Professional Documents

Culture Documents

2001, Casappa, Flow Dividers

Uploaded by

Velibor KaranovićOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2001, Casappa, Flow Dividers

Uploaded by

Velibor KaranovićCopyright:

Available Formats

PLD 02 T A

Replaces: PLD 01 T A - 01/02.2000

Gear flow dividers

DISPLACEMENTS

From To 0.12 cu in/rev 1.99 cu in/rev

Edition: 02/11.2000

l l l l

Modular design Accurate division of flow Compact overall dimension Built-in relief valve

PRESSURE

Max. continuous Max. peak 3600 psi 4000 psi

Polaris

GENERAL FEATURES

Modern machinery with increasingly complex circuits often needs combinations of separate and independent movements. POLARIS 10 and POLARIS 20 flow dividers provide technically advanced, low cost power transmis sion and sol ve ap pli ca tion pro blems whe re ver hydra u lic flow has di vi ded. In line with our po licy of sim plif ying the de sign of hydra u lic cir cu its, our flow di vi ders have re lief val ves bu ilt in to li mit pres su re and pre vent ca vi ta tion. The se com po nents per mit hydra u lic cir cu its to be cle verly op ti mi sed and re du ce in stal la tion costs. The POLARIS flow di vi ders are two or more sec tion di vi ders with a com mon in ter nal con nec ting shaft. T his ma in ta ins a con stant ra tio bet we en the flows thro ugh each sec tion in ac cor dan ce with sec tion dis place ment. The o ret i cal wor king of rotary flow di vi ders do not dis si pa te energy in fact if the out let pres su re of one sec tion drops be low in put pres su re, that sec tion ope ra tes as a mo tor and ta kes energy from the flu id. This energy is not wa sted but tran sfer red by the common shaft to the other sections which operate as pumps and therefore need outlet pressure to be greater than inlet pressure. In working conditions, overall efficiencies depend on the sum of the single sections efficiency. These products can therefore be used as flow equalizers, flow dividers and pressure intensifiers as shown in the table below.

Outlet pressure

Same Different

Sections with same displacement

Flow equa lizers Flow equa li zers

Sections with different displacement

Flow dividers Flow dividers

Pres su re in ten si fiers

Fluid Fluid temperature range

[F]

Mi ne ral oil ba sed hydra u lic flu ids to DIN 51524. For ot her flu ids ple a se consult our sales department. -13 to +176 with Buna N seals -13 to +230 with Vi ton V se als 55 to 455 re com men ded

Fluid viscosity range

[SSU] Up to 3409 permitted

Filtering requirement Contamination class NAS 1638 Contamination class ISO 4406 Achieved with filter x= 75

p > 3000 psi 8 17/14 10 m

p < 3000 psi 10 19/16 25 m

004

D024-004

Polaris

GENERAL FEATURES OF RELIEF VALVES

Re lief val ves al low the ac tua tors to realign at the end of each cycle in both flow di rec tions. As an example when the cylin ders ex tend, they may not all re ach the ir end stops exactly at the same time. In this case as soon as one cylin der re a ches its stop, the re lief val ve in that sec tion di rects flu id to tank un til all the ot her cylin ders re ach the ir stops. Whi le retroacting the relief val ve acts as check valve and opens to prevent cavitation. Relief settings valve and their identification code are listed in the table below.

Stamp code

p nominal setting (2.64 US gpm)

[psi]

p minimum begin opening valve

[psi] 465 667 783 957 1102 1392 1682 1740 1958 2103 2248 2465 2523 2668 2886 2944 3219 3509 3654 3930

34 4 22 23 6 7 17 8 9 26 10 11 35 12 33 14 15 16 27 20

508 725 870 1015 1160 1450 1740 1813 2030 2175 2320 2538 2610 2755 2987 3045 3335 3625 3770 4060

Adjustable felief valves are available on request.

TIGHTENING TORQUE

442 lbf in

D024-004

004

Polaris

GENERAL DATA

PLD 10

Di spla ce ment Type cu in/rev

Max. out let pres su re p1 psi 3600 3600 3600 3600 3600 4000 4000 4000 4000 4000 p2

Max. out let p between sec tions (1) psi 3000 3000 3000 3000 3000

Spe ed min. min - 1 1250 1205 1175 1140 1100 4200 3990 3840 3680 3500 max.

Flow per section min. max.

U S gpm 0.70 1.05 1.32 1.60 1.93 2.35 3.49 4.28 5.15 6.13

PLD 102 PLD 103,15 PLD 104 PLD 105 PLD 106,3

0.12 0.19 0.24 0.30 0.38

p1= Max. continuous pressure

p2= Max. peak pressure

(1): Pressure intensifiers can work at higher pres su re between sections.

For working conditions outside the recommended li mits shown in the table, please consult our sales department.

