Professional Documents

Culture Documents

Bitsstuff

Uploaded by

scrbdgharaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bitsstuff

Uploaded by

scrbdgharaviCopyright:

Available Formats

IADC : Dull Bit Grading

Cutting structure

Inner Outer Dull Char Location Example of bit grading : 2, 4, BT, M, E, X, (CT,WO), DTF. Bearings seals Gauge Other dull char Reason pulled

5

Roller cone N- Nose row

6 4 - Location

7

Fixed cutter C - Cone N - Nose T - Taper

1 - Inner cutting structure (All inner rows.) 2 - Outer cutting structure ( Gauge rows only.)

In columns 1 and 2 a linear scale of 0 ---> 8 is used to describe the condition of the cutting structure according to the following guidelines for specific bit types.

G - Gauge row

S - Shoulder G - Guage A - All areas

Steel toothed bits

Measure of lost tooth height due to abrasion and / or damage

0 - No loss of tooth height 8 - Total loss of tooth

M - Middle row A - All Rows State cone # or #'s I.e. 1, 2, or 3.

Insert bits

Measures total cutting structure reduction of lost, worn, & or broken inserts 0 - No lost worn and / or broken inserts 8 - 0% of inserts and / or cutting structure remaining.

5 - Bearings and seals

Non sealed bearings

A linear scale estimating bearing life is used 0 = No life used ---> 8, 100% bearing life used

Fixed cutter bits

Measure of lost tooth height due to abrasion and / or damage 0 - No lost, worn and / or broken cutting structure 8 - 100% of cutting structure lost, worn and / or broken

Sealed bearings E - Seals effective F - Seals failed N - Not able to grade X - Fixed cutter bit

6 - Gauge

x - in gauge

1/16 - 1/16" out of gauge 1/8 - 1/8" ut of gauge 3/16-3/16" out of gauge

7/16 - 7/16" out of gauge etc.

3 - Dull characteristics

Note: use only cutting structure related codes

BC - Broken cone * BF - Bond failure BT - Broken teeth and cutters BU - Balled up bit CC - Cracked cone * CD - Cone dragged * CI - Cone interference CR - Cored CT - Chipped Teeth & cutters ER - Erosion FC - Flat crested wear HC - Heat checking LD - Junk damage LC - Lost cone * LN - Lost nozzle LT - Lost teeth and cutters OC - Off centre wear PB - Pinched bit PN- Plugged nozzle or flow by areas RG - Rounded gauge RO - Ring out SD - Shirttail damage SS - Shelf sharpening wear TR - Cone tracking WO - Wash out WT - Worn teeth or cutters NO - No dull characteristics

1/4 - 1/14" out of gauge 5/16 - 5/16" out of gauge 3/8 -3/8" out of gauge 1/2 - 1/2" out of gauge 9/16 - 9/16" out of gauge 5/8 - 5/8" out of gauge

7 - Other dull characteristics Refer to column 3 codes 8 - Reasons bit was pulled or run completed

BHA- Change bottom hole assembly DMF - Downhole motor failure DTF - Downhole tool failure DSF - Drill string failure DST - Drill stem test DP - Drill Plug CM - Condition mud CP - Core point FM - Formation change HP - Hole problems LIH - Left in hole HR - Hours on bit LOG - Run logs PP - Pump pressure PR - Penetration rate Rig - Rig repair TD - Total depth / casing depth TW - Twist off TQ - Torque WC - Weather conditions

* Show cone # or #'s under location 4

Kingdom drilling services Ltd. www.kingdomdrilling.co.uk

IADC classification : Rock bits

Series Formation types

1 2 3

3

4

Sealed roller bearing

5

Sealed bearing, gauge protected

6

Friction bearing

7

Sealed friction bearing, gauge protection

8

8

Standard Roller bearing roller bearing air cooled

Milled tooth bits.

