytic processes and their additive response. Part I. Evaluation of stability and additive response, Fuel 74 (1995) 714719. [4] S.P. Heneghan, S. Zabarnick, Oxidation of jet fuels and the formation of deposit, Fuel 73 (1994) 3543. [5] E.G. Jones, L.M. Balster, Impact of additives on the autoxidation of a thermally stable aviation fuel, Energy Fuels 11 (1997) 610614. [6] S.I. Tseregounis, J.A. Spearot, D.J. Kitet, Formation of deposits from thin films of mineral oil base stocks on cast iron, Ind. Eng. Chem. Res. 26 (1987) 886894. [7] BRASIL, Portaria no 197, de 28 de dezembro de 1999. Establishes the minimum specifications to be observed for commercialization of automotive gasolines in whole Brazilian territory and it defines responsibilities of several agents of network logistics. [8] G.E. Collins, R.E. Morris, J.F. Wei, M. Smith, M.H. Hammond, V. Michelet, J.D. Winkler, P.M. Serino, Y. Guo, Spectrophotometric detection of trace copper levels in jet fuel, Energy Fuels 16 (2002) 10541058. [9] Q. Lu, J.F. Wei, G.E. Collins, R.E. Morris, P.M. Serino, Y. Guo, Rapid determination of dissolved copper in jet fuels using bathocuproine, Energy Fuels 17 (2003) 699704. [10] L.S.G. Teixeira, M.A. Bezerra, V.A. Lemos, H.C. dos Santos, D.S. de Jesus, A.C.S. Costa, Determination of copper, iron, nickel and zinc in

76

L.S.G. Teixeira et al. / Fuel Processing Technology 88 (2007) 7376 ethanol fuel by flame atomic absorption spectrometry using on-line preconcentration system, Sep. Sci. Technol. 40 (2005) 25552565. L.S.G. Teixeira, E.S. Leo, A.F. Dantas, H.L.C. Pinheiro, A.C.S. Costa, J.B. de Andrade, Determination of formaldehyde in Brazilian alcohol fuels by flow-injection solid phase spectrophotometry, Talanta 64 (2004) 711715. U. Lechner-knoblauch, E. Heitz, Corrosion of zinc, copper and iron in contaminated non-aqueous alcohols, Electrochim. Acta 32 (1987) 901907. T. Saint'Pierre, R.Q. Aucelio, A.J. Curtius, Trace elemental determination in alcohol automotive fuel by electrothermal atomic absorption spectrometry, Microchem. J. 75 (2003) 5967. E.L. Walters, H.B. Minor, D.L. Yabroff, Chemistry of gum formation in cracked gasoline, Ind. Eng. Chem. 41 (1949) 17231729. [15] ASTM D381, Standard Test Method for Gum Content in Fuels by Jet Evaporation, American Society for Testing and Materials, Washington, DC, 1999. [16] J.A. Waynick, The development and use of metal deactivators in the petroleum industry: a review, Energy Fuels 15 (2001) 13251340. [17] R.C. de Campos, H.R. dos Santos, P. Grinberg, Determination of copper, iron, lead and nickel in gasoline by electrothermal atomic absorption spectrometry using three component solutions, Spectrochim. Acta Part B 57 (2002) 1528. [18] M. Zougagh, A. Garca de Torres, E. Vereda Alonso, J.M. Cano Pavn, Automatic on line preconcentration and determination of lead in water by ICP-AES using a TS-microcolumn, Talanta 62 (2004) 503510.

[11]

[12]

[13]

[14]

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Cynosure Starlux 500 Palomar Technical Service ManualDocument47 pagesCynosure Starlux 500 Palomar Technical Service ManualJF SilvaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Reviews: The Global Epidemiology of HypertensionDocument15 pagesReviews: The Global Epidemiology of Hypertensionrifa iNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Naming Hydrocarbons Worksheet1 Key 12 26 08 PDFDocument2 pagesNaming Hydrocarbons Worksheet1 Key 12 26 08 PDFMarilyn Castro Laquindanum100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chapter 3.c (Centroid by Intergration)Document15 pagesChapter 3.c (Centroid by Intergration)Ariff AziziNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Lecture 12Document8 pagesLecture 12Mechanical ZombieNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Immigrant Italian Stone CarversDocument56 pagesImmigrant Italian Stone Carversglis7100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

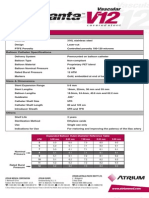

- Advanta V12 Data SheetDocument2 pagesAdvanta V12 Data SheetJuliana MiyagiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Port Name: Port of BaltimoreDocument17 pagesPort Name: Port of Baltimoremohd1khairul1anuarNo ratings yet

- Flight Vehicle Design:: Example 2 (Uav)Document43 pagesFlight Vehicle Design:: Example 2 (Uav)Anmol KumarNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Presentation - Delight Bulb PDFDocument22 pagesPresentation - Delight Bulb PDFShiva KishoreNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Napoleonic WargamingDocument13 pagesNapoleonic WargamingandyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Owner'S Manual: 2023 Chassis CabDocument444 pagesOwner'S Manual: 2023 Chassis CabDmitry DimasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Top Ten Myths About The BrainDocument5 pagesTop Ten Myths About The BrainfayazalamaligNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Lesson Plan in Science 9: I. ObjectivesDocument8 pagesLesson Plan in Science 9: I. ObjectivesmarichuNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Table Equivalent Schedule 40 Steel PipeDocument1 pageTable Equivalent Schedule 40 Steel PipeorisNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Dusta ManaDocument16 pagesDusta ManamahaphalaNo ratings yet

- Fulltext 4 PDFDocument4 pagesFulltext 4 PDFSubhadip Banerjee0% (1)

- Drilling & GroutingDocument18 pagesDrilling & GroutingSantosh Laxman PatilNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Rekomendasi AnimeDocument11 pagesRekomendasi Animeosvaldo manurungNo ratings yet

- Parts Catalogue of Foton: (TC2A504-034K)Document132 pagesParts Catalogue of Foton: (TC2A504-034K)МаксимNo ratings yet

- Poly 103Document20 pagesPoly 103Sharifah Zulaikha BenYahyaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- SambongDocument3 pagesSambongNica Del GallegoNo ratings yet

- Module 4 Active Faults and Other Earthquake Sources: Learning OutcomeDocument3 pagesModule 4 Active Faults and Other Earthquake Sources: Learning OutcomeFatima Ybanez Mahilum-LimbagaNo ratings yet

- Innerwear Industry Pitch PresentationDocument19 pagesInnerwear Industry Pitch PresentationRupeshKumarNo ratings yet

- Study The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaDocument4 pagesStudy The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaJournal of Nutritional Science and Healthy DietNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Gamak MotorDocument34 pagesGamak MotorCengiz Sezer100% (1)

- Fig. 4 Phasor Diagram of P.TDocument31 pagesFig. 4 Phasor Diagram of P.Tdon aNo ratings yet

- Sustainable Events Guide May 30 2012 FINAL PDFDocument118 pagesSustainable Events Guide May 30 2012 FINAL PDFInter 4DMNo ratings yet

- Eldritch HighDocument39 pagesEldritch Highteam_moNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)