Professional Documents

Culture Documents

Aisc Clean Columns Worksheet

Uploaded by

scrbdgharaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisc Clean Columns Worksheet

Uploaded by

scrbdgharaviCopyright:

Available Formats

steel tools

Visit w w w .aisc.org/steeltools for our continuously expanding Steel Tools library.

The Steel Solutions Center is your gateway to powerful tools, facts and project solutions.

Clean Columns V3.1

Least weight is not least cost.

Least weight is not least cost.

Least weight is not least cost. AISC has been saying this for years. Now we'd like to show you.

Clean Columns calculates the lightest column section required to eliminate stiffener and doubler plates.

Puc Beam/Girder Vus Column Mu Pub

Pub Mu Transverse Stiffeners, if Required

Enter Now

Vus Puc

Column Panel-Zone Location of Doubler Plates, if Required

Talk to your favorite fabricator, or consult chapter 3 of Design Guide 13 for more information on the cost of stiffener and doubler plates.

Comments? Questions? Visit us online at www.aisc.org/ASKAISC or contact us at solutions@aisc.org or toll free at 866.ASK.AISC

This spreadsheet has been prepared by AISC Marketing in accordance with recognized engineering principles and information made available to AISC at the time of its preparation. While it is believed to be accurate, it has not been prepared for conventional use as an engineering or construction document and should not be used or relied upon for any specific application without competent professional examination and verification of its accuracy, suitability and applicability by a licensed engineer, architect or other professional. AISC disclaims any liability arising from the unauthorized use of the information contained in this spreadsheet.

Project: Client: Engineer: Remarks:

Sample Project Client Senior Engineer Remarks on this connection evaluation

6/27/2013

Clean Columns V3.1 was developed to return the lightest column section which can be used without stiffeners and/or doubler plates to develop a specified percentage of a selected beam's plastic moment capacity, based on the criteria in AISC Design Guide Series #13. The design of the column for axial load capacity is not considered.

1) Verify the Following Assumptions: The effects of composite floor construction are not included in analysis Wind or low seismic applications (Structure is designed to meet the requirements in the LRFD Specification with no special seismic detailing) dm = d - tf (used to convert the beam moment into flange forces) Panel-zones remain nominally in the elastic range N = beam flange thickness (w = 0, ie. no reinforcing fillet weld included) Welded flange or flange plate connections only. May be overly conservative for end-plate moment connections 2) Provide the Following Parameters: Fyc = 50 ksi Column Specified Minimum Yield Strength Fyb = Vus = Puc = Pub = Mu = 50 ksi 45 kips 1200 kips Beam Specified Minimum Yield Strength Factored Column Story Shear Factored Column Axial Load

Transverse Stiffeners, if Required Vus

Puc Vus Column Mu Pub Beam/Girder Column Panel-Zone Location of Doubler Plates, if Required

Puc

5 kips Factored Beam Axial Load 80% of Mp Factored Bending Moment in Beams as a percentage of the Beam's Plastic Moment Strength 4) Choose a Connection Configuration: Beam Connected on One Side Only

3) Select a Beam using the pulldown menus below: Nominal Depth Beam Section 6) Beam Properties Mp = Mu = Puf = Vu = W24 W24x55 * Group 4 or 5 Shape

5) Verify the Connection Location: 503 kip-ft 402 kip-ft 212 kips 167 kips Plastic Moment Strength Factored Beam End Moment Factored Flange Force Factored Total Panel-Zone Shear Force 3.0 in Beams are not Connected Near the Top of the Column

7) Column Design Results:

Lightest W10 No Stiffener Plates Required No Doubler Plates Required No Stiffener Plates or Doubler Plates Required W10x77 -Lightest W12 W12x96 W12x120 Lightest W14 W14x120 W14x132 Lightest W16 W16x89 -Lightest W18 W18x97 W18x106 Keep in mind that columns larger than W14x426* may not be produced domestically. www.aisc.org

--

W12x120

W14x132

--

W18x106

This spreadsheet has been prepared in accordance with recognized engineering principles and information made available to AISC at the time of its preparation. While it is believed to be accurate, it has not been prepared for conventional use as an engineering or construction document and should not be used or relied upon for any specific application without competent professional examination and verification of its accuracy, suitability and applicability by a licensed engineer, architect or other professional. AISC disclaims any liability arising from the unauthorized use of the information contained in this document.

