Professional Documents

Culture Documents

Teste Bollard Pull PDF

Uploaded by

Andre OliveiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Teste Bollard Pull PDF

Uploaded by

Andre OliveiraCopyright:

Available Formats

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 1 of 16 Effective Date 2011 Revision 04

Table of Contents

Propulsion Test............................................... 2 1. 2. PURPOSE OF PROCEDURE ............ 2 PARAMETERS .................................... 2 2.1 Data Reduction Equations ................ 2 2.2 Definition of Variables ....................... 3 3. DESCRIPTION OF PROCEDURE ... 3 3.1 Model and Installation ....................... 3 3.1.1 Models ........................................... 3 3.1.1.1 Hull Model ................................. 3 3.1.1.2 Propeller/Propulsion Unit Model3 3.1.2 Installation ..................................... 4 3.1.2.1 Hull Model ................................. 4 3.1.2.2 Propeller/Propulsion Unit Model4 3.1.3 Measurement Systems .................. 4 3.2 Instrumentation ..................................5 3.2.1 Thrust ............................................ 5 3.2.2 External Tow Force ....................... 6 3.2.3 Torque ........................................... 6 3.2.4 Rate of Revolution ........................ 6 3.2.5 Speed ............................................. 6 3.2.6 Sinkage and Trim .......................... 7 3.2.7 Temperature .................................. 7 3.3 Calibration .......................................... 7 3.3.1 General Remarks ........................... 7 3.3.2 Propeller dynamometer: ................ 7 3.3.2.1 Propeller Thrust ......................... 7 3.3.2.2 Propeller Torque ........................ 7 3.3.3 External Tow Force ....................... 7 3.3.4 Rate of revolutions ........................ 7 3.3.5 Sinkage and trim ........................... 8 3.3.6 Speed ............................................. 8 3.3.7 Thermometer ................................. 8 3.4 Test Procedure and Data Acquisition8 3.4.1 Methods ......................................... 8 3.4.1.1 Load Varying (or Constant Speed) Method .......................................... 8 3.4.1.2 Constant Loading Method.......... 8 3.4.1.3 Mixed Loading Method ............. 8 3.4.1.4 Bollard/Trawl Pull Test.............. 9 3.4.2 General Remarks ......................... 10 3.4.3 Skin friction correction force ...... 11 3.4.4 Measured Quantities.................... 12 3.4.5 Shaft Tare Test ............................ 12 3.4.6 Correction to Measured Forces ... 13 3.5 Data Reduction and Analysis .......... 13 3.6 Documentation ................................. 15 4. VALIDATION.................................... 15 4.1 Uncertainty Analysis ........................ 15 4.2 Benchmark Tests .............................. 16 5. REFERENCES ................................... 16

Updated 26th ITTC Propulsion Committee Date 04/2011

Approved 26th ITTC Date 09/2011

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 2 of 16 Effective Date 2011 Revision 04

Propulsion Test

1. PURPOSE OF PROCEDURE Resistance Tests, ITTC Recommended Procedure 7.5-02-02-01. 2. 2.1 PARAMETERS Data Reduction Equations

The purpose of the procedure is to ensure consistency of methodology and the acquisition of correct results for the propulsion test and its special cases bollard pull and trawl pull test.. Bollard pull is the static force exerted by a ship on a fixed towline at zero speed. Trawl pull is a force exerted by a ship on a towline at speed. . The propulsion test procedure addresses model scale only and does not consider extrapolation and full scale prediction. For the bollard pull case, however, a direct correlation to full scale is proposed; following the Froude law of similitude, see Section 3.5 below. The procedure is generally applicable for self propulsion tests performed with models propelled by screws, ducted propellers, tipplate propellers, propellers with vane wheels, contra-rotating propellers, Z-drives and podded drives. Multi-screw propulsion systems with split (different) power/RPM distribution between various propellers should also be tested according to the present procedure. The procedure is not applicable for self propulsion tests with models powered by water jets. Waterjet propulsion tests are performed in accordance with ITTC Waterjet Propulsion Performance Prediction Propulsion Test and Extrapolation 7.5-02-05-03.1. The procedure will normally be applied in conjunction with the standard procedure for

Propeller Thrust Coefficient

KT =

K TD =

T n2 D4

Duct Thrust Coefficient Torque Coefficient Advance Coefficient Froude Number Reynolds Number

TD n2 D 4 Q KQ = 2 5 n D V J= A nD V Fr = gL VL Re =

Frictional Resistance Coefficient ITTC 1957 Model-Ship Correlation Line 0.075 CF = 2 ( log10 Re 2 ) Skin Friction Correction Force: FD = 1/2MVM SM[CFM-(CFS+CF)] Additionally, the equation including form factor (1+k) and/or scale effect factor (1-) can be written as: FD = 1/2MVMSM[(1+k)(CFM-CFS)-CF] +(1-)(RTMA-RTM)

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 3 of 16 Effective Date 2011 Revision 04

The equation for cavitation number used in Figure 2 is n = (pA-pv) / (/2 (n D)2). 2.2 Definition of Variables

Mass density of water Cavitation number

(kg/m3) (-)

Subscript M signifies model scale value Subscript S signifies full scale ship value 3. 3.1 3.1.1 DESCRIPTION OF PROCEDURE Model and Installation Models

Roughness allowance (-) CA Propeller diameter (m) D External tow force (N) F Bollard pull (N) FP0 Trawl pull (N) FP 2 Gravity constant (m /s) g Form factor (-) (1+k) Representative length [normally LWL for Fr and LOS for Re] (m) L Longitudinal centre of buoyancy (m) XCB Vertical centre of buoyancy (m) ZCB Length of duct (m) LD Length overall submerged (m) LOS Length on waterline (m) LWL Rate of revolutions (rps) n Ambient Pressure (Pa) pA Vapor Pressure (Pa) pv Propeller torque (Nm) Q Resistance of the appended model (N) RTMA Resistance of the unappended model (N) RTM Wetted surface area (m2) S Propeller thrust (N) T Duct thrust (N) TD Thruster/Pod unit thrust (N) TU Thrust deduction factor (-) t Speed (m/s) V Advance speed of propeller (m/s) VA Thrust wake fraction (-) wT Thruster/Pod unit side force (N) YU Angle of the inclination of the propeller shaft () Appendage drag scale effect correction factor (-) Relative rotative efficiency (-) R Ship model scale factor (-) 2 Kinematic viscosity (m /s)

