Professional Documents

Culture Documents

1569629120-MR Damper FuzzyPID

Uploaded by

Umanath R PoojaryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1569629120-MR Damper FuzzyPID

Uploaded by

Umanath R PoojaryCopyright:

Available Formats

Available online at www.sciencedirect.

com

Procedia Engineering 00 (2012) 000000

International Symposium on Robotics and Intelligent Sensors 2012 (IRIS 2012)

Fuzzy-PID Controller for Semi-Active Vibration Control Using Magnetorheological Fluid Damper

Banna Kasemi *, Asan G. A. Muthalif , M. Mahbubur Rashid, Sharmila Fathima

Department of Mectronics Engineering, International Islamic University Malaysia, Gombak, Kuala Lumpur, 53100, Malaysia

Abstract Magnetorheological (MR) dampers are considered as excellent prospect to the vibration control in automotive engineering. To overcome the effect from road disturbances many control algorithms have been developed and opted to control the vibration of the car. In this study, the methodology adopted to get a control structure is based on the experimental results. Experiments have been conducted to establish the behaviour of the MR damper. In this paper, the behavior of MR damper is studied and used in implementing vibration control. The forcedisplacement and force-velocity response with varying current has been established for the MR damper. The force for the upward motion and downward motion of damper piston is found increasing with current and velocity. In the cycle mode which is the combination of upward and downward motion of the piston, the force having hysteresis behaviour is found increasing with current. Results of this study may serve to aid in the modelling of MR damper for control applications.

2012 The Authors. Published by Elsevier Ltd. Selection and/or peer-review under responsibility of the Centre of Humanoid Robots and Bio-Sensor (HuRoBs), Faculty of Mechanical Engineering, Universiti Teknologi MARA.

Keywords: Magnetorhelogical fluid, MR damper, semi-active vibration, Fuzzy-PID

Nomenclature m k d x f Mass Spring constant Damping constant Distance Force

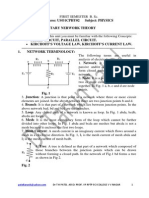

1. Introduction There are mainly three types of control devices: passive devices, active devices and semi-active devices. Semi-active devices offer the versatility and the adaptability of active device, and the reliability of the passive device. They can operate with power supply (active device) and without power supply (passive device). Magnetorheological (MR) dampers, variable orifice dampers and tuned liquid dampers are examples of semi-active devices. MR uids have been regarded as a smart material. Varying external magnetic eld strength is used to vary and control the rheological properties of MR fluids. A typical MR fluid contains 20 40% by volume of relatively pure, soft iron particles having a dimension of 3 to 5 microns. These particles are suspended in mineral oil, synthetic oil, water, or glycol. A variety of proprietary additives similar to those found in commercial lubricants are commonly added to discourage

* Corresponding author. Tel.: 03-6196 4464 , E-mail address: smhbkasemi@gmail.com / asan@iium.edu.my

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

gravitational settling and promote particle suspension, enhance lubricity, modify viscosity, and inhibit wear [1]. In the absence of an applied field, MR fluids exhibit Newtonian-like behaviour. However, in the presence of an applied magnetic field, the iron particles acquire a dipole moment aligned with the external field which causes the particles to form linear chains parallel to the field, as shown in Figure 1(a). This phenomenon can solidify the suspended iron particles and restrict the fluid movement.MR fluid damper or MR damper consists of MR fluid inside and it uses the properties of MR fluid in controlling the vibration of a system. The magnitude of force that an MR damper can deliver depends on the properties of MR fluids, their flow pattern, and the size of the damper. Figure 1(b) represents the structure of MR damper. Recently, MR fluid dampers have been widely applied to control and suppress unwanted vibration and shock for various systems including-landing gear, helicopter lag dampers, vibration isolation systems, vehicle seat suspension systems, civil structures, military equipments, prosthetic limbs. MR dampers possess key performance advantages, including continuously controllable force, rapid response, and low power consumption, which can be readily optimized in design procedures [2-3]. MR dampers can be analyzed using available models and are amenable to innovative design concepts [4-5].

