Professional Documents

Culture Documents

Brick Construction Guide

Uploaded by

cmms88Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brick Construction Guide

Uploaded by

cmms88Copyright:

Available Formats

Guide To

General Technical Reference

Construction

Guide To Brick Construction

Table of Contents Introduction Important Note

Brick Types, Sizes & Estimating Bonds Brick Positions In Wall Joints

Table of Contents

Types, Sizes and Estimating Bonds, Joints and Positions Wall Types Insulating Brick Walls Mortarless Interior Brick Flooring Fireplaces Arches Quoin Corners & Water Table Steps Exterior Paving Brick Driveways Walkways & Patios Brick Cleaning Mailboxes Garden Walls Retaining Walls Exterior Brick Siding Brick Does Not Leak Cold Weather Masonry Garage Door Openings 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Introduction

This publication has been prepared as a guide to brick construction for the home builders. It is especially for the builder who may not be familiar with all areas of brick construction in the home building field. We have attempted to cover particularly those details of construction which will be most often used. However, since we cannot cover all possibilities we hope you will ask for additional information when needed. Simply contact: Brick SouthEast Suite 800 8420 University Executive Park Charlotte, NC 28262 800.62.BRICK/Charlotte, NC 888.37.BRICK/Conyers, GA www.gobricksoutheast.com

Brick Types, Sizes & Estimating

H T H T L L H T L H T L H T L L H T

Joints

Concave

Brick Type Size (actual) Nominal Joint Thickness Units per Square Foot of Wall

STANDARD THL 33/4" 21/4" 8" 3/8"

MODULAR OVERSIZE THL THL 35/8" 21/4" 75/8" 33/4" 23/4" 8" 3/8" 3/8"

QUEEN THL 3" 23/4" 8" 3/8"

CLOSURE UTILITY THL THL 31/2" 31/2" 71/2" 31/2" 31/2" 111/2" 1/2" 1/2"

Vee

Grapevine

6.5

6.75

5.5

5.5

4.5

3.0 Weathered

Cubic Feet 19 of Mortar per 1000 Brick (including waste)

19

20

16

24

30 Flush

Careful estimating is important. Correct quantities and prices will enable completion of the job without unnecessary waste and cost.

Important Note

The products described in this booklet involve the use of hazardous materials, operations and/ or equipment. This booklet does not purport to address all of the safety practices associated with the use of these products. It is the responsibility of the user of this booklet to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to the use of the products described. The information and suggestions contained in this booklet are based on available data and experience of the technical staff of Brick SouthEast. This information should be recognized as recommendations and should be used with judgement. Final decisions on the use of the information discussed herein are not within the purview of Brick SouthEast and must rest with the project owner, designer, or both.

Your brick manufacturer is available to help in estimating and selecting brick sizes and styles. Call on them for their expertise and advice. *Typical unit sizes and dimensions may vary from manufacturer to manufacturer.

Raked

Bonds

Creative use of unique bond variations can add to the subtle elegance of any home or building. Through the use of these bonds and variations of the color and texture of the brick and of joint types and colors, an almost unlimited number of patterns can be developed. Familiarity with these patterns and a little creativity can insure a saleable home.

Brick Positions In Wall

Finishing the mortar joints serves several purposes; it helps insure weathertightness, and also influences the appearance of the wall. Careful selection of joint finishes can substantially enhance the overall appearance of a structure.

Rowlock Rowlock Stretcher Header

Stretcher

Flat Header

Running Bond

Flemish Bond Dutch Corners

Flemish Bond English Corners Soldier Sailor

Guide To Brick Construction

Wall Types

Insulating Brick Walls

Wall Types

Insulating Brick Walls

Insulating The Brick Veneer Wall The brick veneer wall may be insulated by use of standard insulating sheathing and fiber glass batt insulation placed between studs, giving an R value of approximately 14, and a U value of approximately 0.07. Mass of the brick veneer and the nominal one inch air space between veneer and sheathing adds greatly to energy efficiency of the brick veneer wall. Insulating The Brick Cavity Wall One of the most important advantages of the brick cavity wall is that the cavity may be used for placing insulation within the wall. Typical Brick Veneer Wall Details Brick Veneer Wall Brick veneer walls are currently the most widely used walls for residential construction. The brickwork is a veneer since it is a non-loadbearing facing built after framing is complete. This is a drainage type wall. An air space is provided back of the brickwork to allow any penetrating water to fall to the base of the veneer where flashing and weep holes are provided to divert water back out of the wall. Footing size and foundation anchorage should be determined per local building codes. Foundations should extend not less than 12 inches below the finished natural grade or engineered fill and in no case less than the frost line depth. Typical Brick Cavity Wall Details Brick Cavity Wall A cavity wall consists of two wythes of masonry separated by a continuous air space that is between two and four inches in width. The cavity wall is utilized because it is an exceptional all-weather wall. Because of its ease of insulation, it is an efficient energy saver. The cavity wall helps resist noise penetration, is fire resistant and is virtually maintenance free. The two walls are tied together with metal ties. Spacing and type of ties can vary and should be determined on a case by case basis. The brick cavity wall, a drainage type wall, is particularly impervious to moisture penetration because the air cavity (space) allows any moisture to drain to the bottom of the wall. Proper flashing and weep holes are important to drainage. Flashing directs moisture from the interior wythe to the outside of the exterior wythe. Flashing should be installed over all openings, under sills and, most importantly, at the bottom of the cavity wall just above ground level. For additional information you may request Tech Note 21B, Brick Masonry Cavity Walls Detailing. In order to insulate the wall properly it is absolutely essential that the cavity be kept clean during construction. Insulations that have been used in cavity walls include loose fill poured type, rigid board type and foamed-in-place type. R value for a 12 inch brick and brick cavity wall insulated with poured vermiculite or a 2 inch rigid styrene board would be approximately 14, and the U value would be approximately 0.07. Mass of the brickwork provides additional energy saving qualities not recognized in standard U value calculations.