3.1.1.1 Hull Model The model hull should be manufactured according to the Standard Procedure 7.5-01-0101, Ship Models. The condition of the hull model prepared for self propulsion tests should be the same as its condition for the resistance test. The weight and trim of the ballasted model should be the same as the condition of the model for the resistance test. The model is equipped with an electric motor mounted inside the hull and respective devices fitted inboard to enable the measurement of thrust, torque and rate of revolutions of the model propeller(s), as well as thrusters/pod unit thrust and side force. Appendages, such as rudders, single brackets or A-brackets, propeller shafts, shaft protection tubes, short bossings or shaft bossings, extracted stabilizers and openings in the hull such as for bow thrusters, should be in the same condition as for the resistance experiment. 3.1.1.2 Propeller/Propulsion Unit Model The model propeller/propulsor should be manufactured according to the Standard Procedure 7.5-01-01-01, Ship Models.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 4 of 16 Effective Date 2011 Revision 04

The size of the propeller/propulsion unit model for propulsion tests is determined automatically by the size of the ship model and its scale ratio; this in turn means that the size of the model propeller, or say a stock propeller, is also to be taken into consideration when the scale for a ship model is selected. However an adequate Reynolds Number should be used to minimize laminar flow effects during the self propulsion test. During the stock-propeller testing phase, the geometrical particulars of the final design propeller are normally not known. Therefore, the stock propeller pitch (in case of CPP) is recommended to be adjusted to the anticipated propeller shaft power and design propeller revolutions. Furthermore, the blade area ratio should be preferably decided on basis of propeller cavitation performance check. Z-drives, either conventional or podded drives, should be treated as propulsion units. Propeller open water tests should be carried out with the pods and the thrust, torque and rate of revolutions of the propeller and the total thrust of the pod should be measured. In the propulsion test, the thrust of the pod should be measured in addition to what is standard for a propulsion test. This total unit thrust should be used for further analysis. The nozzles of ducted propellers should be treated as part of the propulsion unit. Propeller open water tests should be carried out with the propeller working in the nozzle, where the thrust of the nozzle should be measured simultaneously with the measurements of thrust, torque and rate of revolutions of the propeller.

In the self propulsion test the thrust of the nozzle should be measured in addition to what is standard for a self propulsion test. 3.1.2 Installation

3.1.2.1 Hull Model During the Self Propulsion Test the hull model should be connected to the carriage generally in the same way as for resistance experiments. Depending on the experiment procedure adopted, the model is either towed by the resistance dynamometer to measure the unknown external force during the single runs, or a preselected external tow force is directly applied as a dead load. The external tow force in propulsion experiments should be applied along the same line of action as the tow force in the resistance experiments. 3.1.2.2 Propeller/Propulsion Unit Model The propeller should be in its correct position relative to the hull. If required by the thrust dynamometer, a displacement of not more than 1.5 mm from the mean position may be permitted. It is strongly recommended to couple the thrusters and especially the pod units to a steering machine, allowing for a step-wise rudder angles variation. Thus the optimum (minimum shaft power) pod-unit rudder angle determination and adequate measurement of the pod-unit side force could be efficiently executed. Additionally this set-up would allow dynamic pod loads measurements during model steering. 3.1.3 Measurement Systems

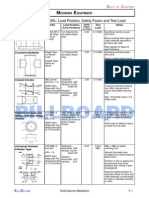

Figure 1 shows a typical measuring system.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 5 of 16 Effective Date 2011 Revision 04

The following quantities are measured: Model speed Resistance/External tow force Propeller thrust Propeller torque Propeller rate of revolutions

CARRIAGE HULL MODEL

Duct/Pod thrust (if fitted) Pod unit side force (recommended) Water temperature (for calculation of viscosity) Sinkage fore and aft (or running trim and sinkage

DUCT/POD

ENVIRONMENTAL CONDITIONS

PROPELLER

SPEED MEASUREMENT

TACHOMETER/ PROBE

RESISTANCE DYNAMOMETER

SINKAGE and TRIM

MEASUREMENT DEVICES

PROPELLER DYNAMOMETER

DYNAMOMETER

TEMPERATURE MEASUREMENT

THERMOMETER

MODEL SPEED

RESISTANCE / EXTERNAL TOW FORCE

SINKAGE and TRIM

THRUST, TORQUE, RATE OF REVOLUTION

DUCT /POD THRUST

TANK WATER TEMPERATURE

SIGNAL CONDITIONING and DATA ACQUISITION

COMPUTER

Figure 1 Typical Measurement System propeller is fitted on a pod or on a Z-drive, the 3.2 Instrumentation resistance of the pod or Z-drive behind or in front of the working propeller has to be considThe quoted bias accuracies are for indicaered as well. tive purposes only. Uncertainty analysis should be used to derive the actual requirements. The indicated propeller thrust is measured by means of a dynamometer usually fitted in 3.2.1 Thrust the model between the motor and the propeller. When a pod or a Z-drive is fitted on the model, The thrust should be measured in the line of the propeller thrust is measured in the line of the propeller shaft. If the propeller is working the propeller shaft in the pod cage. The total in a nozzle, the additional thrust or the resisthrust of the propulsive device is measured in tance of the nozzle has to be measured. If the the model. As recommended in item 3.1.3

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 6 of 16 Effective Date 2011 Revision 04

above, the pod unit side force should be also measured when applicable. The thrust dynamometer should measure the thrust to within 0.2% of the maximum capacity of the dynamometer. This does not necessarily imply that the thrust itself is measured to within the same tolerance of its true value. 3.2.2 External Tow Force

3.2.4

Rate of Revolution

The rate of revolutions of the propeller should be constant throughout that part of the test run during which the measurement is made and also for a suitable time before this. Steadiness of the rate of revolutions is essential in achieving steady model speed. In multi-screw models, rates of revolutions of pairs of nominally identical screws should be equal but the torque and the thrust of each screw should be measured separately. The measurement instrumentation should measure the rate of revolutions to within 0.2% of the maximum rate of revolutions. This does not necessarily imply that the rate of revolutions itself is measured to within the same tolerance of its true value. 3.2.5 Speed