(a)

(b)

Figure 1: (a) Chain-like structure formation in MR uids [6-7], (b) Typical MR damper [6-7]

To practically construct vibration and shock mitigation systems using MR dampers, either a power supply or a current amplifier is required to activate the electromagnetic coils in the MR dampers to supply magnetic field to the MR fluid. There are some key parameters which influence the MR dampers performance. However, there is no simple and effective parametric model with high accuracy for MR damper, though various kinds of models have been proposed and validated [8]. In recent years, researchers are studying ways to improve the performance of MR fluid damper. They are trying to fit the existing well-established models into their investigations with new ideas to achieve better performance. The main problem is the complexity encountered in implementing these models due to the large number of parameters that need to be estimated. The most popular ideas are based on the parametric solutions. These ideas, however, cannot describe the real phenomena of nonlinear system. In this study a simple technique based on the experimental result is suggested to control the vibration with MR damper. As this study is about experimental identifications, it solves the issue of evaluating too many parameters. This paper has tried to establish the characteristic analysis of MR damper with impedance (Force/Velocity) analysis. The main contribution is to achieve a new performance based model of magnetorheological damper. The experimental investigation and the performance analysis are the key for this methodology. This performance test is based on the dynamic force-displacementcurrent (surface) analysis. 2. Experimental Setup to establish behavior of MR damper The experimental setup comprises the MR damper, the wonder box, and a Universal Testing Machine (UTM) which are shown in Figure 2. The UTM was used to test the MR damper. The UTM has an upper and a lower head with grippers that can grasp the damper at the appropriate locations. The upper head is operated by a hydraulic actuator which can take a computer-generated prescribed displacement signal and is the moveable end. The lower head incorporates a load cell, allowing the operator to measure the force applied to the MR damper. The displacement of the damper is measured by a Linear variable differential transformer (LVDT) sensor which is integrated with the test machine. During the experiment, a variable voltage was supplied to provide the current excitation to the damper-coil. The required signal was generated using TRAPEZIUMX software running on a computer and the data was obtained from the software. The MR damper used in this experiment is a product of LORD Corporation, USA. The model number of the particular MR damper is RD-8041-1. The stroke length of the damper is 74 mm and the maximum tensile strength is 8896 N. MR fluid device controller kit, namely Wonder Box Device Controller (Model: LORD RD-3002-03 Wonder Box Device Controller), is a companion product of the MR fluid devices. It provides closed loop current control to compensate for

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

changing electrical loads up to the limit of the power supply (courtesy: LORD user instructions for LORD RD-3002-03 Wonder Box Device Controller). The maximum output current of this controller kit is 2 Ampere. Load cell

MR Damper

Manual controller

LCD Touch Panel

Figure. 2. Experimental set-up

During the experiment, the force and the displacement were analyzed for different velocities and different starting positions of the stroke. The stroke length for the damper is 74 mm. Three equal length positions were taken to test the performance with respect to stroke positions. These positions are shown in Figure 3. The damper was tested for different input currents and different stroke positions.

18.5

18.5

18.5

18.5

1st Stroke Position

Mid Stroke Position

3rd Stroke Position

Figure 3. Different stroke length positions

3. Results and discussions The UTM machine is used in two modes: upward motion and downward motion of piston. 3.1. Force Response The force increases proportionately with increasing field strength. The force is the smallest when the damper is in offstate (without field). It is because the particles are aligned linearly in a rigid chain structure for higher current, due to the corresponding increase in magnetic field. Thus, the mechanical energy needed to yield these chain-like structures increases

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

as the applied field increases. Velocity of the piston has a proportionate effect on the force. Lower piston velocity gives lower force amplitude, while higher velocity gives higher force as shown in Figure 4.

(a)

(b) Figure 4. Comparison of forces for different piston velocities: (a) downward motion mode at 0.60 Ampere (b) upward motion mode at 0.60 Ampere

Figure 5 shows the force versus displacement (stroke length) for varying currents in the cycle mode of 12 mm cycle stroke, when the piston velocity is 500 mm/min. These plots show the hysteresis characteristics.

Figure 5. Three dimensional plot of current, displacement (or stroke length) and force at different stroke positions in cycle mode for 12mm stroke length at Mid stroke position

In the cycle mode, the energy dissipation is calculated from the area of the hysteresis plot for individual current. Figure 6 shows the energy dissipation. The slope of this plot changes twice; slow rise in the beginning turns into much faster rise in the middle, and it returns to slow rise at the end. It is also observed that the energy dissipation is higher at the third stroke.