Project: Client: Engineer: Remarks:

Sample Project Client Senior Engineer Remarks on this connection evaluation

6/27/2013

Clean Column Design Calculations for a W14x398* Column

I) Force Transfer in Unreinforced Columns

A) Required Strength for Local Flange and Web Limit States Design for a W24x55 Beam with 80% of the Nominal Plastic Moment Strength (503 kip-ft) Transferred to the Column Mu = Pub = d= tf = 402 kip*ft 5 kips 23.57 in Factored Beam End Moment Factored Beam Axial Load Beam Depth Beam Flange Thickness Moment Arm between Flange Forces

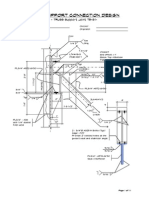

Beam/Girder Transverse Stiffeners, if Required Puc V us Column Mu Pub

0.505 in dm = 23.065 in

d m=d t f

Puf = 212 kips Factored Beam Flange Force (tension or compression)

V us Puc

P uf =

Mu dm

Pu 2

Column Panel-Zone Location of Doubler Plates, if Required

Figure 1. Exterior Column

B) Required Strength for Panel-Zone Shear Moment Connected Beam on One Side Only Vus = 45 kips Factored Column Story Shear Vu = 167 kips Factored Total Panel Zone Shear Force For a column with only one moment connected beam

Puf

(Tension)

dm

Mu

P ub

V u= P uf V us

For a column with two moment connected beams

V u = 2P uf V us

II) Design Strength of an Unreinforced Column

Design Check for Column Section: W14x398* Fy = dtop = 50 ksi DNA Column Minimum Specified Steel Yield Strength Distance from the column end to the top flange of the beam(s)

Puf

(Compression)

tf /2

FIgure 2. Beam Flange Forces

A) Panel-Zone Shear Strength For Calculation Purposes, the behavior of the panel zone remains nominally within the elastic range. Puc = 1200 kips Factored Column Axial Load dc = 18.29 in Column Depth tw = A= Py = Rv = 1.77 in 117.0 in2 5850 kips Column web thickness Column Area Column Yield Strength

Vus Puf Vu P uf

P uf Vus

Puf

P y= F y A

874 kips Panel-Zone Shear Design Strength

For P u 0. 4P y For P u > 0.4P y

B) Local Flange Buckling tf = Ct = 2.85 in 1.0

Rv =0 .9x0.6F y d c t w

R v = 0 . 9x0. 6F y d c t w 1. 4

Figure 3. Panel-Zone Shear

Pu Py

Column Flange Thickness = 0.5 if the distance from the end of the column to the closer face of the beam tension flange is less than 10t f = 1.0 otherwise Local Flange Bending Design Strength

Rn =

2276 kips

R n= 0.9x6 .25t 2f F y xCt

C) Local Web Yielding For calculations purposes, no fillet weld or groove weld reinforcement was used. N= tw = dc = Ct = 0.505 in 1.77 in 18.29 in 1.0 Beam or flange plate thickness Column Web Thickness Column Depth = 0.5 if the distance from the end of the column to the closer face of the beam tension flange is less than d c = 1.0 otherwise Distance from the outside face of column flange to the web toe of the flange-to-web fillet Local Web Yielding Design Strength

k= Rn =

3.50 in 1593 kips

R n=1. 0x {C t ( 5k )+ N } xF y t w

D) Web Crippling For calculations purposes, no fillet weld or groove weld reinforcement was used. N= tw = dc = tf = Ct = 0.505 in 1.77 in 18.29 in 2.85 in 1.0 Beam or flange plate thickness (w=0 because no reinforcing welds are present) Column Web Thickness Column Depth Column Flange Thickness = 0.5 if the distance from the end of the column to the closer face of the beam tension flange is less than dc/2 = 1.0 otherwise = 3N/dc if the distance from the column end to the closer face of the beam tension flange is either: (1) greater than or equal to d c/2; or, (2) less than dc/2 and N/dc is less than or equal to 0.2.

