Professional Documents

Culture Documents

Dupont

Uploaded by

Sai VasudevanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dupont

Uploaded by

Sai VasudevanCopyright:

Available Formats

REPORT ON THE SUPPLY CHAIN MANAGEMENT OF THE COMPANY DUPONT

Company Profile

DuPont has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by collaborating with customers, governments, non-governmental organizations (NGOs), and thought leaders, they can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment. Founded in 1802 in Wilmington, Delaware, DuPont first produced high-grade black powder for explosives. By the early 1900s, the companys focus shifted to chemicals, materials and energy to meet the changing needs of consumers and businesses. Today, DuPont delivers science-powered innovations that make real differences in peoples lives around the world. In fact, most homes and workplaces around the world include dozens of innovations made with DuPont materials. DuPonts ability to adapt to the evolving needs of customers and its foundation of unending scientific inquiry have enabled it to become one of the worlds most innovative and successful companies. DuPont has more than 8,500 scientists and engineers working across more than 75 research and development centres globally. In addition, DuPont continues to closely collaborate with our customers and key partners to meet market needs. To date, DuPont has been awarded patents for more than 35,000 inventionsa new invention every other day for 208 years.

Supply Chain Management

Responding to these growing pains, in May 2000 DuPont turned to G-Log, a global logistics and transportation software provider based in Shelton, Conn. DuPont selected G-Log's Global Command and Control Centre (GC3) software as the foundation for its centralized, web-based transportation and logistics management system called TransOval. When fully integrated, TransOval will be an umbrella, a one-stop shop for all our logistics, information, and services. The G-Log engine will drive about 65 percent of that. According to Derek Gittoes, vice president of product solutions, G-Log, GC3 software has enabled DuPont to adapt its IT infrastructure in three ways:

1. Create unity. One important component of the GC3 system is its ability to unify disparate processes and functions. For DuPont this means that it has one system with one view of all of its logistics-related activitiesregardless of business unit it is in, geography it is shipping to or from, mode it is moving on, or service provider that is involved in the activity. Using TransOval, anyone within DuPont's supply chain can log into the portal and manage logistics activities at any point in the order management cycle. 2. Gain control. The GC3 software similarly provides DuPont with greater cost and inventory control. In terms of cost, having visibility into the entire supply chain helps users identify shipment optimization opportunities. Accordingly, this information enables DuPont to manage and leverage its inventory to more efficiently and cost-effectively match supply to demand.GC3 helps centralize information on the TransOval portal, but also allows DuPont and its partners and customers to manage that information regionally. This dichotomy opens the door for DuPont to quickly react to changes in the supply chain, as well as tack on additional functionalities when necessary. Also, because much of DuPont's logistics activities are outsourced to third-party providers, having a centralized portal that they can plug into is essential in preserving seamless communication within the supply chain. 3. Increase flexibility. The determination when we embarked on the TransOval project was that we wanted to create more independence for the company. This way they will have more flexibility to unplug or plug with various providers based on the services they needed and the quality of services thry were getting. The ability to respond to supply chain initiatives and concernsnew customs requirements for exampleis much easier when information exists in one system rather than disparate business units. To that end, this flexibility allows companies to add on new businesses and partners as they move forward. It similarly gives them greater leverage to be more selective as to what service providers they do business with.

When fully implemented, TransOval will fulfill "four buckets of functionality within the order shipment lifecycle. These functionalities include: 1. Logistics order management integration of order management systems that exist among DuPont's global businesses. 2. Shipment planning and optimization including routing and carrier usage. 3. Execution two-way communication between TransOval and DuPont's business partners. 4. Financial settlement freight payment and cost allocation.

DuPont initially identified strategic elements that would be targeted for improvement to reach the corporate goals. To reflect this significant change, DuPont called the initiative the DuPont Supply Chain Transformation.

