Professional Documents

Culture Documents

Control Valve Servomotor

Uploaded by

PopeyeElectricmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Valve Servomotor

Uploaded by

PopeyeElectricmanCopyright:

Available Formats

Steam Turbine Description

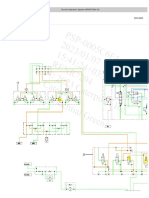

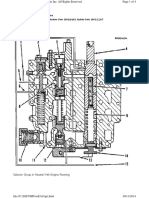

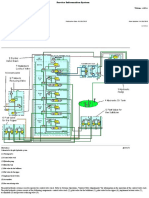

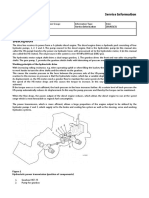

The flow of steam to the turbine is regulated by varying the lift of the HP control valve by means of its servomotor. The HP control valve is actually moved by the piston (9) which is loaded on one side by the disc springs (10) and on the other side by hydraulic pressure. The position of the valve is determined by the secondary oil pressure, which is controlled by the governor. Since large operating forces are required, the servomotor is of the high-pressure type (approx. 32 bar) and has a pre control system. The supply of secondary oil (connection b) controls the auxiliary pilot valve (14) which directs control oil from connection a1 to the appropriate side of the pilot piston (4). The pilot piston operates the main pilot valve (3) through lever (5) so that when the HP control valve is being opened, control oil from connection a is directed to the underside of piston (9). When the valve is being closed, oil drains through the main pilot valve. Pre Control System When the turbine is running and the HP control valve is steady at any particular value of lift, the auxiliary pilot valve (14) will be in the centre position shown in the drawing. In this position the force exerted by the spring (13) and the secondary oil pressure acting on the auxiliary pilot valve are in equilibrium. When the governor varies the secondary oil pressure to open or close the HP control valve, the auxiliary pilot valve is deflected from this centre position. This allows control oil (connection a1 ) to flow to one side of the pilot piston (4) while the other side of the piston is opened to drain. The movement of the pilot piston returns the auxiliary pilot valve to its centre position by means of the feedback linkage (12) thus giving proportionality between secondary oil pressure and pilot piston travel. The degree of proportionality of the pre control system can be adjusted by varying the position of the feedback lever pivot (12). The auxiliary pilot valve is continuously rotated by the action of oil flowing from tangential holes in a disc mounted on auxiliary pilot valve in order to ensure that it moves freely at all times.

Servomotor for HP Control Valve

Main Control System The movement of the pilot piston (4) deflects the main pilot valve (3) from its centre position by means of lever (5) so that either, control oil from connection a is directed to the underside of piston (9) and the HP control valve opens, or the underside of piston is opened to drain so that the disc springs can close the HP control vale. Shortly before the valve cone of HP control valve actually comes into contact with the valve seat, the servomotor piston (9) enters a recess turned in the servomotor casing and throttles the flow of oil draining from the underside of the piston. This slows down the valve closing motion and the valve cone seats gently. The spring (1) pre-loads the linkage and prevents any slackness or lost motion at the pivots. The straight feedback cam (7) mounted on the end of the servomotor piston rod (8) returns the main pilot vale (3) to its centre position by means of a lever system. The slope of the feedback cam is in two stages to give two degrees of proportionality, which produce good linearity of the steam flow characteristics. Testing Device The control valve can be operated either by hand or under power independently of the governor by means of the testing device (11) in order to check the free movement of the HP control valve. The testing device acts on the lever (5) in the same manner as the pilot piston (4); the system demanding the smaller valve lift being in control, Damping Device Fig.2 illustrates the auxiliary pilot valve (14) and the damping device in the secondary oil circuit. Any signals in the secondary oil circuit are damped out by passing the secondary oil through capillary tube (16) before it enters the auxiliary pilot vale (14). Any air carried by the secondary oil is conducted to the free space in the actuator via the screw plug (18), holes in the casing of the damping device and pilot valve.

BHEL Haridwar

5.1-0812-01/1

You might also like

- Condenser Steam Dump Control Valve ServomotorDocument1 pageCondenser Steam Dump Control Valve ServomotorPeter AntonyNo ratings yet

- 320dl Bucket Hydraulic SystemDocument3 pages320dl Bucket Hydraulic SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- EHTCDocument2 pagesEHTCewfsd100% (1)

- Excavator Hydraulic System-Bucket SystemDocument3 pagesExcavator Hydraulic System-Bucket Systemjohn ayengahNo ratings yet

- 7 Hydraulic CKT 18P2Document17 pages7 Hydraulic CKT 18P2M RazzaqueNo ratings yet

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd PartDocument15 pagesEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd Partthan zaw win100% (1)

- Att System OperationDocument41 pagesAtt System OperationchanlinNo ratings yet

- Steam Turbine Hydraulic Servomotor For Description Main and Reheat Control ValvesDocument2 pagesSteam Turbine Hydraulic Servomotor For Description Main and Reheat Control Valvesparthibanemails5779No ratings yet

