Professional Documents

Culture Documents

Evaluating FFU Placement and Cleanroom Lighting Options

Uploaded by

Thanh NhatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluating FFU Placement and Cleanroom Lighting Options

Uploaded by

Thanh NhatCopyright:

Available Formats

Calculating Clean Room Cleanliness: How Many FFUs and Lights?

This tutorial provides practical tips for correlating the desired cleanliness level (per Fed Std 209 and ISO standards) to the required number of FFUs. Also provides guidelines for specifying lights based on the type of operations being conducted.

Cleanroom Gowning Room Design Recommendations

Terra Universal will certify its cleanrooms to guarantee as built compliance with cleanliness standards. What matters, though, is how the cleanroom performs in real world applicationsin your application, with your personnel and processing equipment. Careful consideration of these operating conditions will help you select the configuration that meets your requirements and fits your budget!

Cost vs. Coverage: Evaluating FFU Placement The cleanest modular cleanroom incorporates filter/fan units (FFUs) in every 2' x 4' ceiling bay. This near-100% ceiling coverage provides a laminar flow of filtered air to quickly remove contaminants from the cleanroom, meeting Federal Standard 209(E) for Class 10 or Class 1 environment (depending on the filter types selected, HEPA or ULPA). Of course , 100% ceiling coverage requires substantial investment in FFUs, especially if the cleanroom is very large. In most applications, adequate cleanliness can be achieved with substantially less filter coverage. How many modules you need depends on several operational variables.

Cleanliness Rating Most cleanroom facility engineers agree that Class 1 and Class 10 applications require near-100% ceiling coverage, producing a laminar flow of clean air traveling downward at a velocity of about 90 feet/minute (measured 12" below the filter face). This design ensures a positive pressure inside the cleanroom, which blocks the influx of contaminants through leaks in the cleanroom wall or curtain, and guarantees swift removal of particles generated by people or process equipment inside the enclosure.

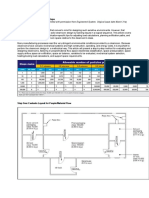

Table 1: Recommended Air Velocity Rates

Class Iso 146144-1 (Standard 209E) ISO 8 (Class 100,000) ISO 7 (Class 10,000) ISO 6 (Class 1,000) ISO 5 (Class 100) ISO 4 (Class 10) ISO 3 (Class 1) ISO 1-2 Average Airflow Velocity 0.005 - 0.041 m/sec (1 - 8 ft/min) 0.051 - 0.076 m/sec (10 - 15 ft/min) 0.127 - 0.203 m/sec (25 - 40 ft/min) 0.203 - 0.406 m/sec (40 - 80 ft/min) 0.254 - 0.457 m/sec (50 - 90 ft/min) 0.305 - 0.457 m/sec (60 - 90 ft/min) 0.305 - 0.508 m/sec (60 - 100 ft/min) Air Changes Per Hour 5 - 48 60 - 90 150 - 240 240 - 480 300 - 540 360 - 540 360 - 600

Note: Actual average velocity and air changes required may vary depending on the application and floor plan. Source: Institute of Environmental Science Table 2: Recommended Ceiling Filter Coverage

Class ISO 8 (Class 100,000) Ceiling Coverage 5 - 15%

Ventilation Efficiency For less critical contamination requirements, experts correlate ventilation efficiency (i.e., the ability to remove contaminants and meet a cleanliness standard) with both the velocity of filtered air passing through the room and also the number of air changes completed in a given time. The air-change figures are usually expressed as a range (see Table 1).

ISO 7 (Class 10,000) ISO 6 (Class 1,000) ISO 5 (Class 100) ISO 4 (Class 10) ISO 3 (Class 1) ISO 1-2

15 - 20% 25 - 40% 35 - 70% 50 - 90% 60 - 100%* 80 - 100%*

Note: Actual average velocity and air changes required may vary depending on the application and floor plan. * ULPA filters required in Class 1/10 applications. HEPA filters required for all others.

