Professional Documents

Culture Documents

Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets

Uploaded by

Lindy KhoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets

Uploaded by

Lindy KhoCopyright:

Available Formats

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A.

, "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

SHEAR STRENGTHENING OF CONTINUOUS RC BEAMS USING EXTERNALLY BONDED CFRP SHEETS

Ahmed Khalifa, Gustavo Tumialan, Antonio Nanni, and Abdeldjelil Belarbi

Synopsis: This paper presents the results of an experimental investigation on the response of continuous reinforced concrete (RC) beams with shear deficiencies, strengthened with externally bonded carbon fiber reinforced polymer (CFRP) sheets. The experimental program consisted of nine full-scale, two-span, continuous beams with rectangular cross section. The tested beams were grouped into three series. Three beams, one from each series, were not strengthened and taken as reference beams, whereas, six beams were strengthened using different schemes. The variables investigated in this study included the amount of steel shear reinforcement, amount of CFRP, wrapping schemes, and 900/00 ply combination. The experimental results indicated that the contribution of externally bonded CFRP to the shear capacity of continuous RC beams is significant and is dependent on the tested variables. In addition, the test results were used to validate shear design algorithms. The proposed algorithms show good correlation with the test results and provided conservative estimates.

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

Ahmed Khalifa, ACI member, is a visiting doctoral candidate in the Department of Civil Engineering, University of Missouri at Rolla, USA. He received his BSc and MSc from Alexandria University, Egypt. His area of interest includes structural engineering, materials science, and concrete structural rehabilitation. He is a member of ASCE. Gustavo Tumialan, is a PhD candidate in the Department of Civil Engineering, University of Missouri at Rolla, USA, where he received his MSc. He pursued his undergraduate studies at the Pontificia Universidad Catolica del Peru. His area of interest includes structural engineering, construction, concrete and masonry rehabilitation. Antonio Nanni, FACI, is the V&M Jones Professor of Civil Engineering and Director of the University Transportation Center (UTC) at the University of Missouri-Rolla. Dr. Nanni is interested in construction materials, their structural performance, and field application. He is an active member in the technical committees of ACI, ASCE, ASTM and TMS. Abdeldjelil Belarbi, ACI member, is an Associate Professor of Civil Engineering at the University of Missouri - Rolla. His area of interest is the constitutive modeling of reinforced and prestressed concrete as well as the use of advanced materials in new construction and strengthening of civil infrastructures. He is an active member of several ACI technical and educational committees.

INTRODUCTION Shear collapse of RC members is catastrophic and occurs with no advance warning of distress. Existing RC beams with shear deficiencies ultimately need strengthening. Deficiencies may occur due to factors such as insufficient shear reinforcement, reduction in steel area due to corrosion, increased service load, and design/construction defects. In such situations, it has been shown that externally bonded FRP sheets increase the shear capacity significantly (1, 2). At present, most of the studies have specifically addressed simply supported beams. The objectives of this study were to investigate the shear behavior and mode of failure of continuous RC beams strengthened with CFRP sheets and to validate a proposed shear design approach (3, 4).

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

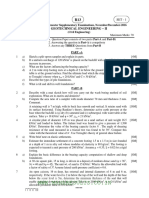

EXPERIMENTAL PROGRAM Test Specimens and Materials The experimental program consisted of nine full-scale, two-span, continuous RC beams with a rectangular cross section of 150 by 305 mm. The beams were grouped into three series labeled CW, CO, and CF (Fig 1). Each series had different longitudinal and transverse steel reinforcement ratios.

