Professional Documents

Culture Documents

Fixing Low Voltage-Undervoltage Problems

Uploaded by

Amany HamdyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixing Low Voltage-Undervoltage Problems

Uploaded by

Amany HamdyCopyright:

Available Formats

Energy Efficiency & Power Quality Series

Power Quality Basics: Fixing Low Voltage & Undervoltage Problems

September, 2009

Utility Systems Technologies, Inc.

Phone: 888 403-9084 Fax: 518 377-2207 Email: sales@ustpower.com Website: www.ustpower.com P.O. Box 110 Latham, NY 12110

Fixing Low Voltage &Undervoltage Problems

hronic low voltage levels are a common problem that can affect any electric customer. The causes of this power quality problem are relatively easy to identify but potential energy saving measures undertaken by the operators of the electric grid could make chronic low voltage levels a significant problem for many. This paper looks at causes, symptoms and solutions for chronic low voltage problems.

Chronic low voltage or undervoltage

The term of art for chronic low voltage is undervoltage and undervoltage is defined as a voltage level 90% or less of the nominal voltage that exists for one minute or more. The key factor in this definition is that of the duration of one minute or more as this distinguishes undervoltage from shorter duration problems such as voltage sags. Undervoltage chronic low voltage

Causes of chronic low voltage undervoltage

Undervoltage is most commonly attributable to reduced voltage levels on the utilitys transmission and distribution system. In areas with low electrical load density, such as suburban and rural locations, voltage drop on electrical conductors is a significant issue. Conductor impedance driven by load demand serves to decrease the voltage along the length of a conductor. The electric utility uses on-load tap changing voltage regulators (OLTCs) at substations and line drop compensating voltage regulators (LDCs) along the length of a conductor to boost (raise) or buck (lower) voltage levels within a proper range for delivery to customers. Customers nearest to an OLTC or LDC will see the highest voltage levels while those farthest away will see the lowest voltage levels. As simply shown in the graphic above, location can play a significant role in voltage level as can the operational characteristics and reliability of OLTCs and LDCs. In many locations the impact of loaddriven voltage drop is seen as daily fluctuations that result in voltage levels being the lowest at the time of peak load demand. Monday through Friday this typically occurs from the late morning through early afternoon when most work and educational activities take place. Voltage drop in utility lines The daily voltage fluctuation becomes more severe when weather increases peak demand such as the air conditioning season in the U.S. If the peak demand for electricity starts to approach the maximum generating capacity, grid operators may intentionally reduce the voltage level of the grid up to 5% in order to maintain the margin between electricity demand and production. This intentional voltage reduction is frequently called a brownout however there is no strict definition for this term. Another factor that may aggravate undervoltage problems is an energy saving concept known as conservation voltage reduction or CVR. Proponents of CVR contend that a permanent 5 to 8% reduction in nominal grid voltage levels can achieve a 0.5 to 3% reduction in the amount of electricity that needs to be produced. The arguments against CVR include an increased susceptibility to voltage sag problems and the reduced efficiency of certain devices rated for higher voltage (e.g. motors).

2009 , Utility Systems Technologies, Inc All rights reserve d

Chronic Low Voltage - Undervoltage Page 2/7

The problem with low voltage - undervoltage

The manufacturer of an electrical device designs his product to operate at a certain standard voltage in order for the product to achieve specified levels of performance, efficiency, safety and reliability. Operating an electrical device near or outside the specified voltage level limitations can lead to problems such as malfunction, shut down, overheating, premature failure, etc. For example, an induction motor operating near its rated load on 90% of nameplate voltage can be expected to have its efficiency reduced 1 to 3%, have its operating temperature increased 10 to 15% and have its running torque reduced nearly 20%. In general, undervoltage tends to reduce electrical efficiency in many devices since lower voltage increases current flow 2 which increases I R or copper losses. Some of the more common symptoms of undervoltage include: Motors run hot than normal and fail prematurely Random equipment shut down due to voltage sags Batteries fail to recharge properly Dim incandescent lighting Hot and noisy equipment Unexplained malfunctions