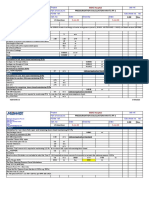

The breadth of these ranges reflects how dramatically people and processes affect cleanliness. Low-end figures within each contamination class generally indicate air velocity and air change requirements for an "as built" or "at rest" facilityone in which no people are present and no contaminating processes are under way. In the presence of higher degrees of contamination (resulting from many cleanroom workers or contaminating manufacturing processes), more air changes are required to maintain the desired cleanliness standard. In fact, many manufacturers insist on as many as 720 air changes per hour to meet Class 10 or cleaner requirements. Deciding on the appropriate velocity and air changes for your application generally requires careful evaluation of such factors as number of personnel, effectiveness of garbing protocol, frequency of access, and cleanliness of process equipment. Once you have established the required air change figure, you can calculate the number of FFUs required by using this formula: No. of FFUs = (Air Changes/Hour 60) x (Cubic ft. in room 650*) *CFM output of a loaded FFU Thus, to meet Class 100 standard using the low-end air change recommendation (240/hour) inside a 12' x 12' x 7' cleanroom, with 1008 cu. ft. of volume, requires 6 FFUs. To meet the same standard using the high-end air change recommendation (480/hour) requires 12 FFUs. Applying this formula to the remaining cleanliness classifications gives us guidelines for ceiling filter coverage (see Table 2).

Partitions: Creating "Clean Zones" to Optimize Performance and Economy Of course, not every square inch of cleanroom space is used the same way. Often, performance can be optimizedand costs reducedthrough the use of partitions to create multiple clean zones with varying degrees of cleanliness. As requirements change, partitions can be removed and filter modules added or rearranged as needed. Highest ceiling filter density can be reserved for areas with the cleanest requirements and the most particles generated. Areas with fewer people or less demanding particle requirements are configured more economically with fewer filters.

Your Best Approach? Thorough Evaluation and Careful Monitoring Because no simple formula is right for every application, Terra contamination specialists work with you to design an effective, economical cleanroom configuration and monitoring program. If requirements change, our modular design allows you to add filters, lighting, ionization, or additional floor spaceall at a fraction of the cost you'd face with other systems.

Typical Configurations Using Partitions

Zone 1: Zone 2: Zone 3: Most Particle Sensitive. Class 1 (ULPA) or (HEPA) 100% Filter Coverage Packaging Area. Class 100 50% Filter coverage Staging Area Class 1,000 30% Coverage

Note: These are typical, not guaranteed, contamination levels for each of the filter configurations depicted. Actual values are related to such variables as the number of garbed personnel present, their activity level, the cleanliness of outside air, and contaminants emanating from process equipment.

Cleanroom Lighting Terra offers three lighting modules. For applications that do not require 100% FFU ceiling coverage, 2' x 4' illuminators can be positioned in unused ceiling grids. For applications that require total or near-total FFU ceiling coverage, teardrop and flow-through lighting modules are available. Teardrop fluorescent lights mount to the ceiling grid below the FFU. Their aerodynamic design does not interfere with the laminar airflow. Each of these single-tube lights requires 6" of vertical clearance below the FFU filter face.

As an alternative to teardrop lights, you can select 2' x 4' flow-through lights, which are stacked below the FFU. Flow-through lights add 4 3/4" to the ceiling height but require no vertical clearance below the filter face, making them ideal for low-ceiling cleanrooms. Use these guidelines in selecting the appropriate number of lighting modules for your application: Light Level Viewing Requirements Dim Average Bright Large Part Sizes, High Contrast Foot-Candles 20 - 50

Small Part Sizes, Medium Contrast 100 - 200 Small Part Sizes, Low Contrast 200 - 500

You might also like

- Journalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachDocument3 pagesJournalize The Following Transactions in The Journal Page Below. Add Explanations For The Transactions and Leave A Space Between EachTurkan Amirova100% (1)

- Cleanroom Performance Testing Specifications - Bio-Medical PharmaceuticalDocument18 pagesCleanroom Performance Testing Specifications - Bio-Medical PharmaceuticalginnaNo ratings yet