Brick Veneer Wall

Brick Cavity Wall

Guide To Brick Construction

Mortarless Interior Brick Flooring

Fireplaces

Mortarless Interior Brick Flooring

Mortarless brick flooring may be placed on a concrete slab or on a wood flooring system as shown in the illustrations. The size of the brick is optional, except for patterns such as basket weave and herringbone, which require brick with length dimensions exactly twice that of the width, such as 4"x8" or 3 3/4"x7 1/2", etc. Thickness of brick used on a concrete slab may vary up to 2 1/4", but maximum thickness of 1 5/8" is recommended for wood flooring systems to reduce weight. Joist spacing of wood flooring systems should be limited to 12" o.c. Building paper is first placed on the supporting base with edges butted rather than lapped. Two layers of 15 lb. felt are recommended. Brick are placed directly on the felt in the desired pattern. Units should be placed tightly together. Clean, dry sand is then placed on the brick and swept into all joints. Surplus sand is swept off and sealer may be applied when floor is completely dry. Sealing is necessary as it locks sand in joints and creates an impervious floor finish. Because sealing is so important, it is suggested that great care be given to choosing and applying a ceiling product. For specific questions on sealing concerns, contact the technical department at Brick SouthEast.

Brick floor on wood support system

Fireplaces

Today, brick fireplaces are considered standard in almost all homes. The need for a backup or secondary heating system has created a renewed interest in the open fireplace that has historically been the Heart of the Home. Todays fireplace is subjected to higher temperatures and more prolonged use than at any other time in memory. Because of increased temperatures and length of use, the home builder must ascertain if his fireplace design meets all requirements of the Building Code and insure that constant supervision be given to the carpentry and masonry crews during construction of the structure and surrounding framing. Since the safety of human life is involved, these details should not be left solely to subcontracting crews.

Size of the fireplace should be in proportion to the room size. The U.S. Department of Agriculture has determined that a fireplace 30 to 36 inch wide is generally suitable for a room having 300 square feet of floor space. A fresh air supply substantially increases the efficiency of a fireplace by reducing the amount of heated air taken from the living space. Details of the adjustable fresh air damper and ductwork are shown. The fireplace builder should be cautioned to leave room in masonry work for expansion of metal lintels, dampers and firebrick linings in order to avoid masonry cracks. For complete details of construction, refer to Brick SouthEasts publications, Good Practice for Construction of Brick Fireplace and Fireplaces.

Brick floor on concrete slab

Also, special attention should be given to determining the type of chimney footing required. Building Codes require that concrete footings for chimneys rest on solid ground, and/or extend down to the level of main foundation footings and that they be bonded with main footings. Solid Ground means firm, undisturbed soil or adequately controlled fill.

Section

Plan & Front Elevation

Guide To Brick Construction

Arches

Quoin Corners Water Table

Arches

The arch provides a method of spanning masonry wall openings that not only has structural advantages over lintels and beams, but gives designers a method of expressing various architectural effects and styles. Arches are constructed with the aid of temporary forming or centering which must carry dead loads until the arch has gained sufficient strength to support itself and other superimposed loads. Generally, forms should remain in place a minimum of ten days after completion of all masonry work to be supported by the arch. To help simplify construction of flat or jack arches, a steel angle (lintel) is sometimes used as a permanent form in brick veneer construction. Complete filling of all mortar joints is especially important in arch construction since joints are vital in maintaining the compression ring or

wedging effect of the arch. Any movement caused by the slightest sliding, settlement or rotation of abutments or supports or the arch itself may result in failure of the arch. Orders for brick arches should be placed with the brick manufacturer at the inception of the job, and detailed drawings, preferable full drawings of a half arch, should accompany the order. The following information should be on drawings: 1. 2. 3. 4. 5. 6. 7. Masonry Opening Dimensions Mortar Joint Thickness Number of Courses High Bonding of Arch (One, Two, Three Piece) Skewback Angle Type and Texture of Brick used Radius of Radiuses, if applicable

Quoin Corners

Quoins are special ornamental projections executed in brickwork to mark corners of buildings and to create an overall appearance of strength, grandeur, and solidity. When constructing quoins, brick is laid in the standard method with a two inch air space allowed between the brick and the sheathing rather than the normal one inch of space. It is important that an adequate number of ties be used. This relatively simple masonry technique is a sign of elegance that will be a lasting reminder of the quality of the builders work

Quoin Elevations; Front & Side

For design information on brick arches, see Brick Institute of America Technical Notes, Number 31 series. Semicircular

Water Table

A brick water table can add that touch of early American architectural detail to any colonial style house. Your brick representative can help in selecting the most appropriate factory-made brick water table design for a particular situation.