1 Soft formations Low compressive strengths

1. Very soft shale 2. Soft shales 3. Medium soft shale / lime 4. Medium lime shale

2 3

Medium - Medium hard formations 1. & 2. Medium lime / shale High compressive strengths 3. Medium hard lime/sand/slate. Hard 1. Hard lime Semi-abrasive formations. 2. Hard lime/dolomite

3. Hard dolomite

TCI/Insert bits.

4 Soft formations Low compressive strengths

1. Very soft shale 2. Soft shales. 3. Medium soft shale / lime 4. Medium lime shale.

Soft - medium hard formations Low compressive strengths Medium - hard formations High compressive strengths Hard semi - abrasive and abrasive formations Extremely hard & abrasive & abrasive

1. Very soft shale / sand. 2. Soft shale / sand. 3. Medium soft shale / lime. 1. Medium lime / shale. 2. Medium hard lime / sand. 3. Medium hard lime/sand/slate 1. Hard lime / dolomite. 2. Hard sand /dolomite. 3. Hard dolomite. 1. Hard chert. 2. Very hard chert. 3. Hard granite.

Kingdom drilling services Ltd. www.kingdomdrilling.com

IADC classification : PDC bits

A

Bit body

"M" "S" "D" Matrix Steel Diamond 2 1

B

Formation type

Very soft

2 3 4

C

Cutting structure

PDC, 19mm PDC, 13mm PDC, 8mm PDC, 19mm PDC, 13mm PDC, 8mm PDC, 19mm PDC, 13mm PDC, 8mm PDC, 19mm PDC, 13mm PDC, 8mm 1 2 3 4

D

Bit profile.

Short fishtail Short profile Medium profile Long profile

Soft

2 3 4

Example

M 4 3 4 Matrix Medium PDC 13mm Long profile 4 3

Soft to medium 2

3 4

Medium

2 3 4

5 6

no code Medium hard

1 2 3 1 2 3 Natural diamond TSP Combination Natural diamond TSP Combination Impregnated diamond

Hard

Extremely hard 1 Natural diamond

4

Kingdom drilling services Ltd www.kingdomdrilling.co.uk

The 4th Character IADC code.

Manufacturer

Feature and 4th Character A B C D E G H J L M S T w X Y Z

Air application (journal bearing with air nozzles) Special bearing bit Centre jet Deviation control Extended jets (full length) Extra gauge / body protection Horizontal / Steering Application Jet deflection Lug pads Motor application Standard steel tooth model Two cone Enhanced cutting structure Predominantly chisel toothed inserts Predominantly conical inserts Other shaped inserts * Prefix, usually precedes bit number, others are suffices. ** Special HDS seal available as standard feature. 2* D CF C* A

Security / DBS

A Standard ** J4 D* E G*, M*, D, SS* Hx*, SS*, MM* JD L SS*, MM*, M*

Hughes

A ATM* C* T* M*, D, G

Reed

Smith

A

JC JX JK M* JD

C A1 E G, L, D, OD M* BH* L M* A1 D

P* MAX* TC* D

JL M*

Kingdom drilling services Ltd. www.kingdomdrilling.co.uk

Total flow area (TFA) of Standard nozzles (ins2)

Number of nozzles

Nozzle size 7/32 3/8 9/32 5/16 11/32 3/8 13/32 7/16 15/32 1/2 17/32 9/16 19/32 5/8 21/32 11/16 23/32 3/4

