Professional Documents

Culture Documents

Contenedores Estructura

Uploaded by

Joseph AguirreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contenedores Estructura

Uploaded by

Joseph AguirreCopyright:

Available Formats

FICHA TECNICA

CONTENEDOR "STANDARD" Standard de 20' largo ancho altura interno interno interna 19'4" 7'8" 7'10" ancho alto peso del mxima de la de la capacidad contenedor capacidad puerta puerta vacio peso 7'8" 7'6" 1,172CuFt 4,916lbs 2,230Kg 47,900lbs 21,770Kg

5.900m 2.350m 2.393m 2.342m 2.280m 33.2CBM Standard de 40' largo ancho altura interno interno interna 39'5" 7'8" 7'10"

ancho alto peso del mxima de la de la capacidad contenedor capacidad puerta puerta vacio peso 7'8" 7'6" 2,390CuFt 8,160lbs 59,040lbs

12.036m 2.350m 2.392m 2.340m 2.280m 67.7CBM

3,700Kg

26,780Kg

CONTENEDOR "ALTO CUBICAJE" Alto Cubicaje de 40' largo ancho altura interno interno interna 39'5" 7'8" 8'10" ancho alto peso del mxima de la de la capacidad contenedor capacidad puerta puerta vacio peso 7'8" 8'5" 2,694CuFt 8,750lbs 3,970Kg 58,450lbs 26,510Kg

12.036m 2.350m 2.697m 2.338m 2.584m 76.3CBM Alto Cubicaje de 45' largo ancho altura interno interno interna 44'6" 7'8" 8'10"

ancho alto peso del mxima de la de la capacidad contenedor capacidad puerta puerta vacio peso 7'8" 8'5" 3,026CuFt 9,061lbs 4,110Kg 58,450lbs 26,510Kg

13.58m 2.350m 2.697m 2.338m 2.584m 85.7CBM

*ESTE ES UN EJEMPLO DE CALCULO QUE ME ENCONTRE Un contenedor o container es un recipiente de carga que se utiliza principalmente en el

transporte martimo donde por normativa se permite apilar un mximo de 5 contenedores, es

decir, un mximo de 12,5 metros de altura. Las dimensiones de los contenedores martimos

utilizados, se encuentran normalizadas para facilitar su manipulacin y montaje, Los contenedores utilizados en el acopio, estn fabricados principalmente de acero corten, con las caractersticas y especificaciones Tcnicas que se detallan ms adelante, las cuales les permiten distribuir los esfuerzos a travs de sus pilares y vigas que son sus elementos soportantes.

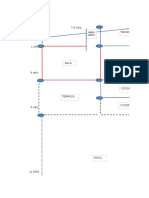

Fig. 2 1. CARACTERISTICAS DEL CONTENEDOR DRY-VAN 20. PESO VACIO 2250 Kg

PESO MAXIMO 28240 Kg

MEDIDAS EXTERNO INTERNO PUERTAS ABIERTAS LARGO 6090 mm 5900 mm ANCHO 2438 mm 2345 mm 2335 mm ALTO 2600 mm 2400 mm 2290 mm VOLUMEN 33,30 m3

2. CARACTERISTICAS DEL CONTENEDOR DRY-VAN 40. PESO VACIO 5000 Kg

PESO MAXIMO 48240 Kg

MEDIDAS EXTERNO INTERNO PUERTAS ABIERTAS LARGO 12090 mm ANCHO 2438 mm 2345 mm 2335 mm ALTO 2600 mm 2400 mm 2290 mm VOLUMEN 73,0 m3

3. Especificaciones Tcnicas de los contenedores utilizados: Refuerzos rectangulares en todas las esquinas.

Perfil en C de 160 mm de altura (ala e= 10,5 mm; cuerpo e= 7,5 mm). Largueros rectangulares de 60x120 mm (e= 2 mm). Perfiles cuadrados de 120 mm (e= 4 mm).