MAX. FLOW FOR INLET SECTION

9.25 US gpm

004

D024-004

Polaris

GENERAL DATA

PLD 20

Di spla ce ment Type cu in/rev

Max. out let pressure p1 psi 3600 3600 3600 3600 3600 3000 3000 3000 3000 4000 4000 4000 4000 4000 3300 3300 3300 3300 p2

Max. out let p bet we en sec tions (1) psi 3000 3000 3000 3000 3000 3000 3000 3000 3000

Speed min. min - 1 1250 1235 1220 1200 1175 1160 1130 1100 1060 4100 3970 3850 3660 3460 3335 3125 2900 2660 max.

Flow per sec tion min. max.

US gpm 1.63 2.15 2.66 3.55 4.50 5.14 6.30 7.64 9.20 5.34 6.90 8.36 10.79 13.22 14.76 17.36 20.13 23.09

PLD 204 PLD 206,3 PLD 208 PLD 2011,2 PLD 2014 PLD 2016 PLD 2020 PLD 2025 PLD 2031,5

0.29 0.39 0.50 0.67 0.87 1.01 1.27 1.58 1.99

p1= Max. continuous pressure

p2= Max. peak pressure

(1): Pressure in tensifiers can work at higher pressure between sections.

For working conditions outside the recommended limits shown in the table, please consult our sales department.

MAX. FLOW FOR INLET SECTION

21.14 US gpm

D024-004

004

Polaris

FLOW EQUALIZERS (WITH EQUAL DISPLACEMENTS)

Flow ac cu racy equalizers is within 2 % if they are ro tat ing in the rec om mended speed range and the dif fer en tial pressure between sections is less than 1450 psi. When several single acting cylinders are operated together, act ing on loads have not suf fi cient mass to win the cir cuits re sis tance, we rec om mend a fur ther gear sec tion act ing as a mo tor in or der to guar an tee the cyl in ders re tract. The dis place ment of this mo tor should be roughly equal to the sum of the displacements of the other sections. Two typical circuit diagrams of applications where flow equalizers are utilized will be found on page 10.

V = Displacement Q = Flow p = Pressure n = Speed

[cu in/rev] [US gpm] [psi] [min- 1]

Q0 = Q1 + Q2 ....+ Q n p0Q0 = p1Q 1 + p2Q2 ....+ pnQn

V (..) =

1000 Q (..) n

DISPLACEMENT SELECTION GUIDE EXAMPLE

Assume that it is ne ces sary to supply power to two cylinders that require a flow rate of 10.6 [US gpm] each. For sim pli city's sake we will igno re pres su re los ses and the com pres sion fac tor of the flu id. The pump must de li ver a flow equal to: Q 0 = Q1 + Q 2 = 21.2 [US gpm]. To find the displacement of the two sections of the flow equalizer, simply lo ca te the flow rate 21.2 [US gpm] on the X axis and then ascend ver ti cally un til the line cor re spon ding to the num ber of sec tions (2) is encountered; now tra ce a ho ri zon tal line to the right un til en co un te ring the li nes re ferring to displacement. Select the displacement with the point of intersection on the graph that lies nearest to the maximum speed in optimum performance range.

004

D024-004

Polaris

DISPLACEMENT SELECTION GUIDE

Performance range

Optimum performance range

Each curve has been obtained at 122F, using oil with viscosity 212 SSU at 104F. D024-004 004 7

Polaris

FLOW DIVIDERS (WITH UNEQUAL DISPLACEMENTS)

Flow di vid ers are used where the same pump must drive sev eral dif fer ent ac tu a tors re quir ing dif fer ent pres sures and flow rates. The dis place ment of each sec tion must be pro por tional to the flow rate re quired by the ac tu a tor to which it is con nected. Two typ i cal cir cuit di a grams of ap pli ca tions where flow di vid ers are uti lizedwill be found on page 11.

V = Displacement Q = Flow p = Pressure n = Speed

[cu in/rev] [US gpm] [psi] [min-1 ]

Q 0 = Q1 + Q2 ....+ Qn p 0Q 0 = p1Q1 + p2Q2 ....+ pnQ n

V (..) =

1000 Q ( . . ) n

DISPLACEMENT SELECTION GUIDE EXAMPLE

Assume two actuators must be dri ven using 13.2 [US gpm] and 5.3 [US gpm] respectively. To find the displacement of the flow di vi der sec tions, simply lo ca te the flow ra tes in que stion on the Yaxis and then move across ho ri zontally until the lines cor re spon ding to the displacement are en co un te red. Se lect a displacement with points of intersection ali gned as near as pos si ble ver ti cally, and the ne a rest to the ma xi mum spe ed in op ti mum per for mance range.