Figure 4. Illustration of parameters N and W

N Reinforcing Fillet Weld W

Nd =

0.08

=

Rn = 2959 kips

4N 0. 2 otherwise dc

Web Crippling Design Strength

R n= 0 . 75 x 135C t t 2 w 1+ N d

{ ( ) }

tw

1.5

F yt f tw

tf

E) Compression Buckling of the Web Buckling is checked for a single compressive force applied at the column flange. tw = dc = k= Ct = 1.77 in 18.29 in 3.50 in 1.0 Column Web Thickness Column Depth Distance from the outside face of column flange to the web toe of the flange-to-web fillet = 0.5 if the distance from the end of the column to the closer face of the beam tension flange is less than dc/2 = 1.0 otherwise Zone of column web subject to compression buckling (out-of-plane)

h=

11.29 in

h = d c 2k

Rn = 12816 kips Compression Buckling Design Strength

R n= 0.90 x

III) Column Design Summary:

4100C t t 3 w F y h

W14x398*

Panel-Zone Shear Strength, Rv =

A) Doubler Plates Required if V u> Rv Factored Total Panel Zone Shear Force, Vu = 167 kips 874 kips

No Doubler Plates are Required. 19% of Column Capacity B) Stiffener Plates are Required if P uf > Rn Local Flange Bending Design Strength = Local Web Yielding Design Strength = Web Crippling Design Strength = Compression Buckling Design Strength = Factored Beam Flange Force, Puf = 212 kips Rn = 2276 kips 1593 kips 2959 kips 12816 kips 1593 kips

No Stiffener Plates are Required. 13% of Column Capacity

Designation W18x311* W18x283* W18x258* W18x234* W18x211* W18x192 W18x175 W18x158 W18x143 W18x130 W18x119 W18x106 W18x97 W18x86 W18x76 W18x71 W18x65 W18x60 W18x55 W18x50 W18x46 W18x40 W18x35

A in2 91.5 83.2 75.9 68.8 62.1 56.4 51.3 46.3 42.1 38.2 35.1 31.1 28.5 25.3 22.3 20.8 19.1 17.6 16.2 14.7 13.5 11.8 10.3

d in. 22.32 21.85 21.46 21.06 20.67 20.35 20.04 19.72 19.49 19.25 18.97 18.73 18.59 18.39 18.21 18.47 18.35 18.24 18.11 17.99 18.06 17.9 17.7

h 15.45 15.48 15.46 15.56 15.55 15.48 15.54 15.47 15.49 15.50 15.47 15.48 15.47 15.52 15.46 15.47 15.48 15.49 15.49 15.49 15.56 15.53 15.45

tw in. 1.52 1.4 1.28 1.16 1.06 0.96 0.89 0.81 0.73 0.67 0.655 0.59 0.535 0.48 0.425 0.495 0.45 0.415 0.39 0.355 0.36 0.315 0.3

tf in. 2.74 2.5 2.3 2.11 1.91 1.75 1.59 1.44 1.32 1.2 1.06 0.94 0.87 0.77 0.68 0.81 0.75 0.695 0.63 0.57 0.605 0.525 0.425

k in. 3 7/16 3 3/16 3 2 3/ 4 2 9/16 2 7/16 2 1/ 4 2 1/ 8 2 1 7/ 8 1 1 1 1 1 1 1 1 1 1 3/ 4 5/ 8 9/16 7/16 3/ 8 1/ 2 7/16 3/ 8 5/16 1/ 4

PZ Shear Str. Rv (kips) 916 826 742 660 592 514 449 380 319 269 240 187 150 108 68 61 32 7 -16 -40 -66 -97 -133

LFB Rn (kips) 2112 1758 1488 1252 1026 861 711 583 490 405 316 249 213 167 130 185 158 136 112 91 103 78 51

LWY Rn (kips) 1345 1151 992 827 706 609 523 451 383 331 303 255 222 185 157 198 173 153 138 120 122 101 92

WC Rn (kips) 2283 1930 1618 1337 1113 918 782 647 529 444 406 327 272 217 170 233 194 166 144 119 125 95 81

CBW Rn (kips) 5933 4627 3539 2617 1999 1492 1184 896 655 506 474 346 258 186 130 205 154 120 100 75 78 53 46

Rn kips 1345 1151 992 827 706 609 523 451 383 331 303 249 213 167 130 185 154 120 100 75 78 53 46

Rn kips 916 826 742 660 592 514 449 380 319 269 240 187 150 108 68 61 32 7 -16 -40 -66 -97 -133

Rn kips 916 826 742 660 592 514 449 380 319 269 240 187 150 108 68 61 32 7 -16 -40 -66 -97 -133

Py kips 4575 4160 3795 3440 3105 2820 2565 2315 2105 1910 1755 1555 1425 1265 1115 1040 955 880 810 735 675 590 515

1 1/ 4 1 3/16 1 1/ 8

You might also like

- Epmc Extended LRFD Asd Aisc New 28-10-2013Document10 pagesEpmc Extended LRFD Asd Aisc New 28-10-2013tamerragaaNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Base Plate FixedDocument4 pagesBase Plate FixedssikhaNo ratings yet