- Cleanroom Design in 10 Easy StepsDocument8 pagesCleanroom Design in 10 Easy StepsPhạm Quang HuyNo ratings yet

- Cleanroom A Complete Guide - 2021 EditionFrom EverandCleanroom A Complete Guide - 2021 EditionRating: 5 out of 5 stars5/5 (2)

- RTG E-One - Manual de Manutenção 41300-41303 (EN)Document328 pagesRTG E-One - Manual de Manutenção 41300-41303 (EN)Conrado Soares100% (1)

- Cleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementDocument3 pagesCleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementdesignselvaNo ratings yet

- Cleanroom Air ChangeDocument2 pagesCleanroom Air ChangeFlu PlantNo ratings yet

- HVAC Design for CleanroomsDocument55 pagesHVAC Design for Cleanroomsdimiz77No ratings yet

- Clean Rooms 101Document11 pagesClean Rooms 101gordoninklNo ratings yet

- Ash Rae Clean Room Design Guide Content DraftDocument6 pagesAsh Rae Clean Room Design Guide Content DraftQuan TranNo ratings yet

- Microbiology Clean Room Design SpecificationDocument2 pagesMicrobiology Clean Room Design SpecificationMHNADNo ratings yet

- Airborne Particulate Cleanliness ClassesDocument4 pagesAirborne Particulate Cleanliness ClassesaKureishiNo ratings yet

- Clean Room PDFDocument62 pagesClean Room PDFMuhammad DanishNo ratings yet

- Introductory Sessions For The AC Design Guide, 2003 EditionDocument50 pagesIntroductory Sessions For The AC Design Guide, 2003 Editionener3333No ratings yet

- Comparison Table of Differential Pressure Rev02Document4 pagesComparison Table of Differential Pressure Rev02Arshavin Watashi WaNo ratings yet

- Cleanroom HVAC Design FundamentalsDocument39 pagesCleanroom HVAC Design FundamentalsAhmad Ramahi100% (3)

- Everything You Need to Know About CleanroomsDocument2 pagesEverything You Need to Know About CleanroomsMai Phuong Phan TranNo ratings yet

- Excel Clean Room TechnologiesDocument9 pagesExcel Clean Room Technologiesxlcleantech100% (2)

- HVAC in Hospital PDFDocument7 pagesHVAC in Hospital PDFMohammed Toema100% (1)

- CLEAN ROOM DESIGN - CASE STUDY Zbook - 2017Document30 pagesCLEAN ROOM DESIGN - CASE STUDY Zbook - 2017ton_bela4911100% (1)

- CLEAN ROOM PresentationDocument54 pagesCLEAN ROOM PresentationSanjay Gade100% (1)

- WHO Guidelines on HVAC Systems for Pharma FacilitiesDocument75 pagesWHO Guidelines on HVAC Systems for Pharma Facilitiesmarkieboy3650% (2)

- Treated Fresh Air Guidelines by BryairDocument13 pagesTreated Fresh Air Guidelines by BryairRajanNo ratings yet

- HVAC Design For Cleanroom FacilitiesDocument33 pagesHVAC Design For Cleanroom FacilitieslakshminarayananNo ratings yet

- Energy-efficient cleanrooms - reducing consumption through analysisDocument11 pagesEnergy-efficient cleanrooms - reducing consumption through analysisshamu081No ratings yet

- A Basic Design Guide For Clean Room ApplicationsDocument61 pagesA Basic Design Guide For Clean Room ApplicationsAlex Chin67% (3)

- Comparison of ASHRAE 52.1 and 52.2 PDFDocument5 pagesComparison of ASHRAE 52.1 and 52.2 PDFChi Kit PhoonNo ratings yet

- Clean Room Pressure ControlDocument26 pagesClean Room Pressure Control981048281867% (3)

- HVAC Design for Cleanroom Facilities CourseDocument55 pagesHVAC Design for Cleanroom Facilities CourseMadhu Gajulapalli100% (1)

- Clean RoomDocument5 pagesClean Roomsenthilarasu5100% (1)