Perfil rectangular de tubo de 60x120 mm (e= 2 mm). Perfil rectangular de tubo de 60x140 mm (e= 3 mm). Perfiles rectangulares de 140x180 mm (e= 5 mm). El resto del conteiner est construido con chapa corrugada de acero y como Suelo dispone de una chapa de 10 mm tambin de acero.

Esta chapa de acero corrugada, NO ACTUA estructuralmente, ya que solamente tiene como funcin cerrar hermticamente los contenedores, debido a que todos los perfiles nombrados SOPORTANTES. en las especificaciones tcnicas son los que actan como pilares y vigas ESTRUCTURALES Estos son los encargados de transmitir las fuerzas admisibles (peso propio) y as poder soportar toda la estructura del acopio y todas sus cargas solicitantes (viento, choque del cargador a las latas). Es decir, son las que se toman en cuenta al momento de realizar un CLCULO ESTRUCTURAL.

Fig. 3 En la figura 3 se puede observar que los contenedores no se apoyan en las vigas para soportar su peso propio, es decir, que todos los esfuerzos se distribuyen a travs de los pilares.

Fig. 4 En la figura numero 4 podemos ver los pilares reforzados con pletina metlica de 5mm. De espesor soldada en la unin de todos los pilares, los que refuerza aun las la estructura y le otorga la resistencia antissmica adecuada para esta zona.

A continuacin realizaremos un clculo estructural para comprobar la seguridad de la estructura construida en base a contenedores martimos por minera Santa Fe en su acopio de mineral. 4. MEMORIA DE CALCULO Se realizara la siguiente memoria de clculo, tomando en cuenta que los contenedores del primer nivel se encuentran rellenados con arena de una densidad de 1800 kg/m3.y el peso propio de los contenedores que se ubican en los niveles superiores es el detallado en el punto 4 del presente informe.

VOLUMEN CONTENEDOR = 12MT X 2,5 MT X 2,5 MT VOLUMEN CONTENEDOR = 75 M3 DENSIDAD ARENA: 1800 KG/M3 PESO CONTENEDOR CON ARENA = 135 TON. PESO CONTENEDOR VACIO = 5 TON. PESO TOTAL COLUMNA DE 4 CONTENEDORES = 150 TON ES DECIR SE CONSIDERA UNA FUERZA ADMISIBLE DE 150 TON, POR LO TANTO, A CONTINUACION SE VERIFICARAN LAS FUERZAS SOLICITADAS Y SE COMPARARAN CON LA FUERZA ADMISIBLE DE LOS 4 CONTENEDORES PARA ASI OBTENER UN FACTOR DE SEGURIDAD. Tomando en cuenta que la velocidad mxima de la carga al descargar mineral al interior del acopio es de 5 km/h Peso de operacin de carga : 5 ton Si nos ponemos en el caso ms desfavorable fuerza solicitante = 25 ton

FACTOR DE SEGURIDAD= FUERZAS ADMISIBLES / FUERZAS SOLICITANTES FACTOR DE SEGURIDAD = 150 / 25 FACTOR DE SEGURIDAD = 6,0

SHIPPING CONTAINER STRUCTURAL COMPONENTS AND TERMINOLOGY

Figure 4.1 Primary Structural Components for a Typical 20' ISO Shipping Container.

4.1.1 Corner Fitting. Internationally standard fitting (casting) located at the eight corners of the container structure to provide means of handling, stacking and securing containers. Specifications are defined in ISO 1161.

4.1.2 Corner Post. Vertical structural member located at the four corners of the container and to which the corner fittings are joined. 4.1.3 Door Header. Lateral structural member situated over the door opening and joined to the corner fittings in the door end frame. 4.1.4 Door Sill. Lateral structural member at the bottom of the door opening and joined to the corner fittings in the door end frame. 4.1.5 Rear End Frame. The structural assembly at the rear (door end) of the container consisting of the door sill and header joined at the rear corner fittings to the rear corner posts to form the door opening.

