Professional Documents

Culture Documents

316L SA 240 Ferguson Metal

Uploaded by

Sugiarto SaptomoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

316L SA 240 Ferguson Metal

Uploaded by

Sugiarto SaptomoCopyright:

Available Formats

Technical Data

Ferguson Metals

Specialist in Specialty Metals

Ferguson Metals, Inc.

Hamilton, Ohio

Stainless Steels Chromium-Nickel-Molybdenum Types 316 (S31600), 316L (S31603), 317 (S31700), 317L (S31703)

LINEAR COEFFICIENT OF THERMAL EXPANSION

Temperature Range C F 20-100 68-212 20-500 68-932 20-1000 68-1832 Coefficients cm/cm/C in/in/F 16.5 x10-6 9.2 x 10-6 18.2 x 10-6 10.1 x 10-6 19.5 x 10-6 10.8 x 10-6

GENERAL PROPERTIES Types 316 (UNS S31600), 316L (S31603), 317 (S31700) and 317L (S31703) are molybdenum-bearing austenitic stainless steels which are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as Type 304. These alloys also offer higher creep, stress-to-rupture and tensile strength at elevated temperature. In addition to excellent corrosion resistance and strength properties, the Types 316, 316L, 317 and 317L Cr-Ni-Mo alloys also provide the excellent fabricability and formability which are typical of the austenitic stainless steels. Applications for Types 316 and 316L alloys include acetic acid compounds, brandy vats, corn products refining equipment, fasteners, kettles for cooking ketchup, pharmaceutical processing equipment, phosphate industry parts, photographic film processing equipment, pitting-corrosion resistance, pulp and paper processing equipment, smokestacks, textile finishing equipment, textile mill kiers, water softener tanks, wire cloth and screens (industrial) and yeast tubes. Applications for Type 317 alloy includes dyeing equipment, flue gas desulfurization units, ink manufacturing equipment, pitting-corrosion resistance, pulp and paper processing equipment. Types 316, 316L, 317 and 317L are available in sheet, strip and plate to ASTM A240 and ASME SA-240 and other pertinent specifications. CHEMICAL COMPOSITION Represented by ASTM A240 and ASME SA-240

Element Carbon Manganese Silicon Chromium Nickel Molybdenum Phosphorus Sulfur Nitrogen Iron Percent by Weight Maximum Unless Range is Specified 316 316L 317 317L 0.08 0.030 0.08 0.030 2.00 2.00 2.00 2.00 0.75 0.75 0.75 0.75 16.00 16.00 18.00 18.00 18.00 18.00 20.00 20.00 10.00 10.00 11.00 11.00 14.00 14.00 15.00 15.00 2.00 2.00 3.00 3.00 3.00 3.00 4.00 4.00 0.045 0.045 0.045 0.045 0.030 0.030 0.030 0.030 0.10 0.10 0.10 0.10 Bal. Bal. Bal. Bal.

THERMAL CONDUCTIVITY

Temperature Range C F 20-100 68-212 W/m K 14.6 Btuin/ hrft2F 100.8

The overall heat transfer coefficient of metals is determined by factors in addition to thermal conductivity of the metal. The ability of Types 302, 304 and 304L to maintain clean surfaces often allows better heat transfer than other metals having higher thermal conductivity. SPECIFIC HEAT

C 20 93 F 68 200 J/kg K 450 485 Btu/lbF 0.108 0.116

MAGNETIC PERMEABILITY

H/m Annealed 1.02 Max @ 200 H

ELECTRICAL RESISTIVITY

Value at 68F (20C) Type 316 Microhm-in. 29.1 Microhm-cm 74.0

MECHANICAL PROPERTIES Room Temperature Tensile Properties Minimum mechanical properties for annealed Types 316, 316L, 317 and 317L austenitic stainless steel plate, sheet and strip as required by ASTM specifications A240 and ASME specification SA-240, are shown below. MINIMUM MECHANICAL PROPERTIES REQUIRED BY, ASTM A240 AND ASME SA-240

Property Yield Strength, 0.2% Offset psi MPa Ultimate Tensile Strength, psi MPa Percent Elongation in 2 in. or 51 mm Hardness, Max., Brinell 217 95 217 95 217 95 217 95 RB Type 316 (S31600) Type 316L (S31603) Type 317 (S31700) Type 317L (S31703)