Quoins: Perspective & Plan

Jack

Segmental Elliptical

Typical Water Table: Brick Veneer Wall

Details

Arch Form

Guide To Brick Construction

Steps

Exterior Paving

Steps

Brick steps can be the final visual touch to provide handsome curb appeal for any home. Since steps are normally exposed to severe weathering, quality materials and good workmanship are essential for good construction and performance. All brick steps should be placed on concrete footings. Concrete should be 2500 PSI (28 days) placed in an area excavated to solid earth with a 12" minimum depth below finished grade. All footings should be a minimum of 8" deep and have a 4" projection past steps except where they abut an adjoining wall. In situations of questionable soil conditions, reinforcing steel should be used. All masonry used in steps should be laid with type S mortar. Rowlock tread steps having 7" risers and 12" treads should be built using factory-made corners which are available from all brick manufacturers. For specific tread and riser dimensions, consult with your local code official. Ogee Rowlock Step Tread Special units add a designer appearance. Check with your brick manufacturer for availability.

Rowlock Tread/7" Riser Use 8"x8"x4" factory made corners

Exterior Paving

Brick walkways, patios and driveways are more popular now than ever before. Homebuilders are finding brick paving a must in todays highly competitive market. Brick paving is an easy way of adding value to the property you are putting on the market. Mortarless paving is much cheaper to build than mortared paving and, if built properly, can provide the same enduring qualities of conventional paving systems and materials. The most important consideration for mortarless paving is a good base. Solidly compacted earth and other base materials will generally eliminate settlement problems. Good drainage of the general area where mortarless paving is to be installed will help maintain a stable base and help prevent growth of algae on paving units. Providing good edge retention of mortarless paving is essential, and, of course, specifying weather-resistant brick paving units is important to a quality installation.

A few patterns

End Elevation and Step Elevation Respectively

Guide To Brick Construction

Driveways

Walkways & Patios

Driveways

Specifications Mortarless brick paving should conform to the alignment and grade as shown on the plans. The subgrade (earth) should be well compacted with all organic material and soft soil removed and replaced with an approved soil. Paving brick should conform to ASTM C902, Class SX. Color and dimensions should be approved from a sample. Mortarless brick paving may be installed by semi-skilled labor. Installation 1. Install a row of curb brick on one side of the driveway, settling units to the required height. Use mortar behind and under curb units as needed for support. Set a temporary form on the opposite side of driveway to proper grade, 2-3 inches outside of the location of curb brick installation. 2. A base course should be placed and compacted. The base material should be of Aggregate Base Course (ABC) conforming to DOT specifications. The aggregate should be placed on an approved subgrade between the curb brick row and the temporary form. The aggregate can be compacted with a vibratory place compactor or by hand and should have a slight crown upon completion. When compaction is complete the base course should be smooth, hard, dense, unyielding and well bonded. Perspective

3. Place a 1/2" to 1" layer of sand or stone screenings on the base course, using screed to spread uniformly over the entire area. Moisten and compact by hand or a mechanical devise. Rescreed this layer as required to bring surface to the exact grade. 4. Begin laying pavers along previously installed rows of curb brick, using specified bonding pattern and continuing until all paving is laid. Normally, paving units are placed tightly together leaving no space between individual pavers. However, if units have very smooth uniform edges or if pavers are very uniform in size, 1/16" should be left between units to allow a space for sand to surround each unit. 5. Remove the temporary form. Install final row of curb brick tightly along the outer row of pavers by removing groups of 5 or 6 pavers from the outer row and excavating a small trench for the curb brick in this area. Place the curb brick in this trench, backfill and tamp on both sides and use mortar behind and under units as needed for support. Set curb units to required grade. Replace and smooth screenings and replace paving brick. 6. Scatter stone screenings or sand over entire surface and sweep into cracks.

Walkways & Patios

Specifications Mortarless brick paving should conform to the grade as shown on plans. The subgrade (earth) should be well compacted with all organic material and soft soil removed and replaced with an approved soil. The paving brick should conform to ASTM C902, Class SX. Color and dimensions should be approved from sample. Installation 1.Install a row of edge brick on one side of the walk to the required alignment and grade. Set a temporary form on the other side of the walk to the proper grade, 2"-3" outside of edge brick location. 2. Complete grading as shown in sketch below and place stone screenings or sand between the forms to approximate required depth using the screed to spread uniformly over the area. Moisten screenings or sand and compact by hand or mechanical equipment. Rescreed screenings or sand, as required, to smooth base and bring surface to the required grade. 3.Start laying pavers along the previously installed row of edge brick, using specified bonding pattern, and continue this until all pavers are laid.