4.1.6 Top End Rail. Lateral structural member situated at the top edge of the front end (opposite the door end) of the container and joined to the corner fittings. 4.1.7 Bottom End Rail. Lateral structural member situated at the bottom edge of the front end (opposite the door end) of the container and joined to the corner fittings. 4.1.8 Front End Frame. The structural assembly at the front end (opposite the door end) of the container consisting of top and bottom end rails joined at the front corner fittings to the front corner posts.

4.1.9 Top Side Rail. Longitudinal structural member situated at the top edge of each side of the container and joined to the corner fittings of the end frames. 4.1.10 Bottom Side Rail. Longitudinal structural member situated at the bottom edge of each side of the container and joined to the corner fittings to form a part of the understructure. 4.1.11 Cross Member. Lateral structural member attached to the bottom side rails that supports the flooring. 4.1.12 Understructure. An assembly consisting of bottom side and end rails, door sill (when applicable), cross members and forklift pockets. 4.1.13 Forklift Pocket. Reinforced tunnel (installed in pairs) situated transversely across the understructure and providing openings in the bottom side rails at ISO prescribed positions to enable either empty capacity or empty and loaded capacity container handling by forklift equipment.

4.1.14 Forklift Pocket Strap. The plate welded to the bottom of each forklift pocket opening or part of bottom siderail. The forklift pocket strap is a component of the forklift pocket. 4.1.15 Gooseneck Tunnel. Recessed area in the forward portion of the understructure to accommodate transport by a gooseneck chassis. This feature is more common in forty foot and longer containers.

Figure 4.2 Exploded axonometric view of a Typical 20' ISO Shipping Container .

4.2 Walls, Roof, and Floor. Refer to Figure 4.2A 4.2.1 Fiberglass Reinforced Plywood (FRP). A material constructed of laminates of fiberglass, polyester resins, and plywood, also known as sandwich panel. 4.2.2 Wall Panel. Corrugated or flat sheet steel, a riveted or bonded aluminum sheet and wall post assembly, FRP, foam and beam, aluminum, or honeycomb material that forms the side wall or end wall.

4.2.3 Wall Post. Interior or exterior intermediate vertical component to which sheet aluminum or steel is riveted or welded to form a wall panel. 4.2.4 Wall Beam. Encapsulated vertical component to which sheet aluminum or steel is bonded to form a wall panel.This is found in foam and beam panels. 4.2.5 Marking Panel. A side wall panel of a corrugated steel configured with a flat portion used for the display of markings and placards. (4.2A) 4.2.6 Lining. Plywood or other like material attached to the interior side and end wall to protect the walls and/or cargo and facilitate loading operations.

4.2.7 Lining Shield. A strip of thin metal installed at the bottom of the interior walls to protect the lower portion of the lining from damage by materials handling equipment during loading or unloading operations.

4.2.8 Kick Plate. A common name for a lining shield installed on the lower portion of the interior front end wall. 4.2.9 Ventilator. Two or more devices permanently attached to the side or end wall panel that provides openings for the exchange of air (but not water) between the outside and the container interior. (4.2A)

4.2.10 Roof Panel. Corrugated or flat sheet steel, sheet aluminum, FRP, or foam and beam and aluminum honeycomb panel that forms the top closure of the container. (4.2A,) 4.2.11 Roof Bow. Lateral non-structural member attached to the top side rails and supporting the underside of the roof panel. Roof bows used with removable cover (tarp) assembly are unattached. Not all container designs require roof bows.

4.2.12 Roof Beam. Encapsulated horizontal component to which sheet aluminum or steel is bonded to form a roof panel. 4.2.13 Roof Reinforcement Plate. An additional metal plate on the interior or exterior of the roof panel adjacent to the top corner fittings that provides protection of the roof panel or top rail components from misaligned handling equipment.

4.2.14 Tarp. Jargon for "tarpaulin" which is a waterproof and flexible fabric used for covering the top of an open-top container. This covering is referred to as a "Tilt" in some countries. 4.2.15 TIR Cable. Plastic sheathed wire rope that is designed in accordance with TIR customs convention (Refer to paragraph 4.5.6) and is threaded through the welded loops on the sides, end panels and door panels of an open-top container to secure the tarp.

