Professional Documents

Culture Documents

Non-HEU Production Technologies For Molybdenum-99 and Technetium-99m.

Uploaded by

Muttaqin Margo NirwonoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Non-HEU Production Technologies For Molybdenum-99 and Technetium-99m.

Uploaded by

Muttaqin Margo NirwonoCopyright:

Available Formats

IAEA Nuclear Energy Series

Technical

Reports

Non-HEU Production

Technologies for

Molybdenum-99 and

Technetium-99m

No. NF-T-5.4

I

A

E

A

N

u

c

l

e

a

r

E

n

e

r

g

y

S

e

r

i

e

s

N

o

.

N

F

-

T

-

5

.

4

N

o

n

-

H

E

U

P

r

o

d

u

c

t

i

o

n

T

e

c

h

n

o

l

o

g

i

e

s

f

o

r

M

o

l

y

b

d

e

n

u

m

-

9

9

a

n

d

T

e

c

h

n

e

t

i

u

m

-

9

9

m

INTERNATIONAL ATOMIC ENERGY AGENCY

VIENNA

ISBN 9789201377104

ISSN 19957807

IAEA NUCLEAR ENERGY SERIES PUBLICATIONS

STRUCTURE OF THE IAEA NUCLEAR ENERGY SERIES

Under the terms of Articles III.A and VIII.C of its Statute, the IAEA is

authorized to foster the exchange of scientific and technical information on the

peaceful uses of atomic energy. The publications in the IAEA Nuclear Energy

Series provide information in the areas of nuclear power, nuclear fuel cycle,

radioactive waste management and decommissioning, and on general issues

that are relevant to all of the above mentioned areas. The structure of the

IAEA Nuclear Energy Series comprises three levels: 1 Basic Principles and

Objectives; 2 Guides; and 3 Technical Reports.

The Nuclear Energy Basic Principles publication describes the rationale

and vision for the peaceful uses of nuclear energy.

Nuclear Energy Series Objectives publications explain the expectations

to be met in various areas at different stages of implementation.

Nuclear Energy Series Guides provide high level guidance on how to

achieve the objectives related to the various topics and areas involving the

peaceful uses of nuclear energy.

Nuclear Energy Series Technical Reports provide additional, more

detailed, information on activities related to the various areas dealt with in the

IAEA Nuclear Energy Series.

The IAEA Nuclear Energy Series publications are coded as follows:

NG general; NP nuclear power; NF nuclear fuel; NW radioactive

waste management and decommissioning. In addition, the publications are

available in English on the IAEAs Internet site:

http://www.iaea.org/Publications/index.html

For further information, please contact the IAEA at PO Box 100, Vienna

International Centre, 1400 Vienna, Austria.

All users of the IAEA Nuclear Energy Series publications are invited to

inform the IAEA of experience in their use for the purpose of ensuring that

they continue to meet user needs. Information may be provided via the IAEA

Internet site, by post, at the address given above, or by email to

Official.Mail@iaea.org.

NON-HEU PRODUCTION TECHNOLOGIES

FOR MOLYBDENUM-99 AND

TECHNETIUM-99m

AFGHANISTAN

ALBANIA

ALGERIA

ANGOLA

ARGENTINA

ARMENIA

AUSTRALIA

AUSTRIA

AZERBAIJAN

BAHRAIN

BANGLADESH

BELARUS

BELGIUM

BELIZE

BENIN

BOLIVIA

BOSNIA AND HERZEGOVINA

BOTSWANA

BRAZIL

BULGARIA

BURKINA FASO

BURUNDI

CAMBODIA

CAMEROON

CANADA

CENTRAL AFRICAN

REPUBLIC

CHAD

CHILE

CHINA

COLOMBIA

CONGO

COSTA RICA

CTE DIVOIRE

CROATIA

CUBA

CYPRUS

CZECH REPUBLIC

DEMOCRATIC REPUBLIC

OF THE CONGO

DENMARK

DOMINICA

DOMINICAN REPUBLIC

ECUADOR

EGYPT

EL SALVADOR

ERITREA

ESTONIA

ETHIOPIA

FIJI

FINLAND

FRANCE

GABON

GEORGIA

GERMANY

GHANA

GREECE

GUATEMALA

HAITI

HOLY SEE

HONDURAS

HUNGARY

ICELAND

INDIA

INDONESIA

IRAN, ISLAMIC REPUBLIC OF

IRAQ

IRELAND

ISRAEL

ITALY

JAMAICA

JAPAN

JORDAN

KAZAKHSTAN

KENYA

KOREA, REPUBLIC OF

KUWAIT

KYRGYZSTAN

LAO PEOPLES DEMOCRATIC

REPUBLIC

LATVIA

LEBANON

LESOTHO

LIBERIA

LIBYA

LIECHTENSTEIN

LITHUANIA

LUXEMBOURG

MADAGASCAR

MALAWI

MALAYSIA

MALI

MALTA

MARSHALL ISLANDS

MAURITANIA

MAURITIUS

MEXICO

MONACO

MONGOLIA

MONTENEGRO

MOROCCO

MOZAMBIQUE

MYANMAR

NAMIBIA

NEPAL

NETHERLANDS

NEW ZEALAND

NICARAGUA

NIGER

NIGERIA

NORWAY

OMAN

PAKISTAN

PALAU

PANAMA

PAPUA NEW GUINEA

PARAGUAY

PERU

PHILIPPINES

POLAND

PORTUGAL

QATAR

REPUBLIC OF MOLDOVA

ROMANIA

RUSSIAN FEDERATION

RWANDA

SAUDI ARABIA

SENEGAL

SERBIA

SEYCHELLES

SIERRA LEONE

SINGAPORE

SLOVAKIA

SLOVENIA

SOUTH AFRICA

SPAIN

SRI LANKA

SUDAN

SWEDEN

SWITZERLAND

SYRIAN ARAB REPUBLIC

TAJIKISTAN

THAILAND

THE FORMER YUGOSLAV

REPUBLIC OF MACEDONIA

TOGO

TRINIDAD AND TOBAGO

TUNISIA

TURKEY

UGANDA

UKRAINE

UNITED ARAB EMIRATES

UNITED KINGDOM OF

GREAT BRITAIN AND

NORTHERN IRELAND

UNITED REPUBLIC

OF TANZANIA

UNITED STATES OF AMERICA

URUGUAY

UZBEKISTAN

VENEZUELA

VIETNAM

YEMEN

ZAMBIA

ZIMBABWE

The Agencys Statute was approved on 23 October 1956 by the Conference on the Statute of the IAEA held at

United Nations Headquarters, New York; it entered into force on 29 July 1957. The Headquarters of the Agency are

situated in Vienna. Its principal objective is to accelerate and enlarge the contribution of atomic energy to peace,

health and prosperity throughout the world.

The following States are Members of the International Atomic Energy Agency:

NON-HEU PRODUCTION TECHNOLOGIES

FOR MOLYBDENUM-99 AND

TECHNETIUM-99m

IAEA NUCLEAR ENERGY SERIES No. NF-T-5.4

INTERNATIONAL ATOMIC ENERGY AGENCY

VIENNA, 2013

IAEA Library Cataloguing in Publication Data

Non-HEU production technologies for molybdenum-99 and technetium-99m.