Stirrups @125 1375 Stirrups @ 80 915 Stirrups @ 125 2290 305 150

300

4880 (a) Series CW 305 Stirrups @125 2290 300 No stirrups 915 Stirrups @125 1375 150

4880 (b) Series CO 305 150 460 1830 300 4880 (c) Series CF 2 D 32 Stirrups D =10 2 D 32 150 (d) Specimen cross-section for Series CW and CO Dimensions in mm 305 2 D 16 Stirrups D = 10 2 D 16 150 (e) Specimen cross-section for Series CF Strain gauge location 305 1830 460

Figure 1. Beam specimens detailing and dimensions Series CW consisted of two beams tested over a total span of 4,880 mm as shown in Fig. 1(a). The central support consisted of a 300-mm offset intended to

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

represent the intersection with a column. The concrete strength was 27.5 MPa. In this series, two 32-mm bars were used as longitudinal reinforcement for both top and bottom face of the cross section to favor shear failure. The beams were reinforced with 10-mm stirrups throughout. The stirrup spacing in the shear span of interest was selected to force failure in that span. For each beam, six strain gauges were attached to three stirrups to monitor the stirrup strain during loading. Series CO consisted of three beams, and had similar longitudinal reinforcement as that of series CW (Fig. 1(b)). No steel stirrups were provided in the tested shear span. The concrete strength for this series was 20.5 MPa. Four beams were tested in series CF (Fig. 1(c)). The concrete strength for this series was 50 MPa. The beams were reinforced with two 16-mm longitudinal steel bars on both top and bottom faces with no shear reinforcement. The mechanical properties of the materials used for manufacturing the test specimens are listed in Table 1. Fabrication of the specimens including surface preparation and CFRP installation is described elsewhere (4). Table 1 Materials properties

Material Specifications Series CW Series CO Series CF D = 32 mm D = 16 mm D = 10 mm t = 0.165 mm Compressive strength (MPa) 27.5 20.5 50.0 ------------Yield point (MPa) ---------460 430 350 ---Ultimate tensile strength (MPa) ---------730 700 530 3500 Modulus of elasticity (GPa) 25 22 33 200 200 200 228

Concrete

Steel CFRP* *Fiber only

Strengthening Schemes and Test Set-up One beam from each series (CW1, CO1, and CF1) was not strengthened and was considered as a reference beam, whereas six beams were strengthened with externally bonded CFRP sheets following different schemes. The test setup as well as the strengthening schemes are shown in Fig. 2. In series CW, beam CW2 was strengthened with two CFRP plies having perpendicular fiber directions (900/00). The first ply was attached in the form of continuous U-wrap with fiber direction oriented perpendicular to the longitudinal axis of the beam (900). The second ply was bonded to the two sides of the beam with fiber direction parallel to the beam axis (00). This ply may provide additional resistance to the horizontal component of the crack opening.

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

Load cell

Load

Steel distribution beam

305 Load cell 460 915 150 150 915 915 915 (a) Beams CW1, CO1, and CF1 (reference beams) 460

(b) Beams CW2 and CF3 (CFRP 90 / 0 )

(c) Beam CO2 (CFRP strips)

(d) Beams CO3 and CF2 (CFRP 90 , U-wrap)

(e) Beam CF4 (CFRP 90 , totally wrapped) LVDT Strain gauge Dimensions in mm

Figure 2. Test set-up and strengthening schemes Two beams were strengthened in series CO. Beam CO2 was strengthened with one-ply CFRP strips in the form of a U-wrap with 900 fiber orientation. The strip width was 50 mm with center-to-center spacing of 125 mm. Beam CO3 was strengthened with one-ply continuous U-wrap.

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

In series CF, three beams were strengthened. Beam CF2 was strengthened with one-ply continuous U-wrap. Beam CF3 was strengthened with two CFRP plies having perpendicular fiber directions (900/00). Beam CF4 was totally wrapped with one-ply CFRP sheets. The sheets were attached to the four sides of the beam with an overlap on the top side. Even though total wrapping may not be possible in the field, this case is representative of the upper threshold. Specimens were tested as continuous beams under concentrated loads applied to the mid-point of each span. Two load cells were used to monitor total applied load and reaction at the span of interest. This allowed the computation of the exact shear force in the span of interest, independently of re-distribution phenomena. The load was applied progressively in few cycles, usually one cycle before cracking followed by three cycles to ultimate. The shear force versus deflection curves shown in this study are the envelopes of these load cycles. Five linear variable differential transformers (LVDTs) were used for each test to monitor the vertical displacement at various locations as shown in Fig. 2. Of these five LVDTs, one was placed at each support to monitor support movement. Three strain gauges were attached directly to the FRP on the sides of each strengthened beam of series CW and CO, and six in beams of series CF as shown in Fig. 2. The strain gauges were oriented in the vertical direction and located at mid-height with distances of 175, 300, and 425 mm from the face of the central support.