1 0.038 0.110 0.062 0.077 0.093 0.110 0.130 0.150 0.173 0.196 0.222 0.249 0.277 0.307 0.338 0.371 0.406 0.442 2 0.075 0.221 0.124 0.153 0.186 0.221 0.259 0.301 0.345 0.393 0.443 0.497 0.554 0.614 0.676 0.742 0.811 0.884 3 0.113 0.331 0.186 0.230 0.278 0.331 0.389 0.451 0.518 0.589 0.665 0.746 0.831 0.920 1.015 1.114 1.217 1.325 4 0.150 0.442 0.249 0.307 0.371 0.442 0.518 0.601 0.690 0.785 0.887 0.994 1.108 1.227 1.353 1.485 1.623 1.767 5 0.188 0.552 0.311 0.383 0.464 0.552 0.648 0.752 0.863 0.982 1.108 1.243 1.384 1.534 1.691 1.856 2.029 2.209 6 0.225 0.663 0.373 0.460 0.557 0.663 0.778 0.902 1.035 1.178 1.330 1.491 1.661 1.841 2.029 2.227 2.434 2.651 7 0.263 0.773 0.435 0.537 0.650 0.773 0.907 1.052 1.208 1.374 1.552 1.740 1.938 2.148 2.368 2.599 2.840 3.093 8 0.301 0.884 0.497 0.614 0.742 0.884 1.037 1.203 1.381 1.571 1.773 1.988 2.215 2.454 2.706 2.970 3.246 3.534 9 0.338 0.994 0.559 0.690 0.835 0.994 1.167 1.353 1.553 1.767 1.995 2.237 2.492 2.761 3.044 3.341 3.652 3.976

Kingdom rilling Services Ltd. www.kingdomdrilling.com

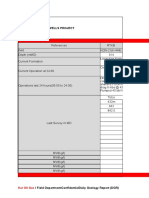

Bit calculations

Insert values to view blue results.

Bit cost () Rig cost (/hr) Trip time (hrs) In hole time (hrs) Footage drilled (ft) 23,000 4,000.00 Mud weight (ppg) Flow rate (gpm) 11 ppg 950 GPM 0.81 sq in 12.25 ins

2 18.0 hrs Total flow area (in ) 200.0 hrs Hole size (inches)

3560 ft

Hole area Bit pressure drop

118 sq in 1129 psi 626 hp 375 ft/sec 5.3 HSI

Cost per foot

251.4 /ft

Bit Hydraulic horse power Jet velocity Hydraulic horse power per square inch Rules of thumb

Water based muds: aim for 4-8 HSI, jet velocities 350-550ft/sec Oil based muds: 3-6 HSI, jet velocities 250-450ft/sec >17 1/2" holes : minimum jet velocities must be attained <17 1/2" hole : 35-50% HHP @ bit. (consider formations to be drilled.) <12 1/4" hole more HSI, up to 65% at bit. (dependant upon formations to be drilled.) 12 1/4" directional hole 800gpm min, 1100gpm max 8 1/2" directional hole 450 - 650gpm.

Kingdom drilling Services Ltd. www.kingdomdrilling.co.uk

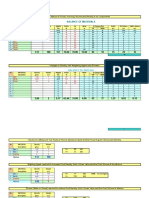

Drill off test

Weight on bit optimisation

Bit weight (Klbs)

50 Klbs 45 Klbs 40 Klbs 35 Klbs 30 Klbs 50 Klbs

Rotary optimisation

Rate of penetration (ft/hr)

36 ft/hr 29 ft/hr 27 ft/hr 22 ft/hr 22 ft/hr 35 ft/hr

Time to drilloff 10K (seconds)

60 secs 68 secs 73 secs 75 secs 82 secs 62 secs

Footage drilled (ft)

0.6 ft 0.6 ft 0.6 ft 0.5 ft 0.5 ft 0.6 ft

RPM

140 RPM 130 RPM 120 RPM 110 RPM 100 RPM 140 RPM

Time to drill 1ft (seconds)

120 secs 110 secs 100 secs 108 secs 118 secs 124 secs

Rate of penetration (ft/hr)

30 ft/hr 33 ft/hr 36 ft/hr 33 ft/hr 31 ft/hr 29 ft/hr

Drill off test (WOB)

40 ft/hr 90 secs

Drill off test (RPM)

82 secs Rate of penetration 80 secs

36 ft/hr

Rate of penetration

35 ft/hr 33 ft/hr 33 ft/hr

75 secs 73 secs 70 secs 68 secs

30 ft/hr

31 ft/hr 30 ft/hr 29 ft/hr

62 secs 60 secs 30 Klbs 40 Klbs Weight on bit 60 secs 50 Klbs 25 ft/hr 100 RPM 120 RPM 140 RPM