4.2.16 Flooring. Material that is supported by the cross members and bottom rails to form a load bearing surface for the cargo. The flooring is usually constructed of laminated wood planks, plywood sheets, or other composition material and is screwed or bolted to the cross members. Some containers have welded steel or aluminum flooring, sandwhich panels or a combination of metal and wood. (4.2A)

4.2.17 Joint Strip. A formed steel or aluminum strip (usually hat-shaped section) installed between joints of the plywood sheet flooring or joints of the plywood sheet lining to help integrate and support the edges of the plywood. (4.2A)

4.2.18 Threshold plate. Plate forward of the door sill to protect the entrance area of the container floor. This plate is commonly referred to as a crash plate. 4.2.19 Steps. Folding steps are found on some ISO Shelters and are used to gain access to the roof. They must be folded up prior to transporting shelter. 4.2.20 Sandwich Panel. A type of fixed or removable panel construction used in ISO Shelters consisting of a thin inner and outer sheet aluminum skin, bonded or fastened to a core constructed of either honeycomb or structural foam and aluminum beams.

4.2.21 Striker Plate. An additional metal plate on the exterior of the roof panel adjacent to the top corner fittings that provides protection to the roof panel or top rail components from misaligned handling equipment.

4.2.22 Sling Pad. An additional metal plate on the exterior of the roof panel located in the center of the roof panel that provides protection to the panel from lowered handling equipment.

You might also like

- Conceptos avanzados del diseño estructural con madera: Parte I: uniones, refuerzos, elementos compuestos y diseño antisísmicoFrom EverandConceptos avanzados del diseño estructural con madera: Parte I: uniones, refuerzos, elementos compuestos y diseño antisísmicoNo ratings yet

- INFORME de Acreditacion Proteccion Contra El Fuego-CASA-HURTADODocument7 pagesINFORME de Acreditacion Proteccion Contra El Fuego-CASA-HURTADOJeniffer SNNo ratings yet

- Elementos de concreto reforzado IFrom EverandElementos de concreto reforzado IRating: 2.5 out of 5 stars2.5/5 (2)

- Memoria de Calculo RTB20Document9 pagesMemoria de Calculo RTB20Nicolás CarrascoNo ratings yet

- Plantilla-Memoria-Albanileria-Armada (Es Confinada Pero Sirve de Plantilla)Document18 pagesPlantilla-Memoria-Albanileria-Armada (Es Confinada Pero Sirve de Plantilla)nicolas contrerasNo ratings yet

- Memoria de Cálculo Contenedores REV BDocument16 pagesMemoria de Cálculo Contenedores REV BLeandro Esteban Zazzali SanchezNo ratings yet

- NCH 1198-2006-047 TEXTO PDFDocument231 pagesNCH 1198-2006-047 TEXTO PDFrodolfo.balboa100% (1)

- Catálogo NatuvenrDocument1 pageCatálogo NatuvenrJuan Ignacio AcuñaNo ratings yet

- NCH 1537 Reduccion de Cargas - RaDocument25 pagesNCH 1537 Reduccion de Cargas - RaFrancisco LobosNo ratings yet

- MEMORIA DE CALCULO ESTRUCTURA CABILDO-Rev1Document27 pagesMEMORIA DE CALCULO ESTRUCTURA CABILDO-Rev1orteanNo ratings yet

- Aci318 - Estribos Llave de Corte Cruz RevDocument2 pagesAci318 - Estribos Llave de Corte Cruz RevpeyostailNo ratings yet

- Diseño Fundaciones Con SafeDocument20 pagesDiseño Fundaciones Con SafeGonzaloAgustinBeuzenbergAlonsoNo ratings yet

- GFHFHDocument30 pagesGFHFHMelisa Oyarce GutiérrezNo ratings yet

- Anexo C Especificaciones Tecnicas en La Construccion de ViviendasDocument24 pagesAnexo C Especificaciones Tecnicas en La Construccion de ViviendasFabrizio Luppichini F.No ratings yet