Vienna : International Atomic Energy Agency, 2013.

p. ; 29 cm. (IAEA nuclear energy series, ISSN 19957807 ;

no. NF-T-5.4)

STI/PUB/1589

ISBN 9789201377104

Includes bibliographical references.

1. Molybdenum Isotopes. 2. Technetium Isotopes. 3. Radionuclide

generators. I. International Atomic Energy Agency. II. Series.

IAEAL 1300786

COPYRIGHT NOTICE

All IAEA scientific and technical publications are protected by the terms of

the Universal Copyright Convention as adopted in 1952 (Berne) and as revised in

1972 (Paris). The copyright has since been extended by the World Intellectual

Property Organization (Geneva) to include electronic and virtual intellectual

property. Permission to use whole or parts of texts contained in IAEA

publications in printed or electronic form must be obtained and is usually subject

to royalty agreements. Proposals for non-commercial reproductions and

translations are welcomed and considered on a case-by-case basis. Enquiries

should be addressed to the IAEA Publishing Section at:

Marketing and Sales Unit, Publishing Section

International Atomic Energy Agency

Vienna International Centre

PO Box 100

1400 Vienna, Austria

fax: +43 1 2600 29302

tel.: +43 1 2600 22417

email: sales.publications@iaea.org

http://www.iaea.org/books

IAEA, 2013

Printed by the IAEA in Austria

February 2013

STI/PUB/1589

FOREWORD

One of the IAEAs statutory objectives is to seek to accelerate and enlarge the contribution of atomic energy

to peace, health and prosperity throughout the world. One way this objective is achieved is through the publication

of a range of technical series. Two of these are the IAEA Nuclear Energy Series and the IAEA Safety Standards

Series.

According to Article III.A.6 of the IAEA Statute, the safety standards establish standards of safety for

protection of health and minimization of danger to life and property. The safety standards include the Safety

Fundamentals, Safety Requirements and Safety Guides. These standards are written primarily in a regulatory style,

and are binding on the IAEA for its own programmes. The principal users are the regulatory bodies in Member

States and other national authorities.

The IAEA Nuclear Energy Series comprises reports designed to encourage and assist R&D on, and

application of, nuclear energy for peaceful uses. This includes practical examples to be used by owners and

operators of utilities in Member States, implementing organizations, academia, and government officials, among

others. This information is presented in guides, reports on technology status and advances, and best practices for

peaceful uses of nuclear energy based on inputs from international experts. The IAEA Nuclear Energy Series

complements the IAEA Safety Standards Series.

The report was compiled in two consultancy meetings held in March 2010 and February 2011. The IAEA

wishes to thank K. Crowley (USA), T.J. Ruth (Canada), C.W. Allen (USA) and G. Vandegrift (USA) for their

contributions to this report. This work was made possible by financial and technical support provided by the Global

Threat Reduction Initiative, managed by the United States Department of Energy, National Nuclear Security

Administration. The IAEA officer responsible for this publication was E. Bradley of the Division of Nuclear Fuel

Cycle and Waste Technology.

EDITORIAL NOTE

This report has been edited by the editorial staff of the IAEA to the extent considered necessary for the readers assistance. It

does not address questions of responsibility, legal or otherwise, for acts or omissions on the part of any person.

Although great care has been taken to maintain the accuracy of information contained in this publication, neither the IAEA nor

its Member States assume any responsibility for consequences which may arise from its use.

The use of particular designations of countries or territories does not imply any judgement by the publisher, the IAEA, as to the

legal status of such countries or territories, of their authorities and institutions or of the delimitation of their boundaries.

The mention of names of specific companies or products (whether or not indicated as registered) does not imply any intention to

infringe proprietary rights, nor should it be construed as an endorsement or recommendation on the part of the IAEA.

CONTENTS

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1. Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2. Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3. Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4. Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5. Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. PRODUCTION OF

99

Mo/

99m

Tc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. ORGANIZATION OF PRODUCTION TECHNOLOGIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. REACTOR BASED PRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1. Fission based (n, f) production in heterogeneous reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1.1. Targets and processing methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1.2. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.3. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2. Fission based (n, f) production in homogeneous reactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.1. Fuel/target solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.2. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.3. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3. Neutron activation production (n, ) in heterogeneous reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.1. Targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.2. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.3. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5. ACCELERATOR BASED PRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1. Fission based (n, f) production using accelerators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.1. Proton accelerator production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2. Deuteron accelerators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.3. Subcritical liquid LEU target for accelerator driven production of fission

99

Mo. . . . . . . . . 16

5.2. Photon based (, n) production using electron accelerators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.1. Target materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2. Recycling of target materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.3. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.4. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3. Neutron induced process

100

Mo(n,2n)

99

Mo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1. Target materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.2. Recycling of target materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.3. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.4. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4. Direct production of

99m

Tc using proton accelerators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4.1. Target materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.2.

99m

Tc pertechnetate yields and purity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.3. Waste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.4. Regulatory issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.

99

Mo/

99m

Tc GENERATOR SYSTEMS AND CHEMISTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1. High specific activity (fission product) generators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.1. Principles of generator operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.2. Chemistry of alumina column based generator and technetium cows . . . . . . . . . . . . . . . . . 25

6.2. Low specific activity

99

Mo/

99m

Tc recovery methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.1. Chemistry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.2. Liquidliquid generator concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.3. Low cost/high efficiency wet extraction using an automated unit . . . . . . . . . . . . . . . . . . . . 27

6.2.4. Post-production isotopic separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.5. Solvent extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.6. Sublimation extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2.7. Post-elution concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3. Low specific activity generator types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.1. Technetium selective separation system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.2. Jumbo alumina column generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.3. Gel moly generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.4. High adsorption capacity column generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3.5. Technetium radiolabelling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7. TECHNOLOGY READINESS TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1. Reactor based technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2. Accelerator based technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8. CONCLUSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

APPENDIX A: TECHNOLOGY READINESS LEVELS (TRLs) AND THEIR DEFINITIONS. . . . . . . . . . 43

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

CONTRIBUTORS TO DRAFTING AND REVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1

1. INTRODUCTION

1.1. BACKGROUND

Technetium-99m (

99m

Tc) is used in approximately 85% of nuclear medicine diagnostic imaging procedures

worldwide. Almost all the

99m

Tc used for this purpose is obtained from the radioactive decay of molybdenum-99

(

99

Mo), which is produced by processing irradiated uranium targets in Belgium (IRE), Canada (AECL/Nordion),

the Netherlands (Covidien) and South Africa (NTP). After irradiation, the uranium targets are processed to extract

99

Mo, which in turn is purified for use in

99

Mo/

99m

Tc generators that are shipped to radiopharmacies, hospitals and

clinics. Demographic and medical trends suggest that, at least in the near future, global demand for

99m

Tc will grow

at an average annual rate of 38% as these diagnostic imaging procedures expand to new markets, such as those in

Asia [1].