RESISTANCE TO CORROSION Types 316, 316L, 317 and 317L are more resistant to atmospheric and other mild types of corrosion than Types 302, 304 and 304L. In general, media that do not corrode Types 302, 304 and 304L, will not attack these molybdenumcontaining grades. One known exception is highly oxidizing acids such as nitric acid to which the molybdenum-bearing stainless steels are less resistant. PHYSICAL PROPERTIES

Melting Range: Density Modulus of Elasticity in Tension Modulus of Shear: 2540-2630F (1390-1440C) 0.29 lb/in3 (8.027 g/cm3) 29 x 106 psi (200 GPa) 11.9 x 106 psi (82 Gpa)

30,000 205

25,000 170

30,000 205

30,000 205

75,000 515 40.0

70,000 485 40.0

75,000 515 35.0

75,000 515 40.0

You might also like

- Technical DataDocument1 pageTechnical DataengrodeNo ratings yet

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Allegheny 316 PDFDocument13 pagesAllegheny 316 PDFJoshua WalkerNo ratings yet

- Stainless Steel Grade 316 (UNS S31600)Document4 pagesStainless Steel Grade 316 (UNS S31600)achari_swapnilNo ratings yet

- AL 316 - 317dataDocument14 pagesAL 316 - 317dataClaudia MmsNo ratings yet

- 316 316L DataBulletinDocument7 pages316 316L DataBulletinAbdurohman RawindaNo ratings yet

- Stainless Steel 316Document1 pageStainless Steel 316Bungsu ZamzamNo ratings yet

- Grade 316 Stainless Steel Properties and ApplicationsDocument2 pagesGrade 316 Stainless Steel Properties and Applicationsd_muamer_116983894No ratings yet

- Incoloy Alloy 25-6MODocument13 pagesIncoloy Alloy 25-6MOsiswoutNo ratings yet

- 316 316L Data SheetDocument2 pages316 316L Data SheetHanna ChanNo ratings yet

- 316 316l Data SheetDocument2 pages316 316l Data SheetDiman Aditya KardiNo ratings yet

- The Role Stainless Steel in Industrial Heat ExchangersDocument46 pagesThe Role Stainless Steel in Industrial Heat ExchangerswholenumberNo ratings yet

- Grade 316 Stainless Steel Properties and ApplicationsDocument2 pagesGrade 316 Stainless Steel Properties and ApplicationsmarklaforestNo ratings yet

- Aisi 316Document4 pagesAisi 316Aliakbar SaifeeNo ratings yet

- DS Alloy 316 316LDocument2 pagesDS Alloy 316 316LshenNo ratings yet

- Spec 316Document4 pagesSpec 316andidesisunarnoNo ratings yet

- 316LNDocument3 pages316LNGanesh KcNo ratings yet

- Grade 316 316LDocument9 pagesGrade 316 316LvsajuNo ratings yet

- Technicals of 316/lDocument2 pagesTechnicals of 316/lASHISH DOSHINo ratings yet

- SS316 - Comparison With SS316LDocument3 pagesSS316 - Comparison With SS316LAdrianus PrimaNo ratings yet

- Brown Metals Company Technical Data Sheet on Types 316 and 316L Stainless SteelsDocument1 pageBrown Metals Company Technical Data Sheet on Types 316 and 316L Stainless Steelstris khanNo ratings yet

- 304 304L Data Sheets 1 28 13 PDFDocument12 pages304 304L Data Sheets 1 28 13 PDFneerajtrvNo ratings yet

- 304 304L Data BulletinDocument8 pages304 304L Data Bulletinmayur2708No ratings yet

- Data Sheet 316LDocument2 pagesData Sheet 316LkhalidNo ratings yet

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocument3 pagesAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNo ratings yet

- Difference Between 304 and 316 Stainless SteelDocument4 pagesDifference Between 304 and 316 Stainless SteelsekarsanthanamNo ratings yet

- 304 VS 316Document2 pages304 VS 316Sheikh ZakirNo ratings yet

- Grade 316 Stainless Steel Properties Applications FabricationDocument4 pagesGrade 316 Stainless Steel Properties Applications FabricationyoyokpurwantoNo ratings yet