Test Results and Discussion In the following discussion, reference is always made to the weak shear span (span of interest). Series CW: A diagonal crack was observed in beam CW1 close to the middle of the shear span when the load was approximately 150 kN. As the load increased, more diagonal shear cracks formed throughout, widened and propagated up to failure, as shown in Fig. 3, at a load of 508 kN which corresponded to a shear force of 175kN. In beam CW2, strengthened with CFRP (900/00), the cracks on the beam sides and bottom were not visible because of the wrapping. Longitudinal cracks were observed on the beam topside at total applied load of 530 kN. The cracks initiated close to the position of the applied load and extended towards the middle support. At failure, the concrete cover on the top side was extensively damaged (Fig. 4). The failure occurred at a total load of 623 kN with a corresponding shear force of 214 kN, a 22% increase in shear capacity as compared to CW1. The applied shear force versus mid-span deflection curves for beams CW1 and CW2 are shown in Fig. 5. The maximum CFRP strain measured at failure in beam CW2 was about 0.0027 mm/mm, which corresponded to 17% of the ultimate strain. This indicates that CFRP can be stretched further and thus increase the shear capacity if properly used.

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

Figure 3. Final failure of beam CW1

Figure 4. Final failure of beam CW2

250 200 Shear force (kN) 150 100 50 0 0 5 10 15 20 25 30 M id-span deflection (m m)

CW 1 CW 2

35

Figure 5. Shear force versus mid-span deflection for beams of series CW

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

In beam CW1, only the third stirrup at distance of 300 mm from face of middle support yielded at ultimate. Comparisons between localized stirrup strains in beams CW1 and CW2 are shown in Fig. 6. The stirrup strains in beam CW2 were smaller than those in beam CW1 at the same load level due to the effect of CFRP.

250 200 Shear force (KN) 150 100 50 0 0 0.5 1 1.5 Stirrup strain (mm/m)

stirrup 1 CW1 stirrup 2 CW1 stirrup 3 CW1 stirrup 1 CW2 stirrup 2 CW2 stirrup 3 CW2

2.5

Figure 6. Shear force versus stirrup strains for beams of series CW Series CO: Series CO showed the largest increase in shear capacity compared to the other series studied in this research. In beam CO1, the reference beam, the first diagonal shear crack was observed at a total load of about 90 kN. As the load increased, more shear cracks appeared throughout the shear span. When the total load reached 145 kN, the corresponding shear force peaked and remained constant thereafter at about 48 kN, while the total load increased to its peak of 220 kN. The relatively large amounts of top and bottom longitudinal steel reinforcement (D=32 mm) kept the beam as one piece until total damage of concrete occurred. In beam CO2, strengthened with CFRP strips, the first diagonal shear crack was observed at a load approximately 140 kN. Failure occurred at the total load of 265 kN due to debonding of the CFRP strips over the main shear crack. The applied shear force at ultimate was 88 KN, an 83% increase in shear capacity over the reference beam CO1. The maximum local vertical CFRP strain at beam failure was 0.0047 mm/mm. Experimental results in terms of applied shear force versus mid-span deflection for beams of series CO are shown in Fig. 7. Beam CO3, which was strengthened with CFRP continuous U-wrap, failed by CFRP debonding at a total load of 330 kN. The applied shear force at ultimate was 113 kN, a 135% increase in shear capacity over the reference beam CO1. In this beam, longitudinal cracks were observed on the top side of the beam before failure just as it was observed in beam CW2.

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

120 100 Shear force (kN) 80 60 40 20 0 0 5 10 15 20 25 30 Mid-span deflection (mm)

CO1 CO2 CO3

35

Figure 7. Shear force versus mid-span deflection for beams of series CO The applied shear force versus vertical CFRP strain for beam CO3 is shown in Fig. 8. The maximum vertical strain in CFRP was about 0.0037 mm/mm. The strain gauges sg1, sg2, and sg3 were located at mid-height at distances of 175, 300, and 425 mm from the face of the middle support, respectively.