Daily voltage fluctuation

Utility and utilization voltage levels

No discussion of undervoltage would be complete without an examination of the regulations and definitions concerning voltage levels. The first point to be noted is that there is no national (U.S.) standard for the voltage levels. Individual states usually point to ANSI standard C84 or some variation of the standard to define the voltage levels that must be supplied. ANSI C84 suggests that the voltage level normally supplied at a customers meter (the service voltage) should be within 5% of the nominal voltage. However, the standard goes on to recognize that the voltage level may infrequently be -10% to +6% of nominal. No specific definition of infrequently is provided however the standard does say the utility-supplied voltage level may be worse than -10 to +6% for brief periods due to unexpected operational issues. And, this is not the end of the voltage level story. The ANSI C84 standard and other industry standards recognize that there will be an additional voltage drop with the customers facility. This is most often assumed to be a voltage drop of 4% from the electric meter to the point where the electricity is consumed the utilization voltage. Many people wonder why motors are typically rated at 460 volts instead of 480 volts. The reason is that an assumption is made that 480 volts will be supplied at the meter and the voltage at the motor will be 4% less than 480 volts: that is 460 volts. Most electrical equipment sold in North America is designed to accept a voltage range of 10 of nameplate voltage. While that may seem to be a generous margin it may not be enough in many cases. Lets say the voltage at the meter is 5% lower than nominal. Adding in the presumed Line drop compensating (LDC) 4% voltage drop within a customers facility means the voltage level voltage regulators (one per phase) seen by an electrical device would be 9% below the nominal utility voltage level. This serves to highlight the need to consider the nameplate voltage and the voltage level limitations of electrical devices.

2009 , Utility Systems Technologies, Inc All rights reserve d

Chronic Low Voltage - Undervoltage Page 3/7

Fortunately, most electricity providers are pretty good at keeping voltage levels with the 5% range most of the time. However, even though electric utilities strive to do their best for everyone, reality dictates that not everyone can receive optimal voltage levels all of the time or even most of the time. Experience shows that complaints to the electric utility about low voltage levels most often result in a voltage level measurement by the utility and notification that the voltage level is within specifications. This is the point when utility customers start to look for solutions for their undervoltage problems.

Solutions for undervoltage

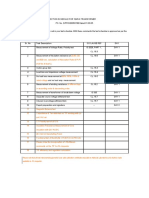

A natural question regarding the resolution of undervoltage problems might be, Why not use what the utility uses? The answer is that one certainly can try this; however it might not yield an acceptable solution. OLTCs and LDCs are designed for voltage regulation of bulk power and have some unique characteristics: Requirement Fine voltage regulation Long maintenance intervals Characteristic Most OLTCs and LDCs use a 32 tap transformer with voltage each tap changing the voltage of 5/8%. This results in a maximum regulation range of 10% of nominal. Since OLTCs and LDCs are mechanical devices with servo-motors, mechanical linkages, brush-type contactors, etc., the number of operations is directly proportional to the maintenance requirements. To reduce maintenance costs, these devices incorporate controls to minimize the number of operations. Such controls often include operational delays ranging from seconds to minutes and adjustable voltage deadbands among others. OLTCs and LDCs may a second or two to correct small voltage deviations up to 10 more seconds for large deviations. The utility purposes this is considered acceptable. Oil is a very effective heat transfer medium very commonly used for cooling utilitygrade electrical products. Oil helps to minimize product size and the use of weatherproof enclosures in high ambient temperature applications. However, oil-filled products are substantially more difficult and expensive to service than air-cooled devices. Use at medium and high voltages minimizes the physical size of the devices for a given power level

Substation transformer with on-load tap changing voltage regulator

Correction speed Small size and weatherproof enclosure Medium and high voltage application