- Type 316-316L Stainless SteelDocument2 pagesType 316-316L Stainless SteelPravin PawarNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationswapneel_kulkarniNo ratings yet

- 316L Stainless Steel Technical Data SheetDocument3 pages316L Stainless Steel Technical Data Sheetchris calonzoNo ratings yet

- S.No Materials Specification DescriptionDocument4 pagesS.No Materials Specification DescriptioniyamNo ratings yet

- Unit-2 Metalic Implants-Stainless SteelDocument16 pagesUnit-2 Metalic Implants-Stainless SteelMUKESH SUNDARARAJANNo ratings yet

- Specification Sheet: Alloy 316/316L Stainless SteelDocument3 pagesSpecification Sheet: Alloy 316/316L Stainless SteelSaúl L Hdez TNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- A4 80Document2 pagesA4 80alwezalokNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationari_prasNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTJhandu KumarNo ratings yet

- Austenitic and Ferritic Stainless Steel GradesDocument5 pagesAustenitic and Ferritic Stainless Steel GradesmariuspiNo ratings yet

- Stainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)Document6 pagesStainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)ganmosesNo ratings yet

- Specs and properties of chromium-nickel stainless steel alloys 304, 304L, and 304HDocument8 pagesSpecs and properties of chromium-nickel stainless steel alloys 304, 304L, and 304HLuis Enrique Carreon TorresNo ratings yet

- PIPING MATERIALS COMPARISON TABLEDocument12 pagesPIPING MATERIALS COMPARISON TABLEJay Vinoth100% (2)

- 301-301LN Stainless SteelsDocument4 pages301-301LN Stainless SteelsTeka KamNo ratings yet

- 316 SS Data SheetDocument3 pages316 SS Data SheetellisforheroesNo ratings yet

- Stainless SteelDocument6 pagesStainless SteelNiko NištićNo ratings yet

- SX 316 / 316L Technical DataDocument3 pagesSX 316 / 316L Technical DatavkmsNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition ChartZaveri SagarNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- AHA Scientific Statement on Self-Care for Cardiovascular Disease and Stroke Prevention and ManagementDocument27 pagesAHA Scientific Statement on Self-Care for Cardiovascular Disease and Stroke Prevention and ManagementSugiarto SaptomoNo ratings yet

- Cir 0000000000000757Document458 pagesCir 0000000000000757Nona Suci rahayuNo ratings yet

- SikaGrout-215 2011-11 - 1 PDFDocument4 pagesSikaGrout-215 2011-11 - 1 PDFFaiz RahmatNo ratings yet

- Allowable Load On Single PileDocument16 pagesAllowable Load On Single PileSugiarto SaptomoNo ratings yet

- Field Estimates Pile Capacity PDFDocument4 pagesField Estimates Pile Capacity PDFAniculaesi MirceaNo ratings yet

- PT Inter World Steel MillsDocument20 pagesPT Inter World Steel Millssugiarto budiNo ratings yet

- Hiley's Piles GeneralDocument34 pagesHiley's Piles GeneralPERUNDINGAZRANo ratings yet

- Data Sheet - Overhead TravellingDocument4 pagesData Sheet - Overhead TravellingSugiarto SaptomoNo ratings yet

- 2 - Retaining Wall Ashton Lawler PDFDocument87 pages2 - Retaining Wall Ashton Lawler PDFtaz_taz3100% (1)

- Demag Crane BrochureDocument20 pagesDemag Crane BrochureSugiarto SaptomoNo ratings yet

- Manual Training FMS 101Document86 pagesManual Training FMS 101Sugiarto SaptomoNo ratings yet

- Design of Structures and Foundations For Vibrating Machines PDFDocument39 pagesDesign of Structures and Foundations For Vibrating Machines PDFsaputrafrandy_958992No ratings yet

- Stainless Steel 316l (SA240)Document2 pagesStainless Steel 316l (SA240)Sugiarto SaptomoNo ratings yet

- Material AsmDocument6 pagesMaterial Asmrawalepushkar123No ratings yet

- Fabory - Fasteners - Technical InformationDocument77 pagesFabory - Fasteners - Technical InformationPieter van der Meer100% (1)