The research reactors used to irradiate targets that produce most of the worlds supply of

99

Mo are over

40 years old. Planned and unplanned shutdowns of some of these reactors have resulted in several recent

99

Mo/

99m

Tc supply interruptions. These interruptions prompted international organizations and several government

agencies to step up efforts to find both short and long term solutions to supply shortages. In response to a Canadian

government initiative, the OECD/NEA established the High Level Group on the Security of Supply of Medical

Radioisotopes (HLG-MR) with participation by the IAEA as an observer. Several Member States of the IAEA

expressed concern about supply shortages during the 2009, 2010 and 2011 Board of Governors Meetings and IAEA

General Conferences (GC). The 2009 Conference, in Resolution GC(53)/RES13, urged the Secretariat to work

cooperatively with other international initiatives ... to implement activities that will contribute to enhancing the

molybdenum-99 production capacity, including in developing countries, in an effort to ensure the security of

supplies of

molybdenum-99 to users worldwide. These calls for action continued throughout 2012 in the work of

the OECD and IAEA. In support of these efforts, the OECD published economic and technology studies on the

99

Mo supply chain [2, 3].

The IAEA convened a group of experts to initiate a new activity specifically aimed at supporting global

efforts to improve

99

Mo/

99m

Tc supply reliability and promoting the conversion of

99

Mo

production from highly

enriched uranium (HEU) to low enriched uranium (LEU). Three of the four facilities used to produce most of the

worlds supply of

99

Mo use HEU targets with

235

U enrichments of up to 93%. The remaining producer, NTP in

South Africa, produces

99

Mo using 19.75% LEU and 45% HEU. Plans for converting South African production to

LEU reached a major milestone in 2010 when LEU based

99

Mo

was imported into the United States of America for

use in patients. The Australian Nuclear Science and Technology Organization is routinely producing

99

Mo

from

LEU targets irradiated in the OPAL reactor. Efforts continue to ramp up production there.

The IAEAs focus on the conversion of

99

Mo production from HEU to LEU is part of a long standing effort to

eliminate HEU use in civilian applications. This effort received a boost in 2009 when the US National Academy of

Sciences concluded that the elimination of HEU in medical isotope production is technically and economically

feasible [4]. The scope of all IAEA activities related to improving

99

Mo/

99m

Tc supplies, including this publication,

supports global efforts to eliminate the civilian use of HEU.

The reliability of

99

Mo/

99m

Tc supply can be improved by increasing diversity and redundancy in all aspects of

the supply chain. Smaller scale production (for domestic and regional use) and well distributed production facilities

are important supplements for increasing supply reliability. Several alternative/supplementary technologies for

producing

99

Mo/

99m

Tc have been proposed. Some of them are not yet commercially proven and some are still in the

early stages of development. International exchanges of information can hasten the development of technically and

economically viable technologies and prepare them for deployment.

1.2. OBJECTIVES

The objectives of this report are to document current and novel

99

Mo/

99m

Tc production technologies that do

not involve the use of HEU and thereby facilitate international cooperation on

99

Mo

supply and technology

2

development. These technologies were compiled from information provided by consultants and participating

Member States.

This report complements other related IAEA and international activities. They include the IAEA coordinated

research project (CRP) on Small Scale Indigenous

99

Mo

Production (2005 to 2011), a CRP on Accelerator Based

Alternatives to Non-HEU Production of

99

Mo/

99m

Tc, the Peaceful Uses Initiative (PUI) and technical cooperation

projects on small scale

99

Mo production technology deployment, as well as robust studies, conducted, for example,

in Canada, Europe, the USA and by the OECD/NEA [2, 3].

1.3. SCOPE

This report considers current and novel non-HEU

99

Mo/

99m

Tc production technologies at all stages of the

production process and on all scales (local to global) of supply. It considers improvements to existing technologies

for producing

99

Mo

involving fission and neutron activation, novel technologies for producing

99

Mo such as

photofission and transmutation as well as technologies for the direct production of

99m

Tc. This report considers

technologies at all stages of development. This approach ensured the most comprehensive review of existing and

novel

99

Mo/

99m

Tc technologies.

The focus of this report is on the technical readiness of

99

Mo/

99m

Tc production technologies. Efforts to

compile the report did not consider non-technical or business related issues such as manufacturing readiness, cost,

supply demand or supply security. Although all of the production technologies considered in this report produce

waste by-products, such production is a result of the application of a technology and not an attribute of technology

development. The report does not consider specific waste management technologies. However, the expected waste

and regulatory requirements associated with the different technologies are discussed.

1.4. INTENDED AUDIENCE

The IAEA cooperated with other international organizations including the HLG-MR of the OECD/NEA

and with Member States throughout the supply crises and the project to produce this report. Specifically, the

IAEA encouraged partnerships, cooperation and complementary implementation of

99

Mo/

99m

Tc production and

supply technologies among interested governmental, scientific and technical organizations. To achieve this end, this

report has been developed for policy and decision makers within these governmental, scientific and technical

organizations.

1.5. STRUCTURE

This report is broken into eight major sections and includes one appendix. The first three sections introduce

the subject, provide background information on

99

Mo production and lay out the technical breakdown of the

remaining discussion.

Section 4 discusses reactor based

99

Mo production. In general, this includes fission of heterogeneous uranium

targets, fission of homogeneous uranium solution and activation of natural and enriched

98

Mo targets. The section

also describes technologies to address low specific activity

99

Mo, a challenge specific to

98

Mo activation based

production.

Section 5 considers accelerator based

99

Mo/

99m

Tc production. Both fission and non-fission production

technologies are described, as are target materials, chemistry, waste and post-production isotopic separation.

Accelerator based production is receiving significant interest and investment, but remains in the development

phase.

Section 6 describes

99

Mo/

99m

Tc generator systems. Generator technology is an important aspect of the

99m

Tc

supply chain. However, a given technology could apply to both reactor and accelerator based technologies.

Therefore generator technology is considered in a separate section.

3

Section 7 includes technology readiness tables for technologies presented in sections 3 and 4. Generator

technology is included within individual production methods. The tables reflect the outcome of an objective,

evidence based review of the different production technologies.

Section 8 includes the conclusion. An appendix explains the technology readiness terminology beyond what

was presented in Section 3. This is followed by a list of references, a glossary and a list of longhand terminology

abbreviated throughout the report.

2. PRODUCTION OF

99

Mo/

99m

Tc

Molybdenum-99 is a radioactive isotope that undergoes beta decay with about a 66 hour half-life (Fig. 1).

About 88% of these decays result in the production of the metastable isotope

99m

Tc (Fig. 1), which subsequently

decays to the ground state (

99g

Tc) with about a 6 hour half-life.

The present gold standard process for producing

99

Mo for medical isotope use involves the neutron fission

of

235

U (i.e.

235

U(n,f)

99

Mo) in multipurpose research reactors (Fig. 2). About 6.1% of the

235

U fissions produce

99

Mo. The cross-section for this reaction is large (~584 barns for thermal neutrons) compared with other production

processes shown in Fig. 2. Multipurpose research reactors are especially well suited for

99

Mo production because

they have space for irradiating multiple targets at high neutron fluence rates (typically in the order of

10

13

10

14

neutrons per square centimetre per second (ncm

2

s

1

)).

Molybdenum-99 can be produced through a number of other schemes illustrated in Fig. 2:

Fission of

235

U with neutrons produced in deuteron and proton accelerators through (D, n) and (p, n) reactions

on heavy targets.

Neutron activation of

98

Mo (i.e.

98

Mo(n,)

99

Mo). This process is only practical for reactor based production

owing to the small activation cross-section (0.13 b for thermal neutrons). Also,

99

Mo produced through this

process has a lower specific activity than neutron fission produced

99

Mo.