Normally, paving units are placed tightly together, leaving no space between individual pavers. However, if the units have very smooth uniform edges or if pavers are very uniform in size, 1/16" should be left between units to allow a space for sand to surround each unit. 4. Remove the temporary form. Install final row of edge brick tightly along outer row of pavers by removing groups of 5 or 6 pavers from outer row and excavating a small trench for edge brick in this area. Place edge brick in this trench, backfill and tamp on both sides, replenish and smooth the screenings or sand and replace paving brick. 5. Scatter stone screenings or sand over entire surface and sweep into the cracks. For additional information see Brick Paver Paths, Patios, & More available from Brick SouthEast.

Sections

Perspective

Sections

10

NOTCH THICKNESS OF BRICK (BOTH ENDS)

11

Guide To Brick Construction

Brick Cleaning

Mailboxes

Brick Cleaning

Four Simple Steps For Better Brick Cleaning Often forgotten, brick cleaning is actually one of the most important parts of new home construction so far as the Home Buyer is concerned. Why not give brick cleaning the same concern given other Final Appearance items? Brick cleaning is not difficult if properly done. First thing to do is to ask the brick manufacturer for recommendation on cleaning the particular brick. If a decision is made to use an acid cleaning system, then a particular acid product should be agreed upon. Before applying acid solution, larger mortar particles should be removed by use of hand tools, reducing unwanted mortar deposits to paperthin smears. Next, apply plenty of water to the masonry, enough to satisfy thirst of the wall and keep water standing on surface of masonry.

Apply acid solutions, mixed according to instruction on container. Scrape any remaining mortar particles, reapply solution and rinse wall thoroughly, flushing off all acid and dissolved mortar particles. Care should be taken to protect nearby painted surfaces, glass, metal, etc. Test areas should be treated and necessary approval secured before continuing. High pressure water systems may be used to rinse masonry, but may not be used to apply acids. Test areas should be rinsed and necessary approval secured before continuing with high pressure water systems. Sandblast cleaning is an acceptable method for cleaning new masonry. As with all cleaning systems, test sections should be cleaned and necessary approval secured before continuing sandblasting. For complete information on the cleaning systems described above and for information on specialty cleaning see the Brick Association publication Cleaning New Brickwork.* * The publication can be accessed at

www.gobricksoutheast.com (professional segment).

Mailboxes

A brick mailbox is a simple, but unique way to dress up your front yard and add that final touch of class to your home. It is a simple, do-it-yourself project that can be done by the weekend mason in the family. Pictured here are just a few of the many designs available. Use one of these or design your own. Brick mailboxes let you be as creative as you like.

1. Remove large particles of mortar with hand tools before washing the wall.

3. Apply cleaning solution with brush, mixed as directed on container. Follow printed instructions as to length of time solution should remain on wall. Scrape as needed, and continue brushing.

12

2. Thoroughly pre-wet with water before cleaning. Plenty of water is the secret of good masonry cleaning. Be sure the brickwork below the area being cleaned is thoroughly soaked with water so dissolved mortar from above wont be drawn into face of the brick below.

4. Rinse thoroughly with water immediately. Remember, the secret of good masonry cleaning is using plenty of water.

13

Guide To Brick Construction

Garden Walls

Retaining Walls

Garden Walls

English Bond with pattern formed by headers alternately projected and omitted

Elevation

Section A-A

Retaining Walls

Note: For back fill up to 3 feet above footing

Flemish Bond with open pattern of crosses

Flemish Bond with open header pattern

14

15

Guide To Brick Construction

Exterior Remodeling with Brick

Brick Does Not Leak

Exterior Remodeling with Brick

Brick Veneer An experienced builder can transform old buildings into new ones with brick veneer. Brick veneer is applied as in regular new brick veneer construction. The brick are secured with metal veneer ties attached to the existing wall and spaced no further Details

apart than 16" vertically, and 24" horizontally. Footings If the existing footing projects at least 5", this is sufficient to start the new brick veneer. Otherwise, an additional concrete footing approximately 8" deep (minimum) should be installed. Note: Engineering analysis required for all details.

Brick Does Not Leak

Occasionally one may encounter the problem of a leaky wall. Experience shows, however, the cause of the problem is not the brick, but improper construction technique. The following improper conditions may contribute to the leaky wall problem and should be avoided:

Poor bond between brick and mortar Use of raked or scratched joints Use of poor quality mortar Excessive mortar droppings in air space or cavity Poor foundation walls In spite of the need to supervise all aspects of construction, it is obvious one cannot be everywhere and do everything. For this reason, we offer this information to acquaint you with some basic techniques to help prevent these problems. It will be helpful if you keep a copy on the job site.

Head Joint Construction

Brick Veneer on Wood Frame

Solid (Composite) Walls

16

17

Guide To Brick Construction

Cold Weather Masonry Construction & Protection Recommendations

Alternate Method for Support of Brick Veneer above Garage Door Openings

Cold Weather Masonry Construction & Protection Recommendations*

Cold weather masonry construction and its quality control require some additional attention to construction practices and protection. Attention should be directed to the following details as well as those normally attended. 1. The cold weather construction and protection recommendation of this recommended practice should be closely followed. 2. Construction materials should be received, stored, and protected in ways that prevent water from entering the materials. 3. If climactic condition warrant, temperatures of construction materials should be measured frozen sand and wet masonry units must be thawed. Masonry units below 20oF must be heated above 20oF without overheating. * This brochure contains general cold weather construction

recommendations. Code specific recommendations for hot and cold weather construction can be found in the Masonry Standards Joint Committee document.