OLTCs and LDCs are not considered power quality correction devices since they lack the performance to solve undervoltage problems required by most end users. Specifically, the slow speed of correction (measured in seconds) and the limited regulation range (10%) are not sufficient to protect sensitive loads or to prevent them from malfunctioning or shutting down. Use of OLTCs and LDCs as power quality devices pose some additional complications: medium and high voltage hardware is usually considered the responsibility of the electric utility and such devices do not lend themselves to protection of small or individual low voltage devices within a facility. The most common types of products used for correction of undervoltage are: Servomotor-controlled variable transformers Servo-mechanical tap switching voltage regulators Servo-mechanical induction voltage regulators Electronic tap switching voltage regulators Ferroresonant transformers Electronic double conversion voltage regulators

2009 , Utility Systems Technologies, Inc All rights reserve d

Chronic Low Voltage - Undervoltage Page 4/7

Servomotor-controlled variable transformers These devices are sometimes referred to as motor-driven variacs. The simplest version of a variable transformer has a continuous, circular winding along which brushes are moved to alter the turns ratio and thereby the output voltage. A control system monitors the output voltage and moves the brushes by actuating the servomotor until the desired voltage level is achieved. These units are generally available in single and three phase models from 100 VA to 50,000 VA. Larger sizes may be available. Pros the servomotor-controlled variable transformer is a very simple and reliable device capable of voltage regulation to very high tolerances such as 0.5%. Electrical efficiencies of 97 to 99% are typical. Cons like all mechanical voltage regulators, the speed of correction may be too slow to support certain sensitive equipment. Frequent operation increases the maintenance requirements, however the simplicity of this product makes service much less of a problem compared to other mechanical voltage regulators. These devices may not be appropriate in applications with large, frequent voltage variations. Servo-mechanical tap switching voltage regulators These devices are very similar to OLTC and LDC except that they: 1) are designed for Sections of a variac showing round low voltage (<1,000 volts), 2) are air-cooled rather than oil-filled, and 3) variable transformers and brushes typically have a much larger voltage regulation range (20% to 25%). The servo-mechanical tap switching voltage regulator uses servomotors to drive a mechanical system to position brushes on a particular tap to control the output voltage. These units are generally available in single and three phase models from 3,000 VA to 1,000,000 VA and larger. Pros the simple technology and low component cost make these devices readily available at relatively low cost worldwide. Unlike OLTCs and LDCs, these devices can easily be placed indoors and sized and configured for the protection of individual loads. Electrical efficiencies of 96 to 99% are typical. Cons like other mechanical voltage regulators, the slow speed of correction (0.3 to 4+ seconds) and potentially high maintenance requirements are the main drawbacks. In less expensive designs there may also a question about the device producing output voltages so high as to be harmful to the load when the device is energized or suffers a drive malfunction. Caution is advised when applying these devices in applications with large, frequent voltage variations. Servo-mechanical induction voltage regulators This type of voltage regulator is quite unique in that it adjusts voltage by changing the orientation of the magnetic flux between the primary and secondary of the transformer rather by changing the turns ratio like tap switching and variable transformers. Looking somewhat like a typical induction motor, the servomotor in the unit simply turns the rotor within the stator through something less than 360 in order to alter the flux field thus altering the output voltage. These units are generally available in single and three phase models from 10,000 VA to about 500,000 VA. Pros theoretically, the servo-mechanical induction voltage regulator offers a continuum of possible output voltages since it does not rely on taps set at fixed ratios. Unlike other mechanical voltage regulators, this device uses no brushes which should eliminate some of the problems associated with brushes like wear, maintenance and arcing. Electrical efficiencies of 96 to 98% are typical. Cons with its advantages, this is still a very mechanical device requiring servomotors and drive systems to move the rotor. As the units power rating increases, the amount of mass that has to be moved also increases and the speed of correction decreases. Larger sizes require large rotor bearings to accommodate the higher rotor weight: which can make service much more technically challenging.

