Professional Documents

Culture Documents

Bollhoff Snaplock Mini

Uploaded by

Ace Industrial SuppliesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bollhoff Snaplock Mini

Uploaded by

Ace Industrial SuppliesCopyright:

Available Formats

0235/01.

02

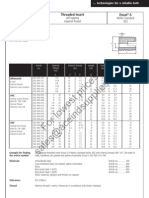

SNAPLOCK mini The new flexible system of detachable fasteners for plastic components

available in various forms and sizes versions with snap fasteners or with internal/external threads positive action or bonded fixings thin-walled centring flanges instead of thick-walled bosses (no sink marks) reduced tooling costs sets new standards for component finish and recycling

sa

le

Fo s@ r l ac ow ei es nd t p su ric pp es lie : s. co m

NEW

SNAPLOCK mini Detachable fastener components made from glassfibre-reinforced plastic

can be configured to suit the main purpose or area of application (snap fasteners, internal or external threads) thin-walled thermoplastic housings can be attached by bonded or positive action fasteners according to your requirements

: plications e p a le ib s Pos obil r cases, m ircuit e t u p m o c c lf-shells, phone ha gs, base units, in board fix nes, trim panels, o h p ... s cordles uch more m d n a g claddin

latest design makes recycling-friendly component use easy

Example of anchorage type: friction weld or ultrasonic weld = bonded fixing

Fo s@ r l o ac w ei es nd t p su ric pp es lie : s. co m

Example of anchorage type: thermal riveting (2-phase) = positive action fixing

After the component has been removed from the mould, the plastic insert is fixed in place by friction welding (or ultrasonic welding). The centring flange on the component ensures the optimum set-up of the weld zone for a bonded fixing.

Advantages:

Advantages: positive action fixing allows the use of components made from higher strength materials (e.g. PA 60 % GF), the flanges can be positioned anywhere including near the edges of components, quick, stress-relieved welding processes, high tensile strength and resistance to twisting, thin-walled centring flanges instead of thick-walled bosses, thus no sink marks in thin-walled housings, ideal for snap fasteners.

the use of compatible components and materials guarantees a homogeneous bonded fixing,

the parts used for the joint contain 60 % glass fibre, quick, low-noise welding processes, high tensile strength and resistance to twisting,

After the component has been removed from the mould, the plastic insert is fixed in place by 2-phase thermal riveting. The pockets are placed on the centring flanges on the component. First the centring flanges are plasticised without contact using hot air, then the rivet heads are formed with a cold punch.

thin-walled centring flanges instead of thick-walled bosses, thus no sink marks in thin-walled housings.

Pat. pending!

sa

Functional model Illustration of housing halfshells fitted with SNAPLOCK mini, snap fastener version.

le

Partnership service innovation

Automotive industry and their suppliers

Fastenings from Steel, Stainless, Steel and Brass Fastenings components from plastic

UNITEC, MEPLAG, TEPRO-technical plastic parts, RIVKLE Elastic-fastening component for vibration proof applications, SNAPLOCK-push on, pull off, rapid fastening system, Plastic threaded parts, Plastic headed, Metal threaded components

Construction Fasteners technology

Upat, Fischer

Quick release fasteners technology

QUICKLOC Grip, turn and release

Screwdriver systems

Automatic fast screwing system UNIQUICK , BM 2100 ff, Automatic feed screw assembly system Machinery manufacturers PANTHER , BM 3100 ff, Stationary screw insertion system MULTIQUICK . From handheld operation to electronic control screwdriver systems all from one source.

HELICOIL, KOBSERT, AMTEC, SEAL LOCK , high strength threads in metals and plastics, thread sealing and vibration resistive

Riveting and metal clinching technology

RIVKLE , RIVQUICK , RIVSET , RIVCLINCH , TAGGER *. Secure threads in sheet metals and hollow sections, Riveting in sheet metals and hollow sections

* Registered trademark of Attexor Tools S. A. and Attexor Clinch Systems S. A., Suisse

sa l

Bllhoff, the international distributor for fastenings and assembly systems with its own production and development engineering. Production plants in Bielefeld (Photo), Sonnewalde, Germany as well as other in France, Brazil, Argentina and USA.