4. Sufficient mortar ingredients should be heated to produce mortar temperatures between 40oF and 120oF. Every effort should be made to produce consecutive batches of mortar with the same temperatures falling within this range. The mortar temperature after mixing and before use should be above 40 oF, maintainable either by auxiliary heaters under the mortar board or by more frequent mixing of mortar batches. Heated mortar on mortar boards should not become excessively hot (greater than 120oF). 5 During below-normal temperatures, masonry should be placed only on sound unfrozen foundations. Masonry should never be placed on a snow or ice-covered surface, because of the danger of movement when the base thaws and the possibility of very little bond being developed between the mortar and the supporting surface. 6. At the end of the day, the top surface of all masonry should be protected to prevent moisture, as rain, snow or sleet, from entering the masonry. This protection must cover the top surface and should extend a minimum of 2 feet down all sides of the masonry. Protection Requirement Cover walls with plastic or canvas at end of work day to prevent water entering masonry. Cover walls and materials for a minimum of 24 hours after construction to prevent wetting and freezing. Covers should be plastic or canvas. With wind velocities over 15mph provide windbreaks during the work day and cover walls and materials at the end of the work day to prevent wetting and freezing. Maintain masonry above freezing for 24 hours using auxiliary heat or insulated blankets.

Alternate Method for Support of Brick Veneer above Garage Door Openings

Typically garage door openings over 10 feet are required to be designed by an engineer. However, some officials recognize an alternate method of support that incorporates the concept of reinforcing the brick veneer. This technique allows the use of ladder wire joint reinforcing in the first few horizontal mortar joints above the openings as described by the diagram below. We recommend presenting this alternate method to your local official for approval in advance of actual construction. Construction Considerations: 1. The maximum openings allowed by this method is 18 feet 3 inches with a minimum of 1 foot 6 inches of brick required on either side of the opening. 2. A maximum height of 5 feet of brick may be supported above the opening provided there is .

a minimum of 13 inches of veneer above the opening edges (approximately 5 brick courses ). 3. A maximum height of 12 feet of brick may be supported above the opening provided there is a minimum of 2 feet of veneer above the opening edges (approximately 9 brick courses ). 4. A maximum height of 35 feet of brick may be supported above the opening provided there is a minimum of 5 feet of veneer above the opening edges (approximately 22 brick courses ). 5. Care must be taken with the placement of additional openings (i.e. windows) above the garage opening. If the height of veneer is less than 3 feet no openings should be placed. For veneer heights above 3 feet the depth of openings should be limited to 1/2 the height of the veneer and they must be placed within 12 inches of the bottom and 6 inches from the top of the veneer. 6. A 5"x 3 1/2"x 5/16" angle should be used to facilitate installation and should be shored for at least 7 days after installation.

Mean Daily Temperature* Above 40oF 40oF32oF

Construction Requirement Normal masonry procedures. Heat mixing water to produce mortar temperatures between 40oF120oF. Heat mixing water & sand to produce mortar temperatures between 40oF120oF

32oF25oF

25oF20oF 20oF 0oF

Mortar on boards should be maintained above 40oF. Heat mixing water & sand to produce mortar temperatures between 40oF120oF Provide enclosures and supply sufficient heat to maintain masonry enclosure above 32oF for 24 hours.

18

* For questions regarding specific temperature concerns, contact the Technical Department of Brick SouthEast.

19

Guide To Brick Construction

Guide To Brick Construction

Notes

Although this document has been provided for your use, it should not be reproduced in part or in whole without prior written permission. Additional copies are available from Brick SouthEast 800.62.BRICK

Copyright 2006 B RICK S OUTH E AST

20

Guide To Brick Construction

www.gobricksoutheast.com 800.62.BRICK Suite 800 8420 University Executive Park Charlotte, NC 28262 888.37.BRICK Suite A 1810 Overlake Drive Conyers, GA 30013

Boral Bricks, Inc. Carolina Ceramics Brick Co. Cherokee Brick & Tile Columbus Brick Co. Cunningham Brick Co. General Shale Brick Hanson Brick Henry Brick Co. Jenkins Brick Co. Lee Brick & Tile Co. Nash Brick Co. New London Brick Works Old Carolina Brick Co. Palmetto Brick Co. Pine Hall Brick Co., Inc. Statesville Brick Co. Taylor Clay Products Co. Triangle Brick Co.