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

Figure 6. Energy dissipated in the hysteresis for different current

3.2. Performance of Fuzzy-PID controller The designed controller needs to supply voltage to the Wonder Box, which will supply a corresponding current to the MR damper, in order to absorb the force for a given stroke length of the piston. In this study, as a semi-active suspension system, a quarter car suspension model is analyzed. This model can be represented by a multiple degrees of freedom vibration system, as shown in Figure 7.

Figure 7. Quarter-Car model [9].

By applying Newtons second law, the equations of motion of m1 and m2 are: (1) (2) Based on the equations of motion in Equation (1) and Equation (2), a MATLAB/Simulink model of the quarter car suspension system is given in Figure 8, where m1=325 Kg, m2=55 Kg, d1=2000 Nsm-1, d2=250 Nsm-1, k1=42000 Nm-1 and k2=180000 Nm-1. Lookup tables based on experimental result are used to design controller. The first lookup table has force and current as input and output respectively, for any given stroke position. The output of the first Lookup Table goes to the input of second Lookup Table. The second Lookup Table has two inputs and one output. Displacement (stated as constant in Figure 8 (b)) is the other input of this Lookup Table. This second Lookup Table carries data of force for different current and for different stroke length. A PID controller is developed and compared with uncontrolled output. A PID controller tuned for a single frequency does not work for other excitation frequencies (tested using chirp signal). To overcome this limitation, an adaptive PID

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

controller is developed using Fuzzy logic. Fuzzy rules are developed to continuously change PID gains according to input excitation frequencies. Figure 9 shows PID, fuzzy-PID controller outputs and uncontrolled output.

(a)

(b)

Figure 8. Simulink model. (a). Total system model (b). System with controller.

Figure 9. Controller response for Chirp signal

Banna Kasemi, Asan G. A. Muthalif, M. M. Rashid, Sharmila Fathima / Procedia Engineering 00 (2012) 000000

The fuzzy-PID provides better result than PID controller only. Fuzzy-PID controller reduces the peak by 68% from that of PID controller in low frequency and it reduced the peak by 83 % from that of uncontrolled one. Fuzzy-PID gives better reduction in high frequency as well, which shows that fuzzy-PID controller works better in broadband range of frequency. Figure 10 provides the results of peak reduction by these two controllers. Uncontrolled

PID: 46.8 % Fz-PID: 17%

Figure 10. Peak reduction: PID controller vs Fuzzy-PID controller

4. Conclusion The technique of developing the controller, using the experimental results, has been shown in this paper, with the details of the block diagram of the control algorithm. At first, a simple PID controller has been tuned and simulated. Its controlled output is compared with the uncontrolled output. PID controller works very well for step and impulse road disturbance inputs. However, it cannot adapt when the condition changes. When the disturbance has varying conditions, PID controllers fail to provide good controlled output, due to its fixed PID gains. It needs to be re-tuned when the surrounding condition varies. In this case, it is observed that PID controller does not give satisfactory results, with the same gain used for the step and impulse input. To achieve adaptive tuning of the gain parameters, a fuzzy based PID controller is used, which shows improved results. Fuzzy-PID controller can adapt to the situation based on the fuzzy rules, and gives the controller a new set of gain parameters. This, of course, works better than the PID controller having fixed gain parameters. It is understood that, the experimented results of force response over varying current and displacement, can be used as MR damper model, which reduces the problem of evaluating too many constant parameters. Using this model, a controller can control the MR damper's variable damping output to control the vibration of a car, which provides the passengers better comfort.