RPM

Kingdomdrilling services Ltd www.kingdomdrilling.co.uk

Bit API Reg. Pin Make up *ft/lbs

O. D. (in) 3-3/4 - 4-1/2 4-5/8 - 5 5-1/8 - 7-3/8 7-5/8 - 9 9-1/2 - 14-1/2 Over 14-1/2 Pin connection, size&type 2 3/8 reg 2 7/8 reg 3 1/2 reg 4 1/2 reg 6 5/8 reg 7 5/8 reg Torque (ftlbs) 3500 ftlbs 7000 ftlbs 9000 ftlbs 16000 ftlbs 32000 ftlbs 40000 ftlbs

API Roller cone bit tolerances..

Bit size : 5 5/8" - 13 3/4" 14" - 17 1/2 " 17 5/8" and larger Nominal ( in inches ) + 1 / 32" minus 0 + 1 / 16" minus 0 + 3 / 32 " minus 0

API Diamond Bit Tolerances - PDC, Natural Diamond, TSP

Nominal Bit Size O.D. (ins) 6-3/4 and Smaller 6-25/32 to 9, Incl. 9-1/32 to 13-3/4, Incl. 13-25/32 to 17-1/2, Incl. O.D. Tolerance (inches) +0, - 0.015 +0, - 0.020 +0, - 0.030 +0, - 0.045

Recommended drilling parameters, PDC bits. Bit size(inches)

5 7/8 6 6 6 7 7/8 8 8 9 7/8 10 5/8 12

Rotary (RPM)

100 - 140 100 - 140 100 - 140 100 - 140 80 - 120 80 - 120 80 - 120 60 - 120 60 - 120 60 - 100

Weight on bit (Klbs)

15 - 40 15 - 40 15 - 40 15 - 40 15 - 40 15 - 40 15 - 40 15 - 40 15 - 40 15 - 40

Flow rate (GPM)

160 - 260 160 - 280 220 - 350 250 - 350 300 - 400 300 - 500 350 - 550 400 - 650 600 - 800 650 - 950

Recommended flow rates for diamond bits. Bit size(inches)

6" Type

MD34 MD31 MD33

Stone Size

2 3 4 1 4-Mar 6 carat 1 2 4-Feb 1 carat

Exp.

n/a n/a n/a 0.05 0.04 0.03 0.45 (appr) 0.5 0.045 0.045 0.06

Flow rate (GPM)

180 180 180 380 380 380 380 700 700 700 500 - 700

8 "

MD34 MD31 MD33 MD70

12 "

MD34 MD31 MD33 MD 197

Kingdom drilling services Ltd www.kingdomdrilling.co.uk

Bit record / hydraulics details.

Field : Well No : Well type : Bit details

No Size 26.00 Mfgr

REED

Rig :

Mud Pump : Oilwell 12-P-160 Liner size : 5 1/2" Pressure rating : 4500 psi.

Depth Feet made 259 Total Hrs 12.5 Rot Hrs 5.5 ROP feet 47

Spud Date & time : TD date and time : Days spent on well to TD :

RT to Seabed = Total (In hole) Hrs = Total rotating Hrs =

379.0

feet.

106 70

Comments

O NO R TD 6 x cutters on 36" hole opener, reamed hole due to angle. Drill cement. Riserless, tertiary, reaming hole due to angle. Last 2.5 hrs on bit <100 ft/hr formation transition. Limestone/Chert, (90% in some samples ) Tertiary Limestone ( TOR, HOD etc. & Claystone.) Add 4.5hrs drilling cmt plugs etc.

