Professional Documents

Culture Documents

CC Related

Uploaded by

Italo JaureguiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CC Related

Uploaded by

Italo JaureguiCopyright:

Available Formats

cc_related.

fm Page 40 Monday, March 21, 2005 4:42 PM

DYNA-SYNC

RELATED PRODUCTS

HE Bushings

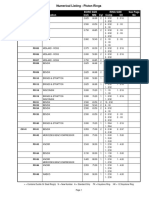

HE BUSHING DIMENSIONS

Bushing

HT Synchrous Belts

HE-25

HE-30

HE-35

HE-40

HE-45

HE-50

HE-60

HE-70

HE-80

HE-100

HE-120

Maximum

Bore

(in.)

2-1/2

3

3-1/2

4

4-1/2

5

6

7

8

10

12

L

(in.)

B.C.

(in.)

F

(in.)

H

(in.)

Number

of Bolts

2-1/4

2-3/4

3

3-1/2

4

4-1/2

5-1/4

6-1/4

7

9

10

3-15/16

4-11/16

5-9/16

6-5/16

7-5/16

8

9-1/4

10-9/16

12-1/8

14-1/2

17-1/2

3/4

7/8

7/8

1

1-1/4

1-1/2

1-3/4

2

2-1/4

3

3

4-5/8

5-5/8

6-5/8

7-1/2

8-3/4

9-5/8

11-1/8

12-3/4

14-1/2

17

20

4

4

4

4

6

6

6

6

6

6

8

Size of

Bolts

(in.)

3/8-16 x 1-3/4

1/2-13 x 2-1/4

9/16-12 x 2-1/4

5/8-11 x 2-1/2

5/8-11 x 2-1/2

3/4-10 x 3

7/8-9 x 3-1/2

1-8 x 4

1-1/8-7 x 4-1/2

1-1/4-7 x 5-1/2

1-1/4-7 x 5-1/2

Sprockets

Wrench Torque

Bushing

Conveyor Components

HE-25

HE-30

HE-35

HE-40

HE-45

HE-50

HE-60

HE-70

HE-80

HE-100

HE-120

Wrench

Torque

(ft.-lbs.)

30

60

90

140

140

200

350

500

500

600

600

HE-25 to HE120

Engineering

Details for TAPER-LOCK Bushings - See page PT6-2

Details for QD Bushings - See page PT6-15

FEATURES/BENEFITS

PAGES PT13-2 - PT13-3

SELECTION/DIMENSIONS

PAGE PT13-10

MODIFICATIONS/ACCESSORIES

PAGE PT13-35

PT13-40

ENGINEERING/TECHNICAL

PAGE PT13-43

HE-30

HE-35

HE-40

1

1-1/8

1-3/16

1-1/4

1-5/16

1-3/8

1-7/16

1-1/2

1-11/16

1-3/4

1-13/16

1-7/8

1-15/16

2

2-1/8

2-3/16

2-1/4

2-5/16

2-3/8

2-7/16

2-1/2

1-3/8

1-7/16

1-1/2

1-11/16

1-3/4

1-15/16

2

2-3/16

2-7/16

2-1/2

2-9/16

2-11/16

2-3/4

2-13/16

2-7/8

2-15/16

3

1-3/16

1-7/16

1-1/2

1-11/16

1-3/4

1-15/16

2

2-3/16

2-1/4

2-3/8

2-7/16

2-1/2

2-11/16

2-3/4

2-7/8

2-15/16

3

3-3/16

3-3/8

3-7/16

3-1/2

1-15/16

2-3/16

2-7/16

2-1/2

2-11/16

2-15/16

3-3/16

3-11/16

3-7/16

3-7/8

3-15/16

4

Part

No.