04.06

You might also like

- Build Better A Guide To Energy Efficient Concepts For New Residential ConstructionDocument167 pagesBuild Better A Guide To Energy Efficient Concepts For New Residential Constructiongdevi80No ratings yet

- ShortTerm Trading SecretsDocument24 pagesShortTerm Trading Secretsbae32383% (30)

- Essential Home Shelter Design and Construction GuideDocument9 pagesEssential Home Shelter Design and Construction Guidetrumpman93No ratings yet

- Construction and DetailingDocument193 pagesConstruction and Detailings.senthil nathan89% (9)

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundFrom EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundNo ratings yet

- Low RiseResidentialConstructionDetailsDocument104 pagesLow RiseResidentialConstructionDetailsGeorgeEdwardNo ratings yet

- Flat Roof Design Considerations Bauder 2019 PDFDocument16 pagesFlat Roof Design Considerations Bauder 2019 PDFMwaNo ratings yet

- Cavity Walls PDFDocument23 pagesCavity Walls PDFAsghar Hussain Shah100% (1)

- Facade FabricsDocument66 pagesFacade FabricsAiswarya SreekumarNo ratings yet

- Electrolux EW23BC71IS0 Refrigerator Tech SheetDocument2 pagesElectrolux EW23BC71IS0 Refrigerator Tech SheetEdison EspinalNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- A Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationFrom EverandA Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationNo ratings yet

- Basic Brickwork DetailsDocument14 pagesBasic Brickwork DetailsAndrew Vincent100% (2)

- Masonry Construction ManualDocument390 pagesMasonry Construction ManualNerijus Adamukaitis95% (42)

- Roof DetailsDocument147 pagesRoof DetailsMartin FoxNo ratings yet

- SKF Bolt-Tightening HandbookDocument44 pagesSKF Bolt-Tightening Handbookcmms88100% (4)

- Fluid Properties: Dr. Akepati S. Reddy Thapar University Patiala (PUNJAB) - 147 004 IndiaDocument29 pagesFluid Properties: Dr. Akepati S. Reddy Thapar University Patiala (PUNJAB) - 147 004 IndiaDr. Akepati Sivarami ReddyNo ratings yet

- Advanced Building Envelope Components: Comparative ExperimentsFrom EverandAdvanced Building Envelope Components: Comparative ExperimentsNo ratings yet

- The Building Envelope: Applications of New Technology CladdingFrom EverandThe Building Envelope: Applications of New Technology CladdingNo ratings yet

- Above Ground Fallout ShelterDocument8 pagesAbove Ground Fallout Shelteragabatti100% (1)

- Design of Box Culverts, KBMDocument17 pagesDesign of Box Culverts, KBMSasinath Msh100% (1)

- Roofs - A Guide To The Repair of Historic Roofs (2010)Document110 pagesRoofs - A Guide To The Repair of Historic Roofs (2010)Aaron Moloney100% (1)

- Modern Residential Architecture Book Highlights Technical and Aesthetic Design DetailsDocument138 pagesModern Residential Architecture Book Highlights Technical and Aesthetic Design DetailsKarla Anna Kovacs100% (4)

- Dry ConstructionDocument114 pagesDry Constructionanbertjonathan100% (2)

- An Architect’S Guide to Engineered Shading Solutions: The Next Generation in Window CoveringsFrom EverandAn Architect’S Guide to Engineered Shading Solutions: The Next Generation in Window CoveringsNo ratings yet

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocument1 pageProper Bolt Axial Tightening Force and Proper Tightening Torquecmms88No ratings yet

- The Open Timber Construction System Architectural DesignDocument116 pagesThe Open Timber Construction System Architectural Designzdravkoiliev100% (8)

- Detail Praxis - Timber ConstructionDocument55 pagesDetail Praxis - Timber Constructionarch.soares6030No ratings yet

- (Basics (Book 82) ) Ludwig Steiger - Basics Timber Construction (2007, Birkhäuser Architecture) - Libgen - LiDocument96 pages(Basics (Book 82) ) Ludwig Steiger - Basics Timber Construction (2007, Birkhäuser Architecture) - Libgen - LiPauloRobertoLiñanFigueiredoNo ratings yet

- Best of Architects Working Details PDFDocument192 pagesBest of Architects Working Details PDFTaraja Jackson100% (2)

- Owner's Engineer - A Viable Solution For Capital ProjectsDocument5 pagesOwner's Engineer - A Viable Solution For Capital Projectscmms88No ratings yet

- Architectural StructuresDocument227 pagesArchitectural StructuresMohamed Zakaria92% (24)

- Bridge Engineering Assignment ReportDocument31 pagesBridge Engineering Assignment ReportChiranjaya HulangamuwaNo ratings yet

- (Architecture Ebook) Detail Praxis - Timber ConstructionDocument55 pages(Architecture Ebook) Detail Praxis - Timber ConstructionEduardo RioNo ratings yet

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- UTP welding consumables guideDocument431 pagesUTP welding consumables guidecmms88100% (1)

- Rate AnalysisDocument3 pagesRate AnalysisNiranjan Shrestha83% (12)

- Boral Installation MasonryGuideDocument25 pagesBoral Installation MasonryGuidem0172No ratings yet

- Catalog Blum ADocument236 pagesCatalog Blum AcriuvosNo ratings yet

- Designing With Light: The Art, Science and Practice of Architectural Lighting DesignFrom EverandDesigning With Light: The Art, Science and Practice of Architectural Lighting DesignNo ratings yet

- AIREX Linear Motor Vacuum CompatabilityDocument3 pagesAIREX Linear Motor Vacuum Compatabilitymsahin1955No ratings yet

