Professional Documents

Culture Documents

Worker Caught Between Machinery and Bin

Uploaded by

Vivek NaikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Worker Caught Between Machinery and Bin

Uploaded by

Vivek NaikCopyright:

Available Formats

Worker caught between machinery and Bin in Construction Site A team of construction workers was assisting in a piling operation

using a boring rig attached with a boring bucket. After every bore, the boring bucket was lifted over a skip bin and its bottom flap opened to discharge the bored earth. The Deceased was tasked to open the bottom flap of the boring bucket. To close the flap, it was pressed against the skip bin and the bucket rotated to lock it in place. Just before the accident, the rotation of the bucket against the skip bin caused the bin to skid on the ground. The Deceased was then walking between the boring rig and the skip bin when it skidded. He was struck in his abdomen by the skip bin and caught in-between the skip bin and the track of the boring rig. He passed away in the hospital later on the same day.

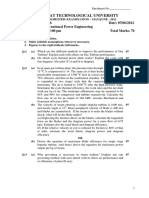

Figure 1: Worker was caught in-between the skip bin and the track of the boring rig

Recommendations *: Industry stakeholders undertaking similar work activities must consider the following measures: Practice good housekeeping at the construction site and implement a traffic management plan to control and separate vehicular traffic from human traffic. Conduct risk assessment to identify residual danger zones at the construction site (including the area around each boring rig) prior to work commencement. Install warning signs and clearly demarcate all danger zones with physical barriers and / or red-white tape. Highlight to workers the location of the danger zones during safety briefings and site walk-around, emphasizing the hazards associated with working in-between objects and the need to stay clear of these areas. Strictly enforce and provide on-site supervision to ensure no entry (including no entry by authorized personnel) into cordoned-off areas when any machine with unguarded moving parts is in operation. Review the work method on the need to open the bottom flap from inside the danger zone of the boring rig. Explore the possibility of opening the bottom flap from outside the danger zone. Ensure that the boring bucket does not come into contact with the skip bin (as well as the contents of the skip bin) while it is rotating as this may cause the bin to twist / skid. Document the safe work method and include into the training programme for workers. Work with the equipment manufacturer in reviewing the design of the boring rig to reduce human-machine interaction, for example, by installing devices to facilitate automatic opening or remote opening of the bottom flap by the boring rig operator or supervisor from a safe location. Provide workers with a means to communicate effectively in a high noise work environment, for example, through the use of walkie-talkie headsets with suitable noise reduction rating. Provide sufficient illumination for work at night or in dark areas. In particular, proper lighting must be provided for all work within a danger zone.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ca Va de SoiDocument15 pagesCa Va de SoiManideep SrirangamNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SITE Check ListDocument14 pagesSITE Check ListVivek NaikNo ratings yet

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDocument4 pagesEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Petrofac Steel Erection Risk AssessmentDocument4 pagesPetrofac Steel Erection Risk AssessmentVivek Naik100% (2)

- Root Cause Analysis Example Near Miss Asphalt Drop FULLDocument9 pagesRoot Cause Analysis Example Near Miss Asphalt Drop FULLnayakya100% (1)

- Customize AutoCAD P&ID with Engineering ItemsDocument33 pagesCustomize AutoCAD P&ID with Engineering ItemsnunosobralNo ratings yet

- AIS Romney 2006 Slides 18 Introduction To Systems DevelopmentDocument153 pagesAIS Romney 2006 Slides 18 Introduction To Systems Developmentsharingnotes123No ratings yet

- ATEX Poster-ISDocument1 pageATEX Poster-ISVivek NaikNo ratings yet

- ATEX Poster-ISDocument1 pageATEX Poster-ISVivek NaikNo ratings yet

- Aligning HR Interventions With Business StrategiesDocument14 pagesAligning HR Interventions With Business StrategiesSunielNo ratings yet

- LSIS - Molded Case Circuit Breaker (MCCB) - CatalogDocument140 pagesLSIS - Molded Case Circuit Breaker (MCCB) - CatalogNguyen LuongNo ratings yet

- Bip 0072-2014 PDFDocument94 pagesBip 0072-2014 PDFgrNo ratings yet

- H2S QuizDocument2 pagesH2S QuizVivek Naik100% (1)

- Alejandrino, Michael S. Bsee-3ADocument14 pagesAlejandrino, Michael S. Bsee-3AMichelle AlejandrinoNo ratings yet