120 100 80 60 40 20 0 0 1 2 3 4 Vertical CFRPstrain (mm/m) sg1 sg2 sg3 5

Figure 8. Measured vertical CFRP strain for beam CO3 Series CF: The failure mode of beam CF1 was shear compression. Failure occurred at total load of 268 kN with a corresponding applied shear force of 93 kN. The use of continuous U-wrap oriented at 900 in beam CF2 caused a change in the final failure mode from shear to flexural. The recorded load at failure was 337 kN corresponding to a shear force of 119 kN, showing an increase of 28% over the reference beam CF1. Fig. 9 shows the experimental results of series CF in terms of shear force versus mid-span deflection. The maximum total applied load achieved by CF3 was 394 kN and the corresponding shear force was 131 kN

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

with increase of 40 and 10% over CF1 and CF2, respectively. The final failure was controlled by flexure. In beam CF4, flexural failure occurred at an applied load of 400 kN corresponding to a shear force of 140 kN. By comparing to the reference beam CF1, the capacity was increased by 50 percent. In addition, a large non-linear phase was recorded showing a notable increment in ductility.

160 140 Shear force (kN) 120 100 80 60 40 20 0 0 5 10 15 20 25 Mid-span deflection (mm)

CF1 CF2

CF3 CF4

30

35

Figure 9. Shear force versus mid-span deflection for beam of series CF

DESIGN APPROACH The design approach for computing the contribution of externally bonded CFRP reinforcement to the shear capacity of RC beams, in ACI Code format, was proposed in a previous research study (3). The model addressed the two possible failure mechanisms of CFRP reinforcement (either CFRP fracture or debonding). Furthermore, two limits on the contribution of CFRP shear reinforcement were proposed, the first limit was set to control the shear crack width and loss of aggregate interlock and the second to preclude web crushing. Also, the concrete strength and CFRP wrapping schemes were incorporated as design parameters. At first, the average bond strength and the effective bond length at CFRP debonding were based on work by Maeda et al.(5). Later, experimental and analytical results from Miller (6) modified the model by Maeda et al. and proposed new equations to predict the effective bond length and the ultimate load at CFRP debonding. Even though both models seemed to yield similar results in terms of ultimate load, the later has been adopted (4). Moreover, the design approach was extended to provide the shear design algorithms in Eurocode format in addition to ACI format.

10

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

In traditional shear design approaches, the shear strength of an RC section is the sum of the shear strengths of concrete and steel shear reinforcement. For beams strengthened with externally bonded FRP reinforcement, the shear capacity may be computed by the addition of a third term to account for the contribution of FRP. The proposed equation to compute CFRP contribution is similar to that for steel stirrups and consistent with ACI and Eurocode formats. In the equation, an effective average CFRP stress, ffe, smaller than its nominal strength, ffu, is used to replace the yield stress of steel. This effective stress is computed by applying a reduction coefficient, R, to the nominal CFRP strength, which is dependent on the governing mode of failure. Failure is governed by either fracture of CFRP reinforcement (at an average effective stress level below nominal strength due to stress concentrations), or debonding of the CFRP reinforcement. In either case, an upper limit of the reduction coefficient is established (Rmax.=0.006/fu where fu is the ultimate tensile CFRP strain) (4) in order to control shear crack width and loss of aggregate interlock. This limit is such that the average effective strain in CFRP materials at ultimate con not be greater than 0.006 mm/mm (without the strength reduction factor, , or the partial safety factor, f). In addition to the upper limit, two equations were proposed (one for each mode of failure) for the computation of the reduction coefficient (and thus the contribution of FRP). The lowest of the three reduction coefficients would control design. Comparing with all available test results in the literature to date, the design model showed acceptable and conservative estimates.(4)