Photofission of

100

Mo (i.e.

100

Mo(,n)

99

Mo). The energetic photons used in this production scheme are

obtained by irradiating heavy targets with electron beams produced by linear accelerators.

FIG. 1.

99

Mo decay.

4

Technetium-99m can also be produced directly through (p, 2n) reactions on targets containing

98

Mo (Fig. 2).

This production scheme eliminates the need for intermediate production steps involving the recovery and

purification of

99

Mo. However, it is suitable only for short (e.g. city scale) supply chains because of the short

half-life of

99m

Tc.

All the production schemes shown in Fig. 2 result in the production of by-product wastes. The major waste

streams include off-gas generated during target processing and liquid and solid processing residues. Some key

waste production characteristics for each production scheme are described in this report.

3. ORGANIZATION OF PRODUCTION TECHNOLOGIES

The discussion of

99

Mo/

99m

Tc production technologies in this report is organized according to the production

schemes shown in Fig. 2. Section 4 describes reactor based production schemes and Section 5 describes accelerator

based production schemes. The following information is provided for each production scheme shown in Fig. 2:

Description of the production scheme;

Target materials and processing;

Waste;

Regulatory issues.

Reactors

Accelerators

Heterogeneous

Homogeneous

Electron

Deuteron

Proton

235

U

98

Mo

235

U

235

U

235

U

100

Mo

98

Mo

e,

target

D,n

target

p,n

target

n,f

n,

n,f

,n

n,f

n,f

p,2n

99

Mo

99

Mo

99m

Tc

100

Mo n,2n

FIG. 2. Schemes for producing

99

Mo and

99m

Tc discussed in this report.

5

Section 6 describes technologies for concentrating and storing

99

Mo/

99m

Tc produced from both reactor and

accelerator based technologies.

Tables 614, which are included at the end of this report, provide estimates of technology readiness level

(TRL) for each of the production schemes. Judgements on TRL were based on information supplied by technology

developers, information available from the literature and also from extrapolations from other technologies. With

respect to extrapolation, one can assume, for example, that processes for isolating

99

Mo

from a uranium target will

be similar regardless of whether the target was irradiated in a reactor or an accelerator. The TRLs shown in the

tables are not judgements about the ability of any particular technology developers to implement a particular

technology. In fact, implementation of any particular technology could require assistance from experienced

technology developers and may entail the use of proprietary information.

4. REACTOR BASED PRODUCTION

4.1. FISSION BASED (n, f) PRODUCTION IN HETEROGENEOUS REACTORS

At present, most of the worlds supply of

99

Mo for medical diagnostic imaging is produced by irradiating solid

targets containing

235

U in heterogeneous reactors. After irradiation in the reactor, the target is digested in acid or

alkaline solutions and

99

Mo is recovered through a series of extraction (separation) and purification steps.

As noted in Section 1, most current

99

Mo production utilizes targets containing HEU. However, LEU targets

have been developed and are currently being used for small to medium scale

1

commercial

99

Mo production by

several organizations:

(1) Targets containing uranium-aluminium dispersed in an aluminium matrix (commonly referred to as UAl

2

or

UAL

x

targets). The dispersion is clad between thin (nominally 0.3 mm) aluminium plates. These targets are

currently being used by CNEA, ANSTO and NECSA

2

to produce

99

Mo. This target is described more fully in

Section 4.1.1.1.

(2) Targets containing uranium metal foil. The foil is clad between aluminium tubes and is separated from the

cladding by a recoil barrier; the barrier prevents the foil from bonding to the cladding. These targets have been

successfully irradiated and processed on a trial basis at BATAN, CNEA and MURR [3]. This target is

described more fully in Section 4.1.1.4.

A 2009 report from the USA National Academy of Sciences concluded that LEU targets that could be used for

large scale production of

99

Mo have been developed and demonstrated. The expert committee that authored this

report also concluded that it saw no technical reasons that adequate quantities (of

99

Mo) cannot be produced from

LEU targets in the future [4]. While the present IAEA report was being developed, ANSTO demonstrated large

scale production of

99

Mo, although it has not yet implemented routine production on a large scale.

The following sections describe LEU target materials and processing methods that could potentially be used

for the production of

99

Mo on small to large scales.

1

NECSA has reported that production will be increased following non-nuclear regulatory approvals in customer countries.

2

NECSA successfully demonstrated their capability to produce

99

Mo from LEU targets in 2010. As of the final edit of this

report, NECSA was continuing to work toward routine production and a complete process conversion to LEU.

6

4.1.1. Targets and processing methods

4.1.1.1. UAl

x

dispersion targets

Uranium-aluminium (UAl

x

) dispersion targets comprised of HEU and LEU are currently being used to

produce

99

Mo worldwide. These targets are manufactured to MTR fuel specifications by both CERCA and CNEA

and are qualified to moderate burnup (i.e. >30%). This burnup is typically several times greater than that

experienced during target irradiation for

99

Mo production. Historically, multiple thousands of HEU dispersion

targets have been safely irradiated and processed to produce

99

Mo of high quality and purity.

The uranium density (also referred as uranium loading) of an LEU dispersion target is in the range of

2.53.0 gU/cm

3

. In contrast, the maximum uranium density of HEU dispersion targets now in use is s1.6 gU/cm

3

.

In comparison, uranium metal targets have a density of 19.0 g/cm

3

. An LEU dispersion target manufactured by

CNEA is shown in Fig. 3.

LEU Al

x

dispersion targets are currently being irradiated on a routine basis to produce

99

Mo in Argentina,

Australia and South Africa. Both Covidien and IRE currently use HEU Al

x

dispersion targets manufactured by

CERCA to produce

99

Mo. CERCA is currently manufacturing LEU Al

x

dispersion targets for NECSA. ANSTO has

used LEU Al

x

dispersion targets supplied by both CERCA and CNEA.

LEU dispersion target fabrication begins with LEU UAl

2

particles matrixed with pure aluminium powder. The

UAl

2

to UAl

3

/UAl

4

phase transformation is inherent to the fabrication process used to manufacture these targets.

(The various steps of the fabrication process convert UAl

2

to UAl

3

/UAl

4

.) The ratio of UAl

3

to UAl

4

in a finished

target will vary from manufacturer to manufacturer depending on the processes and heat treatments that are used in

fabricating the powder, core compacts and target plates [6].

All current

99

Mo producers who use LEU Al

x

targets use an alkaline digestion chemical process. Multiple

targets are digested in a dissolver unit containing sodium hydroxide (NaOH), or, in the case of IRE and PINSTECH,

NaOH and NaNO

3

. The molybdenum in the dissolution liquor is then recovered and purified by a series of

processing steps. The number of purification steps, typically four or five, varies from producer to producer. The

process used by both Covidien and CNEA and subsequently marketed by the GammaService Group International

(GSG) and INVAP is based on technology developed by A.A. Sameh at KfK [79]. The alkaline digestion based

chemical processing scheme for LEU Al

x

dispersion targets has been successfully demonstrated with LEU targets

in Australia, Argentina and South Africa.