004

D024-004

Polaris

DISPLACEMENT SELECTION GUIDE

Performance range

Optimum performance range

Each curve has been obtained at 122F, using oil with viscosity 212 SSU at 104F. D024-004 004 9

Polaris

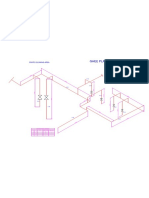

TYPICAL CIRCUITS FOR FLOW EQUALIZERS (WITH EQUAL DISPLACEMENTS)

Diagram with a flow equal izer op er at ing dou ble act ing cylinders.

Diagram with a flow equalizer operating single acting cylinders.

10

004

D024-004

Polaris

TYPICAL CIRCUITS FOR FLOW DIVIDERS (WITH UNEQUAL DISPLACEMENTS)

Diagram with a flow di vider per mit ting the use of a sin gle pump to drive a num ber of dif fer ent actuators re quir ing flows at different pressures.

D024-004

004

11

Polaris

NOTES ABOUT COMPOSITION

Flow divider sections are arranged in descending displacements or groups with the largest displacement to the left as viewed from the out let ports side. Stan dard for mats of flow di vid ers are given beneath; for different configurations please consult our sales department.

STANDARD COMPOSITION FOR 5 SECTIONS

COMPOSITION WITH ADDITIONAL INLET SECTION

CS E. I . CI T. CD

. . . . . .

. . . . . .

. . . . . .

. . . . . .

Left inlet section kit Section Intermediate kit flange Intermediate inlet section kit End cover kit Additional right inlet section kit (only for high delivery)

Type

Max. flow for inlet section

l/min

PLD 10 PLD 20

35 80

Type

Tightening torque

lbf in

PLD 10 PLD 20

221 442

12

004

D024-004

Polaris

STANDARD COMPOSITIONS FOR SECTIONS WITH OR WITHOUT VALVE

2 SECTIONS WITH 1 INLET SECTION

3 SECTIONS WITH 1 INLET SECTION

4 SECTIONS WITH 1 INLET SECTION

5 SECTIONS WITH 2 INLET SECTIONS

6 SECTIONS WITH 2 INLET SECTION

Note: Combinations between different groups (PLD10 / PLD20) are available. For more informations please consult our technical sales department.

D024-004

004

13

Polaris

PORTS DIMENSIONS

IN IN IN

T1

OUT IN . OUT T. . T1 . . . . . . . . . . . . .

OUT

OUT

OUT

OUT

Inlet port Outlet port Drain port Additional drain port

PORTS

Type

BSPP IN OUT T - T1 IN

ODT OUT T - T1

PLD 102 PLD 103,15 PLD 104 PLD 105 PLD 106,3 PLD 204 PLD 206,3 PLD 208 PLD 2011,2 PLD 2014 PLD 2016 PLD 2020 PLD 2025 PLD 2031,5

GE GD GD OD OC OB GD GC GC OB OA OA

14

004

D024-004

Polaris

PORTS DIMENSIONS

BRITISH STANDARD PIPE PARALLEL (BSPP)

Code

Nominal size

B A

G 3/8 G 1/2 G 3/4 mm (in) 14 (0.551) 14 (0.551) 18 (0.709)

GC GD GE

3/8 1/2 3/4

SAE STRAIGHT THREAD PORTS (ODT)

Codce

No mi nal size

B A

9/16-18 UNF-2B 3/4-16 UNF-2B 7/8-14 UNF-2B 1-1/16-12 UN-2B mm (in) 15 (0.591) 14 (0.551) 17 (0.669) 20 (0.787)

OA OB OC OD

3/8 1/2 5/8 3/4

D024-004

004

15

Polaris

SAME GROUP DIMENSIONS

PLD 10

IN and OUT ports dimensions are shown on page 14 and page 15.

A

Type mm (in) 50,2 (1.976) 52 (2.047) 53,4 (2.102) 55 (2.165) 57 (2.244)

B

mm (in) 19,2 (0.756) 21 (0.827) 22,4 (0.882) 24 (0.945) 26 (1.024)

C

mm (in) 31,2 (1.228) 33 (1.299) 34,4 (1.354) 36 (1.417) 38 (1.496)

D

mm (in) 41,8 (1.646) 43,6 (1.717) 45 (1.772) 46,6 (1.835) 48,6 (1.913)

E

mm (in) 40,3 (1.587) 42,1 (1.657) 43,5 (1.713) 45,1 (1.776) 47,1 (1.854)

PLD 102 PLD 103,15 PLD 104 PLD 105 PLD 106,3

16

004

D024-004

Polaris

SAME GROUP DIMENSIONS WITH VALVE

PLD 10

IN, OUT and 4 ports dimensions are shown on page 14 and page 15.