- Diseño de Fundaciones RNDocument11 pagesDiseño de Fundaciones RNBranco Segovia MartínezNo ratings yet

- GalponDocument1 pageGalponpelaoguenoNo ratings yet

- Ejercicios02 PDFDocument4 pagesEjercicios02 PDFlanderxitoNo ratings yet

- GALPÓN 20x20x6: Geometría Cargas de DiseñoDocument1 pageGALPÓN 20x20x6: Geometría Cargas de DiseñoJaimeRamónAtalaConchaNo ratings yet

- Instapanel Manual TuBest PDFDocument53 pagesInstapanel Manual TuBest PDFEnverYangDuranCastroNo ratings yet

- Diseño de CostanerasDocument37 pagesDiseño de CostanerasLuis AlzamoraNo ratings yet

- Fichas TriplexDocument1 pageFichas TriplexCamila Blanco0% (1)

- Diseño y Analisis de LosaDocument19 pagesDiseño y Analisis de LosaJuan Omonte AllccaNo ratings yet

- Manual Ingenieria Tigre-ADS - Cap 3 HidraulicaDocument16 pagesManual Ingenieria Tigre-ADS - Cap 3 HidraulicaemiliolgNo ratings yet

- MC G18 Rev.aDocument18 pagesMC G18 Rev.aLusiana GonzalezNo ratings yet

- MemoriaDocument7 pagesMemoriaClaudio AntrisNo ratings yet

- Pilotes CFADocument55 pagesPilotes CFAcarlosbelmar.big100% (1)

- Calculo CostanerasDocument9 pagesCalculo CostanerasJael MillanNo ratings yet

- Memoria de Calculo L 30mDocument49 pagesMemoria de Calculo L 30mJHASMANY ZARATE DAZANo ratings yet

- Galpón 25x40x6 con detalles geométricos y cargas de diseñoDocument1 pageGalpón 25x40x6 con detalles geométricos y cargas de diseñoEdison GuzmanNo ratings yet

- 01-Manual Instadeck PDFDocument7 pages01-Manual Instadeck PDFpipiyeduNo ratings yet

- Manual de Piso DeckDocument7 pagesManual de Piso DeckIvan FlorentinoNo ratings yet

- Memoria de Calculo Gotitas AmorDocument16 pagesMemoria de Calculo Gotitas AmorMario BuenoNo ratings yet

- Bases de CálculoDocument7 pagesBases de CálculoIgnacio Felipe Marislao GonzalezNo ratings yet

- Tubo o Perfil Tubular HSSDocument20 pagesTubo o Perfil Tubular HSSLORD TRAUMASNo ratings yet

- Memoria de Cálculo Salas Colcura Lota 20 NoviembreDocument8 pagesMemoria de Cálculo Salas Colcura Lota 20 NoviembrecabelmarNo ratings yet

- Entrega B (Eb) Grupo 6Document73 pagesEntrega B (Eb) Grupo 6TomasNo ratings yet

- Manual Ingenieria Tigre-ADS - Cap 6 Retencion y DetencionDocument13 pagesManual Ingenieria Tigre-ADS - Cap 6 Retencion y DetencionJuan Gutierrez CastilloNo ratings yet

- MC Machones de Anclaje Rev BDocument9 pagesMC Machones de Anclaje Rev BmarioNo ratings yet

- TRABAJO PRACTICO INTEGRADOR..... Docx3Document11 pagesTRABAJO PRACTICO INTEGRADOR..... Docx3Julia Josefa TitoNo ratings yet

- Guia Placa Losa ColaboranteDocument13 pagesGuia Placa Losa ColaboranteDAVID EBNER100% (1)

- KoverpolDocument2 pagesKoverpolSergio Felipe0% (1)

- Inspección muros corteDocument117 pagesInspección muros corteIgnacio A. GonzalezNo ratings yet

- Diseño de Anclajes ACI 318-2015Document5 pagesDiseño de Anclajes ACI 318-2015Jorge BazánNo ratings yet