- Process Control Valves TrainingDocument12 pagesProcess Control Valves TrainingpptmnltNo ratings yet

- Low Carb Mixed Dhal DosaDocument1 pageLow Carb Mixed Dhal DosaVivek NaikNo ratings yet

- 3 ways supervisors can battle complacencyDocument2 pages3 ways supervisors can battle complacencyVivek NaikNo ratings yet

- MSH Poster ConfinedSpaceEntryDocument1 pageMSH Poster ConfinedSpaceEntryVivek NaikNo ratings yet

- HandGrinder Guard Removed - AccidentDocument3 pagesHandGrinder Guard Removed - AccidentVivek NaikNo ratings yet

- Height of Fire ExtDocument1 pageHeight of Fire ExtVivek NaikNo ratings yet

- STOP Card-Unsafe ActDocument1 pageSTOP Card-Unsafe ActnayakyaNo ratings yet

- HazcomDocument61 pagesHazcomVivek NaikNo ratings yet

- Hazard and RiskDocument3 pagesHazard and RiskVivek NaikNo ratings yet

- Collapse of CraneDocument3 pagesCollapse of CraneVivek NaikNo ratings yet

- Germs Get Handed AroundDocument2 pagesGerms Get Handed AroundVivek NaikNo ratings yet

- Bed Bugs-FFDocument2 pagesBed Bugs-FFVivek NaikNo ratings yet

- You Need A HandDocument24 pagesYou Need A HandMohd Shahriwan IdrisNo ratings yet

- Cold StressDocument4 pagesCold StressVivek NaikNo ratings yet

- You Need A HandDocument24 pagesYou Need A HandMohd Shahriwan IdrisNo ratings yet

- Auto Parts Manufacturing in China: Ibisworld Industry ReportDocument33 pagesAuto Parts Manufacturing in China: Ibisworld Industry ReportSaira BanuNo ratings yet

- The Changing Face of The NewsDocument2 pagesThe Changing Face of The NewsYanaNo ratings yet

- Dmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderDocument71 pagesDmr-Es10Eb Dmr-Es10Ec Dmr-Es10Eg Dmr-Es10Ep Dmr-Es10Ebl: DVD Video RecorderWILIAM RODRIGUEZNo ratings yet

- GTU BE- Vth SEMESTER Power Engineering ExamDocument2 pagesGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarNo ratings yet

- Operations Management Customer FocusDocument13 pagesOperations Management Customer FocusYusranNo ratings yet

- Preliminary Hazard Identification: Session 3Document19 pagesPreliminary Hazard Identification: Session 3Isabela AlvesNo ratings yet

- The Service Owner Role in ITIL v3: by Kai HolthausDocument6 pagesThe Service Owner Role in ITIL v3: by Kai HolthausSavitha MohanNo ratings yet

- Common Wealth Games Medal ChartDocument9 pagesCommon Wealth Games Medal ChartSanyaNo ratings yet

- Assignment 3 OSDocument5 pagesAssignment 3 OSValerie ThompsonNo ratings yet

- ME116P Weeks 1-4Document243 pagesME116P Weeks 1-4Ska dooshNo ratings yet

- Chapters 1 and 3: ARM Processor ArchitectureDocument44 pagesChapters 1 and 3: ARM Processor ArchitectureTwinkle RatnaNo ratings yet

- Terra Point White PaperDocument10 pagesTerra Point White Paperobi SalamNo ratings yet

- Kotler Mktman 11ce Ch04Document34 pagesKotler Mktman 11ce Ch04Murtaza MoizNo ratings yet

- PSR 640Document188 pagesPSR 640fer_12_328307No ratings yet

- NLPDocument20 pagesNLPAvishek01No ratings yet

- Covey Stephen RDocument90 pagesCovey Stephen RcemgallNo ratings yet

- Gpover Ip FormatDocument61 pagesGpover Ip FormatGaurav SethiNo ratings yet

- List of Portmanteau Words: GeneralDocument7 pagesList of Portmanteau Words: GeneraltarzanNo ratings yet

- Computer LiteracyDocument5 pagesComputer LiteracyMazaasach MazaNo ratings yet

- Broadcast Servers for all WorkflowsDocument2 pagesBroadcast Servers for all WorkflowsJosé FélixNo ratings yet