A

Type mm (in) 50,2 (1.976) 52 (2.047) 53,4 (2.102) 55 (2.165) 57 (2.244)

B

mm (in) 19,2 (0.756) 21 (0.827) 22,4 (0.882) 24 (0.945) 26 (1.024)

C

mm (in) 31,2 (1.228) 33 (1.299) 34,4 (1.354) 36 (1.417) 38 (1.496)

D

mm (in) 41,8 (1.646) 43,6 (1.717) 45 (1.772) 46,6 (1.835) 48,6 (1.913)

E

mm (in) 40,3 (1.587) 42,1 (1.657) 43,5 (1.713) 45,1 (1.776) 47,1 (1.854)

PLD 102 PLD 103,15 PLD 104 PLD 105 PLD 106,3

D024-004

004

17

Polaris

SAME GROUP DIMENSIONS

PLD 20

IN and OUT ports dimensions are shown on page 14 and page 15.

A

Type mm (in) 60,8 (2.394) 62 (2.441) 63,3 (2.492) 63,9 (2.516) 65,5 (2.579) 68 (2.677) 69,8 (2.748) 73 (2.874) 77 (3.031) 82 (3.228)

B

mm (in) 25,5 (1.016) 27 (1.063) 28,3 (1.114) 28,9 (1.138) 30,5 (1.201) 33 (1.299) 34,8 (1.370) 38 (1.496) 42 (1.654) 47 (1.850)

C

mm (in) 36,8 (1.449) 38 (1.496) 39,3 (1.547) 39,9 (1.571) 41,5 (1.634) 44 (1.732) 45,8 (1.803) 49 (1.929) 53 (2.087) 58 (2.283)

D

mm (in) 58,8 (2.315) 60 (2.362) 61,3 (2.413) 61,9 (2.437) 63,5 (2.500) 66 (2.598) 67,8 (2.669) 71 (2.795) 75 (2.795) 80 (3.150)

E

mm (in) 69,8 (2.748) 71 (2.795) 72,3 (2.846) 72,9 (2.870) 74,5 (2.933) 77 (3.031) 78,8 (3.102) 82 (3.228) 86 (3.386) 91 (3.583)

PLD 204 PLD 206,3 PLD 208 PLD 209 PLD 2011,2 PLD 2014 PLD 2016 PLD 2020 PLD 2025 PLD 2031,5 18

004

D024-004

Polaris

SAME GROUP DIMENSIONS WITH VALVE

PLD 20

IN, OUT and 4 ports dimensions are shown on page 14 and page 15. A

Type mm (in) 60,8 (2.394) 62 (2.441) 63,3 (2.492) 63,9 (2.516) 65,5 (2.579) 68 (2.677) 69,8 (2.748) 73 (2.874) 77 (3.031) 82 (3.228)

B

mm (in) 25,5 (1.016) 27 (1.063) 28,3 (1.114) 28,9 (1.138) 30,5 (1.201) 33 (1.299) 34,8 (1.370) 38 (1.496) 42 (1.654) 47 (1.850)

C

mm (in) 36,8 (1.449) 38 (1.496) 39,3 (1.547) 39,9 (1.571) 41,5 (1.634) 44 (1.732) 45,8 (1.803) 49 (1.929) 53 (2.087) 58 (2.283)

D

mm (in) 58,8 (2.315) 60 (2.362) 61,3 (2.413) 61,9 (2.437) 63,5 (2.500) 66 (2.598) 67,8 (2.669) 71 (2.795) 75 (2.795) 80 (3.150)

E

mm (in) 69,8 (2.748) 71 (2.795) 72,3 (2.846) 72,9 (2.870) 74,5 (2.933) 77 (3.031) 78,8 (3.102) 82 (3.228) 86 (3.386) 91 (3.583)

PLD 204 PLD 206,3 PLD 208 PLD 209 PLD 2011,2 PLD 2014 PLD 2016 PLD 2020 PLD 2025 PLD 2031,5 D024-004

004

19

Polaris

HOW TO ORDER

Only for ver sion with val ve

1

PLD 20 /

Se ries

2

3

10

11

12

V

/ CS - GE / 25 - GD / 25 - GD / CI - GE / 25 - GD / CD - GE / VPEF - 50 - GD Left in let sec tion

Sec tion

Sec tion

/ let sec tion /

Interm . i n -

Sec tion

Right in let sec tion

Re lief val v e

1

Po la ris 1 0 Po la ris 2 0

Series

CODE PLD 10 PLD 20

CODE

Outlet port dimensions

PLD 10 PLD 20

BRITISH STANDARD PIPE PARALLEL (BSPP)

GC GD

Number of sections

CODE 2 ... 6 CODE CS

From 2 to 6 sec tions

SAE STRAIGHT THREAD PORTS (ODT)

OA PLD 10 PLD 20 OC CODE

Standard side inlet section

Left in let section (1)

Intermediate inlet section (2)

