Professional Documents

Culture Documents

Pipe SMLS VS Welded PDF

Uploaded by

Lim PaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe SMLS VS Welded PDF

Uploaded by

Lim PaCopyright:

Available Formats

Integrated Solutions Improving Process Accuracy

Seamless vs. Welded Tubing

The difference in the basic manufacturing method is obvious from the names. Seamless tube is extruded and drawn from a billet while welded tube is produced from a strip that is roll formed and welded to produce a tube. Welded tube is considerably less expensive than seamless tube and is readily available in long continuous lengths. Although the working pressure of welded tube is 20% less than that for a similar seamless tube, working pressure is not the determining factor for choosing seamless tube over welded tube for analyzer sample lines. The difference in potential impurities, which reduce the corrosion resistance of the finished tube, is why seamless tube is specified. The weld area is considered to be inhomogeneous thus exhibiting different malleability and less corrosion resistance as well as greater dimensional variation. Drawing welded tube reduces these anomalies. Most tubing (seamless and welded) is drawn to produce final dimensional tolerances. Drawing is an operation, which pulls a tube through a die. There are different methods for drawing a tube however they can be thought of as sunk drawn and a plug drawn. The difference is seen in the ID surface roughness. A sunk drawn tube is done without internal support. Sink drawn tube reduces the diameter without controlling the wall thickness. There is some crunching of the ID and the tube develops a sun burst cross section and wrinkles circumferentially along the inside surface. This can be especially noticeable around the weld on welded tubing. Plug or rod drawn tube is pulled through a die with internal support and produces a much smoother inner surface. Rod or plug drawing breaks up the weld bead on welded tubing and removes any dimensional indication. Final annealing further promotes a homogeneous tube. The term full finished refers to welded tubes that have been rod or plug drawn and annealed sufficiently to both remove any dimensional indication of the weld area and also break up the dendritic structure of the weld bead and expedite homogenization. Often it is very difficult to see the difference between welded and seamless tubing.

ISO 9001:2000

By code the allowable working pressure of welded tubing is reduced by 20%.

Working pressure in PSIG for seamless 316SS tubing at 70F.

Tube OD

1/8" 1/4" 3/8" 1/2"

Tube Wall Thickness 0.028 0.035 0.049

8,500 10,900 5,100 3,300 2,600 7,500 4,800 3,700

For welded tubing multiply pressure rating by 0.80. Temperature Conversion for 400F: multiply above by 0.96

While it is true that most welded tubing cannot be detected by the naked eye recognized standards for working the weld area of tubing are very open and allow great latitude in the degree of homogeneity in the final product.

The basis for much of todays bias regarding seamless vs. welded tubing probably stems from early manufacturing processes when the weld area was not reworked to provide a homogeneous tube wall. Even today the standard for working the weld area is very open allowing great variance in the final product. Seamless tubing simply avoids the potential for any defect in the corrosion resistance of the weld area.

2003 OBrien Corporation QLT-OBA-SEAMWLD 25 APR 03

Plug drawing tube

Fully worked welded tube

As welded tube

Certificate No. CC1504-0 001122

Worldwide Offices: 1900 Crystal Industrial Ct. St. Louis, MO 63114 Ph 314/236-2020 Fax 314/236-2080 Mallekotstraat 65 B 2500 Lier Belgium Ph (+32) 3 491 9875 Fax (+32) 3 491 9876 Suite 400 609 14th Street NW Calgary, AB T2N 2A1 Ph 403/730-7277 Fax 403/730-7279 obcorp@obcorp.com www.obrien-analytical.com

You might also like

- Seamless vs. Welded TubingDocument1 pageSeamless vs. Welded Tubingzero_cool_oooNo ratings yet

- Welded Tube PDFDocument17 pagesWelded Tube PDFhirenkumar patelNo ratings yet

- Seamless VS Welded TubesDocument1 pageSeamless VS Welded Tubeshirenkumar patelNo ratings yet

- Pipe Pile: New Jersey Department of Transportation, Brielle, NJDocument9 pagesPipe Pile: New Jersey Department of Transportation, Brielle, NJvirous08100% (1)