The external tow force (FD) in propulsion experiments should be applied along the same line of action as the tow force in the resistance experiments and the horizontal component of the force measured. The tow force should, where possible, be applied at XCB and ZCB in order to avoid artificial trim effects. The tow force dynamometer should measure the tow force to within 0.2% of the maximum capacity of the dynamometer or 0.05 N, whichever is the larger. This does not necessarily imply that the tow force itself is measured to within the same tolerance of its true value. 3.2.3 Torque

Ideally the speed of the model through the water should be measured directly throughout the measuring run. Since this is in general impractical, one of the following two methods may be employed: (i) the speed of the towing carriage relative to the ground should be measured. (ii) the speed of the towing carriage relative to the water should be measured by a current meter far in front of the model. In this case the current meter wake and waves should be minimised. The speed of the model should be measured to within 0.1% of the maximum carriage speed or to within 3 mm/sec, whichever is the smaller.

The indicated propeller torque of the model propeller is measured by means of a propeller dynamometer. For the torque measurement it is essential to keep the shaft friction losses as low as possible. The torque dynamometer should measure the torque to within 0.2% of the maximum capacity of the dynamometer. This does not necessarily imply that the torque itself is measured to within the same tolerance of its true value.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 7 of 16 Effective Date 2011 Revision 04

3.2.6

Sinkage and Trim

Sinkage fore and aft may be measured with mechanical guides, potentiometers, encoders, LDVTs or with remote (laser or ultrasonic) distance meters. The running trim is calculated from the measured running sinkage fore and aft. The sinkage fore and aft should be measured to within 1.0 mm. 3.2.7 Temperature

measurements is usually not required. Instead, the check on this device is covered by calibrations carried out at regular intervals. 3.3.2 Propeller dynamometer:

3.3.2.1 Propeller Thrust The calibration of the propeller dynamometer in respect of the propeller thrust should be carried out statically and, if possible, dynamically with calibrated weights. The dynamic calibration should be carried out at various rates of revolutions. 3.3.2.2 Propeller Torque

The water temperature should be measured at a depth near half of the model draught using a thermometer. 3.3 3.3.1 Calibration General Remarks

All devices used for data acquisition should be calibrated regularly. For calibration, the measured quantities should be either substituted by calibrated weights and pulses or checked by other measuring devices which have already been calibrated. Calibration diagrams, where the measured quantities (output values) are plotted against the calibration units (input units), may be usefully employed to check the calibration itself as well as the linearity of strain gauge or inductive instruments. Calibration should generally be in accordance with ITTC Quality Manual Standard Procedure 7.6-01-01. Calibrations should preferably include as much of the measurement chain as possible (amplifier, filter, A/D converter). If the check indicates that the required accuracies cannot be met, the calibration should be renewed or the instrument replaced and the check repeated. Daily checking of a pulse counter for speed

The calibration of the propeller dynamometer in respect of the propeller torque should be carried out statically and, if possible, dynamically. For the static calibration, calibrated weights are applied to a lever of known length to simulate a moment on the dynamometer shaft. The dynamic calibration should be carried out, for example, by the use of an eddy current brake. 3.3.3 External Tow Force

The external tow force is measured either by means of the resistance dynamometer or a similar measuring device. The calibration of such devices should be carried out using calibrated weights as an input to the instrument. 3.3.4 Rate of revolutions

The calibration of the respective devices should be carried out by use of precise motor speed transmitters.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 8 of 16 Effective Date 2011 Revision 04

3.3.5

Sinkage and trim

The calibration of linear measuring devices should be performed with a calibrated ruler. 3.3.6 Speed

The calibration of the carriage speed will depend mainly on how the speed is measured. The carriage speed should be checked regularly and respective records should be stored. 3.3.7 Thermometer

The loading range should extend from the lowest to the highest load factors at which ship performance estimates are required, providing always that this range includes a load factor of unity. It is further recommended that, in all cases, the loading should cover the condition of model-self-propulsion (zero tow force). Experiments should be made at not less than four speeds within the required speed range and at different levels of overload. 3.4.1.2 Constant Loading Method Before beginning each test run the model speed should be selected and the corresponding external tow force at the set loading computed. The computed skin friction correction force (FD) is then applied to the model hull as an external assisting tow force. The towing carriage is then accelerated from rest to the selected speed and the propeller rate of rotation simultaneously increased until the model is freely propelled at the same speed as the towing carriage or the desired FD is achieved. Measurements are then made after a period of steady running. Repeat runs should be made at each of several speeds. The speed range should extend from the lowest to the highest speeds at which propulsion data are required. An extension of the speed range of at least 5% below and above the lowest and the highest speeds is recommended. If there are tests in a short speed range (e.g. to check the influence of a modification of the model on its performance) at least three runs at different speeds should be carried out. 3.4.1.3 Mixed Loading Method

Thermometers should be calibrated according to common standards and/or following the advice of the manufacturer and should have an accuracy of not less than 0.1 C. 3.4 3.4.1 Test Procedure and Data Acquisition Methods

3.4.1.1 Load Varying (or Constant Speed) Method Before beginning each test run the model speed and the desired propeller loading should be selected and the corresponding propeller thrust estimated. The towing carriage should be accelerated from rest and simultaneously the propeller rate of revolutions increased also from rest so that the estimated thrust is reached as soon as possible after steady carriage speed is attained. The model should then be released so that it is towed by the resistance dynamometer and running conditions allowed to settle. A short period will then normally be allowed before measurements are begun. Repeat runs at the same speed should be made at different loadings and the whole series of runs then repeated at each of the speeds within the test range.