Inter me dia te in let sec tion

4

PLD 1 0 PLD 2 0

Inlet port dimensions

CODE

CI CODE CD CODE VPEF CODE

BRITISH STANDARD PIPE PARALLEL (BSPP)

GD GE

Supplementary inlet section (2) 8

Right in let sec tion (1)

SAE STRAIGHT THREAD PORTS (ODT)

PLD 1 0 PLD 2 0 OB OD

Relief alve

Re lief alve

Valve setting [bar]

See page 3

10

Displacement

cu in/rev

CODE

.... CODE

Polaris 10

0.12 0.19 0.24 0.30 0.38 PLD 10-2 PLD 10-3,15 PLD 10-4 PLD 10-5 PLD 10-6,3

T Outlet port dimensions

PLD 10 PLD 20

11

BRITISH STANDARD PIPE PARALLEL (BSPP)

GC GD

SAE STRAIGHT THREAD PORTS (ODT)

OA PLD 10 PLD 20 OB CODE .... V Buna (3) Viton

Polaris 20

0.29 0.39 0.50 0.67 0.87 1.01 1.27 1.58 1.99 PLD 20-4 PLD 20-6,3 PLD 20-8 PLD 20-11,2 PLD 20-14 PLD 20-16 PLD 20-20 PLD 20-25 PLD 20-31,5

Seals

12

(1) Looking at the sections from the outlet ports side. (2) Choice the inlet sections number according to the general data on page 4 and 5. (3) Omit this code for Buna seals.

CASAPPA S.p.A. - Parma - Italy - Tel.: (+ 39) 0521 304111 - Fax: (+ 39) 0521 804600

CASAPPA Corp. - Batavia, IL 60510 U.S.A. - Phone: 630 761-0041 - Fax: 630 761-0048 CASAPPA GmbH - Stuttgart - Germany - Tel.: + 49 711 7811770 - Fax: + 49 711 7811771 CASAPPA SARL - Janneyrias - France - Tel.: + 33 4 72462112 - Fax: + 33 4 72462100 http://www.casappa .com - e-mail: info@casappa.com

You might also like

- 330 CDocument2 pages330 CMarco Olivetto0% (1)

- Transmission Circuit RecommendationsDocument40 pagesTransmission Circuit RecommendationsanandsubbiahNo ratings yet

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocument10 pagesHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataNo ratings yet

- MHV Proportional Directional Control Valve Series MHV... K: FeaturesDocument28 pagesMHV Proportional Directional Control Valve Series MHV... K: FeaturesthijssilderhuisNo ratings yet

- A11vo 130 Lrdu2Document1 pageA11vo 130 Lrdu2xxsh100% (1)

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Sop For Eco SystemDocument6 pagesSop For Eco SystemSonratNo ratings yet

- Cat 797F Sist HyDocument6 pagesCat 797F Sist HyJorge Mendoza100% (1)

- Mcv110 Valve PilotDocument8 pagesMcv110 Valve PilotJose Manuel Bautista Martinez100% (1)

- 2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFDocument28 pages2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFVelibor Karanović100% (1)

- HydraulicsDocument253 pagesHydraulicsvelavansuNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Industrial Hydraulic CircuitsDocument16 pagesIndustrial Hydraulic CircuitskingkakingNo ratings yet

- Unloading Pressure Hk66j102Document12 pagesUnloading Pressure Hk66j102seaqu3stNo ratings yet

- Design and Optimation of Arm ExcavatorDocument6 pagesDesign and Optimation of Arm Excavatoranon_664850107No ratings yet

- 3D-07-13F1-135 SP3D+Operator+Training+Guide+ Lab8+Piping+Task ENDocument34 pages3D-07-13F1-135 SP3D+Operator+Training+Guide+ Lab8+Piping+Task ENHarry Laksana100% (1)

- Clickable List: E - HydraulicsDocument9 pagesClickable List: E - Hydraulicssaeed65No ratings yet

- Hydraulic TechnologyDocument76 pagesHydraulic TechnologyOgulcan CafNo ratings yet

- 2011, Sauer Danfoss, ElectroHydraulic ActuatorDocument88 pages2011, Sauer Danfoss, ElectroHydraulic ActuatorVelibor KaranovićNo ratings yet

- 2011, Sauer Danfoss, ElectroHydraulic ActuatorDocument88 pages2011, Sauer Danfoss, ElectroHydraulic ActuatorVelibor KaranovićNo ratings yet

- CM p4766 69 SJTP Issue ADocument53 pagesCM p4766 69 SJTP Issue Azzz zzzNo ratings yet

- Re91401 A2foDocument20 pagesRe91401 A2foTaz Juan GNo ratings yet

- Pos.14 - Hydrokraft Piston Pump - PVW - 2016Document73 pagesPos.14 - Hydrokraft Piston Pump - PVW - 2016Дмитрий МазуренкоNo ratings yet