They identified supply chain development and interaction for Customer and markets Metrics and measurement capability Supply chain and enterprise systems Processes and process capability People development and competency. DuPont has adopted SCOR model for supply chain management. The Supply Chain Operations Reference (SCOR) model provides a unique framework that links performance metrics, processes, best practices, and people into a unified structure. The framework supports communication between supply chain partners and enhances the effectiveness of supply chain management, technology, and related supply chain improvement activities. SCOR is a consensus model. It was developed and continues to evolve with the direct input

of industry leaders who manage global supply chains and use it daily to analyze and improve the performance of their organizations. It features an intentionally broad scope and definitions that can be adapted to the specific supply chain requirements of any industry or application. SCOR model include: Rapid assessment of supply chain performance Clear identification of performance gaps Efficient supply chain network redesign and optimization Enhanced operational control from standard core processes Streamlined management reporting and organizational structure Alignment of supply chain team skills with strategic objectives A detailed game plan for launching new businesses and products Systematic supply chain mergers that capture projected saving

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Business and Operations of Li & FungDocument4 pagesBusiness and Operations of Li & FungSai Vasudevan0% (1)

- Li and FungDocument3 pagesLi and FungSai VasudevanNo ratings yet

- Geographic Segmentation - Demographic Segmentation - Psychographic SegmentationDocument6 pagesGeographic Segmentation - Demographic Segmentation - Psychographic SegmentationSai VasudevanNo ratings yet

- Insurance Regulatory and Development ActDocument13 pagesInsurance Regulatory and Development ActSai VasudevanNo ratings yet

- PEST ANALYSIS OF KENYA'S POLITICAL, ECONOMIC, SOCIAL AND TECHNOLOGICAL ENVIRONMENTDocument6 pagesPEST ANALYSIS OF KENYA'S POLITICAL, ECONOMIC, SOCIAL AND TECHNOLOGICAL ENVIRONMENTSai VasudevanNo ratings yet

- GermanyDocument9 pagesGermanySai VasudevanNo ratings yet

- Pest Analysis Sri LankaDocument8 pagesPest Analysis Sri LankaSai VasudevanNo ratings yet

- Orchid Hotel Mumbai IntroductionDocument1 pageOrchid Hotel Mumbai IntroductionSai VasudevanNo ratings yet

- Pest Analysis Sri LankaDocument8 pagesPest Analysis Sri LankaSai VasudevanNo ratings yet

- Pest Analysis of MalaysiaDocument8 pagesPest Analysis of MalaysiaSai VasudevanNo ratings yet

- AUSTRALIA - Porters 5 ForcesDocument14 pagesAUSTRALIA - Porters 5 ForcesSai Vasudevan100% (1)

- Siemens LimitedDocument12 pagesSiemens LimitedSai VasudevanNo ratings yet

- Corporate Governance in TATA MotorsDocument9 pagesCorporate Governance in TATA MotorsSai VasudevanNo ratings yet

- IndiaDocument6 pagesIndiaSai VasudevanNo ratings yet

- IRDADocument3 pagesIRDASai VasudevanNo ratings yet

- Import and Export Policy 2009-2014Document14 pagesImport and Export Policy 2009-2014Sai VasudevanNo ratings yet

- Porters Five Force On U.A.EDocument15 pagesPorters Five Force On U.A.ESai Vasudevan50% (2)

- Import and Export Policy 2009-2014Document14 pagesImport and Export Policy 2009-2014Sai VasudevanNo ratings yet

- Collective BargainingDocument7 pagesCollective BargainingSai VasudevanNo ratings yet

- Infosys Corporate Governance Impact PerformanceDocument9 pagesInfosys Corporate Governance Impact PerformanceSai VasudevanNo ratings yet

- NTPC (CSR, MGT, Financil RPT)Document15 pagesNTPC (CSR, MGT, Financil RPT)ashish_5112No ratings yet

- Kotak Mahindra BankDocument23 pagesKotak Mahindra BankSai VasudevanNo ratings yet

- BRICDocument8 pagesBRICSai VasudevanNo ratings yet

- HCL TechnologiesDocument8 pagesHCL TechnologiesSai VasudevanNo ratings yet

- How MNCs Can Win in IndiaDocument17 pagesHow MNCs Can Win in IndiaSai VasudevanNo ratings yet

- Nternational Companies of ArgentinaDocument16 pagesNternational Companies of ArgentinaSai VasudevanNo ratings yet

- Tata Motors LimitedDocument10 pagesTata Motors LimitedSai VasudevanNo ratings yet

- Globalization and Indian EconomyDocument12 pagesGlobalization and Indian EconomySai VasudevanNo ratings yet

- Strategic Management-I: Presentation On Hero MotocorpDocument5 pagesStrategic Management-I: Presentation On Hero MotocorpSai VasudevanNo ratings yet

- Vishal Mega MartDocument22 pagesVishal Mega MartSai Vasudevan100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SACO SHIPPING LINE BILL OF LADING FOR DIESEL ENGINE PARTSDocument1 pageSACO SHIPPING LINE BILL OF LADING FOR DIESEL ENGINE PARTStaaj77No ratings yet