Combinations of the load varying (constant speed) and constant loading methods may be

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 9 of 16 Effective Date 2011 Revision 04

used. For example, a speed variation at constant (or close to constant) loading may be used, together with a supplementary load-variation test at one speed. 3.4.1.4 Bollard/Trawl Pull Test Typically the bollard/trawl pull test is conducted as a part of the self-propulsion test, which implies that the ship model, propulsors/nozzles, measuring equipment and instrumentation is usually the same as those for the self-propulsion test. However, the bollard pull test can be distinguished from the ordinary self-propulsion test by a few major specific differences: The bollard pull test is conducted at zero speed of advance; The concepts of wake and relative rotative efficiency are no more applicable in bollard pull condition, whereas the interaction with the hull is accounted for by the familiar thrust deduction coefficient. This also implies that the propeller open water characteristics are not necessarily required for the bollard pull analysis; At bollard pull condition, the propeller induces very high axial and tangential velocities and actually acts as an axial pump. The flow through propeller disc is accelerated and creates a current in the towing tank, which strength is depending on the propeller loading, the tank dimensions (specifically depth and width) and the longitudinal position of the ship model/propeller relative to the tank length; Due to the heavy loading and induced axial and tangential velocities in the propeller slip stream, there is relatively

strong interaction between the propeller and rudder, which is exhibited as internal system force and is included in the measured total bollard pull; At some conditions with very high loading, the propeller blades may start to ventilate due to air suction from free surface. This will significantly affect thrust and torque measurements. Furthermore, possible propeller cavitation and its influence on bollard pull performance cannot be modeled in a standard atmospheric pressure tank. If there is a danger of cavitation the test must be made in a pressurized tank or cavitation tunnel. The diagram in figure 2 (Mertes and Heinke, (2008)) is recommended for evaluation of the possible occurrence of cavitation. The trawl pull test is distinguished by the bollard pull test with its low speed of advance (typically 2 to 4 knots). This implies somewhat reduced propeller loading relative to bollard and necessity to consider the actual model resistance, corrected with the appropriate skin friction correction force.

Bollard/trawl pull tests are typically carried out with final design propulsors to verify its bollard performance. However, it could be also a common practice for the propeller designer to require bollard pull tests with stock propellers/ducts to check the hull interaction (basically the level of thrust deduction). Therefore, the proposed bollard pull procedure is equally valid for stock and final design propulsors/ducts.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 10 of 16 Effective Date 2011 Revision 04

4.0

Estimation of the risk for a bollard pull reduction due to cavitation (Basis: results of model and full-scale measurements with different tugs and ducted propellers (LD/D 0.50) at bollard pull condition)

3.5

no risk

3.0

risk of bollard pull reduction no risk

thrust breakdown could be possible

n [-]

2.5

risk of bollard pull reduction

2.0 mean values of the data base

1.5

1.0 0.30

0.35

0.40

0.45

0.50 10K Q [-]

0.55

0.60

0.65

0.70

Figure 2. Risk of Bollard Pull Reduction Due to Cavitation

3.4.2

General Remarks

The measured quantities during the single test runs are the thrust, torque and rate of revolutions of the propulsor(s) together with the model speed and external tow force. There should be sufficient waiting time between consecutive runs in order to achieve similar conditions and to obtain consistent results. This waiting time will depend on the size and type of model, model speed and test facility. The waiting times should be recorded. For the bollard/trawl pull tests the ship model is connected to the towing carriage through the resistance gauge, which measures

directly the achieved bollard pull (at VM = 0); or the trawl pull (after considering the skin friction correction force FD) (at VM 0). The model should be free in heave and pitch, but restrained in surge, sway and yaw. The rudders/thrusters/pods should be set at their neutral position. For the trawl pull test only, a skin friction correction force FD should be calculated as per section 2.1 above, and applied as an additional constant (for each speed) towing force to the model. In order to achieve a fair bollard pull the build-up of water circulation has to be avoided. The ship model should be located approximately at the middle (length-wise) of the tank to minimize effect of propeller induced current

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 11 of 16 Effective Date 2011 Revision 04

and not to obstruct the propeller slip stream. Furthermore, it is recommended to move the ship model at least 3 model lengths ahead in the tank between consecutive measurements, utilizing more calm (induced current free) water conditions. During the bollard pull test the propeller revolutions are varied stepwise such that the propeller shaft power varies from about 100% to 40% of maximum continuous rating (MCR). The maximum (MCR=100%) bollard/trawl pull test should be conducted first (being of highest interest for the Client), while the tank water is still undisturbed as possible. It is recommended to carry out the subsequent (at lower power ratios) bollard pull measurements at time intervals of about 10 to 15 min, to allow for the induced current to die out. The build-up of water circulation around the ship model is recommended to be monitored (with dedicated current-meter, for example). 3.4.3 Skin friction correction force

If a form factor or an appendage scale effect correction factor is used for the calculation of the friction correction, it should be the same as that used in the resistance test. For the estimation of the correct friction correction, the influence of the hull appendages on the propulsive power is of great importance, especially for multi-screw ships. Several approaches can be used for the determination of the full scale resistance of hull appendages such as single brackets, A-brackets, short bossings, shaft bossings, propeller shafts, shaft protection tubes, rudders, stabilising fins when extracted, but not for hull openings, depending on where they are on the model. However, none of these methods is completely satisfactory. Basically, three different methods of treating appendage drag in model experiments are used: (i) Extrapolation of model appendage drag to full scale either by means of a constant appendage scale-effect factor or by extrapolation on the basis of the Reynolds number of the appendage. ReApp = V . ( SApp / 2 ) 2

1

The skin friction correction force (FD), applied as an external tow force, is to achieve the theoretically correct propeller loads during the self propulsion test. It takes into account the difference in skin friction coefficients between the model and the full scale ship. The skin friction correction force (FD) may be calculated using the ITTC-1957 formula, incorporating a form factor (1+k) and an appendage scale effect factor (1-). The wetted surface of the model in the condition as used for the resistance test is used for the calculation of the respective friction correction values. The wetted surfaces of propulsors and propulsion units should not be taken into account when the wetted surface is estimated.