World-wide Availability The global nature of our business requires International licensing agreements in respect of a number of proprietary fastenings. Certain items within our total product range may not be available from all Bllhoff outlets. However, such products are available through Bllhoffs licenced partners and we will be pleased to provide such sourcing information.

Bllhoff GmbH

Fastening and assembly systems P.O. Box 14 02 29 33622 Bielefeld Archimedesstrae 1 4 33649 Bielefeld Germany Phone (+49) 5 21 / 44 82 - 03 (3 19) Fax (+49) 5 21 / 4 48 26 58 Internet: www.boellhoff.com E-mail: smoreau@boellhoff.de

es Fo @ r lo ac w ei es nd t p su ric pp es lie : s. co m

Our internal and field engineers provide a technical service based on sound product knowledge delivered in a competent and friendly manner.

Threaded inserts from metals and plastics

Electrical and sheet metal industries

Building construction and civil engineering

Furniture and timber trades

Subject to technical changes without notice 08/01 Printed in Germany Reprints extracts are not permitted without written authorisation.

You might also like

- Bollhoff Competence in MiniaturisationDocument8 pagesBollhoff Competence in MiniaturisationAce Industrial SuppliesNo ratings yet

- Recotec Rotafil enDocument16 pagesRecotec Rotafil enJordan RileyNo ratings yet

- Eternit PločeDocument28 pagesEternit PločedarkopavicNo ratings yet

- Connection Technology From Ifm.Document32 pagesConnection Technology From Ifm.ifm electronicNo ratings yet

- Connector Brochure UKDocument24 pagesConnector Brochure UKifm electronicNo ratings yet

- Schletter-Product_Sheets-Roof_Systems-FlatGridDocument6 pagesSchletter-Product_Sheets-Roof_Systems-FlatGridf789sgacanonNo ratings yet

- Fall Protection Systems For The Construction Industry 2013 CatalogueDocument29 pagesFall Protection Systems For The Construction Industry 2013 Cataloguesystema safety - Fall Protection Systems for the Construction IndustryNo ratings yet

- Dynaflow Lecture Presentation Gaskets 7-10-2010Document125 pagesDynaflow Lecture Presentation Gaskets 7-10-2010Jan SmitNo ratings yet

- Ejot Solar Full enDocument24 pagesEjot Solar Full enJie RongNo ratings yet

- Terminales y EmpalmesDocument167 pagesTerminales y EmpalmesJose Luis Limongi VeltriNo ratings yet

- Crouse Hinds Control StationsDocument127 pagesCrouse Hinds Control StationsLaurence MalanumNo ratings yet

- DGSL enDocument54 pagesDGSL enDanielNo ratings yet

- Dodge Thread InsertsDocument40 pagesDodge Thread InsertsAmit PanditaNo ratings yet

- Bollhoff Quicksert Expansion InsertsDocument4 pagesBollhoff Quicksert Expansion InsertsAce Industrial SuppliesNo ratings yet

- Automotive en 20082Document165 pagesAutomotive en 20082Nishant ShahNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- BT Innovation Btspannschloss Web enDocument28 pagesBT Innovation Btspannschloss Web enartomiNo ratings yet

- Bollhoff Quicksert Expansion InsertsDocument4 pagesBollhoff Quicksert Expansion InsertsAce Industrial SuppliesNo ratings yet

- Catalogue Skylight PDFDocument16 pagesCatalogue Skylight PDFDaniel DediuNo ratings yet

- MSE 210 On-Roof en LOW KEY PDFDocument6 pagesMSE 210 On-Roof en LOW KEY PDFJesus de NazarethNo ratings yet

- Connector Product Locations: GermanyDocument56 pagesConnector Product Locations: Germanywww.erwer9No ratings yet

- Neftegasdiagnostica Group Offers Oil & Gas Pipeline InspectionDocument31 pagesNeftegasdiagnostica Group Offers Oil & Gas Pipeline InspectionAMIGONo ratings yet

- Estadry D-Type DBDocument12 pagesEstadry D-Type DBcharleselitb92No ratings yet

- Data Sheet SSG4600Document8 pagesData Sheet SSG4600Anonymous OnzJpzNo ratings yet