- Architect's Facade ManualDocument240 pagesArchitect's Facade ManualLaura Gardner93% (15)

- Approved Construction Details: For Part L2 (England and Wales) and Part J (Scotland)Document76 pagesApproved Construction Details: For Part L2 (England and Wales) and Part J (Scotland)Eleanor Knowles100% (6)

- Comparative Analysis of Building LawsDocument2 pagesComparative Analysis of Building LawsJasper John RiveroNo ratings yet

- Concrete: Design Construction ExamplesDocument110 pagesConcrete: Design Construction Examplesjavi flowNo ratings yet

- Settlement BH-02 WaingapuDocument225 pagesSettlement BH-02 WaingapuAlifiya Malika ZahraNo ratings yet

- ITaaS - EMC2 IT-as-a-Service HandbookDocument23 pagesITaaS - EMC2 IT-as-a-Service Handbookcmms88No ratings yet

- Brick Veneer WallDocument16 pagesBrick Veneer Wallpilapil_jNo ratings yet

- Computer Integrated ConstructionFrom EverandComputer Integrated ConstructionH. WagterNo ratings yet

- 2014 - 004 Plumbing FixturesDocument58 pages2014 - 004 Plumbing FixturesRon Julienne Rebugio100% (2)

- Molykote High Temperature GreasesDocument1 pageMolykote High Temperature GreasesProject Sales Corp100% (1)

- Drillability IndexDocument10 pagesDrillability Indexeduardoenrique08289100% (1)

- Strategies Using ETFsDocument16 pagesStrategies Using ETFscmms88No ratings yet

- Kalzip ConstructiondetailsDocument87 pagesKalzip ConstructiondetailsIrina PlopeanuNo ratings yet

- Ar Bricks-21Document34 pagesAr Bricks-21ManishaChary100% (1)

- Systems For Flat RoofDocument44 pagesSystems For Flat Roofazure2007No ratings yet

- Low Cost HousingDocument48 pagesLow Cost HousingManish Solanki71% (7)

- P91 Welding ProcedureDocument1 pageP91 Welding ProcedureJaymin100% (2)

- Corrosion and Protection GuideDocument6 pagesCorrosion and Protection Guidexaekne100% (4)

- Sustainable Facades: Design Methods for High-Performance Building EnvelopesFrom EverandSustainable Facades: Design Methods for High-Performance Building EnvelopesRating: 4.5 out of 5 stars4.5/5 (1)

- Data Center Evaluation ChecklistDocument6 pagesData Center Evaluation Checklistcmms88No ratings yet

- Ventilated FacadesDocument31 pagesVentilated Facadeschoppersure100% (1)

- Ageing Plant Summary GuideDocument53 pagesAgeing Plant Summary GuideEyoma EtimNo ratings yet

- Integrated Buildings: The Systems Basis of ArchitectureFrom EverandIntegrated Buildings: The Systems Basis of ArchitectureRating: 5 out of 5 stars5/5 (1)

- Architectural Details FinalDocument29 pagesArchitectural Details FinalNadia Martinelli100% (2)

- Brick Book 18 English - SmallDocument292 pagesBrick Book 18 English - SmallThanh Nguyen DucNo ratings yet

- Thermal Inertia in Energy Efficient Building EnvelopesFrom EverandThermal Inertia in Energy Efficient Building EnvelopesRating: 4.5 out of 5 stars4.5/5 (3)

- TCH Seminar Cavity WallDocument30 pagesTCH Seminar Cavity WallSachin AbhiramNo ratings yet

- Above Shelter DesignDocument8 pagesAbove Shelter Designwhite171No ratings yet

- Brick Bearing Wall Technical NotesDocument11 pagesBrick Bearing Wall Technical NotesniroNo ratings yet

- 26 Single Wythe Bearing WallsDocument15 pages26 Single Wythe Bearing WallsMuslimsNo ratings yet

- CW Sheltrh122Document8 pagesCW Sheltrh122warhawkjohnnyNo ratings yet

- Brick masonry detailing guideDocument8 pagesBrick masonry detailing guideHekato AssumiNo ratings yet

- Crack Control for Concrete Masonry VeneersDocument10 pagesCrack Control for Concrete Masonry VeneersAdam JonesNo ratings yet

- Part 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary NotesDocument9 pagesPart 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary Notesmohannad eliassNo ratings yet

- TT FloorexpansionjointsDocument4 pagesTT FloorexpansionjointsSardar Qasim Sultan DogarNo ratings yet

- TLB TechnicalNotes ClayBrickworkDocument10 pagesTLB TechnicalNotes ClayBrickworkSadeep MadhushanNo ratings yet

- Construction of A 3 Bedroom BungalowDocument13 pagesConstruction of A 3 Bedroom BungalowElujekwute Benjamin100% (1)

- On Brick Construction: Technical NotesDocument8 pagesOn Brick Construction: Technical NotesSharad SinghNo ratings yet

- Guidelines For Construction of Masonry With Siporex BlocksDocument12 pagesGuidelines For Construction of Masonry With Siporex Blockspremadhikari007No ratings yet