GSG is also marketing a chemical digestion processes called ROMOL99 [10]. The process involves the

dissolution of UAl

x

dispersion targets in a closed system under reduced pressure conditions (and without generation

FIG. 3. CNEAs LEU-aluminium dispersion targets. These targets have been used since 2002 to produce

99

Mo in Argentina. The target

is 13.0 cm in length and 3.5 cm in width [5].

7

of H

2

) including a NH

3-

and iodine removal process step. The process is being operated using semiautomated

process control. This process is currently being used with HEU targets by PINSTECH and in Dimitrovgrad

(Russian Federation) with a production capacity of 200250 6 day Ci (74009250 GBq).

4.1.1.2. U

3

Si

2

-Al dispersion targets

U

3

Si

2

has been successfully used as research reactor fuel for many years. This fuel is manufactured to

established and industry accepted MTR fuel specifications [11]. It has been qualified to a uranium loading of

4.8 g/cm

3

for research reactors [12]. For use as a

99

Mo production target, a uranium loading of 6.0 g/cm

3

is

achievable [13].

In October 1988 the US Nuclear Regulatory Commission (NRC) approved the use of U

3

Si

2

-Al dispersion fuel

in its licensed plate type reactors at densities of up to 4.8 gU/cm

3

and up to power densities and

235

U burnup values

typical of fuels tested in the 30 MW Oak Ridge Research Reactor at the Oak Ridge National Laboratory. Since that

time regulatory authorities in many other countries have approved the use of U

3

Si

2

-Al plate type fuel.

The French research reactor fuel fabricator (CERCA) announced in 1992 that it could provide U

3

Si

2

-Al

dispersion fuels up to a density of 6.0 gU/cm

3

[14]. Five fuel plates with uranium densities of 5.8 and

6.0 gU/cm

3

were irradiated at the Silo reactor in Grenoble, France, to a burnup of 55% in 1995 to 1997 and two

5.8 gU/cm

3

fuel assemblies were irradiated in Osiris to a burnup of 74% in 1997 and 1998. These irradiations

produced very good results [13].

These manufacturing developments and irradiations have shown that higher density U

3

Si

2

-Al dispersion fuel

can be manufactured reliably and perform well under irradiation. By the definition of qualified fuel presented in

Ref. [15], 6.0 gU/cm

3

U

3

Si

2

-Al dispersion fuel can be considered to be qualified for use under conditions that do not

exceed those of the test irradiations described above.

Uranium silicide-aluminium (U

3

Si

2

) dispersion targets have been evaluated for use to produce

99

Mo [16].

Dissolution of 4.8 gU/cm

3

U

3

Si

2

-Al targets by a process has been demonstrated on a laboratory scale. The

mechanism and rates for dissolution of the aluminium cladding, aluminium in the fuel matrix and the silicide

particles are understood. Irradiated silicide has a slow dissolution rate owing to the bonding of silicide particles

during irradiation. A chemical method to break up the fused silicide particles before or during dissolution is

required to successfully process these targets.

The use of alloyed aluminium cladding (e.g. Al type 6061) necessitates a solids separation step following

cladding dissolution. Hydroxide precipitates of alloying elements are suspended in the spent cladding dissolver

solution. Separation of this low density precipitate from the high density U

3

Si

2

is possible.

U

3

Si

2

cannot be readily dissolved by sodium hydroxide (NaOH) solutions or NaOH solutions containing

sodium nitrate (NaNO

3

). Therefore, the cladding and aluminium powder in the fuel matrix are dissolved in one step

using potassium hydroxide (KOH) and a second step is required using a more powerful reagent, such as

hydrofluoric acid, to dissolve the U

3

Si

2

. Because some of the

99

Mo is lost to the aluminium matrix due to fission

recoil, it must be recovered during both dissolution steps to maximize the

99

Mo yield of a production batch.

The dissolution and chemical processing of a U

3

Si

2

target containing greater than 4.8 gU/cm

3

has not yet been

demonstrated.

GSG is marketing a further developed version of this process as the Karlsruhe Sameh Silicide (KSS) process.

4.1.1.3. Uranium nitride (UN) dispersion targets

Uranium nitride MTR fuel plates have been developed and fabricated on a laboratory scale [17]. Uranium

nitrides are denser, more stable and conduct heat better than mixed uraniumplutonium oxide reactor fuels

properties that suggest these fuels could run cooler in power reactors to generate more thermal energy.

In the mid-1980s, a method to create a discrete compound of uranium nitride was discovered. The compound

is uranium nitrid important because its ceramic state, uranium mononitride, was identified as a candidate for reactor

nuclear fuel.

Published reactor fuel characteristics, for alloy in an aluminium matrix, identify the uranium loading of the

dispersed phase as approximately 13.5 g/cm

3

. When fabricated to the requirements of MTR fuel specifications, the

maximum uranium loading of a UN fuel plate (or target) is 7.0 g/cm

3

.

8

4.1.1.4. Uranium foil targets

Argonne has developed an LEU foil target for

99

Mo production (Fig. 4). The uranium loading of the LEU foil

is approximately 19 g/cm

3

. This is much higher than the uranium loading of HEU or LEU dispersion targets, which

typically contain no more than 1.6 gU/cm

3

and between 2.5 and 3.0 g U/cm

3

, respectively, as noted previously.

The target consists of a thin (typically 100150 m thick) uranium foil sandwiched between 15 m thick

nickel or 40 m thick aluminium fission recoil barriers. The foil barrier sandwich is contained in a tubular

aluminium cladding. The fission barrier prevents the LEU foil from bonding with the aluminium cladding during

irradiation.

After irradiation, the foil is removed from the aluminium cladding for chemical processing and the cladding

is discarded as low activity solid waste. The removal of the foil from the cladding prior to chemical processing

reduces the processing time and the volume of processing waste compared to LEU dispersion targets. The target has

been chemically processed using the LEU Modified Cintichem process developed by Argonne, which involves

dissolution in nitric acid (HNO

3

).

LEU foil targets have a limited irradiation history. Targets have been successfully irradiated in Argentina,

Indonesia, Australia and the USA. Approximately thirty LEU foil targets have been irradiated worldwide to date.

Furthermore, LEU foil targets are not currently manufactured to an industry accepted standard or

specification. Such a standard or specification must be developed and a corresponding target qualification

programme must be implemented before this target can be adopted for widespread use.

Additionally, LEU foil targets have not been industrially adapted to the alkaline target dissolution processes

used by many current

99

Mo producers. Argonne has developed two front end options for using LEU foil targets in

alkaline based processes for use with these targets. It is anticipated that they will be demonstrated on a production

scale in 2013 [18].

A small scale

99

Mo producer (BATAN in Indonesia) planned to convert to LEU foil targets after exhausting its

inventory of HEU. (At the time of this report, BATAN was not producing LEU foil target based

99

Mo.)

Consequently, for small scale

99

Mo production, target fabrication and chemical processing of LEU foil targets is not

yet fully mature.

Work is in progress by the University of Missouri, Argonne and B&W Y-12 to develop LEU foil annular

target specifications, a manufacturing method for high volume target production and quality control test criteria [19,

20]. Work is also in progress to transition the annular design to a plate (flat or curved) geometry as an option [21,

22]. Thin uranium metal foils manufactured by B&W Y-12 and KAERI are shown in Figs 5 and 6, respectively.