- Contur KatalogDocument48 pagesContur KatalogDang Minh HuongNo ratings yet

- Marco Full Product CatalogDocument54 pagesMarco Full Product Catalogjonathan1479No ratings yet

- Main Catalog: 06 Subracks / 19" ChassisDocument140 pagesMain Catalog: 06 Subracks / 19" Chassisusriko9999No ratings yet

- Hi SpanDocument54 pagesHi Spangdoyle7282No ratings yet

- Tyco AutoTerminalsDocument20 pagesTyco AutoTerminalslink2u_007No ratings yet

- Sandwich Panels en Lo RUUKKIDocument8 pagesSandwich Panels en Lo RUUKKIszeestherNo ratings yet

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8No ratings yet

- Rotalock™: Quick Opening ClosureDocument2 pagesRotalock™: Quick Opening Closureagung wijayaNo ratings yet

- Mounting systems for solar technologyDocument22 pagesMounting systems for solar technologyArianit ZeqiriNo ratings yet

- 3M Terminales 3MDocument92 pages3M Terminales 3MEDGARPRADOCNo ratings yet

- Rittal Technical System Catalogue Compact Enclosures AE 5 2591 PDFDocument10 pagesRittal Technical System Catalogue Compact Enclosures AE 5 2591 PDFMaxi SchremmelNo ratings yet

- General CatalogueDocument68 pagesGeneral CatalogueMohamed ShameerNo ratings yet

- Schletter Montage Und Projektierung enDocument32 pagesSchletter Montage Und Projektierung enKirsten HernandezNo ratings yet

- Self-Locking Fasteners: 4 Tips Every Engineer Should KnowDocument7 pagesSelf-Locking Fasteners: 4 Tips Every Engineer Should Knowcamohunter71100% (1)

- Seals and Sealing Systems For PressesDocument334 pagesSeals and Sealing Systems For PressesMykola TitovNo ratings yet

- V RingsDocument16 pagesV RingsNCvetarskyNo ratings yet

- BTi Ausschnitt Katalog BT-Spannschloss R en WebDocument10 pagesBTi Ausschnitt Katalog BT-Spannschloss R en WebvishalgoreNo ratings yet

- System Plast Full Bearing Larrique Rulemanes S.A.Document131 pagesSystem Plast Full Bearing Larrique Rulemanes S.A.Paisaje SilenciosoNo ratings yet

- ClampFit Productsheet PDFDocument4 pagesClampFit Productsheet PDFCamilo Andres Bayona AguileraNo ratings yet

- Mechanical Seals in AgitatorsDocument6 pagesMechanical Seals in AgitatorsLy Ca TieuNo ratings yet

- Harness SealingDocument30 pagesHarness Sealingpapipapii100% (1)

- EJOT Building Fasteners 2022 enDocument395 pagesEJOT Building Fasteners 2022 enMurat AcarNo ratings yet

- Air Brake Tubes End - Fittings Champions For MohanDocument12 pagesAir Brake Tubes End - Fittings Champions For MohanSamarjit Karar100% (1)

- WPC120 PDFDocument2 pagesWPC120 PDFHamzaHashimNo ratings yet

- Heat Staking Procedures and Processes: Procedures, Process Parameters, and Guidelines For Plastics AssemblingDocument4 pagesHeat Staking Procedures and Processes: Procedures, Process Parameters, and Guidelines For Plastics Assemblingawdhut kulkarniNo ratings yet

- Flupec Catalog SimeringuriDocument315 pagesFlupec Catalog Simeringuriman666onNo ratings yet

- Gask o Seal PDFDocument24 pagesGask o Seal PDFThang CaoNo ratings yet

- Engineering Guide User InterfacesDocument12 pagesEngineering Guide User Interfacessav33No ratings yet

- Dywidag DSI Bonded PT SystemDocument44 pagesDywidag DSI Bonded PT SystemxlogicyNo ratings yet

- The Advantages at A Glance: The Unique & Versatile SystemDocument2 pagesThe Advantages at A Glance: The Unique & Versatile SystemVikrant MapuskarNo ratings yet