References

[1] Yang, G., 2001. Large-Scale Magnetorheological Fluid Damper for Vibration Mitigation: Modeling, Testing and Control. PhD Dissertation, University of Notre Dame, Indiana. [2] Nguyen, Q. H., Han, Y. M., Choi, S.B., Choi, Y.T., & Wereley, N. M., 2007. Geometry Optimization of MR Valves Constrained in a Specific Volume Using the Finite Element Method. Smart Mater. Struct., 16(6), pp. 22422252. [3] Nguyen, Q. H., & Choi, S.B., 2009. Optimal Design of a Vehicle Magnetorheological Damper Considering the Damping Force and Dynamic Range. Smart Mater. Struct., 18(1), 015013. [4] Cook, E., Hu, W., & Wereley, N. M., 2007. Magnetorheological Bypass Damper Exploiting Flow Through a Porous Channel. J. Intell. Mater. Syst. Struct., 18(12), pp. 11971203. [5] Hitchcock, G. H., Wang, X., & Gordaninejad, F., 2007. A New Bypass Magnetorheological Fluid Damper. ASME J. Vibr. Acoust., 129(5), pp. 641 647. [6] Avraam, M. T., 2009. MR-uid brake design and its application to a portable muscular rehabilitation device. PhD Thesis, Univ. Libre de Bruxelles, Brussels, Belgium. [7] Carlson, J. D., 2007. Semi-active vibration suppression. In CISM Course: Semi-Active Vibration Suppression-the Best from Active and Passive Technologies. Udine, October 2007. [8] Wang, D. H., & Liao, W. H., 2011. Magnetorheological fluid dampers: a review of parametric modelling. Smart Materials And Structures, 20(2011), 023001. [9] Kasemi, B., Muthalif, A.G.A., Rashid, M.M., Rahman, M., 2011. Optimizing dynamic range of Magnetorheological fluid dampers: Modeling and simulation. Paper presented at the 4th International Conference On Mechatronics (ICOM), Kuala Lumpur, 17-19 May

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 4.failure Theories and Stress ConcentrationsDocument21 pages4.failure Theories and Stress ConcentrationsAmr El SaeedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Technical Report PDFDocument184 pagesTechnical Report PDFSrinivasan RajenderanNo ratings yet

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 pagesIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- SLTRT Service Level Testing Reporting ToolDocument110 pagesSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- EASA Part 66 Module 7 MCQ and Essay QuestionsDocument4 pagesEASA Part 66 Module 7 MCQ and Essay QuestionsazadairNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- HCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFDocument228 pagesHCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFliviuemanuelNo ratings yet

- SPINTRONICSDocument33 pagesSPINTRONICSSyam Pradeep ReddyNo ratings yet

- The Companies Bill 2012Document7 pagesThe Companies Bill 2012Raju ShawNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- The Companies Bill 2012Document7 pagesThe Companies Bill 2012Raju ShawNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- The Companies Bill 2012Document7 pagesThe Companies Bill 2012Raju ShawNo ratings yet

- Chapter 02Document55 pagesChapter 02Umanath R PoojaryNo ratings yet

- The Companies Bill 2012Document7 pagesThe Companies Bill 2012Raju ShawNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- Substance Abuse PresentationDocument12 pagesSubstance Abuse PresentationUmanath R PoojaryNo ratings yet

- The Companies Bill 2012Document7 pagesThe Companies Bill 2012Raju ShawNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- Determinants of Youth Sexual Behaviour: Program Implications For IndiaDocument9 pagesDeterminants of Youth Sexual Behaviour: Program Implications For IndiaUmanath R PoojaryNo ratings yet

- 10 0000@compass Astm org@generic-B5B61491F36D PDFDocument7 pages10 0000@compass Astm org@generic-B5B61491F36D PDFUmanath R PoojaryNo ratings yet

- QgklsDocument12 pagesQgklsUmanath R PoojaryNo ratings yet

- 10 0000@compass Astm org@generic-B5B61491F36D PDFDocument7 pages10 0000@compass Astm org@generic-B5B61491F36D PDFUmanath R PoojaryNo ratings yet

- Plimi Ym Nvestigation of ThponsivenessDocument8 pagesPlimi Ym Nvestigation of ThponsivenessUmanath R PoojaryNo ratings yet

- Levels of Care Types of Facilities/AgenciesDocument3 pagesLevels of Care Types of Facilities/AgenciesUmanath R PoojaryNo ratings yet

- Ion ReisoDocument8 pagesIon ReisoUmanath R PoojaryNo ratings yet

- Cromeal Asis of An StomerDocument13 pagesCromeal Asis of An StomerUmanath R PoojaryNo ratings yet