- Pipe Schedule: Welded and Seamless Wrought Steel PipeDocument10 pagesPipe Schedule: Welded and Seamless Wrought Steel PipePrasad BhosaleNo ratings yet

- Butting Seamless or WeldedDocument4 pagesButting Seamless or Weldedkhanz88_rulz1039No ratings yet

- Column Plant LayoutDocument7 pagesColumn Plant Layoutsteepa22No ratings yet

- Difference Between Seamless and Welded PipeDocument1 pageDifference Between Seamless and Welded PipealokbdasNo ratings yet

- Improvements To C303 Bar Wrapped Steel Cyl Conc Pipe RMielke 2 7 11 - 1 - UPLOADEDDocument12 pagesImprovements To C303 Bar Wrapped Steel Cyl Conc Pipe RMielke 2 7 11 - 1 - UPLOADEDMartin HumbirdNo ratings yet

- Conex Cuprofit TechnicalDocument24 pagesConex Cuprofit TechnicalLawrence FoxNo ratings yet

- Z211 Inst Tube FittingsDocument44 pagesZ211 Inst Tube FittingsSajeen100% (1)

- Visual Inspection of Seamless PipesDocument20 pagesVisual Inspection of Seamless PipesFasil Paruvanath100% (2)

- Inspection Manual For PipingDocument184 pagesInspection Manual For Pipingzula74No ratings yet

- Threaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20Document3 pagesThreaded Fittings General - Definition and Details - ASME B16.11 and ASME B1.20abhay_patil_22No ratings yet

- ASWP Manual - Section 3 - Joints (10!6!12)Document12 pagesASWP Manual - Section 3 - Joints (10!6!12)shah1980No ratings yet

- Piping JointsDocument25 pagesPiping JointstowiwaNo ratings yet

- Thin Wall TitaniumDocument9 pagesThin Wall Titaniumsopian320No ratings yet

- InSitu Analysis of Pipeline Metallurgy - tcm153-574187Document14 pagesInSitu Analysis of Pipeline Metallurgy - tcm153-574187Welkin Sky100% (1)

- Pipe and Tube Bending PrinciplesDocument5 pagesPipe and Tube Bending PrinciplesPravin SatheNo ratings yet

- Coupling InformationDocument4 pagesCoupling Informationamanpreet_ahujaNo ratings yet

- V-Wire Continuous Slot Water Well Screens PipesDocument2 pagesV-Wire Continuous Slot Water Well Screens PipesIgnatius SamrajNo ratings yet

- Part - I: Chapter 2 - Piping ComponentsDocument8 pagesPart - I: Chapter 2 - Piping ComponentsAshish PatelNo ratings yet

- Pipe Drafting Q and ADocument7 pagesPipe Drafting Q and AHamed FaragNo ratings yet

- Practical Design of Water DistributionDocument29 pagesPractical Design of Water DistributionUSHAJYOTHISHETTYNo ratings yet

- Types of Piping JointsDocument4 pagesTypes of Piping Jointsravish kumarNo ratings yet

- To Understand The Production of Steel PipeDocument8 pagesTo Understand The Production of Steel PiperameshNo ratings yet

- Acom87 - 1 Corrosion Engineering of High Pressure Piping in RO-PlantsDocument8 pagesAcom87 - 1 Corrosion Engineering of High Pressure Piping in RO-Plantspipedown456No ratings yet

- New Welding Tubular Joint Used For JacketDocument6 pagesNew Welding Tubular Joint Used For JacketTien Hong DoNo ratings yet

- 3.4. Standard Types of FlangesDocument7 pages3.4. Standard Types of FlangesHoàng Hữu QuốcNo ratings yet

- Spiro Gills Fin Tubing BrochureDocument16 pagesSpiro Gills Fin Tubing BrochureSaravanan PeriyasamyNo ratings yet

- Welding Procedures and Inspection Methodology For In-Service WeldingDocument14 pagesWelding Procedures and Inspection Methodology For In-Service WeldingEl_memitoNo ratings yet

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenNo ratings yet

- Swagelok Tubing DataDocument8 pagesSwagelok Tubing DataSyahirul Alim100% (1)