- GF Flange PPDocument8 pagesGF Flange PPRosi Nuraeni YusfiNo ratings yet

- The Complete Guide To Pressure and Vacuum Sealing AssembliesDocument22 pagesThe Complete Guide To Pressure and Vacuum Sealing AssembliesLuiz Carlos Vidal100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- HeliCoil Stud-Lock InsertsDocument2 pagesHeliCoil Stud-Lock InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UNDocument4 pagesHeliCoil NPT Inserts 8UNAce Industrial SuppliesNo ratings yet

- PowerCoil Screw Thread InsertsDocument103 pagesPowerCoil Screw Thread InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Product RangeDocument40 pagesHeliCoil Product RangeAce Industrial SuppliesNo ratings yet

- Bollhoff Rivkle RivnutsDocument52 pagesBollhoff Rivkle RivnutsAce Industrial SuppliesNo ratings yet

- HeliCoil Pipe Thread Inserts NPT ANPT NPSCDocument8 pagesHeliCoil Pipe Thread Inserts NPT ANPT NPSCAce Industrial SuppliesNo ratings yet

- HeliCoil Self Tapping InsertsDocument4 pagesHeliCoil Self Tapping InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless ApplicationsDocument2 pagesHeliCoil Tangless ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs MetricDocument1 pageHeliCoil Insert Specs MetricAce Industrial SuppliesNo ratings yet

- HeliCoil Tangless Gall Resistant InsertsDocument2 pagesHeliCoil Tangless Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Stud-Lock ApplicationsDocument2 pagesHeliCoil Stud-Lock ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket KIts Sav-A-Thread HTDocument1 pageHeliCoil Aftermarket KIts Sav-A-Thread HTAce Industrial SuppliesNo ratings yet

- HeliCoil Insert Specs ImperialDocument1 pageHeliCoil Insert Specs ImperialAce Industrial SuppliesNo ratings yet

- HeliCoil Screw Thread InsertsDocument36 pagesHeliCoil Screw Thread InsertsAce Industrial Supplies0% (1)

- HeliCoil Serrated Spark Plug InsertsDocument4 pagesHeliCoil Serrated Spark Plug InsertsAce Industrial Supplies100% (1)

- HeliCoil Gall Resistant InsertsDocument2 pagesHeliCoil Gall Resistant InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II InsertsDocument2 pagesHeliCoil Primer Free II InsertsAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Oxygen SensorDocument1 pageHeliCoil Aftermarket Kits Oxygen SensorAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket CatalogueDocument24 pagesHeliCoil Aftermarket CatalogueAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 307 308 SeriesDocument1 pageEnsat Self Tapping Inserts 307 308 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil Primer Free II ApplicationsDocument2 pagesHeliCoil Primer Free II ApplicationsAce Industrial SuppliesNo ratings yet

- HeliCoil NPT Inserts 8UN 2Document2 pagesHeliCoil NPT Inserts 8UN 2Ace Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Catalogue 2Document24 pagesHeliCoil Aftermarket Catalogue 2Ace Industrial SuppliesNo ratings yet

- Ripp Lock WashersDocument8 pagesRipp Lock WashersAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series MetricDocument1 pageEnsat Self Tapping Inserts 302 Series MetricAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 302 Series ImperialDocument1 pageEnsat Self Tapping Inserts 302 Series ImperialAce Industrial SuppliesNo ratings yet

- Ensat Self Tapping Inserts 303 SeriesDocument1 pageEnsat Self Tapping Inserts 303 SeriesAce Industrial SuppliesNo ratings yet

- HeliCoil Aftermarket Kits Head Bolt Thread RepairDocument1 pageHeliCoil Aftermarket Kits Head Bolt Thread RepairAce Industrial SuppliesNo ratings yet

- RivclinchDocument28 pagesRivclinchAce Industrial SuppliesNo ratings yet

- Rivkle ElasticDocument12 pagesRivkle ElasticAce Industrial SuppliesNo ratings yet

- 9.6 Inner Floor InstallationDocument17 pages9.6 Inner Floor InstallationVishwasen KhotNo ratings yet