- BAHARUDocument20 pagesBAHARUcrysNo ratings yet

- Visahal Mega Mart Promotion StrategiesDocument39 pagesVisahal Mega Mart Promotion StrategiessuryakantshrotriyaNo ratings yet

- SAP Overview QMDocument50 pagesSAP Overview QMAdityaPandeyNo ratings yet

- Chap 004Document15 pagesChap 004Ahmad Restu FauziNo ratings yet

- Inventory Control SystemDocument49 pagesInventory Control SystemDorin BaranetchiNo ratings yet

- Blowout Technical RefrenceDocument89 pagesBlowout Technical Refrenceparsa2400No ratings yet

- PortDocument13 pagesPortlulu luvelyNo ratings yet

- 220kv Twin Moose Z-3 Master Bom AdDocument22 pages220kv Twin Moose Z-3 Master Bom Adnissar AhamedNo ratings yet

- Scmpe Compiler 4.0 - Ca Final - by Ca Ravi AgarwalDocument824 pagesScmpe Compiler 4.0 - Ca Final - by Ca Ravi Agarwalaella shivaniNo ratings yet

- Fashion - H&M Case European CommunityDocument8 pagesFashion - H&M Case European CommunityAmnon ArmoniNo ratings yet

- A Comprehensive Study on Amul's Logistics and Supply Chain Management and its Effect on CSRDocument9 pagesA Comprehensive Study on Amul's Logistics and Supply Chain Management and its Effect on CSRRonisha ShresthaNo ratings yet

- Demand Driven Supply ChainsDocument15 pagesDemand Driven Supply Chainskat_bg100% (1)

- Big Bazaar Is An Indian Retail Chain of HypermarketsDocument8 pagesBig Bazaar Is An Indian Retail Chain of HypermarketsSatya vratNo ratings yet

- Mirakle Courier CompanyDocument51 pagesMirakle Courier Companyalinanoble0% (1)

- Logistics, Site Automation, and Robotics - Automated and Robotic On-Site Factories (PDFDrive)Document342 pagesLogistics, Site Automation, and Robotics - Automated and Robotic On-Site Factories (PDFDrive)muhammed saheerNo ratings yet

- Network Design Decisions in Supply Chain ManagementDocument41 pagesNetwork Design Decisions in Supply Chain ManagementJanmejai BhargavaNo ratings yet

- 04 64Document53 pages04 64Pumate ChangwardworrachodNo ratings yet

- Logistics StartupsDocument16 pagesLogistics Startupsanuj rakhejaNo ratings yet

- Sap - MDG - Governanca - InglesDocument242 pagesSap - MDG - Governanca - InglesTchordach2020No ratings yet

- Maritime English Documents GuideDocument37 pagesMaritime English Documents GuideZamolxes100% (2)

- CIPS L2M5 exam questions on inventory, logistics and expeditingDocument5 pagesCIPS L2M5 exam questions on inventory, logistics and expeditingEng. Abdulaziz A. Al-Massabi100% (1)

- Performance AppraisalDocument88 pagesPerformance AppraisalKishore NNo ratings yet

- GoWines Single-Serve Eco PackagingDocument93 pagesGoWines Single-Serve Eco PackagingMC Ivana PerezNo ratings yet

- AT GLOBAL RISK MANAGEMENTDocument7 pagesAT GLOBAL RISK MANAGEMENTJie ChiNo ratings yet

- Hyster-Yale Cross OverDocument5 pagesHyster-Yale Cross OverEriflona80% (5)

- Import-Export Procedures at CFSDocument19 pagesImport-Export Procedures at CFSShubham GhandadeNo ratings yet

- Commercial Invoice: Cohaco Merchandising and Development Corporation Invoice No: I-16/04/0065R Invoice Date: 08/04/2016Document1 pageCommercial Invoice: Cohaco Merchandising and Development Corporation Invoice No: I-16/04/0065R Invoice Date: 08/04/2016Sarah EvaristoNo ratings yet

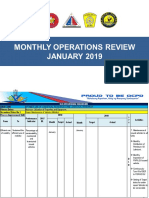

- Efficient Utilization of Logistical Resources and Equipment DashboardDocument20 pagesEfficient Utilization of Logistical Resources and Equipment DashboardEmmanuel BatinganNo ratings yet

- Obl Melo Rainer PDFDocument1 pageObl Melo Rainer PDFeka pasificharvestNo ratings yet