- Aa2fm Model CodeDocument27 pagesAa2fm Model CodeCristianNo ratings yet

- Rexroth 92500Document48 pagesRexroth 92500EVCY100% (1)

- Salami Catalog Group3 Zupcaste PumpeDocument32 pagesSalami Catalog Group3 Zupcaste Pumpeado_22No ratings yet

- Slayer Series Product BookletDocument16 pagesSlayer Series Product BookletLorcán McGrathNo ratings yet

- Wind RowerDocument234 pagesWind RowercengizyurdalNo ratings yet

- Hyd Power Unit 5831Document119 pagesHyd Power Unit 5831Victor RoblesNo ratings yet

- Repair Parts Sheet RC-25 Series Hydraulic Cylinders RC-256, RC-258, RC-2510, RC-2512, RC-2514Document2 pagesRepair Parts Sheet RC-25 Series Hydraulic Cylinders RC-256, RC-258, RC-2510, RC-2512, RC-2514JonathanDavidDeLosSantosAdornoNo ratings yet

- Nagel PLC Upgradtion ProjectDocument35 pagesNagel PLC Upgradtion Projectnarendramaharana39No ratings yet

- Load Control - Holding ValvesDocument1 pageLoad Control - Holding ValvesGeorge BasnoNo ratings yet

- Air Driven Hydraulic PumpsDocument32 pagesAir Driven Hydraulic Pumpsdejanr111No ratings yet

- Floor Loading BrochureDocument19 pagesFloor Loading BrochurefgfdgfdgdfgNo ratings yet

- ST-1001 ManualDocument57 pagesST-1001 ManualSoo SeoNo ratings yet

- Hydraulic Commissioning ManualDocument7 pagesHydraulic Commissioning Manualranjit2150No ratings yet

- Use and Maintenance Manual: Spider 13.80 RadioDocument146 pagesUse and Maintenance Manual: Spider 13.80 RadioMario HurtadoNo ratings yet

- 09-CB Counterbalance Valves CatalogDocument46 pages09-CB Counterbalance Valves CatalogFederico TomiNo ratings yet

- High Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)Document26 pagesHigh Torque Geared Motors: T 238.000 NM Output Torque (175.500 LBF - FT)SAKDA MAPRADITKULNo ratings yet

- Combination Module PVGI Tech NoteDocument8 pagesCombination Module PVGI Tech NoteHYDRAULICGURU100% (1)

- BLN 9884Document24 pagesBLN 9884Rachan EngchanilNo ratings yet

- TroubleshootingDocument7 pagesTroubleshootingg665013No ratings yet

- Eaton Walterscheid TrilogyDocument12 pagesEaton Walterscheid TrilogyM MNo ratings yet

- Katalog Hagglunds Motor CBM TypeDocument28 pagesKatalog Hagglunds Motor CBM TypeRudianto SakkaNo ratings yet

- Field Testing of A Closed Loop PumpDocument4 pagesField Testing of A Closed Loop Pumpmagarmat1980No ratings yet

- PVG16Document60 pagesPVG16Cesar Muñoz OssesNo ratings yet

- Cylinders FullDocument110 pagesCylinders FulltnvishNo ratings yet

- MSC Disertation CANopen IO Card ImplementationDocument158 pagesMSC Disertation CANopen IO Card ImplementationMosab YaseenNo ratings yet

- A Complete Mechanics of Solid Lab Test ManualDocument38 pagesA Complete Mechanics of Solid Lab Test ManualAli ZafarNo ratings yet

- HDM HDS - 100 P 000040 e 02Document10 pagesHDM HDS - 100 P 000040 e 02Eng-Mohammed SalemNo ratings yet

- Steering SystemsDocument48 pagesSteering SystemsOscar Coaquira FelicianoNo ratings yet

- Installation and Commisioning of Servo & Propotional Control ValvesDocument3 pagesInstallation and Commisioning of Servo & Propotional Control ValvesIdehen KelvinNo ratings yet

- WalvoilDocument64 pagesWalvoilSamad A BakarNo ratings yet

- Hydraulics CatalogueDocument4 pagesHydraulics Catalogueanushka_desilvaNo ratings yet

- Hydraulic Valves DSVDocument87 pagesHydraulic Valves DSVMuhammadNo ratings yet

- Solenoid Control Hk66o102Document40 pagesSolenoid Control Hk66o102seaqu3stNo ratings yet

- Re77502 2004-05Document20 pagesRe77502 2004-05pamururamuNo ratings yet

- 5500 Centrifuge Hydraulic Backdrive Operations ManualDocument138 pages5500 Centrifuge Hydraulic Backdrive Operations ManualTaher Yusuf0% (1)