2009 , Utility Systems Technologies, Inc All rights reserve d

Chronic Low Voltage - Undervoltage Page 5/7

Electronic tap switching voltage regulators As the name implies, these all solid state devices switch taps to change output voltage but eliminate the slow speed and maintenance problems of mechanical by using power semiconductors to do the switching. Voltage corrections with these devices take place in about one electrical cycle (0.016 seconds) and are done non-sequentially: changing from one tap to another tap while bypassing the taps in between. These units are generally available in single and three phase models from 5,000 VA to about 2,000,000 VA. Pros the correction speed of these devices makes them the device of choice to protect sensitive electronic and electrical loads. They are also ideal for applications with large and/or frequent voltage fluctuations since there are no moving parts to wear out. Electrical efficiencies of 97 to 99% are typical. Cons the switching power semiconductors used in electronic tap switching voltage regulators can be very susceptible to the failure when used with certain types of loads: large inrush current, poor power factor, frequent overload, small minimum load, etc. Industrial-grade electronic tap switching voltage regulators eliminate all of the concerns about the weakness of the power semiconductors and can be easily applied almost anywhere.

Controls and electronic switches in an electronic tap switching voltage regulator

Ferroresonant transformers This is the grandfather of voltage regulators having been designed in the 1930s. Little changed from the original design, these devices continue to see widespread application. The ferro takes advantage of a unique characteristic of transformers: when operated in the saturation region, a large change in the input voltage results in a small change in the flux density and therefore the output voltage. Ferroresonant transformers have no moving parts, fast correction speed and modern designs incorporate a tuned circuit to remove objectionable harmonics that can be produced by operation in the saturation region. These devices are only for single phase application in sizes from 100 VA to 20,000 VA. Pros these units are very Ferroresonant transformer operation occurs in the saturation region durable and may offer very long warranties. They are also effective at current limiting since they basically turn into a choke should the current exceed more than 150 to 200% of rated current. Cons ferroresonant transformers may be best known for two characteristics being incredibly noisy and hot because they are very inefficient. Manufacturers often claim efficiency up to 90% or more but in actual practice it is frequently less than 85%. The current limiting capability that is a benefit in certain applications becomes a liability in high inrush current applications and results in the device needing to be sized much larger than the load and further reducing its electrical efficiency.

Ferroresonant transformer with capacitors for tuning circuit

2009 , Utility Systems Technologies, Inc All rights reserve d Chronic Low Voltage - Undervoltage Page 6/7

Electronic double conversion voltage regulators These devices are similar too or may actually be a UPS (uninterruptible power supply) without batteries. The incoming AC power is converted to DC and then converted back to AC. During the process of re-creating the AC power from DC, voltage, frequency and other characteristics of the output power can be very precisely manipulated: for example, converting 480 volt, 60 Hz to 380 volt, 50 Hz. The typical UPS is used to supply power from its batteries during a power interruption and provide voltage regulation when utility power is available but some models are marketed as voltage regulators when sold without batteries. These units are generally available in three phase 500 kVA UPS w/o batteries UPS battery racks models from 10,000 VA to about 200,000 VA. Pros the double conversion process provides good voltage regulation with fast correction speed. The potential to add batteries and regulate output frequency are capabilities not found in other voltage regulators. Cons a double conversion UPS with or without batteries must often be sized much larger than the load in order to handle load inrush current. The double conversion process (AC-DC, DC-AC) by its nature is relatively inefficient. Low inherent efficiency combined with low load factor due to over-sizing requirements can result in real-world efficiencies of 85% or less. Voltage regulating performance can be different between the same unit when used with and without batteries since the lack of battery power to stabilize the DC bus can compromise voltage regulation and unit performance.

Utility Systems Technologies, Inc. is the leading manufactures of industrial-grade power conditioning products for voltage regulation, power conditioning and voltage sag protection. As a leader in the field of green power quality, all UST products have the highest performance and efficiencies available.