Bit hydraulics

Ser No

JE2828

Parameters (Average)

WOB

6

Mud details

Type

SW

IADC Bit Grade

I 1 O 1 D NO L B G A E I

Type

Y11

Jets 32'nds 20 20 20 20

TFA 1.2

HSI

ft/sec

Out 638

RPM

60/90

TQ

4/12

GPM

1200

PSI

800

Wt 8.6

Vis PV YP ~ ~ ~

1 rr3

0.7

312

2 3 rr2 4 5 6 7

26.00

REED

Y12

JE2828

20

20

20

20

1.2

0.8

286

638

0.5

5/15

60/90

4/6

1100

800

SW

8.6

NO

A E I

NO

TD

17.50

Smith

MSHOD

CER4749

20

20

18

18

1.1

1.7

294

2550

1912

20

12.6

152

5/15

130

2/6

1020

2000

SW

8.6

No

A E I

NO BT WT BT

TD

12.25

DBS

QP19M

5940299

13

0.9

4.3

306

5761

3211

29

16.9

190

25/55

50/110

2/6

871

3650

WBM

11.8

46

27 23

LT

CN X I

FM

12.25

Reed

EHP 51HDL

5940299

18

18

18

0.7

6.4

374

6148

387

16

14.3

27

35/50

120

2/6

871

3650

WBM

11.8

46

27 26

LT

G12 1/16"

PR

12.25

BBits

BB657

BB404413

2x

12

4x

14

0.8

5.1

336

7070

922

23

19.0

49

15/35

140/170

4/18

860

3600

WBM

11.8

46

28 24

No

A X I

No

TD

8.50

Bbits

BB657

405424RR

12

0.7

3.7

242

7085

15

1.0

15

7580

170

2/6

500

3900

OBM

13.5

70

40 20

Kingdom drilling services Ltd. www.kingdomdrilling.co.uk

Bit conditions descriptions

Code number 1

Subject of description Amount of life used of inner row of cutters

Chioice code 0 1-7 8 0 1-7 8 BC BT BU CC CD CI CR CT EC FC HC JD LC LT NO OC PB PN RG RO SD SS TR WO WT A C G H M N S T 0 1-7 8 E

Amount of life used of outer row of cutters

Description of damage or condition

Area of wear

Amount of bearing life used

F X or D 6 Gauge 1 - 16 I As in code '3' BC BHA CM CP DMF DP DST DTF FM HP HR LN LOG PR RR TD TQ TW WC WK WT

7 8

Second description of damge/condition Reason for pulling the bit

Description of choice code No life used Eights of life used Total life used No life used Eights of life used Total life used Broken cone Broken teeth Balled up bit Cracked cone Cone dragged Cone Interferance Cored Chipped teeth Eroded cone Flat crested wear Heat checking Junk damage Lost cone Lost teeth No dull char offcentre wear Penched bit Plugged jet/flow Rounde gauge Ring out Shirt tail damage Self sharpening Tracking Washed out Worn teeth All areas Cone Gauge Heel raw Middle raw Nose Shoulder Taper No life used Eights of life used Total life used Seal effective for journal bearing

Seal failed for journal bearing For bearing less bits Sixteenth of inch under gauge In gauge As in code '3' Bit Change change of BHA Condition mud Core point Down hole motor failure Drill plug Drill stem test Down hole tool failure Formation change Hole problem Hours Lost nozzle Run logs Penetration rate Rig repair Total depth Torque Twistoff drill string Weather conditions Well kick Washed out drill string

You might also like

- Tim Burton's The Nightmare Before Christmas ScriptDocument37 pagesTim Burton's The Nightmare Before Christmas Scriptphantom14No ratings yet

- Hole Volume Mu-135aDocument8 pagesHole Volume Mu-135afadli.lpgNo ratings yet

- SDU Ver142beta1 - Demo Print 1 PDFDocument12 pagesSDU Ver142beta1 - Demo Print 1 PDFreza khNo ratings yet

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- LWD MWD AnadrillDocument38 pagesLWD MWD AnadrillJose SantiagoNo ratings yet

- Amal-18 Sta DDR#18 29-02-2020Document30 pagesAmal-18 Sta DDR#18 29-02-2020eng7mohamed7hashimNo ratings yet