- Cálculo Zanja InfiltraciónDocument1 pageCálculo Zanja InfiltraciónCristian Ruiz RiquelmeNo ratings yet

- Placa Base Patty - ASDDocument36 pagesPlaca Base Patty - ASDPatty Martinez0% (1)

- Presentación N°4 Diseño Columnas de HormigónDocument32 pagesPresentación N°4 Diseño Columnas de HormigóncaradechalaNo ratings yet

- Manual Tubest C-2020Document20 pagesManual Tubest C-2020salozuraNo ratings yet

- Temario - M4T4 - Depósitos Prefabricados y MetálicosDocument63 pagesTemario - M4T4 - Depósitos Prefabricados y MetálicosMario GuillenNo ratings yet

- 6701 Tec No 306006620Document4 pages6701 Tec No 306006620christianramirezrNo ratings yet

- Tutorial RW de Ram Elements V8iDocument14 pagesTutorial RW de Ram Elements V8itoky-topo100% (1)

- Memoria Calculo Jardin Infantil Girasol 22-11-16Document24 pagesMemoria Calculo Jardin Infantil Girasol 22-11-16Mauricio Valenzuela100% (2)

- NCh1186 1997Document19 pagesNCh1186 1997Carolina BeatrizNo ratings yet

- Galpón KonyDocument107 pagesGalpón KonyDaniel Francisco Contreras PerezNo ratings yet

- Especificaciones Tecnicas HormigonDocument140 pagesEspecificaciones Tecnicas HormigonEnrique Jara LopezNo ratings yet

- Mce Tótem Sodimac Rev ADocument20 pagesMce Tótem Sodimac Rev ARuperto BravoNo ratings yet

- Memoria de Cálculo - Estructura PostdecantadorDocument28 pagesMemoria de Cálculo - Estructura PostdecantadorDiego Fuentes RománNo ratings yet

- CargasDocument10 pagesCargasLuis Enrique Chaco CcallomamaniNo ratings yet

- MC CasaStoDomingo Rev 1Document84 pagesMC CasaStoDomingo Rev 1Nicolas Ignacio Yañez CarrascoNo ratings yet

- Construccion de Un TanqueDocument9 pagesConstruccion de Un TanqueAgustin de la CruzNo ratings yet

- Partes de Un ContenedorDocument7 pagesPartes de Un ContenedorGalia MoscosoNo ratings yet

- Medidas Cimentacion Casa AmpliacionDocument8 pagesMedidas Cimentacion Casa AmpliacionJoseph AguirreNo ratings yet

- ZapataCargaAxialDocument8 pagesZapataCargaAxialWilber Condori100% (1)

- Valor R Prototipo Los OlivosDocument3 pagesValor R Prototipo Los OlivosJoseph AguirreNo ratings yet

- R C D FDocument119 pagesR C D FRoberto Martinez100% (1)

- Trabajo Spa EntregaDocument24 pagesTrabajo Spa EntregaJoseph AguirreNo ratings yet

- R C D FDocument119 pagesR C D FRoberto Martinez100% (1)

- Analisis de SitioDocument2 pagesAnalisis de SitioJoseph AguirreNo ratings yet

- TELETIRANÍADocument3 pagesTELETIRANÍAJoseph AguirreNo ratings yet

- Correcciones de Metodo 3 CORREGIDODocument36 pagesCorrecciones de Metodo 3 CORREGIDOKarol VRNo ratings yet

- Presentacion CompostajeDocument21 pagesPresentacion CompostajeTatiana Aroca ParamoNo ratings yet

- Capítulo 6 EN ESPAÑOL Del Handbook VaporDocument77 pagesCapítulo 6 EN ESPAÑOL Del Handbook VaporSergio GarcíaNo ratings yet

- Reconocimiento de ProteinasDocument9 pagesReconocimiento de ProteinasMONICA MICHELL AYALA TORRESNo ratings yet

- Manual Armaduras Gerdau-AzaDocument285 pagesManual Armaduras Gerdau-AzaSergio Olguin UmanzorNo ratings yet