2009 , Utility Systems Technologies, Inc All rights reserve d Chronic Low Voltage - Undervoltage Page 7/7

You might also like

- Operating and MaintenanceDocument3 pagesOperating and Maintenancesoni90kumarNo ratings yet

- Axter General Solar PV Inspection and Routine Maintenance GuideDocument4 pagesAxter General Solar PV Inspection and Routine Maintenance GuideBAlaNo ratings yet

- Limitorque L 120-40 ManualDocument44 pagesLimitorque L 120-40 ManualDanel Gonzalez100% (1)

- Sierra SeriesDocument292 pagesSierra SeriesHéctor VanzNo ratings yet

- Limitorque Instruction and Maintenance L120Document16 pagesLimitorque Instruction and Maintenance L120Supratim PalNo ratings yet

- First Line MaintenanceDocument1 pageFirst Line MaintenanceAgus F RahmanNo ratings yet

- Induction Motors Faults and ProtectionDocument2 pagesInduction Motors Faults and ProtectionMuhammad Ali Khan AwanNo ratings yet

- Incon 1250Document35 pagesIncon 1250Hugo MoralesNo ratings yet

- Unbalanced Fault Analysis Lec 8Document20 pagesUnbalanced Fault Analysis Lec 8Bante TadeleNo ratings yet

- Manual MotorsDocument10 pagesManual Motorst_syamprasadNo ratings yet

- He A IgnitorDocument36 pagesHe A IgnitorE.C.MADHUDUDHANA REDDYNo ratings yet

- DFR Measurement On CT PDFDocument26 pagesDFR Measurement On CT PDFdkymq100% (1)

- GE Motors Catalog Feb2015Document324 pagesGE Motors Catalog Feb2015Edson França RodriguesNo ratings yet

- Motor Thermal ModelDocument15 pagesMotor Thermal ModelnagarajasarmaNo ratings yet

- Wpii Vs TefcDocument3 pagesWpii Vs TefcJhonatan OyolaNo ratings yet

- PUR002r-Tooling Management ProcedureDocument10 pagesPUR002r-Tooling Management ProcedureabraNo ratings yet

- Induction MotorDocument50 pagesInduction MotorsunhuynhNo ratings yet

- Service Failure Analysis of D C Motor Co PDFDocument6 pagesService Failure Analysis of D C Motor Co PDFOmar QatawnehNo ratings yet

- Product BrochureDocument28 pagesProduct Brochureno nameNo ratings yet

- US Vertical Motors - In509-1dDocument48 pagesUS Vertical Motors - In509-1dcario_mak_ainsworthNo ratings yet

- MV BreakerDocument40 pagesMV BreakerphanindraNo ratings yet

- Nfpa 70e Arc FlashDocument3 pagesNfpa 70e Arc FlashceciliagaitanNo ratings yet

- Option Checklist No 1 Electric MotorsDocument2 pagesOption Checklist No 1 Electric MotorsMohammed Al-OdatNo ratings yet

- Relay Symbols and Fuction NumDocument14 pagesRelay Symbols and Fuction NumPrasanna DharmapriyaNo ratings yet

- Solid q50 Denind 1808 V11webDocument2 pagesSolid q50 Denind 1808 V11webNinditya NugrohoNo ratings yet

- 2013edition CatalogDocument156 pages2013edition CatalogthotalnNo ratings yet

- The Benefits of Surge and Hipot Testing of Electric MotorsDocument5 pagesThe Benefits of Surge and Hipot Testing of Electric Motorsamk2009No ratings yet

- Installation and Operation Manual: Protech 203 Overspeed Protection SystemDocument36 pagesInstallation and Operation Manual: Protech 203 Overspeed Protection SystemscribdkhatnNo ratings yet

- Diagnostics Testing of High Voltage MotorDocument9 pagesDiagnostics Testing of High Voltage MotorSanjayNo ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Instruction Manual TA2102Document51 pagesInstruction Manual TA2102Roshin99No ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- GE Motors Product LineDocument8 pagesGE Motors Product LineidontlikeebooksNo ratings yet

- CB Monitor: On Line Circuit Breaker Monitoring SystemDocument4 pagesCB Monitor: On Line Circuit Breaker Monitoring Systemashu_2787No ratings yet

- Motors and GeneratorsDocument8 pagesMotors and GeneratorsHealthyCut FarmsNo ratings yet