It has long been recognised that significant scale effects are generally present on the appendage resistance and this has led to the use of the empirical scale-effect correction factor . Values of in the range of 0.6 to 1.0 should be generally used, depending on the empirical data of the individual towing tanks. A typical value of 0.75 is suggested for conventional driven twin screw ships. This approach has proved to work well in many cases despite the following drawbacks:

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 12 of 16 Effective Date 2011 Revision 04

model tests on appended ship models might easily involve uncontrolled and unpredictable laminar flow and separation on the appendages due to the relatively low Reynolds numbers at model scale the scale effect correction factor should in principle depend on the model and ship Reynolds numbers the drag and the scale effect on the drag of a particular appendage is influenced by a complexity of factors which are unlikely to be described accurately by the simple coefficient . These cause, for example, differences in the flow field (hull boundary layer) where the appendage is placed, and then influence the resistance of the hull (interference drag) the method requires that both bare-hull and appended resistance tests be carried out.

should be recorded. Temperature measurements should be recorded at the beginning and end of each test sequence. 3.4.5 Shaft Tare Test

The friction of the model propeller shaft(s) in the(ir) bearing(s) should be adjusted to zero when the model is set in the water and the model propeller(s) is(are) removed. The calibration should be valid over the entire range of rates of revolutions expected for the self propulsion test. If a constant calibration cannot be achieved for the expected range of rates of revolutions, the friction of the model propeller shaft(s) should be measured as a function of its turning rate and respective corrections have to be applied on the measured torque quantities gained during the self propulsion test. The friction of the model propeller shafts in the bearings should be affected neither by the torque nor by the thrust applied to the model propeller. Further, because of the weight-effect of a possible inclination of the propeller shaft(s) on the recorded thrust value(s), they should be measured without model propeller(s) and calibrated or adjusted to zero at the beginning of a self propulsion test. Careful checks of torque and thrust readings of the propeller shaft(s) without the model propeller(s) after the self propulsion test is highly recommended. A preferable alternative approach to thrust and torque measurements, especially for pods and azimuthing thrusters, is to make the thrust and torque measurements inside the propeller hub in such a manner that mechanical friction from seals and bearings is eliminated.

(ii) Addition of theoretically computed fullscale appendage drag to full scale barehull drag extrapolated from model test results. (iii) Application of the form factor concept to fully appended ship models. 3.4.4 Measured Quantities

During each run the measured values of model speed, external tow force, thrust, torque, rate of revolutions of the screw(s) and sinkage fore and aft should be recorded continuously. Water temperature should be measured at a depth near half of the model draught. If there is a non-homogeneous temperature in the tank it

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 13 of 16 Effective Date 2011 Revision 04

3.4.6

Correction to Measured Forces

sponding to the required ship speeds should be taken from the diagram. The speed should, if necessary, be corrected for blockage according to the methods described in the Resistance Tests Procedure, ITTC Recommended Procedure 7.5-02-02-01. Values of water density and viscosity should be determined according to ITTC Recommended Procedure 7.5-02-01-03. The analysis of the data requires the resistance and propeller open water data, as indicated in Fig. 3. The required values of t, wT, R and H are calculated according to the data reduction equations given in Section 2.1 and as follows: For the calculation of the thrust deduction factor the respective resistance values are required for the case of trawl pull test: F + RTM FD t = 1 PM TM In self propulsion test the trawl pull is zero and R FD t = 1 TM TM For the case of bollard pull RTM and FD are zero and F t = 1 P0M TM

The forces and other quantities measured during the test run require correction for shaft losses, speed errors, etc. In additional to frictional losses, the measured dynamometer thrust may differ from the required propulsive thrust because of effects due to the shaft rake. Before and after the propulsion experiments, the propeller(s) should be removed and replaced by a cylinder of equal weight. Known forces should then be applied at the propeller position at each of several different rates of revolutions of the shaft covering the estimated test range. The relationship between the dynamometer measured thrust and the required propulsive thrust is thus obtained. If the procedure is carried out only for zero applied load at the propeller, it is necessary to assume that the thrust losses are independent of the load. Similarly, the measured dynamometer torque may differ from the torque delivered to the propeller. With the propeller replaced by a short cylinder of equal weight, known torques should be applied to the shaft at different rates of revolutions, and the relationship between delivered and measured torques determined. If the procedure is carried out only for zero applied torque, it is necessary to assume that the torques losses are independent of the applied torque. 3.5 Data Reduction and Analysis

The model data derived from the experiment, namely external tow force, thrust, torque and rate of revolutions, should be plotted against the model speed. The respective curves should be faired and the model values corre-

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 14 of 16 Effective Date 2011 Revision 04

RESISTANCE TEST

SELF PROPULSION TEST

RT

FD T n Q

t OPEN WATER TEST

wT

Figure 3 Analysis of Data

These formulas are valid for single screw and symmetric twin screw ships. The effective wake fraction is calculated using the advance coefficient (JT/JQ) derived from the propeller open water test results, based on propeller thrust and/or torque identity:

R =

KQT KQ

The hull efficiency is calculated using the effective wake fraction and the thrust deduction factor:

J nD wT = 1- T V

The relative rotative efficiency is calculated by division of the torque/thrust derived from the propeller open water diagram (KQT/KTQ), using a thrust/torque identity, by the torque/thrust gained from the self propulsion experiment (KQ/KT).

H =

(1 wT )

(1 t )

The above procedure is valid for single screw ships and for symmetric twin screw ships. In the case of twin screw ships the sums of the thrust and torque are used and the mean of the rpm if the port and starboard values differ.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 15 of 16 Effective Date 2011 Revision 04

Given the scale factor , the full scale bollard/trawl pull, propeller revolutions and power can be calculated by the following equations:

FPS = FPM

nS = nM

S 3 M

Model Scale Main dimensions and particulars (see ITTC Recommended Procedure 7.5-0101-01 Ship Models)

Particulars of the towing tank, including length, breadth and water depth Test date Parametric data for the test: - Water temperature - Water density - Kinematic viscosity of the water - Form factor (even if (1+k) = 1.0 is applicable, this should be stated) - Appendage drag scale effect correction factor (even if a factor for scale effect correction is not applied, this should be stated). For each speed the following data should be given as a minimum: - External tow force - Sinkage fore and aft, or sinkage and trim - Propeller thrust, torque and rate of revolutions. VALIDATION Uncertainty Analysis

PD =

S 3.5 2 nM QM M

Note that in the proposed correlation procedure, no correction for scale effect on the propeller open water characteristics, neither scale effect on the nozzle drag is applied. Minchev et al. (2009) reported several bollard pull results using the present direct extrapolation and comparison with full scale bollard data. A very good agreement was found, which encourages the implementation of the direct correlation approach for the bollard pull results. 3.6 Documentation

The results from the test should be collated in a report which should contain at least the following information: Model Hull Specification: - Identification (model number or similar) - Loading condition - Turbulence stimulation method - Model scale Main dimensions and hydrostatics (see ITTC Recommended Procedure 7.5-01-0101 Ship Models). Model Propeller Specification - Identification (model number or similar)

4. 4.1

Uncertainty analysis should be performed in accordance with Uncertainty Analysis in EFD, Uncertainty Assessment Methodology as described in QM 7.5-02-01-01 and Uncertainty Analysis in EFD, Guidelines for Uncertainty Assessment as described in QM 7.5-0201-02. In addition to the above, an example Uncertainty Analysis, Example for Propulsion Test is provided in QM 7.5-02-03-2.2.