206623

206744

206615

206745

206747

206748

206617

206750

206752

206754

206756

206758

206619

206760

205997

206763

206765

206767

206768

206621

206770

206635

206625

206637

206639

206772

206627

206774

206775

206629

206777

206838

206631

206778

206779

206780

206633

206781

206648

206649

206784

206786

206839

206640

206788

206790

206792

206794

206642

206795

206796

206798

206800

206644

206801

206803

206840

206646

206807

206658

206659

206810

206811

206650

206652

206812

206813

206654

206841

206656

206815

FEATURES/BENEFITS

PAGES PT13-2 - PT13-3

Wt.

4

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

6

6

6

6

6

6

6

6

6

6

6

6

5

5

5

6

5

8

8

8

8

9

9

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

13

13

13

13

13

13

13

13

13

21

13

12

Bush.

No.

Bushing

Keyway

Shaft

Keyway

1/4 x 1/8

1/4 x 1/8

5/16 x 5/32

5/16 x 5/32

3/8 x 3/16

HE-45

3/8 x 3/16

HE-50

1/2 x 1/4

1/2 x 1/4

5/8 x 3/16

5/8 x 5/16

5/16 x 5/32

5/16 x 5/32

3/8 x 3/16

3/8 x 3/16

HE-60

HE-70

1/2 x 1/4

5/8 x 5/16

1/2 x 1/4

5/8 x 5/16

HE-80

3/4 x 1/8

3/4 x 3/8

1/4 x 1/8

1/4 x 1/8

3/8 x 3/16

3/8 x 3/16

1/2 x 1/4

1/2 x 1/4

5/8 x 5/16

5/8 x 5/16

HE-100

HE-120

3/4 x 3/8

3/4 x 3/8

Bore

1-15/16

2-7/16

2-15/16

3-7/16

3-1/2

3-15/16

4-3/16

4-7/16

4-1/2

2-15/16

3-7/16

3-15/16

4-7/16

4-15/16

5

3-15/16

4-1/4

4-7/16

4-15/16

5-7/16

5-1/2

5-15/16

6

5-15/16

6

6-7/16

6-1/2

6-15/16

7

6-7/16

7-1/2

6-15/16

7-7/16

7-15/16

8

7-1/2

7-15/16

8

8-1/2

8-15/16

9

9-1/2

10

8-1/2

9

9-1/2

10

10-1/2

11

11-1/2

12

Part

No.

206670

206660

206662

206664

206671

206666

206672

206668

206673

207998

206817

206818

206675

206677

206821

206686

206687

206688

206680

206682

206823

206684

206825

206690

207396

206692

206845

206694

206847

206700

206849

206702

206704

206706

206708

206710

206712

206718

206720

206714

206722

206724

206716

207380

207382

207384

207386

207388

207390

207392

207394

Wt.