- Controlled Switching of High-Voltage Circuit-BreakersDocument8 pagesControlled Switching of High-Voltage Circuit-BreakersBaris GurbuzNo ratings yet

- CCJ - How To Prevent Collector-Ring FiresDocument7 pagesCCJ - How To Prevent Collector-Ring Firesabdulyunus_amirNo ratings yet

- 110 Electrical Skills StoryBoardDocument11 pages110 Electrical Skills StoryBoardshyamNo ratings yet

- HIPOT TEST The Truth About Arc DetectionDocument3 pagesHIPOT TEST The Truth About Arc DetectionJOSE LUIS FALCON CHAVEZ0% (1)

- Field Inspection and Test ReportDocument19 pagesField Inspection and Test ReportAe SuwaphanNo ratings yet

- Motor DatasheetDocument1 pageMotor DatasheetMuzzamilNo ratings yet

- Components of Substation CdsDocument12 pagesComponents of Substation CdsSaradaprasan DasNo ratings yet

- Understanding Insulation Resistance Testing: Maintenance, Repair & Operations Test & MeasurementDocument5 pagesUnderstanding Insulation Resistance Testing: Maintenance, Repair & Operations Test & Measurementmatthew kagurabadzaNo ratings yet

- Stator Winding Fault Diagnosis in Three-PhaseDocument7 pagesStator Winding Fault Diagnosis in Three-PhaseitcmiguelNo ratings yet

- Manual Surge Test Baker St106aDocument2 pagesManual Surge Test Baker St106aDiego AndradeNo ratings yet

- Isolated Phase Bus Inspection & Maintenance Best Practices: Mohsen Tarassoly Electrical Builders, Inc. (EBI)Document50 pagesIsolated Phase Bus Inspection & Maintenance Best Practices: Mohsen Tarassoly Electrical Builders, Inc. (EBI)bobyNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Dhaval VDRDocument57 pagesDhaval VDRPriyanth AcharyaNo ratings yet

- Voltage Regulators and Sag Correctors: (Voltage Compensation Devices) Questions & AnswersDocument9 pagesVoltage Regulators and Sag Correctors: (Voltage Compensation Devices) Questions & Answersjcrodriguez83No ratings yet

- Simulation of STATCOM For The Reduction of T.H.D by Using F.L.CDocument5 pagesSimulation of STATCOM For The Reduction of T.H.D by Using F.L.CdeepikaNo ratings yet

- How To Specify Motor VoltageDocument4 pagesHow To Specify Motor VoltageCyrix.OneNo ratings yet

- Voltage Quality Improvement DVRDocument30 pagesVoltage Quality Improvement DVRKeerthi PriyankaNo ratings yet

- "Power Quality Issues": Dayananda Sagar College of EngineeringDocument19 pages"Power Quality Issues": Dayananda Sagar College of EngineeringAnand SinghNo ratings yet

- Statcom FullDocument89 pagesStatcom Fullfawadn_84No ratings yet

- Power Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Document41 pagesPower Quality Enhancement Using Dynamic Voltage Restorer (D.V.R)Aayush guptaNo ratings yet

- Overview of Custom Power ApplicationsDocument7 pagesOverview of Custom Power ApplicationssunilgurubaxaniNo ratings yet

- Four Aspects of The Quality of Life The Balance MoDocument11 pagesFour Aspects of The Quality of Life The Balance MoAmany HamdyNo ratings yet

- Hitachi Energy MV Surge Arrester Application GuidelinesDocument31 pagesHitachi Energy MV Surge Arrester Application GuidelinesAmany HamdyNo ratings yet

- IEEE STD 1268™-1997-Guide-For-Safety-In-The-Installation-Of-Mobile-Substation-EDocument26 pagesIEEE STD 1268™-1997-Guide-For-Safety-In-The-Installation-Of-Mobile-Substation-EAmany HamdyNo ratings yet

- Force Calculation 28 MvaDocument12 pagesForce Calculation 28 MvaAmany HamdyNo ratings yet