- SPE 107240 4th-Generation Coiled-Tubing Manufacturing TechnologyDocument3 pagesSPE 107240 4th-Generation Coiled-Tubing Manufacturing Technologymsmsoft90No ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- DIN-2353 Metrics - Hose and Fittings SourceDocument18 pagesDIN-2353 Metrics - Hose and Fittings SourceEr.Amritpal SinghNo ratings yet

- Fluid Power Fluid Power Equipment Tutorial - Pipe Work: Outcome 2Document12 pagesFluid Power Fluid Power Equipment Tutorial - Pipe Work: Outcome 2cataiceNo ratings yet

- Tube Expander Process Manual - CompressedDocument419 pagesTube Expander Process Manual - CompressedAgni DuttaNo ratings yet

- Module 4 Lecture 8 FinalDocument17 pagesModule 4 Lecture 8 Finaltejap314No ratings yet

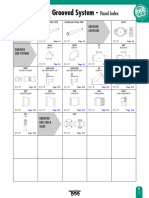

- Grooved Piping System: Product DescriptionDocument4 pagesGrooved Piping System: Product DescriptionDGWNo ratings yet

- Introduction To Flanges, Pipe & FittingDocument41 pagesIntroduction To Flanges, Pipe & FittingguravdrNo ratings yet

- Piping Design Enginerring & Construction: Atul PatelDocument19 pagesPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलNo ratings yet

- Piping Components EbookDocument45 pagesPiping Components Ebooksrinivasanssc100% (2)

- Chapter 6 - NotesDocument7 pagesChapter 6 - NotesPraneethNo ratings yet

- CorrView Piping Technical Bulletin P-01Document14 pagesCorrView Piping Technical Bulletin P-01jjgonzalezquinaNo ratings yet

- Welding of Field Joints For Pipelines Internally Lined With Thin-Film Heat Sensitive MaterialsDocument10 pagesWelding of Field Joints For Pipelines Internally Lined With Thin-Film Heat Sensitive MaterialsJose Anisio de Oliveira e SilvaNo ratings yet

- Study of Carbon Steel Pipes 2013Document26 pagesStudy of Carbon Steel Pipes 2013Deepak Ramchandani100% (1)

- Root Gap and Root Face For Diff Wall ThicknessDocument18 pagesRoot Gap and Root Face For Diff Wall ThicknesspipinguserNo ratings yet

- TUBE To HEADER JOINTS PDFDocument4 pagesTUBE To HEADER JOINTS PDFRiza KhanNo ratings yet

- Solidworks PipingDocument1 pageSolidworks Pipingabhi_mohit2005No ratings yet

- Piping StandardsDocument57 pagesPiping Standardsdsnm777100% (1)

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongNo ratings yet

- Bonney Forge Branch ConnectionsDocument45 pagesBonney Forge Branch ConnectionsperoooNo ratings yet

- Hydraulic Fittings and FlangesDocument11 pagesHydraulic Fittings and FlangesJosh WhiteNo ratings yet

- Fabrication of Steel PipeworkDocument10 pagesFabrication of Steel PipeworkjoseritoNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- MPSA-SOP - 07 Cranes and Lifting EquipmentDocument14 pagesMPSA-SOP - 07 Cranes and Lifting EquipmentLim PaNo ratings yet

- Tubemac Section e PDFDocument16 pagesTubemac Section e PDFLim PaNo ratings yet

- Malleable Iron Threaded FittingsDocument16 pagesMalleable Iron Threaded Fittingsenvitech72No ratings yet

- Victaulic PDFDocument10 pagesVictaulic PDFLim PaNo ratings yet

- Saes H 200Document9 pagesSaes H 200راجہ شہزاد انورNo ratings yet

- Installation Manual: Split System Air ConditionersDocument20 pagesInstallation Manual: Split System Air ConditionersbenNo ratings yet

- Performance Analysis of Shell and Tube As Preheater Fuel For BiodieselDocument6 pagesPerformance Analysis of Shell and Tube As Preheater Fuel For BiodieselAchmad WijayaNo ratings yet