22

22

22

22

22

21

21

21

21

30

40

35

29

23

50

47

65

50

49

40

49

38

72

71

71

71

69

69

111

105

108

105

102

100

200

198

195

193

196

191

189

190

415

395

375

353

330

308

285

261

Bushing

Keyway

1/2 x 1/4

5/8 x 5/16

3/4 x 3/8

Shaft

Keyway

1/2 x 1/4

5/8 x 5/16

3/4 x 3/8

7/8 x 7/16

7/8 x 7/16

1 x 1/2

1 x 1/2

1 x 1/4

1 x 1/2

7/8 x 7/16

7/8 x 7/16

1 x 1/2

1 x 1/2

1-1/4 x 1/4

1-1/4 x 5/8

1 x 1/2

1 x 1/2

1-1/4 x 5/8

1-1/4 x 5/8

1-1/2 x 1/4

1-1/2 x 3/4

1-1/2 x 3/4

1-1/2 x 3/4

1-3/4 x 1/4

1-3/4 x 3/4

1-1/2 x 3/4

1-1/2 x 3/4

1-3/4 x 3/4

1-3/4 x 3/4

2 x 3/4

2 x 3/4

1-3/4 x 3/4

1-3/4 x 3/4

2 x 3/4

2 x 3/4

2-1/2 x 7/8

2-1/2 x 7/8

2 x 3/4

2 x 3/4

2-1/2 x 7/8

2-1/2 x 7/8

3x1

3x1

Keys Furnished For These Sizes Only

HT Synchrous Belts

HE-25

Bore

Reborable HE Bushings

7/8 x 3/16

7/8 x 7/16

1/2 x 1/4

1/2 x 1/4

5/8 x 5/16

5/8 x 5/16

3/4 x 3/8

3/4 x 3/8

7/8 x 7/16

7/8 x 7/16

1 x 1/4

1 x 1/2

Bushing

Part

Number

Minimum

Bore

HE25

HE30

HE35

HE40

HE45

HE50

HE60

HE70

HE80

HE100

HE120

207960

207961

207962

207963

230794

207965

207966

207967

207968

207969

207970

15/16

15/16

1-3/16

1-15/16

1-15/16

2-15/16

3-7/16

4-7/16

5-7/16

6-15/16

7-15/16

SELECTION/DIMENSIONS

PAGE PT13-10

Maximum

Bore (in.)

Sq. Key

2-1/4

2-3/4

3-1/4

3-3/4

3-15/16

4-1/2

5-1/2

6-1/2

8

10

12

MODIFICATIONS/ACCESSORIES

PAGE PT13-35

PT13-41

Inch

Maximum

Bore (in.)

Shallow Key

2-1/2

3

3-1/2

4

4-1/2

5

6

7

-

Metric

Minimum

Maximum

Bore

Bore (mm)

(mm)

24

60

24

75

32

85

50

100

50

110

75

125

90

150

120

170

140

200

180

250

220

300

ENGINEERING/TECHNICAL

PAGE PT13-43

Engineering

Bush.

No.

Sprockets

HE Bushings

Conveyor Components

RELATED PRODUCTS

DYNA-SYNC

cc_related.fm Page 41 Monday, March 21, 2005 4:42 PM

cc_related.fm Page 42 Monday, March 21, 2005 4:42 PM

DYNA-SYNC

RELATED PRODUCTS

Keyless Locking Assemblies

The DODGE Pulley Pros have been designing and fabricating special pulleys with Keyless Locking Assemblies for

over 30 years. Hubs are computer designed for use with

single or dual locking assemblies.

HT Synchrous Belts

Keyless locking assemblies are available in two basic configurations short series and long series. Long series locking assemblies feature a longer length thru bore with a

corresponding increase in contact area between the locking assembly and the shaft and hub.

Most conveyor pulley applications require only one short

series locking assembly in each pulley hub to transmit the

bending and torsional moments. Heavier loaded pulleys

require long series or dual short series locking assemblies

to transmit increased loads. The DODGE Pulley Pros have

the experience and expertise to determine the best keyless

locking assembly configuration for any application.

Sprockets

DODGE Keyless Locking Assemblies are self-contained,

high torque capacity, shaft-hub locking devices. They provide many features and benefits to conveyor pulley assemblies, including no keyway stress concentration, no axial

movement during assembly, high torque capacity, and easy

assembly and disassembly. The locking assembly design

includes concentric, tapered rings. As the locking screws

are torqued, the locking assembly clamps down on the

shaft and expands into the hub bore, establishing a tight

mechanical shrink fit.

Short Series Locking Assembly

Long Series Locking Assembly

Conveyor Components

Short Series

Duplex Series

Locking Assembly

Long Series

Locking Assembly

Engineering

Available in Weld On Hub, Integral Hub or T-Section. See Page PT13-30.