Summary of Proposed Design Algorithms-ACI Format The proposed design algorithms for computing the shear capacity of RC beams strengthened in shear with externally bonded CFRP sheets are summarized below: The effective width of CFRP sheet, wfe, may be computed first according to the suggested bonded surface configuration (3). wfe = df Le wfe = df 2 Le If the sheet is in the form of a U-wrap without end anchor If the sheet is bonded to only the sides of the beam (1) (2)

Where df is the effective depth of CFRP shear reinforcement (usually equal to the effective beam depth, d, for rectangular sections and d-ts for T sections, where ts is the slab thickness) and Le is the effective bonded length (Le =75mm). The shear capacity of the section may be found by first computing the reduction coefficient, R, on the ultimate strength of the CFRP. The reduction coefficient should be taken as the least of:

11

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

R = 0.5622(f Ef)2 1.2188 (f Ef) + 0.778 (f'c )2 3 w fe [ R= 738.93 4.06 (t f E f )] 10 6 fu d f 0.006 R= fu

(3)

(4) (5)

In the above equations, Ef is the elastic modulus of CFRP in GPa, f is the CFRP area fraction (f = (2tf/bw)(wf/sf)), tf is the thickness of CFRP in mm, bw is the width of the beam cross section in mm, wf is the width of CFRP strip (Fig. 10 shows the dimensions used to define df, wf, , and sf), sf is the spacing of CFRP strips (the maximum spacing, sfmax. was suggested equal to wf + d/4), and fc is the nominal concrete compressive strength in MPa. Note that, Equation 3 provides R for failure mode controlled by CFRP fracture and applicable for f Ef 0.7 GPa, whereas Equation 4 describes the failure mode controlled by CFRP debonding and applicable for CFRP axial rigidity, tfEf, ranging from 20 to 90 GPa. Equation 4 may be disregarded if the sheet is wrapped entirely around the beam or an effective end anchor is used.

df

wf

sf (a)

wf

sf (b)

Figure 10. Dimensions used to define the area of FRP (a) Vertical FRP strips. (b) Inclined strips

The shear contribution of the CFRP, Vf, may then be found from the following expressions: ffe = R ffu Vf = (6) (7)

2 f c b w d A f f fe (sin + cos )d f Vs sf 3

Where, Af is the area of CFRP shear reinforcement (Af = 2tfwf), is the angle between fiber orientation and longitudinal axis of beam, and Vs is the nominal shear strength provided by stirrups. Note that if continuous vertical sheets are used, wf and sf should be equal. The shear capacity of the beam may finally be computed from:

12

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

Vn = 0.85(Vc + Vs) + 0.70Vf

(8)

Where is the strength reduction factor (suggested equal to 0.7 for CFRP contribution), Vn is the nominal shear strength, Vc is the nominal shear strength provided by concrete.

Shear Capacity of a CFRP Strengthened Section-Eurocode Format

The proposed design equation (Eq. 7) for computing the contribution of CFRP reinforcement may be rewritten in Eurocode format as Equation (9).

A f (f f e f ) (0.9d f ) (1 + cot ) sin [VRd2 (VRd1 + Vwd )] (9) sf Where Vfd is the design shear contribution of CFRP to the shear capacity, f is the partial safety factor for CFRP materials (suggested equal to 1.3), VRd2 is the maximum design shear force that can be carried without web failure, VRd1 is the design shear capacity of concrete, and Vwd is the design contribution of steel shear reinforcement. Vfd =

Comparison between Test Result and Calculated Values

The computed design contributions of CFRP in ACI code format, including the factor, to the shear strength of the tested beams CW2, CO2, and CO3 were 24.6, 16.5, and 41 kN, respectively. Compared to the experimental contributions, 39, 40, and 65 kN, the design algorithms give acceptable and conservative results.

CONCLUSIONS

In this study, the shear behavior and modes of failure of two-span continuous RC beams strengthened with CFRP sheets were investigated. The test results indicated that the externally bonded reinforcement can be used to enhance the shear capacity of the beams in positive and negative moment regions. For the beams tested in the experimental program, increases in shear strength ranged from 22 to 135%. Test results also indicated that the CFRP contribution is enhanced to a large degree for beams without stirrups than for beams with adequate steel shear reinforcement. The test results were used to validate design algorithms for computing the shear contribution of externally bonded CFRP sheets. The calculated values gave conservative results.