- MTG Contest Proposal Power - Within - GenerationsDocument3 pagesMTG Contest Proposal Power - Within - GenerationsAmany HamdyNo ratings yet

- Les Taches Actualisé 25 2 2016Document3 pagesLes Taches Actualisé 25 2 2016Amany HamdyNo ratings yet

- Handling Objection-FinalDocument49 pagesHandling Objection-FinalAmany HamdyNo ratings yet

- Behavioral Public Administration Ad FontesDocument18 pagesBehavioral Public Administration Ad FontesAmany HamdyNo ratings yet

- WIE Affiity Group Petition FormDocument1 pageWIE Affiity Group Petition FormAmany HamdyNo ratings yet

- Transformer Losses CalculationDocument4 pagesTransformer Losses CalculationAmany HamdyNo ratings yet

- Towards Effective Mitigation of The Digital Transformation andDocument22 pagesTowards Effective Mitigation of The Digital Transformation andAmany HamdyNo ratings yet

- Transformer ProtectiponDocument116 pagesTransformer ProtectiponAmany HamdyNo ratings yet

- 16MVA Transformer Test Schedule CommentsDocument1 page16MVA Transformer Test Schedule CommentsAmany HamdyNo ratings yet

- Wor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Document11 pagesWor - 2021 - 70 4 - Wor 70 4 Wor210476 - Wor 70 Wor210476Amany HamdyNo ratings yet

- The New Era of Digital Transformation and COVID-19 Effect On TheDocument27 pagesThe New Era of Digital Transformation and COVID-19 Effect On TheAmany HamdyNo ratings yet

- The Impact of COVID-19 On The Efficiency of Packing Lines inDocument16 pagesThe Impact of COVID-19 On The Efficiency of Packing Lines inAmany HamdyNo ratings yet

- MinitrackDTHICSS 542020Document2 pagesMinitrackDTHICSS 542020Amany HamdyNo ratings yet

- The Reality of Resistance To Change Behaviour at The Department ofDocument14 pagesThe Reality of Resistance To Change Behaviour at The Department ofAmany HamdyNo ratings yet

- Digitization of The Economy of Ukraine StrategicDocument8 pagesDigitization of The Economy of Ukraine StrategicAmany HamdyNo ratings yet

- The Impact of Job Stress On Employee Productivity During Covid-19Document12 pagesThe Impact of Job Stress On Employee Productivity During Covid-19Amany HamdyNo ratings yet

- Revitalization of Remote Control Centre at Elektro Primorska (SloveniaDocument4 pagesRevitalization of Remote Control Centre at Elektro Primorska (SloveniaAmany HamdyNo ratings yet

- Barczak Sotysik Jarosz Zakrzewska KozowskiDocument18 pagesBarczak Sotysik Jarosz Zakrzewska KozowskiAmany HamdyNo ratings yet

- Balance Between Test Result and Analysis For Medium Voltage SystemDocument4 pagesBalance Between Test Result and Analysis For Medium Voltage SystemAmany HamdyNo ratings yet

- Enhancing Performance of Mwasalat Misr Company in GreaterDocument16 pagesEnhancing Performance of Mwasalat Misr Company in GreaterAmany HamdyNo ratings yet

- Water Absorption by Oil in MV SwitchgearDocument4 pagesWater Absorption by Oil in MV SwitchgearAmany HamdyNo ratings yet

- 2022 OpenNursingJournal theModerationEffectofAffectiveDocument9 pages2022 OpenNursingJournal theModerationEffectofAffectiveAmany HamdyNo ratings yet

- Stamping Machine: TP601 Festo DidacticDocument8 pagesStamping Machine: TP601 Festo DidacticSanjar MirzalievNo ratings yet

- 942006-001 TQP-RS Manual Rev2Document40 pages942006-001 TQP-RS Manual Rev2week redNo ratings yet

- Cisco D9865 DVB-S - S2 Directv Receiver 4028650000000Document260 pagesCisco D9865 DVB-S - S2 Directv Receiver 4028650000000ronnycamachoNo ratings yet