FEATURES/BENEFITS

PAGES PT13-2 - PT13-3

SELECTION/DIMENSIONS

PAGE PT13-10

MODIFICATIONS/ACCESSORIES

PAGE PT13-35

PT13-42

ENGINEERING/TECHNICAL

PAGE PT13-43

You might also like

- Pressure Relief Grease Fittings GuideDocument2 pagesPressure Relief Grease Fittings GuidezhenyupanNo ratings yet

- Taperlock BushesDocument4 pagesTaperlock BushesthexsamNo ratings yet

- Tech Tips: Fitting Torque ChartDocument7 pagesTech Tips: Fitting Torque ChartAnthony David Martínez VallejoNo ratings yet

- PARTS LISTING TITLEDocument19 pagesPARTS LISTING TITLEJose Antonio Acosta Ortiz100% (1)

- Keystone Betterfly Valves AR1 y AR2 KEYMC-0025-USDocument4 pagesKeystone Betterfly Valves AR1 y AR2 KEYMC-0025-USpca97No ratings yet

- ChumaceraDocument42 pagesChumaceraJoseth Revilla OchoaNo ratings yet

- Lasco Fittings - Tech80Document14 pagesLasco Fittings - Tech80cario_mak_ainsworthNo ratings yet

- 5 Pipe FittingsDocument100 pages5 Pipe FittingsHaroon GhaniNo ratings yet

- Aurora A 03 201Document36 pagesAurora A 03 201macsosaNo ratings yet

- APV Delta SW4 (Seat Valve)Document7 pagesAPV Delta SW4 (Seat Valve)carherjiNo ratings yet

- Pocket Bolt Reference Chart: Sealing Global - Servicing LocalDocument2 pagesPocket Bolt Reference Chart: Sealing Global - Servicing Localgazwang478No ratings yet

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- D Series: Centrifugal PumpsDocument8 pagesD Series: Centrifugal PumpsdaniellizzardNo ratings yet

- World Flange StandardsDocument10 pagesWorld Flange StandardsIsaac KendallNo ratings yet

- Hand ToolsDocument98 pagesHand ToolsAndry Perdana PutraNo ratings yet

- Catalog Keystone Butterfly ValveDocument4 pagesCatalog Keystone Butterfly ValvePawrij Suriyaaroonroj100% (2)

- Designmate 3024/3036 Top Assembly and Final Assembly Illustrated Parts BreakdownDocument11 pagesDesignmate 3024/3036 Top Assembly and Final Assembly Illustrated Parts BreakdownSerge MaciaNo ratings yet

- Section B 30 Series PDFDocument6 pagesSection B 30 Series PDFPartsGopher.comNo ratings yet

- EIM CodeDocument1 pageEIM CodeRayan AlfredNo ratings yet

- Ac Brake Dat Series PetheDocument1 pageAc Brake Dat Series Pethekinner3No ratings yet

- Regulador Pilotado Mod. GP2000Document2 pagesRegulador Pilotado Mod. GP2000vanguevNo ratings yet

- High Pressure Ball ValvesDocument5 pagesHigh Pressure Ball ValvesNilesh MistryNo ratings yet

- Visual Index: Catalog 4400 USDocument17 pagesVisual Index: Catalog 4400 USPartsGopher.comNo ratings yet

- Detailed assembly drawings for gas separator towerDocument1 pageDetailed assembly drawings for gas separator towerDmmxy14No ratings yet

- ChillersDocument1 pageChillersJorge Lozano RizkNo ratings yet

- Xpag BoltsDocument9 pagesXpag BoltsNakkolopNo ratings yet

- Series 150 Flange Series 600 Flange Series 300 FlangeDocument4 pagesSeries 150 Flange Series 600 Flange Series 300 FlangeBhartendu PatniNo ratings yet

- Browning 307 ReducerDocument2 pagesBrowning 307 Reducercav444433% (3)

- Orttech Shaft Diameter Key Combinations TableDocument1 pageOrttech Shaft Diameter Key Combinations TableDan JeremyNo ratings yet

- Tchart PDFDocument3 pagesTchart PDFferdyak1No ratings yet

- Service Kit Pumpex PC2001Document8 pagesService Kit Pumpex PC2001Siding BarroNo ratings yet