ITTC Recommended Procedures and Guidelines

Propulsion/Bollard Pull Test

7.5-02 -03-01.1

Page 16 of 16 Effective Date 2011 Revision 04

4.2

Benchmark Tests

Benchmark data are collected and described in Benchmark Database for CFD, Validation for Resistance and Propulsion, QM 7.5-03-0202. 5. REFERENCES

ITTC 1999b, Benchmark Database for CFD, Validation for Resistance and Propulsion. 22nd International Towing Tank Conference, Seoul/Shanghai, Quality Manual, Procedure 4.9-04-02-02. Mertes, P., and Heinke, H.-J., 2008, Aspects of the Design Procedure for Propellers Providing Maximum Bollard Pull, Proceedings ITS 2008, Singapore Minchev, A., Nielsen J.R., and Lundgren E., 2009, Ducted Propeller Design and Verification for Contemporary Offshore Support Vessels, Proc. First International Symposium on Marine Propulsors, SMP09, Trondheim, Norway

ITTC 1960, 9th International Towing Tank Conference. ITTC 1999a, Propulsion, Performance Propulsion Test, 22nd International Towing Tank Conference, Seoul/Shanghai, Quality Manual, Procedure 4.9-03-03-01, Revision 00.

You might also like

- Calculation of Required Bollard Pull: BV Rules and FormulasDocument2 pagesCalculation of Required Bollard Pull: BV Rules and FormulasRahul JagdaleNo ratings yet

- Equipment Numeral Calculator For A ShipDocument16 pagesEquipment Numeral Calculator For A ShipBolarinwaNo ratings yet

- Barge Roll Motion PDFDocument8 pagesBarge Roll Motion PDFJym GensonNo ratings yet

- TowingDocument1 pageTowingRahul JagdaleNo ratings yet

- 4x 65 Ton AHTS Specification Rev 0Document85 pages4x 65 Ton AHTS Specification Rev 0pal_malay100% (1)

- NI184 Lifting AppliancesDocument344 pagesNI184 Lifting Appliancesksangeeth2000100% (1)

- COSLBoss PDFDocument2 pagesCOSLBoss PDFDenny HermawanNo ratings yet

- Surya Putra JayaDocument4 pagesSurya Putra JayaIhwan AsrulNo ratings yet

- Perhitungan Propeller MT AFDAL MAMMARDocument17 pagesPerhitungan Propeller MT AFDAL MAMMARMuhamad Rifki AfanNo ratings yet

- HSC Code 2000 PDFDocument251 pagesHSC Code 2000 PDFCarlos FrancoNo ratings yet

- Requirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesDocument34 pagesRequirements Concerning Mooring, Anchoring and Towing: International Association of Classification SocietiesBorza DorinNo ratings yet

- 3.2 Design Development of Corrugated BulkheadsDocument17 pages3.2 Design Development of Corrugated BulkheadsТеодора Недялкова100% (1)

- Bollard Rope Friction - The Load and Effort Force in The RopeDocument3 pagesBollard Rope Friction - The Load and Effort Force in The Ropesantoshgs191811No ratings yet

- IBS - IMO SEEMP Part II - Template (Blank Form)Document10 pagesIBS - IMO SEEMP Part II - Template (Blank Form)sakis papasNo ratings yet

- Scaldis - Installation VesselDocument18 pagesScaldis - Installation VesselJoel GancedoNo ratings yet

- Report 2 Gross Tonnage Crew Fresw Water Oil NeedDocument19 pagesReport 2 Gross Tonnage Crew Fresw Water Oil Needpsda kseNo ratings yet

- Fuel Oil Consumption Data Collection Plan SampleDocument2 pagesFuel Oil Consumption Data Collection Plan SampleJCANo ratings yet

- Anchor Chain Calibration: (Nama Kapal) (Pemilik)Document4 pagesAnchor Chain Calibration: (Nama Kapal) (Pemilik)Andriyas Rizky Widya PratamaNo ratings yet

- Part B. Mooring Equipment Design PhilosophyDocument37 pagesPart B. Mooring Equipment Design Philosophy郑辉No ratings yet

- Air Bag Launching SystemsDocument7 pagesAir Bag Launching SystemsJhon GreigNo ratings yet

- Bollard JIS F-2001Document1 pageBollard JIS F-2001andrewsmithbatam100% (1)

- Towing Plan-BES PioneerDocument1 pageTowing Plan-BES PioneerMahesh Kumar K BNo ratings yet

- UKOOA Management of Offshore Helideck Ops ISS5 Feb 05Document279 pagesUKOOA Management of Offshore Helideck Ops ISS5 Feb 05perkjartanNo ratings yet

- Syncro LiftDocument3 pagesSyncro Liftjoshivishal800No ratings yet

- Teras 361 Specs GA Updated 28.08.18Document4 pagesTeras 361 Specs GA Updated 28.08.18Cees van ZandvlietNo ratings yet

- Bow Thruster Tb35tDocument5 pagesBow Thruster Tb35tGiyan Arpero ManiaNo ratings yet

- WalkToWorkVessels DP Gezina DP GalynaDocument8 pagesWalkToWorkVessels DP Gezina DP GalynaOlympia HellasNo ratings yet

- Stability and Loading Scenario 58Document3 pagesStability and Loading Scenario 58Laurencia LaveniaNo ratings yet

- Stability Calculations by Barnes MethodDocument6 pagesStability Calculations by Barnes MethodgksahaNo ratings yet