- 10 0000@compass Astm org@generic-B5B61491F36D PDFDocument7 pages10 0000@compass Astm org@generic-B5B61491F36D PDFUmanath R PoojaryNo ratings yet

- Plimi Ym Nvestigation of ThponsivenessDocument8 pagesPlimi Ym Nvestigation of ThponsivenessUmanath R PoojaryNo ratings yet

- Plimi Ym Nvestigation of ThponsivenessDocument8 pagesPlimi Ym Nvestigation of ThponsivenessUmanath R PoojaryNo ratings yet

- Research Article: Analysis and Testing of Chain Characteristics and Rheological Properties For Magnetorheological FluidDocument7 pagesResearch Article: Analysis and Testing of Chain Characteristics and Rheological Properties For Magnetorheological FluidUmanath R PoojaryNo ratings yet

- Ion ReisoDocument8 pagesIon ReisoUmanath R PoojaryNo ratings yet

- Entral ScotomDocument4 pagesEntral ScotomUmanath R PoojaryNo ratings yet

- Eyee Ading With Laint And.16Document10 pagesEyee Ading With Laint And.16Umanath R PoojaryNo ratings yet

- Ubber Mount TestDocument8 pagesUbber Mount TestUmanath R PoojaryNo ratings yet

- Tutorials: Tutorial 1Document16 pagesTutorials: Tutorial 1Umanath R PoojaryNo ratings yet

- Ferro HydroDocument7 pagesFerro HydroUmanath R PoojaryNo ratings yet

- Calibration of A Pressure GaugeDocument6 pagesCalibration of A Pressure GaugeThapelo100% (2)

- Us01cphy02 Unit 1 2014 THPDocument18 pagesUs01cphy02 Unit 1 2014 THPapi-264723824No ratings yet

- User's Guide: BondekDocument8 pagesUser's Guide: BondekMing ChongNo ratings yet

- Price Quotation: Quote/Project Description Ref. Details: Project DetailDocument3 pagesPrice Quotation: Quote/Project Description Ref. Details: Project DetailAhmad AyyoubNo ratings yet

- Sauer-Danfoss Loop Flushing ValveDocument8 pagesSauer-Danfoss Loop Flushing Valvedmt wayNo ratings yet

- Data Collector 2.03.00Document20 pagesData Collector 2.03.00vyaskingNo ratings yet

- CHM096-Tutorial 1 (Alkanes & Alkenes)Document4 pagesCHM096-Tutorial 1 (Alkanes & Alkenes)Anonymous RD1CrAINo ratings yet

- Stand Cons T DetailsDocument164 pagesStand Cons T DetailsmirfanjpcgmailcomNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNo ratings yet

- Next Gen Ford Ranger Digital BrochureDocument10 pagesNext Gen Ford Ranger Digital BrochureTri BureauNo ratings yet

- Solidworks SyllabusDocument7 pagesSolidworks SyllabusArun SubramanianNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- Leg Foot Massager 1026 ManualDocument5 pagesLeg Foot Massager 1026 ManualBhushan BhikeNo ratings yet

- Oracle E-Business Suite Release 11i Upgrade To R12.1Document60 pagesOracle E-Business Suite Release 11i Upgrade To R12.1Vladimir PacotaipeNo ratings yet

- CNA09016 SGDocument8 pagesCNA09016 SGSatyarth SampathNo ratings yet

- Theory of Metal Cutting-Module 1Document116 pagesTheory of Metal Cutting-Module 1rejeesh_rajendranNo ratings yet

- CP 05 - Determine The Young S Modulus of A MaterialDocument2 pagesCP 05 - Determine The Young S Modulus of A MaterialABBIE ROSENo ratings yet

- Verilog Interview Questions & AnswersDocument6 pagesVerilog Interview Questions & AnswersKrishna Saroja SankaNo ratings yet

- AGA-3 Comparison Normal BetaDocument12 pagesAGA-3 Comparison Normal BetahailriqNo ratings yet

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 pagesBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasNo ratings yet

- Dwarkadas J Sanghvi College of Engineering Provisional Merit ListDocument4 pagesDwarkadas J Sanghvi College of Engineering Provisional Merit ListSharth NairNo ratings yet