13

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

ACKNOWLEDGEMENTS

This work was conducted with partial support from the University Transportation Center on Advanced Materials and Non-Destructive Testing (NDT) Technologies based at the University of Missouri - Rolla. The Egyptian Cultural and Educational Bureau provided support to the first author.

REFERENCES

(1) Arduini, M., Nanni, A., Di Tommaso, A., and Focacci, F., Shear Response of Continuous RC Beams Strengthened with Carbon FRP Sheets, NonMetallic (FRP) Reinforcement for Concrete Structures, Proceeding of the Third Symposium, Vol. 1, Japan, Oct. 1997, pp. 459-466. (2) Triantafillou, T.C., Shear Strengthening of Reinforced Concrete Beams Using Epoxy-Bonded FRP Composites, ACI Structural Journal, Vol. 95 No. 2, March-April 1998, pp. 107-115. (3) Khalifa, A., Gold, W., Nanni, A., and Abdel -Aziz M. I., Contribution of Externally Bonded FRP to the Shear Capacity of RC Flexural Members, Journal of Composites for Construction - ASCE, Vol. 2, No. 4, Nov. 1998, pp. 195-202. (4) Khalifa, A., Shear Performance of Reinforced Concrete Beams Strengthened with Composites, Ph.D Thesis, Structural Engineering Department, Alexandria University, Egypt, 1999. (5) Maeda, T., Asano, Y., Sato, Y., Ueda, T., and Kakuta, Y., A Study on Bond Mechanism of Carbon Fiber Sheet, Non-Metallic (FRP) Reinforcement for Concrete Structures, Proceeding of the Third Symposium, Vol. 1, Japan, Oct. 1997, pp. 279-286. (6) Miller, B., Bond between Carbon Fiber Reinforced Polymer Sheets and Concrete, MSc Thesis, Department of Civil Engineering, University of Missouri, Rolla, MO, 1999.

14

Khalifa, A., Tumialan, G., Nanni, A. and Belarbi, A., "Shear Strengthening of Continuous RC Beams Using Externally Bonded CFRP Sheets," SP-188, American Concrete Institute, Proc., 4th International Symposium on FRP for Reinforcement of Concrete Structures (FRPRCS4), Baltimore, MD, Nov. 1999, pp. 995-1008.

Keywords:

Bond; Carbon fiber; Continuous beam; Externally bonded

reinforcement; Fiber reinforced polymer (FRP); Flexural strength; Reinforced Concrete; Shear strength; Strengthening

15

You might also like

- Fringe KnowlefringeDocument128 pagesFringe Knowlefringeddj.tech268No ratings yet

- Cahill FinalPaper) PDFDocument25 pagesCahill FinalPaper) PDFLindy KhoNo ratings yet

- EtabsDocument75 pagesEtabsIndira Kei83% (6)

- Tyfo SCH AnchorsDocument2 pagesTyfo SCH AnchorsLindy KhoNo ratings yet

- Seismic Retrofit of Concrete With FRPDocument12 pagesSeismic Retrofit of Concrete With FRPLindy KhoNo ratings yet

- Pss100 Guide (Canon Camera)Document0 pagesPss100 Guide (Canon Camera)mattytahaNo ratings yet

- Reinforced Concrete Beam DesignDocument8 pagesReinforced Concrete Beam DesignLindy Kho100% (1)

- Foci MeterDocument41 pagesFoci MeterPomchopUKNo ratings yet

- Shear StrengtheningDocument13 pagesShear StrengtheningLindy KhoNo ratings yet

- Traditional Type 1 Joint in Structural Steel - A Clear & Present DangerDocument13 pagesTraditional Type 1 Joint in Structural Steel - A Clear & Present DangerLindy KhoNo ratings yet

- Hint of IonDocument17 pagesHint of IonWilliam HobbaNo ratings yet

- Quantum Gravity Progress ReportDocument72 pagesQuantum Gravity Progress ReportLindy KhoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Types of HVAC SystemsDocument6 pagesTypes of HVAC Systemsm2110100% (1)