- Tolkien Studies 01 - Tolkien StudiesDocument194 pagesTolkien Studies 01 - Tolkien StudiesRosa Erentxun100% (6)

- HH 83-1D SurveyDocument3 pagesHH 83-1D SurveyMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Little Prince Hat PDFDocument1 pageLittle Prince Hat PDF1_teach100% (1)

- Miffy Amigurumi CuteDocument3 pagesMiffy Amigurumi CuteNasi Is100% (1)

- China Business Database With Full InformationsDocument716 pagesChina Business Database With Full InformationsNatsumamaNo ratings yet

- Cementing Job - 5 Inch Liner Al Raja 37Document2 pagesCementing Job - 5 Inch Liner Al Raja 37Doni KurniawanNo ratings yet

- 13.375 Inter I - 68 PPFDocument12 pages13.375 Inter I - 68 PPFAnonymous XbmoAFtINo ratings yet

- Video Training Courses in Offshore Structures DesignDocument102 pagesVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- DOX Generated Default BHADocument1 pageDOX Generated Default BHAEl que lo peta CordovaNo ratings yet

- 0973r04 OKIOC Marine ManualDocument79 pages0973r04 OKIOC Marine ManualscrbdgharaviNo ratings yet

- SD-24P Bit Record 2Document1 pageSD-24P Bit Record 2Them Bui XuanNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- Well Kick Data: Sheet No. 2Document2 pagesWell Kick Data: Sheet No. 2Raul Dolo QuinonesNo ratings yet

- Specification For A Land 2000 HP DrillinDocument33 pagesSpecification For A Land 2000 HP Drillinanthonmirandas100% (1)

- 7'' Liner CMT CalculationDocument1 page7'' Liner CMT CalculationEslam Atif AzkolNo ratings yet

- RheologyDocument24 pagesRheologyPercy Herrera Figueroa100% (1)

- Drill Collar Specifications and Connection DetailsDocument6 pagesDrill Collar Specifications and Connection Detailswasim78622No ratings yet

- Crochet AppleDocument0 pagesCrochet AppleAlxandra PinzaruNo ratings yet

- 20 in Surf - 94 PPFDocument12 pages20 in Surf - 94 PPFAnonymous XbmoAFtINo ratings yet

- Watch Journal April 2015Document132 pagesWatch Journal April 2015Σατανάς Σατανάς100% (2)

- WELL DATADocument3 pagesWELL DATAscrbdgharaviNo ratings yet

- Bit GradingDocument17 pagesBit GradingnugratamaNo ratings yet

- 1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDDocument1 page1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDAntonio Hdez JmnzNo ratings yet

- 9.625 Inter-Prod 53.5 PPFDocument17 pages9.625 Inter-Prod 53.5 PPFAnonymous XbmoAFtINo ratings yet

- BHA#006 8.5in PDXceed +EcoScope+ TeleScopeDocument1 pageBHA#006 8.5in PDXceed +EcoScope+ TeleScopeKelly Cubillos quirozNo ratings yet

- Blooming Flowers Bracelet From The Book Shrink Shrank ShrunkDocument8 pagesBlooming Flowers Bracelet From The Book Shrink Shrank ShrunkEnju Scribe100% (1)

- Intomind Workbook A4Document85 pagesIntomind Workbook A4globowens100% (2)

- DAILY DRILLING REPORT FOR WELL HH 83/1 ADocument1 pageDAILY DRILLING REPORT FOR WELL HH 83/1 AMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- Drilling Operations Preparation and ProceduresDocument24 pagesDrilling Operations Preparation and Proceduresfatehul alamNo ratings yet

- Egyptian Mud Engineering & Chemicals Company: Page 1 of 1Document1 pageEgyptian Mud Engineering & Chemicals Company: Page 1 of 1GPCNo ratings yet

- Daily Drilling Report for HERUNEFER W-13 WellDocument3 pagesDaily Drilling Report for HERUNEFER W-13 WellIslam AtifNo ratings yet