FIG. 4. LEU foil annular target comparison to a typical HEU dispersion target. Annular target shown with nickel wrapped 24 gU

(LEU)

foil exposed. A typical HEU dispersion target contains ~5 gU

(HEU)

. Both targets yield about the same activity of

99

Mo if irradiated with

the same thermal neutron flux and irradiation time.

9

4.1.1.5. Uranium metal targets

The concept of uranium metal targets is by no means new. Natural uranium metal slugs electroplated with

nickel (~7 m in thickness) and clad in aluminium (1.27 mm in thickness) were used to produce plutonium in the

Savannah River reactors [23]. Thousands of these slugs were routinely irradiated and chemically processed over a

period of about fifty years.

CINR Rossendorf routinely irradiated and processed natural uranium metal pellet targets to produce

99

Mo

from 19631980 [24]. The target material was dissolved in HCl and

99

Mo was separated from the dissolution liquor

using an alumina column. Commercially available 5% enriched uranium metal in the form of pellets, disks or strips

could be used in lieu of natural uranium target material for

99

Mo production. GSG developed a processing system

concept, LITEMOL, which aims to provide a small scale

99

Mo production capability to those institutions operating

research reactors with moderate neutron flux densities (15 10

13

). The chemistry of the LITEMOL concept is

identical to that used at CINR. However, this processing concept has not yet been demonstrated using the

commercially available 5% enriched uranium metal disks or strips.

4.1.1.6. Uranium oxide (UO

2

) targets

ANSTO routinely irradiated 1.8% enriched UO

2

pellets to produce

99

Mo in the early 1980s. The enrichment

of the pellets was later increased to 2.2%. The density of UO

2

in a dispersed phase was approximately 9.7 g/cm

3

.

The pellets were irradiated for up to 7 days in a double encapsulated aluminium can configuration. The small gap

between the fuel pellets and the aluminium irradiation can was filled with magnesium oxide (MgO) to enhance heat

dissipation.

Following irradiation, the pellets were separated from the MgO powder by sieving, followed by dissolution in

concentrated nitric acid.

The solution was passed through an alumina column, which sorbed the

99

Mo. The

remainder of the solution, which contained uranium and most of the fission products, passed through the column.

The alumina column was then washed in sequence with nitric acid, purified water and a dilute ammonia solution to

remove traces of contaminants.

The purified

99

Mo was eluted from the column with concentrated ammonia solution, followed by boiling the

solution to remove residual traces of iodine and ruthenium. The alumina column separation was repeated to produce

99

Mo of the specified purity [25].

The EOB yield of a target batch was approximately 135 Ci (5,000 GBq). Up to five production runs were

performed on a weekly basis, totalling 675 Ci (25,000 GBq) at EOB. Technetium-99m generator production was

spread out over the entire week. ANSTO continued to produce

99

Mo using the UO

2

pellets until late 2006, when it

began transitioning to LEU UAl

x

targets.

FIG. 5. Uranium metal foil fabricated on a trial basis by

B&W Y-12. The thickness of the foil is ~115 m.

FIG. 6. Uranium metal foil fabricated by KAERI using their

cooling roll casting method. The average thickness of the foil is

~140 m.

10

JAERI also produced

99

Mo in 1977 using UO

2

pellets (2.6% enrichment) as a target material. JAERI

irradiated 120 g of pellets in the JRR-2 or JRR-3 reactor for up to 7 days at a maximum neutron flux of

3 10

10

ncm

2

s

2

. A batch of about 20 Ci (740 GBq) of

99

Mo per week was routinely shipped to a local

99

Tc

generator manufacturer [26].

AECL designed an HEU UO

2

powder annular target for irradiation in the MAPLE reactors. The UO

2

powder

was vibra-packed between two concentric cylinders made from zirconium and hot isostatic pressed to seal the target

and provide good thermal contact between the target meat and cladding. These targets were fabricated by B&W but

were never used.

From the early 1970s to 1989, the Cintichem reactor facility prepared targets using HEU electroplated from a

uranyl oxalate system onto the inside surface of a stainless steel tube [27]. After electroplating, the tubes were

heated to convert the uranium to UO

2

and their tops and bottoms were welded shut. After irradiation, the tubes

served as dissolver vessels.

4.1.1.7. Uranium aluminide alloy targets

The target is fabricated from UAl alloy rods clad with aluminium. This target is manufactured by AECL

using HEU and is of the same basic construction as the HEU fuel rods that were used in the NRU reactor before its

conversion.

LEU based targets of the same general design and dimensions would yield less

99

Mo activity than the HEU

targets they replace. The amount of decrease would depend on the density of

235

U in the LEU target compared to the

HEU target.

4.1.1.8. Uranium metal particle aluminium matrix dispersion targets

This target design is being developed by KAERI. An atomization process produces 50150 m uniform

spherical uranium metal particles, which are incorporated into an aluminium metal matrix to produce the target

meat. A uranium volume fraction is anticipated of up to 50% (approximately 9.0 gU/cm

3

) in the target meat with

these small particle sizes.

Small amounts of silicon, chromium, iron or other elements can be alloyed with the uranium metal and/or a

small amount of silicon can be alloyed with the pure aluminium matrix to retard the interaction with uranium metal

particles [28].

4.1.2. Waste

Uranium fission production schemes generate higher volume and activity waste compared with other

production schemes described in this report. Uranium fission production also requires substantially higher shielding

for targets, processing and waste handling. The liquid processing wastes must be solidified and stored until a

permanent disposal pathway becomes available.

Production of

99

Mo using LEU targets will generate waste with the same characteristics as that produced from

HEU targets. However, waste volumes could be different (larger or smaller) depending on target design.

4.1.3. Regulatory issues

Regulatory approvals will be needed before new target designs can be irradiated on a routine basis and also

before

99

Mo produced from these targets can be used in medical procedures.

The safety aspects of target use are evaluated in a manner consistent with the evaluation of reactor fuel.

Thermohydraulic considerations will dictate the maximum thermal power (kW) of the targets, their uranium mass

and the requirements for their positioning in the reactor. Also, a target failure in containment analyses must be

performed as part of the safety case for target irradiation. Historically, targets fabricated from the same material as

the reactor fuel material have been easiest to qualify and license. The safety aspects of target processing must also

be addressed.

The production of

99

Mo using LEU targets is almost identical to the present gold standard process for

producing

99

Mo using HEU, and chemical processing is in many cases almost identical. In some cases, however,

11

chemical processing might have to be modified to accommodate larger masses of LEU target material. The LEU

based production process and products will have to be validated and approved by regulatory bodies, but past

experience suggests that this will be a straightforward process when carried out in close coordination with

regulators.

4.2. FISSION BASED (n, f) PRODUCTION IN HOMOGENEOUS REACTORS

A pseudo-prototype system,

99

Mo production and recovery from an aqueous homogeneous reactor (ARGUS),

has been demonstrated on a pilot scale in the Russian Federation. The Kurchatov Institute, in collaboration with

Argonne and Technology Commercialization International, a private company from the USA that is no longer in

business, developed an LEU uranyl sulphate based aqueous homogeneous reactor at ARGUS to produce

99

Mo. The

concept never progressed beyond laboratory scale development, but a similar concept is now being pursued by

CJSC Resources and Technologies [29] and ROSATOM.