- Design of Monolithic Corbels and Brackets According To Aci 318 - 99Document1 pageDesign of Monolithic Corbels and Brackets According To Aci 318 - 99Sulaiman Mohsin AbdulAzizNo ratings yet

- Joist DesignDocument1 pageJoist Designalexkirokos0% (1)

- Clipconn All Bolt 13Document22 pagesClipconn All Bolt 13NEONo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Precast Driven Pile Section Analysis: Input DataDocument1 pagePrecast Driven Pile Section Analysis: Input DatacivixxNo ratings yet

- ACI ShearDocument3 pagesACI Shearمصطفى عبدالرحيم100% (1)

- AISC Vertical Brace Connection DesignDocument115 pagesAISC Vertical Brace Connection DesigndongxiaoNo ratings yet

- Aisc - Chapter JDocument13 pagesAisc - Chapter JDinesh KumarNo ratings yet

- CompositeFloorBeam 2014 OK VIGUETA W16x40 L 9.55mDocument6 pagesCompositeFloorBeam 2014 OK VIGUETA W16x40 L 9.55mValiente ImperatorNo ratings yet

- Steel Beam Flexural CapacityDocument6 pagesSteel Beam Flexural CapacitykstayroskNo ratings yet

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- ACI Beam LedgeDocument7 pagesACI Beam LedgeMahmoud ShakerNo ratings yet

- Imp Design GuideDocument32 pagesImp Design GuideRahulNo ratings yet

- 07-Design of Stringer BracingDocument17 pages07-Design of Stringer BracingTran Nhu HoaNo ratings yet

- Beam End Connection Using Clip Angles Per AISC 9th Edition (ASD)Document36 pagesBeam End Connection Using Clip Angles Per AISC 9th Edition (ASD)cengizNo ratings yet

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Document22 pagesSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNo ratings yet

- CivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFDocument9 pagesCivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFhemantcabhaleNo ratings yet

- Check of Z Section On Principle Axes: Data InputDocument3 pagesCheck of Z Section On Principle Axes: Data InputAlden CayagaNo ratings yet

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerGANESHNo ratings yet

- Mill BuildingDocument135 pagesMill BuildingKaraline MarcesNo ratings yet

- Steel Joists, Joist Girders and Hollow Structural Sections (HSS)Document55 pagesSteel Joists, Joist Girders and Hollow Structural Sections (HSS)jeffuangNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- Decking (Composite & 2 Layers Reinf)Document41 pagesDecking (Composite & 2 Layers Reinf)Than Than SoeNo ratings yet

- BEAMDocument3 pagesBEAMTano BahabobaNo ratings yet

- Connections I V2.1.0.aDocument72 pagesConnections I V2.1.0.ajh50000No ratings yet

- 3.1a - Reliability & RedundancyDocument6 pages3.1a - Reliability & RedundancyklynchelleNo ratings yet

- PurlinDocument1 pagePurlinCe WinNo ratings yet

- AISC Properties ViewerDocument1 pageAISC Properties ViewerAulia MirzaNo ratings yet

- BraceconnectionDocument10 pagesBraceconnectionLeonardo PimentelNo ratings yet

- Software Verification: AISC-360-16 Example 003Document5 pagesSoftware Verification: AISC-360-16 Example 003alejandro mantillaNo ratings yet

- Anchor Bolt Design As Per American CodeDocument1 pageAnchor Bolt Design As Per American CodeS A K ClostreNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- AISC MetricDocument73 pagesAISC MetricTeju AshuNo ratings yet

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- Shear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design CriteriaDocument1 pageShear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design Criteriaridho ziskaNo ratings yet

- Pile Cap Design For 3-Piles Pattern Based On ACI 318-14Document18 pagesPile Cap Design For 3-Piles Pattern Based On ACI 318-14VikasVarmaNo ratings yet

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- Calculation & Formuals: ReferenceDocument3 pagesCalculation & Formuals: ReferenceAddrien DanielNo ratings yet

- LRFD Beam Column DesignDocument242 pagesLRFD Beam Column DesignChristian FTNo ratings yet

- Steel Section AISC360-10Document4 pagesSteel Section AISC360-10osman_sultan100% (1)

- Double Angle ConnectionDocument8 pagesDouble Angle ConnectionrunkirNo ratings yet