- 38-character for advantages of concrete masonry constructionDocument4 pages38-character for advantages of concrete masonry constructionLyca LamNo ratings yet

- City Gas Handbook On Gas Supply Nov13Document57 pagesCity Gas Handbook On Gas Supply Nov13cmms88No ratings yet

- DBS Deposit GuideDocument24 pagesDBS Deposit Guidecmms88No ratings yet

- SP800-64-Revision2 - Security Considerations in The System Development Life CycleDocument67 pagesSP800-64-Revision2 - Security Considerations in The System Development Life Cyclecmms88No ratings yet

- Surface Preparation Standards Comparison ChartDocument2 pagesSurface Preparation Standards Comparison ChartajuhaseenNo ratings yet

- Brochure Steel GratingDocument11 pagesBrochure Steel Gratingcmms88No ratings yet

- Initial Gasket Compression Is Key To Safe, Reliable Flange JointsDocument3 pagesInitial Gasket Compression Is Key To Safe, Reliable Flange Jointscmms88No ratings yet

- Caterpillar Marine Propulsion Systems BrochureDocument8 pagesCaterpillar Marine Propulsion Systems Brochurecmms88100% (2)

- Torque Value GuideDocument2 pagesTorque Value GuideSaurabh KaushikNo ratings yet

- FXCM New To Forex GuideDocument27 pagesFXCM New To Forex Guidecmms88100% (1)

- SSPC - Surface Prep STDDocument4 pagesSSPC - Surface Prep STDcmms88No ratings yet

- Tripac Technical Data - Bolt - Wrench Sizes ChartDocument19 pagesTripac Technical Data - Bolt - Wrench Sizes Chartcmms88100% (2)

- Tips Critical Crane Lift PDFDocument7 pagesTips Critical Crane Lift PDFb_wooNo ratings yet

- Incoloy Alloys 800H 800HTDocument16 pagesIncoloy Alloys 800H 800HTkaramniaNo ratings yet

- High performance solvent-free potable water tank coatingDocument4 pagesHigh performance solvent-free potable water tank coatingvicbaradatNo ratings yet

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 pagesPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNo ratings yet

- Tips Critical Crane Lift PDFDocument7 pagesTips Critical Crane Lift PDFb_wooNo ratings yet

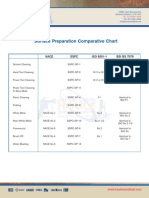

- Surface Preparation Comparative ChartDocument1 pageSurface Preparation Comparative Chartcmms88No ratings yet

- Atlas Technical Handbook Rev July 2010Document49 pagesAtlas Technical Handbook Rev July 2010cmms88100% (1)

- Neer Ground Clamps: GC: Bronze Clamps GC: Zinc ClampsDocument2 pagesNeer Ground Clamps: GC: Bronze Clamps GC: Zinc ClampsLuis Guillermo BenitezNo ratings yet

- Steady Incompressible Flow in Pressure Conduits: Lecture - 10Document34 pagesSteady Incompressible Flow in Pressure Conduits: Lecture - 10Nawaz441No ratings yet

- Splined ShaftDocument2 pagesSplined Shaftjmpateiro1985No ratings yet

- Flux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 SteelDocument14 pagesFlux-Cored Wire For Ar+CO Gas Shielded Arc Welding For ASTM A387 Gr.91 Steelamit singhNo ratings yet

- 08 Counterbalance Valve Mini CatalogDocument60 pages08 Counterbalance Valve Mini Catalogs bNo ratings yet

- Commercial Construction Timeline TemplateDocument11 pagesCommercial Construction Timeline TemplateEng Abdikarim WalhadNo ratings yet

- Estimation SampleDocument14 pagesEstimation SampleNoor MohdNo ratings yet

- 25.03 - Vitaulic RanuradoDocument3 pages25.03 - Vitaulic RanuradoABAD ALEXANDER MORENO ZÁRATENo ratings yet

- Review of P-Y Relationships in Cohesionless SoilDocument33 pagesReview of P-Y Relationships in Cohesionless SoilMalik RizwanNo ratings yet

- Fosroc and Sika Concrete Admixture in JharkhandDocument4 pagesFosroc and Sika Concrete Admixture in JharkhandsirfmeinNo ratings yet

- GCPAT Procor Composite Waterproofing System Us 1676Document7 pagesGCPAT Procor Composite Waterproofing System Us 1676Saurav Negi EtherealNo ratings yet

- Technical DocumentationDocument84 pagesTechnical Documentationpotolok7767100% (2)

- Light Commercial INVERTER Top Discharge CDU type Service ManualDocument99 pagesLight Commercial INVERTER Top Discharge CDU type Service ManualAbel Recinos100% (1)

- Electrode Classifications 2Document1 pageElectrode Classifications 2aguirretoNo ratings yet

- Portland Cement: Joe Diedrich Technical Services ManagerDocument44 pagesPortland Cement: Joe Diedrich Technical Services ManagerdoxamariaNo ratings yet

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaNo ratings yet

- GulfSea AB Cooloil SeriesDocument2 pagesGulfSea AB Cooloil SeriesObydur RahmanNo ratings yet