Babcock and Wilcox has developed a conceptual design for a 200 kW aqueous homogeneous reactor and

recovery system to produce

99

Mo, called MIPS. The reactor fuel solution, which contains LEU salt dissolved in

water and acid, is also the target material for

99

Mo production. The reactor would be operated to allow the buildup

of

99

Mo in the fuel solution. The reactor would then be shut down and the fuel solution pumped through a recovery

column that preferentially sorbs molybdenum. Molybdenum-99 would be recovered by stripping (i.e. eluting) the

recovery column and subsequently conditioned by one or more purification steps.

Babcock and Wilcox estimate that a single 200 kW MIPS is capable of producing about 10 000 Ci

(370 000 GBq) of

99

Mo at the EOB (5 day irradiation). The expected yield from sorbent extraction is 90%.

Assuming a 10 hour processing time, approximately 8000 Ci (~1700 6 day Ci) (296 000 GBq or ~62 900 6 day

GBq) can be produced on a weekly basis

3

. A comprehensive description of the MIPS concept is presented in

IAEA-TECDOC-1065 [30].

A key technical challenge in utilizing solution reactor technology for the production of

99

Mo is the

development of an efficient method for extracting or separating the product isotope from the irradiated fuel

solution. Specifically, the effects of radiation and fission product buildup on the separation of

99

Mo by an adsorbent

media must be determined. Several different adsorbent media have been evaluated: Termoxid 52 (T52), Termoxid

5M (T5M), titanium dioxide (TiO

2

) and alumina (Al

2

O

3

) [31]. Because of the relatively high uranium nitrate or

uranium sulphate concentration of the fuel solution, alumina has insufficient sorption properties for use in the

molybdenum recovery system.

4.2.1. Fuel/target solutions

Two types of aqueous fuel solutions have been considered for

99

Mo production using an AHR: (1) uranium

nitrate [UO

2

(NO

3

)

2

] and (2) uranium sulphate [UO

2

SO

4

]. Some characteristics of these solutions are described in

the following sections.

4.2.1.1. Uranyl nitrate fuel solution

Uranyl-nitrate solutions have superior chemical properties for the separation of Mo and for waste treatment

relative to uranyl-sulphate solutions. However, the radiolytic decomposition of an aqueous uranyl-nitrate solution is

far more complex than that of the sulphate salt. In addition to the radiolysis production of H

2

and O

2

from water,

nitrate is reduced forming nitrite, nitrogen and nitrogen oxide (NO

x

) gases and ammonium ions are also generated

from the radiolytic decomposition of the fuel solution. A subsystem to remove the NO

x

gases may be required in the

design of the off-gas system to prevent degradation of the charcoal filters (if charcoal is chosen as a sorbent for

fission gas removal).

3

This information was reported by Babcock and Wilcox in a

99

Mo production R&D survey submitted to the IAEA.

12

4.2.1.2. Uranyl sulphate fuel solution

Uranyl sulphates main advantage is that only H

2

and O

2

are formed by the radiolytic decomposition of the

fuel solution. These gases can be recombined to water using a catalyst bed (recombiner) and the condensed water

can then be returned to the fuel solution. Its disadvantages are related to the chemistry of sulphate and its salts. This

is the concept pursued by the Kruchatov Institute at the ARGUS reactor.

4.2.2. Waste

The operation of homogeneous reactors will produce off-gas wastes and liquid waste streams, primarily the

reactor fuel/target and process wastes from

99

Mo purification steps. The reactor fuel/target solutions will have to be

periodically replaced or replenished. The waste will have to be solidified and stored until a disposal pathway

becomes available.

4.2.3. Regulatory issues

Regulatory concern is expected to focus on the stated subcritical nature of the system and design features that

will assure that it will remain subcritical. There may also be regulatory issues regarding the disposition of process

wastes from these systems.

Over time, fission products will accumulate in the solution as discussed above. Changes to the solution may

have to be addressed to satisfy non-nuclear/pharmacoepeia regulatory requirements.

4.3. NEUTRON ACTIVATION PRODUCTION (n, ) IN HETEROGENEOUS REACTORS

Neutron activation based

99

Mo production (i.e.

98

Mo (n, )

99

Mo) is a viable and proven technology that dates

back to the 1960s. As an example, MURR began producing low specific activity neutron activation for the USA by

irradiating pressed sintered metal natural

98

Mo targets in 1967. MURR continued producing

99

Mo by this method

into the early 1980s. Production was suspended because neutron capture based

99

Mo could not compete

economically with the high specific activity fission product

99

Mo produced domestically at the Cintichem reactor

facility (see Section 4.1.1.6).

The production of neutron activation based

99

Mo is being carried out in several countries on a routine basis,

including India, Japan, Kazakhstan, Peru, the Russian Federation and Uzbekistan.

4.3.1. Targets

Several types of

98

Mo target can be used to produce

99

Mo through the (n, ) scheme. These are described in the

following sections.

4.3.1.1. Molybdenum metal/molybdenum trioxide (MoO

3

) powder

There are 35 known isotopes of molybdenum, 7 of which occur naturally with atomic masses of 92, 94, 95,

96, 97, 98 and 100. Of these naturally occurring isotopes, 6 are stable, with atomic masses from 92 to 98.

Molybdenum-100 is the only naturally occurring isotope that is not stable. Molybdenum-100 has a half-life of

approximately 8.0 10

18

years and undergoes double beta decay into

100

Ru. All unstable isotopes of molybdenum

decay into isotopes of niobium (Nb), technetium (Tc) and ruthenium (Ru). Molybdenum-98 is the most common

isotope, comprising 24.1% (natural abundance) of all molybdenum on Earth. In comparison, the natural abundance

of

100

Mo is only 9.6%.

High specific activity

99

Mo cannot be produced using natural Mo targets because the thermal neutron cross-

section for

98

Mo neutron capture reaction (n, ) is only about 0.13 barn (b); this is a factor of about 4400 times less

than the

235

U thermal fission cross-section, which is about 584 b. Irradiation of natural Mo targets in an epithermal

neutron flux of >1 10

13

n/cm

2

-s would produce higher specific activity

99

Mo because the epithermal neutron

cross-section for the

98

Mo neutron capture (n, ) reaction is about 6.7 b. This is a factor of about 50 times greater

13

than the thermal neutron capture cross-section but still well below the

235

U fission cross-section. However, a

marked increase in production rate is not seen due to the reduction in the thermal neutron flux available for

98

Mo

when other natural Mo nuclides are present. These have much higher thermal cross-sections (0.34 b, 13.4 b, 0.5 b,

14.4 b and respectively for

94, 95, 96

and

97

Mo) and hence capture neutrons that would otherwise be available for

98

Mo.

Most of these have much higher epithermal cross-sections as well.

Although the enriched

98

Mo would have four times the

98

Mo atoms compared to the natural Mo, much higher

production rates are often observed due to the (a) high epithermal neutron captures as well as (b) availability of the

neutrons otherwise lost to the competing reactions from other Mo isotopes. The actual increase seen will depend

upon the epithermal neutron flux available.