- Atlas Copco - Air MotorDocument80 pagesAtlas Copco - Air MotorNo HopeNo ratings yet

- HVDC Jan SvenssonDocument13 pagesHVDC Jan SvenssonWilber William Moscoso ZamudioNo ratings yet

- Centro de Procesado de Barras de Cobre Cu-Flex eDocument19 pagesCentro de Procesado de Barras de Cobre Cu-Flex eBoschert MéxicoNo ratings yet

- Kalibrasyon Ts en Iso/Iec 17025Document20 pagesKalibrasyon Ts en Iso/Iec 17025sales3 iaescoNo ratings yet

- RTV 900 WSM enDocument31 pagesRTV 900 WSM enwireless303No ratings yet

- SST39SF020 - Flash BiosDocument23 pagesSST39SF020 - Flash BiosFélix NicolauNo ratings yet

- ABB RCCB F 804Document12 pagesABB RCCB F 804catalinccNo ratings yet

- Vk3ye Dot Com - Compact L-Match For Portable UseDocument7 pagesVk3ye Dot Com - Compact L-Match For Portable Usetito351No ratings yet

- Minor Project ReportDocument30 pagesMinor Project ReportA 60 Rohan bansiyarNo ratings yet

- Ucs c220 m7 Rack Server DsDocument9 pagesUcs c220 m7 Rack Server DsAlfredo Juarez AriasNo ratings yet

- Internship Project Report 1Document17 pagesInternship Project Report 1Aniruddha verulkar50% (2)

- Basic Parts or Elements of A RobotDocument3 pagesBasic Parts or Elements of A RobotRenjith RajendraprasadNo ratings yet

- Report1:Inverters: Power ElecrtonicsDocument12 pagesReport1:Inverters: Power ElecrtonicsghadeerNo ratings yet

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniNo ratings yet

- TM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 6Document122 pagesTM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 6AdvocateNo ratings yet

- Technical Data Servo Motor 662R5001/003/5009 ... 1,2 Nm/3 Nm/9NmDocument4 pagesTechnical Data Servo Motor 662R5001/003/5009 ... 1,2 Nm/3 Nm/9NmAlvaro Diaz De BlasNo ratings yet

- Cellocator Manual PDFDocument29 pagesCellocator Manual PDFYimmy F MontañoNo ratings yet

- Eur - Cover/Bosch Fl./conical 1:8 Gr.I: Gear Pumps Group I LeftDocument2 pagesEur - Cover/Bosch Fl./conical 1:8 Gr.I: Gear Pumps Group I LeftTadas PNo ratings yet

- Airdryers: HamrinDocument30 pagesAirdryers: HamrinGuillermoNo ratings yet

- 395 XPDocument124 pages395 XPSara Rodriguez castroNo ratings yet

- TM 11-6625-2781-24P-4 - PL-1400U - Plug - in - (HP8555) - 1982 PDFDocument88 pagesTM 11-6625-2781-24P-4 - PL-1400U - Plug - in - (HP8555) - 1982 PDFWurzel1946No ratings yet

- Ecran SonyDocument28 pagesEcran SonyyeeepaNo ratings yet

- Destacking NewDocument1 pageDestacking NewRomly MechNo ratings yet

- Totem-Pole Output StageDocument18 pagesTotem-Pole Output StageSlanky BirOe PulauNo ratings yet

- Continental Device India Limited: Boca Semiconductor Corp. BSCDocument2 pagesContinental Device India Limited: Boca Semiconductor Corp. BSCJeSyBarrigaNo ratings yet

- Brochure Ec55d t3 en c5 20050456 ADocument12 pagesBrochure Ec55d t3 en c5 20050456 APT MORSA MEGAH PERKASANo ratings yet

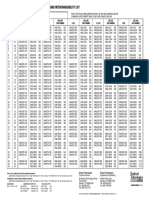

- Heli-Coil Metric Inserts Aerospace Standard Interchangeability ListDocument2 pagesHeli-Coil Metric Inserts Aerospace Standard Interchangeability ListshadiNo ratings yet