- Re-Frac Job by HBTDocument31 pagesRe-Frac Job by HBTEvence ChenNo ratings yet

- Well Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)Document2 pagesWell Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)scrbdgharaviNo ratings yet

- Drillstring Vib BR PDFDocument4 pagesDrillstring Vib BR PDFMohammed Abdul SamiNo ratings yet

- Mud Motor Operation Key PointsDocument3 pagesMud Motor Operation Key Pointssanjeet giriNo ratings yet

- Trex 01157Document17 pagesTrex 01157OSDocs2012No ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- Optimizing bit hydraulics and hole cleaning calculationsDocument1 pageOptimizing bit hydraulics and hole cleaning calculationsDian SikumbangNo ratings yet

- Amal-18 Sta DDR#20 02-03-2020Document30 pagesAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimNo ratings yet

- Well Name: Horizontal Demo Well CLF 0: Surface BOP ? 1Document58 pagesWell Name: Horizontal Demo Well CLF 0: Surface BOP ? 1bohog39663No ratings yet

- Notes 4Document18 pagesNotes 4Ruben ChirinosNo ratings yet

- 16 BHA Tally FormatDocument2 pages16 BHA Tally FormatShraddhanand MoreNo ratings yet

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- DST BhaDocument1 pageDST Bhajairaso2950No ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- Goldenman Petroluem Equipment Co., Limited: Quotation ListDocument4 pagesGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoNo ratings yet

- Morning Report 19 - 24 April 2012Document3 pagesMorning Report 19 - 24 April 2012tolstoy potemkinNo ratings yet

- DDR 27-10Document1 pageDDR 27-10GPCNo ratings yet

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocument2 pagesBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarNo ratings yet

- Comp Tally W.P#14Document3 pagesComp Tally W.P#14nabiNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- MR86L - Drilling MontageDocument1 pageMR86L - Drilling MontageGabriel PlazasNo ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument16 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarNo ratings yet

- P&a Cmt. Calcu.Document2 pagesP&a Cmt. Calcu.francisryan4519No ratings yet

- DRL TorqDocument1 pageDRL TorqscrbdgharaviNo ratings yet

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsDocument1 pageTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaNo ratings yet

- MIS - XLSX S.E 2Document390 pagesMIS - XLSX S.E 2GPCNo ratings yet

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 page16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroNo ratings yet

- 01 - Drill 16'' Hole Section & POOHDocument3 pages01 - Drill 16'' Hole Section & POOHDrilling Engineering ChannelNo ratings yet

- GEOREPORT Mudlogging ExampleDocument2 pagesGEOREPORT Mudlogging ExampleCarmen Ibeth Olivos PradaNo ratings yet

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoNo ratings yet

- BHA - 66 Opción 2 SlimpulseDocument1 pageBHA - 66 Opción 2 SlimpulseDiego Fabian Ruiz VacaflorNo ratings yet

- DAILY DRILLING REPORT FOR WELL HH 83/1DDocument5 pagesDAILY DRILLING REPORT FOR WELL HH 83/1Danon_975742003No ratings yet

- DrillingDocument9 pagesDrillingHakan ÖzkaraNo ratings yet

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Ref 4Document1 pageRef 4scrbdgharaviNo ratings yet

- E&pfor 1Document36 pagesE&pfor 1scrbdgharaviNo ratings yet

- Ref 17Document1 pageRef 17scrbdgharaviNo ratings yet

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Agip KCO Aircraft Manuals IndexDocument1 pageAgip KCO Aircraft Manuals IndexscrbdgharaviNo ratings yet

- HSE Management - Guidelines For Working Together in A Contract EnvironmentDocument72 pagesHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviNo ratings yet

- 1856r0 Procedure No 1 HSSE Policies and Mandatory RulesDocument13 pages1856r0 Procedure No 1 HSSE Policies and Mandatory RulesscrbdgharaviNo ratings yet

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDocument6 pagesU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviNo ratings yet

- Environmental Performance Monitoring Reporting GuidelineDocument17 pagesEnvironmental Performance Monitoring Reporting GuidelinescrbdgharaviNo ratings yet