For the purpose of relative comparison, the specific activity of

99

Mo produced using the neutron capture (n, )

versus fission product (n, f) method is presented below:

(1) Neutron capture (n, ) production

High thermal neutron flux irradiation (EOB):

Natural isotopic abundance target ~1 Ci (37 GBq)

99

Mo/g of Mo irradiated

Highly enriched

98

Mo target 4 Ci (148 GBq)

99

Mo/g of Mo irradiated

(2) Fission product (n, f) production (EOB):

Reactor irradiation >10,000 Ci (370,00 GBq)

99

Mo/g of total Mo

However, scientists at the Delft University of Technology in the Netherlands developed a methodology to

increase the specific activity of neutron activated

99

Mo by a factor of more than 1000 by chemical separation of

99

Mo from the Mo target using SzilardChalmers chemistry, rendering a specific activity level in the order of that

produced via fission

99

Mo [3234]. The methodology can be applied to both natural and

98

Mo enriched targets.

This

process is currently in the stage of being scaled up towards demonstration of commercial production feasibility. The

target material is to be recycled.

Two types of natural Mo target material are typically used to produce (n, )

99

Mo: molybdenum trioxide and

molybdenum metal. These target materials are shown in Fig. 7.

FIG. 7. Natural abundance and high purity pressed sintered metal Mo targets (32 g) once irradiated at MURR shown with

molybdenum trioxide powder for comparison.

14

The crystalline density of molybdenum trioxide (MoO

3

) is about 4.7 g/cm

3

; the loose packed powder density

would be about half that. MoO

3

powder can be easily dissolved in sodium hydroxide (NaOH). The density of

pressed sintered metal targets is 30%95% of the theoretical density of 10.3 g/cm

3

(i.e. about 3.1 g/cm

3

to

9.8 g/cm

3

). Granulated Mo metal can also be used as a target material.

High density pressed sintered natural Mo metal targets are commercially available. They are typically

manufactured in the range of about 70%95% of theoretical density. Molybdenum metal targets can be dissolved in

alkaline hydrogen peroxide (H

2

O

2

) or electrochemically.

The metal form takes more time to dissolve than the powder form. However, the advantage of using metal is

that more natural Mo can be irradiated per target, producing a greater yield of

99

Mo per unit volume of irradiation

space and making more effective use of irradiation space.

The purity of the natural Mo target material should be >95% and should contain no detectable tungsten (W).

The irradiation of tungsten produces

188

Re (rhenium) by the radioactive decay of

188

W, which is difficult to separate

from

99m

Tc because it has similar chemical properties.

4.3.1.2. Enriched molybdenum-98

The use of

98

Mo target material (powder or metal) with an enrichment of >95% offers the advantage of

increased

99

Mo production yield. The purity of the enriched

98

Mo target material should be >95% with no detectable

tungsten (W) for the reasons described previously. However, because of the relatively high cost of highly enriched

target material, it might be necessary to recover the unused irradiated

98

Mo in a purified chemical form suitable for

new target production. This material is radioactive and must decay for at least 30 days before it can be classified as

non-radioactive.

4.3.2. Waste

Since neutron activation does not involve the presence of mixed fission products, the dose considerations for

production and waste handling and storage are significantly less. Shielding requirements through the whole process

are much less than for fission product

99

Mo. The other activation products present in the waste streams decay within

a reasonable period of time such that both solid and liquid wastes can be removed from the cell environment as low

activity waste after about 6 months.

4.3.3. Regulatory issues

Neutron activation based production involves no fissile material. Nuclear regulatory/safety approvals are

anticipated to be of similar complexity as the irradiation of other, non-fissile material.

5. ACCELERATOR BASED PRODUCTION

5.1. FISSION BASED (n, f) PRODUCTION USING ACCELERATORS

The use of accelerators as opposed to reactors to generate high fluxes of thermal neutrons (neutrons of

energy ~0.02 eV) for stimulating

235

U fission has been proposed for a number of years, initially using HEU. More

recently, yield calculations have been performed for LEU targets.

Two accelerator based production schemes are described in this report: The first uses a proton accelerator to

produce neutrons through the (p, n) reaction. The second uses a deuteron accelerator to produce neutrons through

the (D, n) reaction. These production schemes are illustrated in Fig. 2 [35].

15

5.1.1. Proton accelerator production

The driver for producing high energy protons has generally been a linear accelerator with high power, with the

combination of proton energy and beam current usually in the range of 150500 MeV with up to 2 milliamps of

beam current (~10

16

particles/s). The goal is to produce an order of magnitude more secondary neutrons inside the

target from

235

U fission.

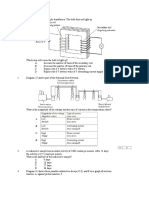

As an example, the schematic system shown in Fig. 8 [35] consists of a target made of 0.5 mm thick metallic

LEU foils with a radius of 5 cm separated by 1 mm thick water channels for cooling. A target assembly containing

142 foils would generate nearly 5000 6 day Ci/week (185 000 6 day GBq/week) using a proton beam of 350 MeV

with a flux of 1 mA. In other words, this scheme would be suitable for large scale

99

Mo production.

5.1.1.1. Targets

The target(s) for this approach will consist of a series of LEU discs surrounded by a beryllium reflector to

enhance neutron interaction with the target material as well as a water moderator for thermalizing the neutrons.

5.1.1.2. Waste

The waste issues associated with accelerator based fission processes are essentially the same as for reactor

based fission processes. Both processes would produce liquid waste containing uranium fission products. However,

current reactor based processes utilize uraniumaluminium dispersion targets, which have a greater mass than the

uranium foil targets that would be used in the accelerator based process. Consequently, the accelerator based

process might produce smaller volumes of waste than current reactor based processes. Specific waste stream

volumes would not be known until the target configuration and design have been developed.

5.1.1.3. Regulatory issues

The fission based accelerator production methods are closest to the present gold standard of reactor based

thermal neutron fission of HEU; thus, the chemical processing would be identical. However, chemical processing

might have to be modified to account for the final target configuration discussed above. The LEU based production

process and products will have to be validated and approved by regulatory bodies.

FIG. 8. Subcritical reactor schematic using LEU target assembly with moderator and beryllium reflector [35].

16

5.1.2. Deuteron accelerators

Low energy accelerators can be used to produce neutrons via the D,T reaction or the photon induced breakup

of D

2

O. These neutrons can be directed to a target composed of a solution of uranyl nitrate or sulphate similar to the

solution reactor.

A high intensity neutron source with a very high neutron yield and efficiency has been developed at Phoenix

Nuclear Laboratory (PNL) [36]. The source was created by directing a collimated deuterium ion beam into a tritium

gas target in an aluminium container. This process produces yields consistent with those predicted by theoretical

calculations. The neutrons are produced via the low energy (300 keV) acceleration of deuterons on a tritium target.

Based on current yield estimates, this scheme could be used for medium scale production of

99

Mo to meet

regional needs. A cluster of devices could achieve large scale production.

The final design will require beam currents in the order of 50 mA, which have been exceeded in reliable, high

intensity light ion injectors by groups at LANL and LBNL. The lifetime of the ion source also must be increased

from several hours to months. The next generation prototype neutron source will incorporate higher voltage,

advanced pumping and improved beam focusing resulting in higher neutron output.

5.1.2.1. Targets

The target material is almost identical to aqueous homogenous reactor fuel consisting of a few kg of

235

U.

There are plans to study separation methods on both uranyl sulphate and uranyl nitrate target solutions. Questions

remain regarding the number of times that the solution can be recycled and reused due to waste product buildup.

The chemical processing of the solution reactor will follow established fission product chemistry. After about