- Temperature Sensors From Ifm. A Selection Guide.Document17 pagesTemperature Sensors From Ifm. A Selection Guide.ifm electronicNo ratings yet

- Vacon NX OPTC6 CanOpen Board User Manual DPD00896ADocument48 pagesVacon NX OPTC6 CanOpen Board User Manual DPD00896ATanuTiganuNo ratings yet

- 5892 - Timken Bearing Damage Analysis PDFDocument36 pages5892 - Timken Bearing Damage Analysis PDFedgarpol100% (1)

- TT US Ctrbal POCk-Oct-2016N PDFDocument10 pagesTT US Ctrbal POCk-Oct-2016N PDFKemalNo ratings yet

- Hydraulic Planetary Recovery Winch: Installation, Maintenance, and Service ManualDocument45 pagesHydraulic Planetary Recovery Winch: Installation, Maintenance, and Service ManualQC RegianNo ratings yet

- Gear Pump Division: Rotary Flow Dividers and Pressure IntensifiersDocument33 pagesGear Pump Division: Rotary Flow Dividers and Pressure IntensifiersMehdi MansourianNo ratings yet

- Technical Manual ICVD 1111Document24 pagesTechnical Manual ICVD 1111Angelo MedinaNo ratings yet

- Block Making Machine - Types & FeaturesDocument6 pagesBlock Making Machine - Types & FeaturesVikas MishraNo ratings yet

- Divisor Pld-02-T-ADocument20 pagesDivisor Pld-02-T-ADANIZACHNo ratings yet

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- 2000, Barrett, M.,Analytical Ferrography - Make It Work For YouDocument6 pages2000, Barrett, M.,Analytical Ferrography - Make It Work For YouVelibor KaranovićNo ratings yet

- 2008, Potteiger, J.,Why Oil Goes BadDocument3 pages2008, Potteiger, J.,Why Oil Goes BadVelibor KaranovićNo ratings yet

- Contamination Technical ArticleDocument18 pagesContamination Technical Articlechandushar1604No ratings yet

- 2005, Badal, L.,The Importance of ISO Cleanliness CodesDocument4 pages2005, Badal, L.,The Importance of ISO Cleanliness CodesVelibor KaranovićNo ratings yet

- 2002, Briski, M.,Znacaj Analize MazivaDocument10 pages2002, Briski, M.,Znacaj Analize MazivaVelibor KaranovićNo ratings yet

- 2008, Safwat, A.,Filter Analysis Describes The History of WearDocument3 pages2008, Safwat, A.,Filter Analysis Describes The History of WearVelibor KaranovićNo ratings yet

- 1980, Tribology in Industry, Vol 2, No 3Document23 pages1980, Tribology in Industry, Vol 2, No 3Velibor KaranovićNo ratings yet

- 2013, Oil Analyzers Inc.,Fluid Analysis ProgramDocument16 pages2013, Oil Analyzers Inc.,Fluid Analysis ProgramVelibor KaranovićNo ratings yet

- 2008, Eaton, Flow DividersDocument20 pages2008, Eaton, Flow DividersVelibor KaranovićNo ratings yet

- Bio DepositDocument22 pagesBio DepositVelibor KaranovićNo ratings yet

- 2010, Fitch, J.,Today's Oil Detectives Have A New Bag of TricksDocument3 pages2010, Fitch, J.,Today's Oil Detectives Have A New Bag of TricksVelibor KaranovićNo ratings yet

- Blind Guardian - Bards SongDocument6 pagesBlind Guardian - Bards SongVelibor KaranovićNo ratings yet

- 1980, Tribology in Industry, Vol 2, No 4Document19 pages1980, Tribology in Industry, Vol 2, No 4Velibor KaranovićNo ratings yet

- 1980, Tribology in Industry, Vol 2, No 2Document25 pages1980, Tribology in Industry, Vol 2, No 2Velibor KaranovićNo ratings yet

- 1980, Tribology in Industry, Vol 2, No 2Document25 pages1980, Tribology in Industry, Vol 2, No 2Velibor KaranovićNo ratings yet

- 1979, Tribology in Industry, Vol 1, No 3Document32 pages1979, Tribology in Industry, Vol 1, No 3Velibor KaranovićNo ratings yet

- 1979, Tribology in Industry, Vol 1, No 4Document27 pages1979, Tribology in Industry, Vol 1, No 4Velibor KaranovićNo ratings yet

- 1980, Tribology in Industry, Vol 2, No 1Document26 pages1980, Tribology in Industry, Vol 2, No 1Velibor KaranovićNo ratings yet

- 1999, Eaton Vickers, Hydraulic Fluid Recommendations PDFDocument3 pages1999, Eaton Vickers, Hydraulic Fluid Recommendations PDFVelibor KaranovićNo ratings yet