- Parul University: Faculty of Engineering & Technology Mechanical Engineering (MCQ)Document2 pagesParul University: Faculty of Engineering & Technology Mechanical Engineering (MCQ)JayNo ratings yet

- Mil DTL 7601Document12 pagesMil DTL 7601Michaël REYNAULTNo ratings yet

- Steel Tubes HhhhhhhhhhkutreDocument2 pagesSteel Tubes HhhhhhhhhhkutreKarthikeyan PanchatcharamNo ratings yet

- CN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsDocument128 pagesCN Aquatherm, The One Stop Supplier For Aqua-Therm Products & Building MaterialsYang XianjieNo ratings yet

- Sct1375 Technical SpecDocument315 pagesSct1375 Technical SpecMUTHUKKUMARAMNo ratings yet

- Din 2394-1Document5 pagesDin 2394-1sharrrstar826No ratings yet

- NS1 Work Plan Procedure For CW Piping Installation Rev.4Document47 pagesNS1 Work Plan Procedure For CW Piping Installation Rev.4namdq-1No ratings yet

- DETROIT SERIE 60 - Series 60 Delta Pressure Sensor Removal KitsDocument7 pagesDETROIT SERIE 60 - Series 60 Delta Pressure Sensor Removal KitsJuan Felipe Garza GNo ratings yet

- SplitSleeve Install PDFDocument44 pagesSplitSleeve Install PDFgeorgeNo ratings yet

- 2015 CatalogueDocument48 pages2015 CatalogueSouhardh K SNo ratings yet

- DI Pipe Installation GuideDocument108 pagesDI Pipe Installation Guideblackk7No ratings yet

- 1 DwgindxnDocument25 pages1 Dwgindxnrahman21420No ratings yet

- Pipe Stress Analysis - 5Document24 pagesPipe Stress Analysis - 5Ismail Magdy Ismail100% (1)

- DZR Fixed Orifice Commissioning Valve (FODRV) - ISO 228 Parallel Thread, With Regulation, Isolation and Flow Measurement FunctionsDocument7 pagesDZR Fixed Orifice Commissioning Valve (FODRV) - ISO 228 Parallel Thread, With Regulation, Isolation and Flow Measurement FunctionsMd EtNo ratings yet

- Duplex Material PDFDocument4 pagesDuplex Material PDFmengelito almonteNo ratings yet

- Cida Bullein of Construction Statistics October 2020Document28 pagesCida Bullein of Construction Statistics October 2020Niruban ThaventhiranNo ratings yet

- Listado de ActualizacionDocument5 pagesListado de ActualizacionromancusNo ratings yet

- Инструкция Сервисная HAIER AB (092-182), AC (142-148), AD (092-148), AF (092-122), AS (072-222) PDFDocument174 pagesИнструкция Сервисная HAIER AB (092-182), AC (142-148), AD (092-148), AF (092-122), AS (072-222) PDFmikeNo ratings yet

- Is 1916 1989 PDFDocument12 pagesIs 1916 1989 PDFdheerajdorlikarNo ratings yet

- ImmersionDocument164 pagesImmersionsvpd2006No ratings yet

- PLK-G2516 Instruction ManualDocument43 pagesPLK-G2516 Instruction ManualYeni WulandariNo ratings yet

- WPS - 003 BDocument7 pagesWPS - 003 BMAT-LIONNo ratings yet

- Corrosion Ring CalculationDocument6 pagesCorrosion Ring CalculationEko Januarto0% (1)

- Check List For Piping Material Take-Off (MTO)Document7 pagesCheck List For Piping Material Take-Off (MTO)MohamedNo ratings yet

- Brazing Road SP PDFDocument32 pagesBrazing Road SP PDFFAYAZNo ratings yet

- Consolidated Piping Boq For Grade-Cs-Rev-01 PDFDocument4 pagesConsolidated Piping Boq For Grade-Cs-Rev-01 PDFSalz EngineeringNo ratings yet

- Klinger KGS/VD: The First Infinitely Adjustable GasketDocument4 pagesKlinger KGS/VD: The First Infinitely Adjustable Gasketperdhana2000No ratings yet