- VWSDocument8 pagesVWSErwin Paulian SihombingNo ratings yet

- Presentation 1Document30 pagesPresentation 1BN JadhavNo ratings yet

- Ship EquipmentDocument3 pagesShip EquipmentviahulNo ratings yet

- Light Ship and Tonnage Check ListDocument9 pagesLight Ship and Tonnage Check ListLegend AnbuNo ratings yet

- Safety Guidelines For Design, Construction & Operation of TugsDocument50 pagesSafety Guidelines For Design, Construction & Operation of TugsTomash Verbitsky100% (2)

- 125 Ton AHTSSV SpecificationDocument86 pages125 Ton AHTSSV SpecificationChakma NhikiNo ratings yet

- Ship Fittings by A NyghDocument12 pagesShip Fittings by A NyghTyasno PrasetyoNo ratings yet

- 80 Ton AHTS Specification Rev 0Document81 pages80 Ton AHTS Specification Rev 0Mark Samsel RohanNo ratings yet

- ET Inc Exp NotesDocument7 pagesET Inc Exp NotesOrville monteiroNo ratings yet

- Double Bollards - Din 82607Document1 pageDouble Bollards - Din 82607Anca GeaninaNo ratings yet

- Deck Crane Lifting OperationsDocument9 pagesDeck Crane Lifting OperationsJitendra Kumar100% (1)

- Compro Citra Shipyard (SI) 091221Document64 pagesCompro Citra Shipyard (SI) 091221Dimas Arie KusumoNo ratings yet

- BS MA 55 Lifeboat WinchesDocument8 pagesBS MA 55 Lifeboat WinchesZohair AftabNo ratings yet

- Bollard RequirementDocument2 pagesBollard RequirementCaptIsqan100% (1)

- Vessel Due To ArriveDocument1 pageVessel Due To Arrivebasuki41cryptoNo ratings yet

- ISO 3913 1980 First RevisionDocument15 pagesISO 3913 1980 First RevisionDaniel SlavčićNo ratings yet

- Adinda Celinna - Ship Particular-1Document1 pageAdinda Celinna - Ship Particular-1kucing_batamNo ratings yet

- Pad Eyes DimensionDocument1 pagePad Eyes DimensionrewmarineNo ratings yet

- Shafting CalculationsDocument4 pagesShafting Calculationsmohammad shihabNo ratings yet

- Basic Stability For Small VesselsDocument43 pagesBasic Stability For Small VesselsHuascar Brito FeijoNo ratings yet

- Stability Calculation Form For MV MaineborgDocument9 pagesStability Calculation Form For MV MaineborgtrananhnganNo ratings yet

- LCT 600DWTDocument1 pageLCT 600DWTkucing_batamNo ratings yet

- 7.5 02 03 01.1 PDFDocument14 pages7.5 02 03 01.1 PDFidhoe81uh2132No ratings yet

- ITTCDocument14 pagesITTCAlham DulillahNo ratings yet

- Ship Resistance & Propulsion (Tutorial 1)Document10 pagesShip Resistance & Propulsion (Tutorial 1)Zulkarnain MustafarNo ratings yet

- ITTC High Speed Marine Vehicles-Propulsion TestDocument6 pagesITTC High Speed Marine Vehicles-Propulsion TestGayatri LakkimsettiNo ratings yet

- Propulsion PDFDocument98 pagesPropulsion PDFavciahmNo ratings yet

- 1978 ITTC Performance PredictionDocument31 pages1978 ITTC Performance PredictionqursenNo ratings yet

- Control of Marine PropellersDocument322 pagesControl of Marine PropellersPelmus LiviuNo ratings yet

- Volume2 1powering Perf Pred PDFDocument35 pagesVolume2 1powering Perf Pred PDFmedievoloNo ratings yet

- 7 5-04-01-01.2 Analysis of Speed Power Trial Data PDFDocument25 pages7 5-04-01-01.2 Analysis of Speed Power Trial Data PDFNestor Gómez RojasNo ratings yet

- T11BENGDocument159 pagesT11BENGAndre OliveiraNo ratings yet

- Principe de AsturiasDocument2 pagesPrincipe de AsturiasAndre OliveiraNo ratings yet

- Autodyn Theory ManualDocument235 pagesAutodyn Theory ManualAndre OliveiraNo ratings yet

- ANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityDocument56 pagesANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityGz2239No ratings yet

- T03ENGDocument128 pagesT03ENGAndre OliveiraNo ratings yet

- Seismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADocument16 pagesSeismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ACamv VenturaNo ratings yet

- T08ENGDocument32 pagesT08ENGAndre OliveiraNo ratings yet

- Example #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Document14 pagesExample #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Andre OliveiraNo ratings yet

- DM DeletFaceThicknesses ACT Extension Description v160 v1Document1 pageDM DeletFaceThicknesses ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- E10ENGDocument41 pagesE10ENGAndre OliveiraNo ratings yet

- Example 21Document14 pagesExample 21Andre OliveiraNo ratings yet

- Non Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADocument12 pagesNon Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.AAndre OliveiraNo ratings yet

- E03ENGDocument12 pagesE03ENGAndre OliveiraNo ratings yet

- Example 7Document11 pagesExample 7Andre OliveiraNo ratings yet

- Example 13Document10 pagesExample 13Andre OliveiraNo ratings yet

- Example 2Document16 pagesExample 2Andre OliveiraNo ratings yet

- Example 5Document23 pagesExample 5Andre OliveiraNo ratings yet

- TDAS ACT Extension Description v160 v1Document1 pageTDAS ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- Push-Over Analysis: Problem DescriptionDocument51 pagesPush-Over Analysis: Problem DescriptionAndre OliveiraNo ratings yet

- Example 8Document11 pagesExample 8Andre OliveiraNo ratings yet

- DM Cross Section Lib ACT Extension Description v160 v1Document1 pageDM Cross Section Lib ACT Extension Description v160 v1Andre OliveiraNo ratings yet

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDocument112 pagesCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- Tut 16Document36 pagesTut 16Andre OliveiraNo ratings yet

- Example 5Document23 pagesExample 5Andre OliveiraNo ratings yet

- 4 Polyflow - 12.1 Polyflow BDocument17 pages4 Polyflow - 12.1 Polyflow BAndre OliveiraNo ratings yet