- PG 1048 eDocument6 pagesPG 1048 escrbdgharaviNo ratings yet

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferDocument8 pagesAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviNo ratings yet

- PG 1025 eDocument6 pagesPG 1025 escrbdgharaviNo ratings yet

- Pigging Multi-Diameter Lines and Other Specialist TechniquesDocument6 pagesPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviNo ratings yet

- PG 3052 eDocument4 pagesPG 3052 escrbdgharaviNo ratings yet

- PG 3005 eDocument8 pagesPG 3005 escrbdgharaviNo ratings yet

- Pre On-Line Inspection Pigging: by C KershawDocument6 pagesPre On-Line Inspection Pigging: by C KershawscrbdgharaviNo ratings yet

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinDocument4 pagesInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviNo ratings yet

- PG 3150 eDocument4 pagesPG 3150 escrbdgharaviNo ratings yet

- PG 3025 eDocument6 pagesPG 3025 escrbdgharaviNo ratings yet

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonDocument6 pagesSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviNo ratings yet

- Measurement of Distance: - There Are Two Main Methods of Determining DistanceDocument19 pagesMeasurement of Distance: - There Are Two Main Methods of Determining DistanceSyed Azmat Ali ShahNo ratings yet

- G9 Basketry M2Document23 pagesG9 Basketry M2Jhudy Anne Samuela SantosNo ratings yet

- TDS-BS 3262 ThermoplasticsDocument2 pagesTDS-BS 3262 ThermoplasticstimphNo ratings yet

- Foa G Dec 1712 PublicDocument711 pagesFoa G Dec 1712 PublicKadir EmirNo ratings yet

- A Death in Tlie FamilyDocument29 pagesA Death in Tlie FamilyFloreria Luz Marina AqpNo ratings yet

- Fabio Penuela ResumeDocument5 pagesFabio Penuela Resumedayro herreraNo ratings yet

- Warp Way DefectsDocument11 pagesWarp Way Defectsharshal52855No ratings yet

- Countries, nationalities and professions grammar guideDocument93 pagesCountries, nationalities and professions grammar guidegabrielaNo ratings yet

- DictionaryDocument86 pagesDictionaryAimee HernandezNo ratings yet

- Characteristics of ReptilesDocument2 pagesCharacteristics of ReptilesPatricia HariramaniNo ratings yet

- Ppc-Visayas Culture and TraditionsDocument49 pagesPpc-Visayas Culture and TraditionsElyzaGutierrezCabacesNo ratings yet

- GBG-Charms, Amulets, TalismansDocument10 pagesGBG-Charms, Amulets, TalismansEverton CardosoNo ratings yet

- The Story of The Two Brothers: Aidean S. Licaros Grade 8-CristobalDocument10 pagesThe Story of The Two Brothers: Aidean S. Licaros Grade 8-Cristobalmeryroselicaros525No ratings yet

- Eternal Mana Weapon SynthesisDocument8 pagesEternal Mana Weapon SynthesisBriseño OmarNo ratings yet

- Aamir Khan Is Titan Brand Ambassador From Kiran Theosophical College, HopsetDocument9 pagesAamir Khan Is Titan Brand Ambassador From Kiran Theosophical College, Hopsetkirantalur20032003No ratings yet

- NCC Standard TemplateDocument4 pagesNCC Standard TemplateMarlene LunaNo ratings yet

- Likes and Hates Rune Factory 2Document235 pagesLikes and Hates Rune Factory 2piusndNo ratings yet

- The Romance of A Busy BrokerDocument4 pagesThe Romance of A Busy BrokerSelena CookNo ratings yet

- Imo 2019 TSTDocument2 pagesImo 2019 TSTThanh QuangNo ratings yet

- First FS - Writing - AK - Test 1Document2 pagesFirst FS - Writing - AK - Test 1aisthesicNo ratings yet

- Baby NamesDocument183 pagesBaby Nameshizumi28No ratings yet