- Manual Partes 1B40V-1B50V PDFDocument38 pagesManual Partes 1B40V-1B50V PDFromaldoagurtoNo ratings yet

- MDHC Inventory Part NumberDocument25 pagesMDHC Inventory Part NumberMiluco AntónNo ratings yet

- BS 10 1962Document3 pagesBS 10 1962S Prabakaran SanmugasundaramNo ratings yet

- Rotorseal Tech Specs PDFDocument19 pagesRotorseal Tech Specs PDFMykola TitovNo ratings yet

- Normas ChavetasDocument5 pagesNormas ChavetasjofeluNo ratings yet

- Dodge Bearings FC f4b P2b-Larrique Rulemanes S.A.Document122 pagesDodge Bearings FC f4b P2b-Larrique Rulemanes S.A.Wilson Nery Romero ArezoNo ratings yet

- Airnet Parts Catálogo Nuevo PDFDocument94 pagesAirnet Parts Catálogo Nuevo PDFcyathus123No ratings yet

- 3 Point LinkageDocument19 pages3 Point LinkageJack GibsonNo ratings yet

- Staffa: Accessories CatalogDocument6 pagesStaffa: Accessories CatalogSAKDA MAPRADITKULNo ratings yet

- Footer ValveDocument200 pagesFooter Valveali96161No ratings yet

- 1 - 8 - PTF Grease Fittings, 1 - 8 - PTF Zerk Fittings, 1 - 8 - PTF Lubrication FittingsDocument4 pages1 - 8 - PTF Grease Fittings, 1 - 8 - PTF Zerk Fittings, 1 - 8 - PTF Lubrication FittingszhenyupanNo ratings yet

- Product Dimensions: SDV Basic UnitDocument1 pageProduct Dimensions: SDV Basic UnitMiguel MancillaNo ratings yet

- Catalogo Anillos GrantDocument62 pagesCatalogo Anillos GrantOrlando SilvaNo ratings yet

- Series Style "H" Steel Frame Take-Ups... Setscrew Locking: Mounted Ball BearingsDocument1 pageSeries Style "H" Steel Frame Take-Ups... Setscrew Locking: Mounted Ball BearingsVladimir Illich PinzonNo ratings yet

- TPHK Series Immersible Pump Performance GuideDocument16 pagesTPHK Series Immersible Pump Performance GuideSparkboys SparkNo ratings yet

- G 61 Ilq 3 T 8 DKM 91 S 4Document41 pagesG 61 Ilq 3 T 8 DKM 91 S 4Dominador J. Santos Jr.No ratings yet

- Use With 781, 782TC, 782ST Hoses. Visual Index: Catalog 4400 USDocument10 pagesUse With 781, 782TC, 782ST Hoses. Visual Index: Catalog 4400 USPartsGopher.comNo ratings yet

- Cooper BearingsDocument4 pagesCooper BearingsChris BellNo ratings yet

- ANSI B16.1 Flanged CatalogDocument20 pagesANSI B16.1 Flanged Catalogjdsa123No ratings yet

- Guide To Steel Pipes For Vessels - Wide Flange Beams ExcelDocument195 pagesGuide To Steel Pipes For Vessels - Wide Flange Beams ExcelAlmario SagunNo ratings yet

- Rawmill LubricationDocument22 pagesRawmill Lubricationsivareddy143No ratings yet

- YORK Ventilation Con Vectors ENGDocument28 pagesYORK Ventilation Con Vectors ENGBulclimaNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- ISL Cummins EspecificacionesDocument2 pagesISL Cummins EspecificacionesItalo Giuliano Tronci Iriarte0% (2)

- HSC Crane scx1800Document56 pagesHSC Crane scx1800Abdur RahimNo ratings yet

- HGS-HSM-SL-21-001 - Improvement of Safety Function For DF EngineDocument6 pagesHGS-HSM-SL-21-001 - Improvement of Safety Function For DF Engineajshsu5682No ratings yet