- Mech-UCO 120 WS-07 FilterDocument32 pagesMech-UCO 120 WS-07 FilterAndre OliveiraNo ratings yet

- ReadmeDocument1 pageReadmeAndre OliveiraNo ratings yet

- Tutorial For Ansys Fluent Porous MediaDocument30 pagesTutorial For Ansys Fluent Porous MediaLykaios Schultz DohrnNo ratings yet

- Tug OperationsDocument14 pagesTug Operationsseamaniac100% (1)

- Application Form 1.personal DetailsDocument3 pagesApplication Form 1.personal DetailsRica VenturianuNo ratings yet

- Topaz Jumeirah Vessel SpecsDocument7 pagesTopaz Jumeirah Vessel SpecsJym GensonNo ratings yet

- THE NAVAL SERVICE of CANADA Its Official History VOLUME I ORIGINS AND EARLY YEARS by GILBERT NORMAN TUCKER, PH.D. (CANTAB.)Document473 pagesTHE NAVAL SERVICE of CANADA Its Official History VOLUME I ORIGINS AND EARLY YEARS by GILBERT NORMAN TUCKER, PH.D. (CANTAB.)Dana John NieldNo ratings yet

- MV RescuerDocument2 pagesMV RescuerselleriverketNo ratings yet

- Santa María (Ship) - WikipediaDocument7 pagesSanta María (Ship) - Wikipediakirthi83No ratings yet

- USCG Foreign Freight Vessel Examination BookDocument52 pagesUSCG Foreign Freight Vessel Examination Bookfredy2212No ratings yet

- IMLAM 2019 Moot Scenario FINAL 30.1.19 PDFDocument79 pagesIMLAM 2019 Moot Scenario FINAL 30.1.19 PDFBayu Calvin100% (1)

- Everything Wormhole 1.09Document79 pagesEverything Wormhole 1.09Jurek Z AriówNo ratings yet

- Voyage FlowchartDocument1 pageVoyage Flowchartumesh100% (1)

- 00 - Ship Design and Construction - Damage To Hull PDFDocument79 pages00 - Ship Design and Construction - Damage To Hull PDFEngineerAleNo ratings yet

- IAPH-WPSP Port Economic Impact Barometer: 9 April 2020Document6 pagesIAPH-WPSP Port Economic Impact Barometer: 9 April 2020Sacheel OrtizNo ratings yet

- EU Standards For BoatsDocument11 pagesEU Standards For BoatsRaniero FalzonNo ratings yet

- Fairmont Shipping Corp. and Fairwinds Ocean Carriers Corp., Owners of The Steamship Western Eagle v. Chevron International Oil Company, Inc., 511 F.2d 1252, 2d Cir. (1975)Document16 pagesFairmont Shipping Corp. and Fairwinds Ocean Carriers Corp., Owners of The Steamship Western Eagle v. Chevron International Oil Company, Inc., 511 F.2d 1252, 2d Cir. (1975)Scribd Government DocsNo ratings yet

- Paradip International Cargo TerminalDocument2 pagesParadip International Cargo TerminalmanpreetNo ratings yet

- JMS SNAME Paper 2010-1Document10 pagesJMS SNAME Paper 2010-1hgmNo ratings yet

- Ves05 Errv Survey Guidelines Issue 5Document42 pagesVes05 Errv Survey Guidelines Issue 5Shah GulNo ratings yet

- 100 Questions Answer 1Document188 pages100 Questions Answer 1Amy CastanedaNo ratings yet

- Form F (Abstracts of The Workmen's Compensation Act, 1923)Document6 pagesForm F (Abstracts of The Workmen's Compensation Act, 1923)Jignesh T. RayNo ratings yet

- Ultimate Load Capacities of Mooring Bollards and Hull Foundation StructuresDocument8 pagesUltimate Load Capacities of Mooring Bollards and Hull Foundation StructuresValentin Claudiu PapucNo ratings yet

- Brochure Sea Indonesia 2023.Document12 pagesBrochure Sea Indonesia 2023.legal bbsNo ratings yet

- KUNCI Jawaban LKS Ekcellent Bahasa Inggris Kelas XIIDocument16 pagesKUNCI Jawaban LKS Ekcellent Bahasa Inggris Kelas XIIXerxes Xanthe Xyza74% (23)

- NBPWS 1149 - Atlantic ShippingDocument4 pagesNBPWS 1149 - Atlantic ShippingЕгор ЛядовNo ratings yet

- Engine Room Technical EnglishDocument23 pagesEngine Room Technical EnglishCamilo Boeri VelozNo ratings yet

- Terminal Port Information and Regulations BookletDocument49 pagesTerminal Port Information and Regulations Bookletmohd1khairul1anuarNo ratings yet

- Marine Communication MSN 243: Introduction For The GMDSS Global Maritime Distress and Safety SystemDocument10 pagesMarine Communication MSN 243: Introduction For The GMDSS Global Maritime Distress and Safety SystemAboody AL-ghamdy100% (1)

- Inchmaree Clause Definition - InvestopediaDocument2 pagesInchmaree Clause Definition - InvestopediaRICROD71No ratings yet

- Ship Stability - Curves of Statical Stability Load Line Requirements For Minimum Stability ConditionsDocument3 pagesShip Stability - Curves of Statical Stability Load Line Requirements For Minimum Stability ConditionsAbd HafidzNo ratings yet

- IMO - BCH Code - 1994 PDFDocument86 pagesIMO - BCH Code - 1994 PDFAlex KulikNo ratings yet

- Floating Houses in Ijburg 75 Homes in Various Sectors Steigereiland Ijburg AmsterdamDocument19 pagesFloating Houses in Ijburg 75 Homes in Various Sectors Steigereiland Ijburg AmsterdamlineajonNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Heat Transfer Engineering: Fundamentals and TechniquesFrom EverandHeat Transfer Engineering: Fundamentals and TechniquesRating: 4 out of 5 stars4/5 (1)

- Smart Power Distribution Systems: Control, Communication, and OptimizationFrom EverandSmart Power Distribution Systems: Control, Communication, and OptimizationNo ratings yet

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsFrom EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksFrom EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksNo ratings yet

- Renewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksFrom EverandRenewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksNo ratings yet