- XyzDocument64 pagesXyzP S HARSHITANo ratings yet

- Plate DesignDocument6 pagesPlate DesignUmesh ChamaraNo ratings yet

- Design of Concrete Corbel/bracketDocument5 pagesDesign of Concrete Corbel/bracketThomas John Doblas AgrabioNo ratings yet

- Truss Conn Final 1Document314 pagesTruss Conn Final 1amachmouchiNo ratings yet

- Copedwbeamseat - Xls (Revision 1.1)Document4 pagesCopedwbeamseat - Xls (Revision 1.1)sergiooiNo ratings yet

- AISC Tension MemberDocument3 pagesAISC Tension Membermodulor3dNo ratings yet

- Spreadsheet IndexDocument1 pageSpreadsheet IndexPrabhuNo ratings yet

- Software Verification: ACI 318-14 Example 002Document4 pagesSoftware Verification: ACI 318-14 Example 002yudhi putraNo ratings yet

- Ocbf IbcDocument3 pagesOcbf IbcNikki RobertsNo ratings yet

- Angle Seat DetailDocument4 pagesAngle Seat DetailpiziyuNo ratings yet

- Aisc Clean Columns WorksheetDocument5 pagesAisc Clean Columns WorksheetOsman Carrillo SotoNo ratings yet

- Formulae: Two-Way Shear With Negligible Moment TransferDocument7 pagesFormulae: Two-Way Shear With Negligible Moment TransferKory EstesNo ratings yet

- Strut and Time MethodDocument30 pagesStrut and Time MethodkrishNo ratings yet

- Reference 15: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 15: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 14: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 14: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 19: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 19: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Video Training Courses in Offshore Structures DesignDocument102 pagesVideo Training Courses in Offshore Structures Designscrbdgharavi100% (2)

- Reference 18: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 18: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Ref 17Document1 pageRef 17scrbdgharaviNo ratings yet

- Ref 4Document1 pageRef 4scrbdgharaviNo ratings yet

- Reference 6: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 6: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 3: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 3: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Reference 16: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 16: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- Agip KCO Aircraft Manuals IndexDocument1 pageAgip KCO Aircraft Manuals IndexscrbdgharaviNo ratings yet

- PG 3005 eDocument8 pagesPG 3005 escrbdgharaviNo ratings yet

- Environmental Performance Monitoring Reporting GuidelineDocument17 pagesEnvironmental Performance Monitoring Reporting GuidelinescrbdgharaviNo ratings yet

- 1856r0 Procedure No 1 HSSE Policies and Mandatory RulesDocument13 pages1856r0 Procedure No 1 HSSE Policies and Mandatory RulesscrbdgharaviNo ratings yet

- HSE Management - Guidelines For Working Together in A Contract EnvironmentDocument72 pagesHSE Management - Guidelines For Working Together in A Contract EnvironmentscrbdgharaviNo ratings yet

- E&pfor 1Document36 pagesE&pfor 1scrbdgharaviNo ratings yet

- Reference 2: Schedule 'D' Health, Safety, Environment and SecurityDocument1 pageReference 2: Schedule 'D' Health, Safety, Environment and SecurityscrbdgharaviNo ratings yet

- PG 1025 eDocument6 pagesPG 1025 escrbdgharaviNo ratings yet

- 0973r04 OKIOC Marine ManualDocument79 pages0973r04 OKIOC Marine ManualscrbdgharaviNo ratings yet

- PG 1048 eDocument6 pagesPG 1048 escrbdgharaviNo ratings yet

- An Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferDocument8 pagesAn Intelligent Pigging Project: Start To Finish: by William R Gwartney, JR, and Ed SchaeferscrbdgharaviNo ratings yet

- Pre On-Line Inspection Pigging: by C KershawDocument6 pagesPre On-Line Inspection Pigging: by C KershawscrbdgharaviNo ratings yet

- Internal Cleaning and Coating of In-Place Pipelines: by C KleinDocument4 pagesInternal Cleaning and Coating of In-Place Pipelines: by C KleinscrbdgharaviNo ratings yet

- U.S. Government Pipeline Safety Regulation: by J C CaldwellDocument6 pagesU.S. Government Pipeline Safety Regulation: by J C CaldwellscrbdgharaviNo ratings yet

- Pigging Multi-Diameter Lines and Other Specialist TechniquesDocument6 pagesPigging Multi-Diameter Lines and Other Specialist TechniquesscrbdgharaviNo ratings yet

- Solutions To Unpiggable' Pipelines: by Allen A PenningtonDocument6 pagesSolutions To Unpiggable' Pipelines: by Allen A PenningtonscrbdgharaviNo ratings yet