- 2004, CETOP, Hydraulics Programme (H1) - SeminarDocument10 pages2004, CETOP, Hydraulics Programme (H1) - SeminarVelibor KaranovićNo ratings yet

- 2012, Christopher, J.,Hydraulics Provide A Versatile Solution PDFDocument11 pages2012, Christopher, J.,Hydraulics Provide A Versatile Solution PDFVelibor KaranovićNo ratings yet

- 1979, Tribology in Industry, Vol 1, No 2Document31 pages1979, Tribology in Industry, Vol 1, No 2Velibor KaranovićNo ratings yet

- 1979, Tribology in Industry, Vol 1, No 1Document35 pages1979, Tribology in Industry, Vol 1, No 1Velibor KaranovićNo ratings yet

- 2012, Nippon Accumulator, Accumulator Sizing Procedure PDFDocument8 pages2012, Nippon Accumulator, Accumulator Sizing Procedure PDFVelibor KaranovićNo ratings yet

- 2010, Engineering Review, Keeping The Hydraulic System HealthyDocument3 pages2010, Engineering Review, Keeping The Hydraulic System HealthyVelibor KaranovićNo ratings yet

- Sc4379-461-01 Fo Service SystemDocument12 pagesSc4379-461-01 Fo Service SystemChandni JhaNo ratings yet

- Technical Offer Rev 0 - OptDocument47 pagesTechnical Offer Rev 0 - OptRafeek AliNo ratings yet

- Valvula de Control DireccionDocument5 pagesValvula de Control DireccionRafael RodriguezNo ratings yet

- Model Question (Hydraulic Structures)Document5 pagesModel Question (Hydraulic Structures)Debanjan Banerjee71% (7)

- Item Canvassed Report: Category Item Description UnitDocument9 pagesItem Canvassed Report: Category Item Description UnitNino Joycelee TuboNo ratings yet

- Fire and Safety Certification Training ChennaiDocument9 pagesFire and Safety Certification Training ChennaiConserve AcademyNo ratings yet

- Penawaran Harga 0102Document4 pagesPenawaran Harga 0102Diana PutriNo ratings yet

- Installation - Maintenance Manual F15 and F30 Series 150 and 300 Lb. Flanged Full Port Ball ValvesDocument5 pagesInstallation - Maintenance Manual F15 and F30 Series 150 and 300 Lb. Flanged Full Port Ball ValvesBureau VeritasNo ratings yet

- Saudi Aramco FRM - Inspectable - Items - XLSX 3 6 2019Document1,252 pagesSaudi Aramco FRM - Inspectable - Items - XLSX 3 6 2019584222584No ratings yet

- BMS Timers ListDocument1 pageBMS Timers ListJawad AslamNo ratings yet

- PT. Guna Karya Mekanika: Engineering Procurement and ContractingDocument1 pagePT. Guna Karya Mekanika: Engineering Procurement and ContractingHukleberipenNo ratings yet

- Ball Valves: Code Item Description Current StockDocument21 pagesBall Valves: Code Item Description Current StockMuhammad RidwanNo ratings yet

- BETE WaterandAirFlow DataDocument2 pagesBETE WaterandAirFlow DataChevronelleNo ratings yet

- Booster Pump Submittal PackageDocument5 pagesBooster Pump Submittal PackageMohammad Mustafa AkbariNo ratings yet

- Dresser Pilot PSVDocument72 pagesDresser Pilot PSVKuldeep28883No ratings yet

- 7 Types of Pumps - GPTDocument3 pages7 Types of Pumps - GPTnatee8632No ratings yet

- Cotizacion NetafinDocument3 pagesCotizacion NetafinDiogenes AndradeNo ratings yet

- Enerpac P392FP CatalogDocument1 pageEnerpac P392FP CatalogTitanplyNo ratings yet

- Lec 40Document33 pagesLec 40khaledaj1977No ratings yet

- Theory of Pressure Relief, 1Document6 pagesTheory of Pressure Relief, 1petrochemNo ratings yet

- Legris Compression Fitting With PLDocument36 pagesLegris Compression Fitting With PLhannahveluz_iasNo ratings yet

- GHEE PLANT-Model - PDF ISODocument1 pageGHEE PLANT-Model - PDF ISONarasimman NarayananNo ratings yet

- Crane Main Directional Control ValveDocument4 pagesCrane Main Directional Control ValveMiguelNo ratings yet

- Me401A Lab Report: Experiment Number: 2 Group Number: B2Document7 pagesMe401A Lab Report: Experiment Number: 2 Group Number: B2Rishu KatiyarNo ratings yet

- Orange County Utilities Water Division Backflow Prevent Er Field Test ReportDocument1 pageOrange County Utilities Water Division Backflow Prevent Er Field Test ReportRoNo ratings yet