- TB 9-2300-247-40 This Bulletin Supersedes TB 9-2300-247-40, 23 February 1971Document51 pagesTB 9-2300-247-40 This Bulletin Supersedes TB 9-2300-247-40, 23 February 1971rauterjNo ratings yet

- Hub City Beveal Gear DrivesDocument5 pagesHub City Beveal Gear DrivesJuan CaceresNo ratings yet

- Information # 1Document1 pageInformation # 1Mantenimiento MelgarNo ratings yet

- Preparing Shells & FuzesDocument10 pagesPreparing Shells & Fuzesjbart252100% (1)

- Building A Powdercoat Oven: Construction Page Design Page Material List Contact LinksDocument23 pagesBuilding A Powdercoat Oven: Construction Page Design Page Material List Contact Linkselkabong20gmailcom100% (1)

- WELL NUT Metric Threaded InsertsDocument2 pagesWELL NUT Metric Threaded InsertsStan AcderfNo ratings yet

- Meritor-Diferencial Com Redutor Simple PDFDocument79 pagesMeritor-Diferencial Com Redutor Simple PDFClovis SantosNo ratings yet

- 2013 TBX Tower CatalogDocument12 pages2013 TBX Tower CatalogDaren NeradNo ratings yet

- Pneumatic Auto Feed Riveting MachineDocument4 pagesPneumatic Auto Feed Riveting MachinePushpa Mohan RajNo ratings yet

- Profiled Metal Roofing Design GuideDocument32 pagesProfiled Metal Roofing Design GuideMladen PanticNo ratings yet

- Scottsdale building systems roll formers technical guideDocument10 pagesScottsdale building systems roll formers technical guideAlparslan GureNo ratings yet

- Inch Fastener Standards 8th Edition PreviewDocument18 pagesInch Fastener Standards 8th Edition Previewtnchsg50% (4)

- API575 Closed Book Q For 653 StudyDocument26 pagesAPI575 Closed Book Q For 653 StudyTasneemAhmad100% (1)

- Bdtronic - Webinar - Heatstaking For The Automotive IndustryDocument41 pagesBdtronic - Webinar - Heatstaking For The Automotive IndustryoswaldoNo ratings yet

- Catalog JT Vol 3Document148 pagesCatalog JT Vol 3BillNo ratings yet

- Dmm1 Lesson PlanDocument65 pagesDmm1 Lesson Planrkadiraj7011100% (1)

- Me8381 - Computer Aided Machine Drawing Manual - by LearnEngineering - inDocument96 pagesMe8381 - Computer Aided Machine Drawing Manual - by LearnEngineering - insonasenthil2399No ratings yet

- Mechanics of Deformable Bodies: Prepared byDocument48 pagesMechanics of Deformable Bodies: Prepared byNelgine Moreno GepuitNo ratings yet

- Interior Decoration & FurnishingDocument120 pagesInterior Decoration & FurnishingMichael StephenNo ratings yet

- B-5 IRC-Final (22-03-21) - CompressedDocument136 pagesB-5 IRC-Final (22-03-21) - CompressedGobinder Singh VirdeeNo ratings yet

- DHC-6 300 MX Service Bulletin SupplementDocument57 pagesDHC-6 300 MX Service Bulletin SupplementHéctor SánchezNo ratings yet

- ST 03Document4 pagesST 03harshNo ratings yet

- Aircraft Construction, Repair & Modification Mock Board Exam 10Document5 pagesAircraft Construction, Repair & Modification Mock Board Exam 10July TadeNo ratings yet

- 1472636232Document48 pages1472636232Mushini Nagabhushan33% (3)

- Sheet Metal (C) FabricationDocument67 pagesSheet Metal (C) FabricationAl VlaerNo ratings yet

- Powers Blind Rivets GuideDocument24 pagesPowers Blind Rivets Guidebammer122No ratings yet

- Find and order parts from online listDocument171 pagesFind and order parts from online listArmin HaiqalNo ratings yet

- Estore Catalogue PDFDocument224 pagesEstore Catalogue PDFmanulals100% (2)

- Amt 213 Lab Project Guide2Document24 pagesAmt 213 Lab Project Guide2Gildo L. Destreza Jr.No ratings yet