- Yanmar 6AYM WET DatasheetDocument2 pagesYanmar 6AYM WET Datasheetafandybaharuddin100% (4)

- JsaDocument106 pagesJsaRoy Dwi PrasetyoNo ratings yet

- BECK USA Electrical ActuatorsDocument56 pagesBECK USA Electrical ActuatorsnprashanNo ratings yet

- Introduction Letter Format Sga 01.07.2017Document4 pagesIntroduction Letter Format Sga 01.07.2017SURYANo ratings yet

- Ignition System Honda CITY IDSIDocument12 pagesIgnition System Honda CITY IDSImuhammad nazir100% (2)

- EC5 AMPLEO Parts ListDocument8 pagesEC5 AMPLEO Parts ListAmiroucheBenlakehalNo ratings yet

- Manual 820-Pp AsDocument12 pagesManual 820-Pp AsjabalpuramitNo ratings yet

- Rolls-Royce RB211: SpecificationsDocument3 pagesRolls-Royce RB211: SpecificationsMajah Malaya CanlasNo ratings yet

- MEK Marine Turbochargers Spare PartsDocument6 pagesMEK Marine Turbochargers Spare PartsMEK MarineNo ratings yet

- Iom Biffi Morin Series A B C S en en Us 6089118Document37 pagesIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNo ratings yet

- Lombardini-Diesel-Motor-Catalog-9LD625-2Document16 pagesLombardini-Diesel-Motor-Catalog-9LD625-2bacharskateNo ratings yet

- Cameron FLS Gate Valve - PDS0112Document2 pagesCameron FLS Gate Valve - PDS0112Karl TbsgNo ratings yet

- Delta SV SVS 8001 01 08 2008 UsDocument4 pagesDelta SV SVS 8001 01 08 2008 Usterrazas.daniel@gmail.comNo ratings yet

- Bharat Heavy Electrical Limited, JhansiDocument132 pagesBharat Heavy Electrical Limited, JhansiMAYMODERN STEELNo ratings yet

- Flexible Pin Bush CouplingsDocument3 pagesFlexible Pin Bush CouplingsMAYURANDULKARNo ratings yet

- A Power Point Presentation of BHELDocument24 pagesA Power Point Presentation of BHELSiddharth SharmaNo ratings yet

- Aircraft Part Numbers and Descriptions SpreadsheetDocument587 pagesAircraft Part Numbers and Descriptions SpreadsheetGregory KimNo ratings yet

- Drilling FundamentalsDocument10 pagesDrilling FundamentalsZhong YingNo ratings yet

- Net Flywheel Power 177 KW - 240 HP Operating Weight 30 400 KGDocument4 pagesNet Flywheel Power 177 KW - 240 HP Operating Weight 30 400 KGYumar M ValladolidNo ratings yet

- Research On Influence Factors of Landing Gear Retractile HydraulicDocument5 pagesResearch On Influence Factors of Landing Gear Retractile HydraulicPrateek GadagiNo ratings yet

- FGW2 Weichai Genset WP2.3 Series 60HZ 15 50kwe LTPDocument4 pagesFGW2 Weichai Genset WP2.3 Series 60HZ 15 50kwe LTPMahmoud KokoNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Replace Timing Belt / Water Pump Honda Accord 1990-1995 4 CylinderDocument7 pagesReplace Timing Belt / Water Pump Honda Accord 1990-1995 4 Cylinderkararoy100% (5)

- Ic EngineDocument8 pagesIc EngineLohith Narasimha swamyNo ratings yet

- Immobilizer System - KIADocument26 pagesImmobilizer System - KIAAhmed Alsheikh100% (1)

- Banshee Wildcard InfoDocument1 pageBanshee Wildcard InfobuilttorideNo ratings yet

- A - C Control System - Autoo PDFDocument4 pagesA - C Control System - Autoo PDFANH LÊNo ratings yet