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDocument16 pagesGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanNo ratings yet

- 5131 PDFDocument9 pages5131 PDFucc rd minesNo ratings yet

- Manual WiloDocument25 pagesManual Wilocarr123No ratings yet

- Alloy Guide PDFDocument12 pagesAlloy Guide PDFArjed Ali ShaikhNo ratings yet

- Technical Data 3CR12Document15 pagesTechnical Data 3CR12rudiskw456No ratings yet

- Brochure Pressure VesselsDocument12 pagesBrochure Pressure VesselsAbdulhadi ZafarNo ratings yet

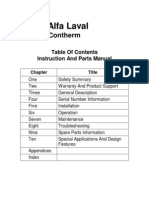

- Alfa Laval CONTHERM InstructionDocument352 pagesAlfa Laval CONTHERM Instruction何宗仁100% (1)

- Analysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesDocument7 pagesAnalysis of Stainless Steel Welded Joints A Comparison Between Destructive and Non-Destructive TechniquesKhalid M. HafezNo ratings yet

- Nitro Nic 60 BookDocument36 pagesNitro Nic 60 BookGerman ToledoNo ratings yet

- Paper 032 Durability Guidelines For Materials in SWRO Brine - FinalDocument13 pagesPaper 032 Durability Guidelines For Materials in SWRO Brine - FinalMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Pressure Controls: Allen-BradleyDocument8 pagesPressure Controls: Allen-BradleysoayNo ratings yet

- Bounds and Tesch - Design SPDocument22 pagesBounds and Tesch - Design SPVitória MarcenariaNo ratings yet

- Heat Treatment of Special SteelDocument11 pagesHeat Treatment of Special SteelSyed Shoaib RazaNo ratings yet

- Pivot Master Brochure REV 5 1508 PDFDocument4 pagesPivot Master Brochure REV 5 1508 PDFulasNo ratings yet

- 2001 - Recent Metallic Materials For Biomedical ApplicationsDocument10 pages2001 - Recent Metallic Materials For Biomedical Applicationspr194537No ratings yet

- 17.20 Duplex Flexible Coupling S77DXDocument5 pages17.20 Duplex Flexible Coupling S77DXguita riefNo ratings yet

- Ansul Foam PourerDocument2 pagesAnsul Foam PourerAnonymous rKzIfkK9No ratings yet

- Metal Solid IronDocument48 pagesMetal Solid IronVinoth SangNo ratings yet

- Cat Okuma 2014 EuropaDocument41 pagesCat Okuma 2014 EuropajclenerNo ratings yet

- Hawke PL612 EnclosureDocument2 pagesHawke PL612 EnclosureDang Minh HuongNo ratings yet

- SS DCC7r13 PDFDocument48 pagesSS DCC7r13 PDFHernan Rincon GomezNo ratings yet

- Reliable Steel Rolling Mill Solution ProviderDocument7 pagesReliable Steel Rolling Mill Solution Provideranon_647217551No ratings yet

- Web STEAM HIGH TEMPERATURE STERILIZER EN - 01 PDFDocument24 pagesWeb STEAM HIGH TEMPERATURE STERILIZER EN - 01 PDFEyad AlarjawiNo ratings yet

- Brochure - Split Case Fire Pumps For Industrial and Offshore ApplicationsDocument2 pagesBrochure - Split Case Fire Pumps For Industrial and Offshore ApplicationsAaaNo ratings yet

- ASTM A240 A240M-15b Standard Specification For Chromium and Chromium-Nickel Stainless Steel Plate... and For General ApplicationsDocument14 pagesASTM A240 A240M-15b Standard Specification For Chromium and Chromium-Nickel Stainless Steel Plate... and For General ApplicationsElizabeth White100% (1)

- 1.fabric Dyeing MachinesDocument16 pages1.fabric Dyeing MachinesMark ManNo ratings yet

- CINTEC Design Guide European VersionBDocument29 pagesCINTEC Design Guide European VersionBDavid MiguelNo ratings yet

- Welding of Ferritic/martensitic Stainless Steels: Job KnowledgeDocument2 pagesWelding of Ferritic/martensitic Stainless Steels: Job KnowledgeMuhammed SulfeekNo ratings yet