- EU GMP Annex 1 - Sterile Medicinal Product - 2008Document16 pagesEU GMP Annex 1 - Sterile Medicinal Product - 2008tungquacert100% (1)

- Difficulties Testing HEPA Filters VolumetricallyDocument3 pagesDifficulties Testing HEPA Filters Volumetricallyzivko13No ratings yet

- Particle Counting and Environmental Monitoring in Pharma CleanroomsDocument93 pagesParticle Counting and Environmental Monitoring in Pharma Cleanroomsdavincicode888No ratings yet

- Lab ACH Rates Standards & Guidelines PDFDocument15 pagesLab ACH Rates Standards & Guidelines PDFGopinath GopiNo ratings yet

- Clean RoomDocument20 pagesClean RoomSuchitK100% (1)

- Clean Room TechnoDocument71 pagesClean Room TechnoAhmed MostafaNo ratings yet

- Cleanroom Design in 10 Easy StepsDocument5 pagesCleanroom Design in 10 Easy StepsWerner SchrammelNo ratings yet

- CTV PRC007M en - 09152015Document40 pagesCTV PRC007M en - 09152015razali131266100% (1)

- Staircase pressurization calculationDocument4 pagesStaircase pressurization calculationAbdul Sami100% (1)

- Hospital Pharmacy Assignment Submitted To: DR Zubair Malik Submitted By: Ansar Mushtaq (20) Topic of AssignmentDocument9 pagesHospital Pharmacy Assignment Submitted To: DR Zubair Malik Submitted By: Ansar Mushtaq (20) Topic of AssignmentAnsar MushtaqNo ratings yet

- Clean Rooms L Essentiel 3Document4 pagesClean Rooms L Essentiel 3Sweekar BorkarNo ratings yet

- HEPA Cleanroom Filter Testing PDFDocument4 pagesHEPA Cleanroom Filter Testing PDFprovaoralNo ratings yet

- Clean Room Protocols and DesignDocument54 pagesClean Room Protocols and DesignSaravanakumar Bagavthy100% (2)

- Cleanroom Design in 10 Easy StepsDocument10 pagesCleanroom Design in 10 Easy StepsNEDALNo ratings yet

- Introduction to Clean Room WebinarDocument91 pagesIntroduction to Clean Room WebinarPriyawan SukisnoNo ratings yet

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39No ratings yet

- Moisture Load CalculationDocument2 pagesMoisture Load CalculationNguyễn Anh TuấnNo ratings yet

- Principles and Practices of Contamination Control and CleanroomsFrom EverandPrinciples and Practices of Contamination Control and CleanroomsNo ratings yet

- Cleanroom Class Limits and Certification GuideDocument2 pagesCleanroom Class Limits and Certification GuideK'hng Beng HooiNo ratings yet

- D B I C: Clean Air Technology, Inc. Esigns, Uilds and Nstalls LeanroomsDocument2 pagesD B I C: Clean Air Technology, Inc. Esigns, Uilds and Nstalls LeanroomsRajeshNo ratings yet

- Clean RoomDocument23 pagesClean RoomHumaid Shaikh100% (1)

- Mcat v5 n15 020912132739Document56 pagesMcat v5 n15 020912132739civodulNo ratings yet

- The 4 Elements of Cleanroom Design, Certification and Maintenance Part 1Document36 pagesThe 4 Elements of Cleanroom Design, Certification and Maintenance Part 1designselvaNo ratings yet

- GMP For Bioprocess Industries: Dr. Huzairy Hassan School of Bioprocess Engineering, Unimap Semester 1 2018/2019Document42 pagesGMP For Bioprocess Industries: Dr. Huzairy Hassan School of Bioprocess Engineering, Unimap Semester 1 2018/2019Nasirah RadziNo ratings yet

- Articol Flux Laminar ESCODocument3 pagesArticol Flux Laminar ESCOAlin NicolaeNo ratings yet