- Canteras de La Localidad de Bellavista - JaenDocument16 pagesCanteras de La Localidad de Bellavista - JaenDalin Jesus Diaz MalcaNo ratings yet

- Mecánica de Materiales: Esfuerzo y Deformación Axial y de Corte PuroDocument14 pagesMecánica de Materiales: Esfuerzo y Deformación Axial y de Corte PuroIndra Damaris Tiburcio LonginosNo ratings yet

- R8 PSS 4 Hoja de Seguridad Clean CosDocument5 pagesR8 PSS 4 Hoja de Seguridad Clean CosJessica AlvaradoNo ratings yet

- Taller Procesos de ManufacturaDocument4 pagesTaller Procesos de ManufacturaJhonatan VargasNo ratings yet

- Asflub D 1000Document5 pagesAsflub D 1000Vafec FunezNo ratings yet

- Segunda Prueba Fusión (13 Diciembre 2021)Document2 pagesSegunda Prueba Fusión (13 Diciembre 2021)Camila SilvaNo ratings yet

- Eett Rejillas Ventanas y MamparasDocument9 pagesEett Rejillas Ventanas y Mamparasventas100% (1)

- Cerramientos arquitectónicosDocument13 pagesCerramientos arquitectónicosmechipatinoNo ratings yet

- Manual de Estructura MTI PDFDocument175 pagesManual de Estructura MTI PDFWilfredo DinarteNo ratings yet

- PRACTICA N4 Analisis Intrumental 2007Document12 pagesPRACTICA N4 Analisis Intrumental 2007Hans LozanoNo ratings yet

- Proceso potabilización agua EPMDocument14 pagesProceso potabilización agua EPMSandra Milena Londoño RNo ratings yet

- Laminados Aislantes - Flexiblesroyalplac - PresspanDocument3 pagesLaminados Aislantes - Flexiblesroyalplac - PresspanEmilio BonnetNo ratings yet

- Ladrillos Con Relaves MinerosDocument32 pagesLadrillos Con Relaves MinerosSantiaguito Yunga BustamanteNo ratings yet

- CristaloquimicaDocument127 pagesCristaloquimicakevix9363100% (5)

- Los Pisos Polimeros en Las EdificacionesDocument22 pagesLos Pisos Polimeros en Las EdificacionesWalter VivasNo ratings yet

- Cuestionario #6: EstequiometriaDocument1 pageCuestionario #6: EstequiometriaJoel Daniel Guarabia AguirreNo ratings yet

- Practica Domicilria Circuitos MagneticosDocument6 pagesPractica Domicilria Circuitos MagneticosAccel EspinozaNo ratings yet

- Tema 2: 1. Propiedades de Ácidos Y BasesDocument12 pagesTema 2: 1. Propiedades de Ácidos Y BasesJonathan MedinaNo ratings yet

- Cobalto: propiedades, usos y aplicaciones del metalDocument11 pagesCobalto: propiedades, usos y aplicaciones del metalInés Revilla LuengoNo ratings yet

- GGDocument1 pageGGErnestina Ruiz VillamarinNo ratings yet

- NomenclaturaDocument4 pagesNomenclaturaOlga MalaverNo ratings yet

- Resuelto - (ACV-S02) Cuestionario de Laboratorio Calificado 1 - FISICOQUIMICA (8608)Document5 pagesResuelto - (ACV-S02) Cuestionario de Laboratorio Calificado 1 - FISICOQUIMICA (8608)cristianNo ratings yet

- Practica 2. Tubos Concentricos PDFDocument15 pagesPractica 2. Tubos Concentricos PDFDiana GonzalezNo ratings yet

- Power Point Equipo - de - Elite-CAADocument105 pagesPower Point Equipo - de - Elite-CAAFrancis ParedesNo ratings yet

- Catalogo Petrolero v1.0 - 2Document14 pagesCatalogo Petrolero v1.0 - 2Ricardo OrtegaNo ratings yet