- Bezinal XPDocument2 pagesBezinal XPHeca WahyuniNo ratings yet

- Ch22 h3 Solutions PDFDocument4 pagesCh22 h3 Solutions PDFld393563No ratings yet

- Heat Treatment Methods for Improving Mechanical PropertiesDocument2 pagesHeat Treatment Methods for Improving Mechanical PropertiesDeshraj SehraNo ratings yet

- Investigatory Project File 2Document12 pagesInvestigatory Project File 2hepele8650No ratings yet

- Studying Pendulum MotionDocument13 pagesStudying Pendulum MotionMubashir AijazNo ratings yet

- Interference of Light: Presnted By: Jignasha PatelDocument16 pagesInterference of Light: Presnted By: Jignasha PatelBhargavNo ratings yet

- UeeDocument4 pagesUeeAditya ShrivastavNo ratings yet

- Computer Applications in Hydraulic Engineering EbookDocument310 pagesComputer Applications in Hydraulic Engineering EbookJavier F. Via GiglioNo ratings yet

- Astm A781 PDFDocument13 pagesAstm A781 PDFIslam Fawzy100% (6)

- 5000 Series Brochure - V1.1Document12 pages5000 Series Brochure - V1.1Yelena ObyazovaNo ratings yet

- CRE NotesDocument103 pagesCRE NotesShagun DahiyaNo ratings yet

- Chapter 1 7Document76 pagesChapter 1 7Ian ReyesNo ratings yet

- The Weather and The Seasons 53858Document2 pagesThe Weather and The Seasons 53858Aftiniei IulianNo ratings yet

- 5th IJSO-Test Solution PDFDocument7 pages5th IJSO-Test Solution PDFВук РадовићNo ratings yet

- WDM technology multiplies fiber capacity using laser wavelengthsDocument8 pagesWDM technology multiplies fiber capacity using laser wavelengthsAnkit SharmaNo ratings yet

- Pressure Die CastingDocument5 pagesPressure Die CastingIdrisNo ratings yet

- 4-Transfer Function and Modeling of Mechanical SystemDocument35 pages4-Transfer Function and Modeling of Mechanical SystemUsama KaleemNo ratings yet

- Model and Analyze Hydraulic SystemsDocument16 pagesModel and Analyze Hydraulic Systemsعلي كامل الاسديNo ratings yet

- International Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmDocument7 pagesInternational Journal of Heat and Mass Transfer: Matej Kranjc, Anze Zupanic, Damijan Miklavcic, Tomaz JarmOthman Ben CheikhNo ratings yet

- International Temperature Scale of 1990 PDFDocument4 pagesInternational Temperature Scale of 1990 PDFSamNo ratings yet

- Materials Science Course OutlineDocument4 pagesMaterials Science Course OutlineSalem GarrabNo ratings yet

- 8P2A.3 & 4 Newton's Laws of Motion PPT 2017Document52 pages8P2A.3 & 4 Newton's Laws of Motion PPT 2017Jerome Nicolas Jr. MoraNo ratings yet

- Torsion Shaft DesignDocument24 pagesTorsion Shaft DesignHARSHWARDHAN SINGH SENGARNo ratings yet

- Foxboro CFT50 Digital Coriolis Mass Flow TransmitterDocument4 pagesFoxboro CFT50 Digital Coriolis Mass Flow TransmitterPhaniNo ratings yet

- WWW - Manaresults.Co - In: Geotechnical Engineering - IiDocument1 pageWWW - Manaresults.Co - In: Geotechnical Engineering - IimaheshNo ratings yet

- Sae - Ams 2759-7B - 01.14Document15 pagesSae - Ams 2759-7B - 01.14Fahri YüzerNo ratings yet

- Ballistic impact responses of textile materialsDocument3 pagesBallistic impact responses of textile materialsLary LysuNo ratings yet

- Diffraction Property of WavesDocument4 pagesDiffraction Property of Wavessaed cabdiNo ratings yet

- An Introduction to Pulsed Dye LasersDocument9 pagesAn Introduction to Pulsed Dye LasersRavi AutiNo ratings yet