- HVACDocument11 pagesHVACSumi BhowmickNo ratings yet

- Clean RoomDocument2 pagesClean RoomThanh NhatNo ratings yet

- Standards For Classification of Clean RoomsDocument8 pagesStandards For Classification of Clean Roomszvieizikovics50% (2)

- 3M 535 SpecificationDocument4 pages3M 535 SpecificationThanh NhatNo ratings yet

- GACP WHO (Vietnamese)Document104 pagesGACP WHO (Vietnamese)Thanh NhatNo ratings yet

- GMP Plant DesignDocument4 pagesGMP Plant DesignThanh NhatNo ratings yet

- Jounce Therapeutics Company Events and Start DatesDocument48 pagesJounce Therapeutics Company Events and Start DatesEquity NestNo ratings yet

- Growth Developt Pearl MilletDocument17 pagesGrowth Developt Pearl MilletdarmaNo ratings yet

- Material Handling EquipmentsDocument12 pagesMaterial Handling EquipmentsRahul SheelavantarNo ratings yet

- Apc 8x Install Config Guide - rn0 - LT - enDocument162 pagesApc 8x Install Config Guide - rn0 - LT - enOney Enrique Mendez MercadoNo ratings yet

- Physical Education Worksheet AssessmentsDocument3 pagesPhysical Education Worksheet AssessmentsMichaela Janne VegigaNo ratings yet

- Piping Material Classes GuideDocument98 pagesPiping Material Classes GuideLuis Pottozen VillanuevaNo ratings yet

- BCM Continuous ImprovementDocument22 pagesBCM Continuous ImprovementnikoNo ratings yet

- The Girls Center: 2023 Workout CalendarDocument17 pagesThe Girls Center: 2023 Workout Calendark4270621No ratings yet

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerNo ratings yet

- 01 - 01 - SK10 - JXNipponDocument1 page01 - 01 - SK10 - JXNipponredevils86No ratings yet

- RA8485 Animal Welfare Act (Carabao Slaughter)Document2 pagesRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- MR23002 D Part Submission Warrant PSWDocument1 pageMR23002 D Part Submission Warrant PSWRafik FafikNo ratings yet

- SVIMS-No Que-2Document1 pageSVIMS-No Que-2LikhithaReddy100% (1)

- XDocument266 pagesXTrần Thanh PhongNo ratings yet

- Đề cương ôn tập tiếng anh 9Document28 pagesĐề cương ôn tập tiếng anh 9Nguyễn HoaNo ratings yet

- Ensure Even Preload with Proper Tightening Tools and SequenceDocument2 pagesEnsure Even Preload with Proper Tightening Tools and SequenceMachineryengNo ratings yet

- Quality ImprovementDocument3 pagesQuality ImprovementViky SinghNo ratings yet

- BOF, LF & CasterDocument14 pagesBOF, LF & CastermaklesurrahmanNo ratings yet

- New930e-4se Ceam031503 930e4se Omm A31937 Up PDFDocument273 pagesNew930e-4se Ceam031503 930e4se Omm A31937 Up PDFSergelen SakhyabazarNo ratings yet

- English Financial Assistance ApplicationDocument4 pagesEnglish Financial Assistance ApplicationAlyssa JenningsNo ratings yet

- Indonesia Organic Farming 2011 - IndonesiaDOCDocument18 pagesIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarNo ratings yet

- Test Report OD63mm PN12.5 PE100Document6 pagesTest Report OD63mm PN12.5 PE100Im ChinithNo ratings yet

- Hinduism Today April May June 2015Document43 pagesHinduism Today April May June 2015jpmahadevNo ratings yet

- Elem. Reading PracticeDocument10 pagesElem. Reading PracticeElissa Janquil RussellNo ratings yet

- Pack Alimentacion Clin in Perin 14Document194 pagesPack Alimentacion Clin in Perin 14Paz BustosNo ratings yet

- Mabuhay Wedding Package2006Document3 pagesMabuhay Wedding Package2006Darwin Dionisio ClementeNo ratings yet

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 pagesInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESNo ratings yet

- Fuck Your LawnDocument86 pagesFuck Your Lawnhuneebee100% (1)