- PG 3150 eDocument4 pagesPG 3150 escrbdgharaviNo ratings yet

- PG 3025 eDocument6 pagesPG 3025 escrbdgharaviNo ratings yet

- PG 3052 eDocument4 pagesPG 3052 escrbdgharaviNo ratings yet

- Characterization of Mechanical Properties and Fracture Mode of PLADocument12 pagesCharacterization of Mechanical Properties and Fracture Mode of PLAatef.selmi01No ratings yet

- Earthquake MethodsDocument24 pagesEarthquake MethodsCesar MalenabNo ratings yet

- Groundwater Recharge EstimationDocument207 pagesGroundwater Recharge EstimationValen RamiirezNo ratings yet

- FerrocementDocument16 pagesFerrocementBaghya LakshmiNo ratings yet

- UCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnDocument23 pagesUCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnBhabani Shankar DasNo ratings yet

- Roof Truss GuideDocument12 pagesRoof Truss Guidephamquocdat123100% (1)

- Sanitation Code - Chapter 17 Revised IRRDocument32 pagesSanitation Code - Chapter 17 Revised IRRBoni MagtibayNo ratings yet

- Design of Machine Elements - Design Under Variable LoadingDocument76 pagesDesign of Machine Elements - Design Under Variable LoadingPraveenNo ratings yet

- Airconditioning Daily Maintenance ChecklistDocument1 pageAirconditioning Daily Maintenance ChecklistOdyssey Bartolome100% (1)

- Column CFRPDocument15 pagesColumn CFRPLenielle AmatosaNo ratings yet

- Shell Gadus S2 V220 0 TDSDocument2 pagesShell Gadus S2 V220 0 TDSsvntamil_159541837No ratings yet

- 콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Document108 pages콘크리트 사장교의 장기거동 해석을 위한 예측 모델의 비교Jin-hwan KimNo ratings yet

- BT4 4Document1 pageBT4 4JasNo ratings yet

- Shansep PDFDocument53 pagesShansep PDFHoàng HiệpNo ratings yet

- Lec 1-Week 1 - (Wastewater Collection System)Document32 pagesLec 1-Week 1 - (Wastewater Collection System)jahanzaibchNo ratings yet

- Green Interior Guidelines and Best Practice For Shapath-VDocument22 pagesGreen Interior Guidelines and Best Practice For Shapath-VDeshGujarat79% (14)

- Biaya Bor Dan Cementing Lubang UCGDocument8 pagesBiaya Bor Dan Cementing Lubang UCGzoel tekmira100% (1)

- Airframe and Systems, ElectricsDocument430 pagesAirframe and Systems, ElectricsdkskmuiaeemkgftsmrNo ratings yet

- Foundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDocument1 pageFoundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDanica Mae Amicay100% (1)

- Presented By: Rahul Bhardwaj B. Arch 7 SEM Nims School of Architecture and PlanningDocument18 pagesPresented By: Rahul Bhardwaj B. Arch 7 SEM Nims School of Architecture and PlanningVernika AgrawalNo ratings yet

- Isolated Footing Design by SefianDocument6 pagesIsolated Footing Design by SefianManoj Kumar Pal80% (5)

- Ideal Isar He30 Boiler Installation Manual - InstDocument68 pagesIdeal Isar He30 Boiler Installation Manual - InstAdamBeyonceLoweNo ratings yet

- CIEN 30043 Lecture No. 4Document24 pagesCIEN 30043 Lecture No. 4One Less than TwiceNo ratings yet

- Everyday DetailsDocument7 pagesEveryday DetailsJake WilliamsNo ratings yet

- Structural Pot Bearing4 CompressDocument30 pagesStructural Pot Bearing4 CompressChai Weng KuakNo ratings yet

- Construction ScheduleDocument11 pagesConstruction ScheduleScienceYilma YilmaNo ratings yet

- CPT en Practica Geotecnica - Lunne, Robertson, PowellDocument332 pagesCPT en Practica Geotecnica - Lunne, Robertson, PowellEloy Jiménez OntiverosNo ratings yet

- NSCP Timber Beam DesignDocument27 pagesNSCP Timber Beam DesignDiztrict GarageNo ratings yet

- Design of Box Culvert 3.5 M 3.5mDocument33 pagesDesign of Box Culvert 3.5 M 3.5mNivethaNo ratings yet

- Prob #1: Check For Slenderness of ColumnDocument7 pagesProb #1: Check For Slenderness of ColumnAman Raj VermaNo ratings yet