- Bucket Hydraulic SystemDocument3 pagesBucket Hydraulic Systemjuan david loyola100% (1)

- Bucket Hydraulic System: Operación de SistemasDocument4 pagesBucket Hydraulic System: Operación de SistemasvidalNo ratings yet

- 980c Especificaciones InglesDocument19 pages980c Especificaciones InglesEdgar TorresNo ratings yet

- To Study Different CarburetorsDocument4 pagesTo Study Different CarburetorsSamadhan Ware PatilNo ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- Fuel Inject 1Document13 pagesFuel Inject 1caterpillar971No ratings yet

- Hydraulic Ratchet and Clutch ControlDocument4 pagesHydraulic Ratchet and Clutch ControlPremragunathan D (Instrumentation)100% (1)

- Sistema HidráulicoDocument36 pagesSistema HidráulicoValdir AlexandreNo ratings yet

- Pilot Valve (Command Control Steering) 966Document16 pagesPilot Valve (Command Control Steering) 966Ahmed RezkNo ratings yet

- Sistema de DireccionDocument18 pagesSistema de DireccionFredy ReyesNo ratings yet

- Select GroupDocument4 pagesSelect Groupbasem elhosanyNo ratings yet

- 320dl Swing SystemDocument10 pages320dl Swing SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- Steering System: Systems OperationDocument12 pagesSteering System: Systems Operationhidekel crafort vinicioNo ratings yet

- Maneuvering Diagram With ExplanationDocument8 pagesManeuvering Diagram With ExplanationArun S100% (1)

- Aircraft Propeller Control and OperationDocument8 pagesAircraft Propeller Control and OperationMohammed Rashedul Islam Gazi100% (1)

- 938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesDocument15 pages938F Wheel Loader 7SN00001-UP (MACHINE) POWERED BY 3116 Engine (SEBP2374 - 53) - Sistemas y ComponentesCarlos Andres Campos TorresNo ratings yet

- Secondary Steering SystemDocument5 pagesSecondary Steering SystemYehezkiel BayuNo ratings yet

- Techdoc Print PageDocument47 pagesTechdoc Print PageBuku DigitalNo ratings yet

- Cat 3412 Pump Tecni 1Document22 pagesCat 3412 Pump Tecni 1INGISMAELMORENO100% (5)

- Kaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK HidraulicoDocument249 pagesKaltfrase - BM - 1000 - 1200 - 1300 - 30 - 2 - & - 2 - PB - BK Hidraulicosebastian blancoNo ratings yet

- Swing Hydraulic System: Systems OperationDocument12 pagesSwing Hydraulic System: Systems OperationRainer Lopez ENo ratings yet

- Unitrigmt6500 Hyd Dump SysDocument19 pagesUnitrigmt6500 Hyd Dump Sysnikbeam0% (1)

- Aircraft Propeller Control and OperationDocument26 pagesAircraft Propeller Control and Operationgulshan100% (2)

- Case 695Document22 pagesCase 695ДмитрйиNo ratings yet

- L180E-Engine - Fuel System, DescriptionDocument3 pagesL180E-Engine - Fuel System, Descriptionyoga_jpbmbmNo ratings yet

- Device For Controlling Clutch Hyd PRDocument9 pagesDevice For Controlling Clutch Hyd PRRajesh CNo ratings yet

- Negative Flow Control System: Systems OperationDocument9 pagesNegative Flow Control System: Systems OperationYudi setiawanNo ratings yet

- 580 590 Series 3 Variable Volume Pilot Controls PDFDocument62 pages580 590 Series 3 Variable Volume Pilot Controls PDFG & C Maquinaria100% (1)

- Pilot Circuit ExcavatorDocument24 pagesPilot Circuit ExcavatorFiqi AinurNo ratings yet

- SM VOLVO L90C WHEEL LOADER Service Repair ManualDocument16 pagesSM VOLVO L90C WHEEL LOADER Service Repair ManualMarco Yarasca Romero100% (2)

- Operación de Sistema2nfnDocument14 pagesOperación de Sistema2nfnroqueNo ratings yet

- Section 5 Steering SystemDocument13 pagesSection 5 Steering SystemPriscila RodriguesNo ratings yet

- Detroit Diesel DD 13 - 15 Fuel SystemDocument15 pagesDetroit Diesel DD 13 - 15 Fuel SystemAhmetCan YüzükçüNo ratings yet

- 04 Hydraulic System OperationDocument24 pages04 Hydraulic System OperationJUAN MANUEL RUIZ BERMEJONo ratings yet

- Bomba 140gDocument29 pagesBomba 140gMuriel Remberto100% (1)

- CH 21 AnswersDocument26 pagesCH 21 AnswersArjav DesaiNo ratings yet

- Displacement Change ValveDocument5 pagesDisplacement Change ValveJuan Daniel Martinez Montoya100% (1)

- Air Motor Starting System For Auxiliary Engines On ShipsDocument3 pagesAir Motor Starting System For Auxiliary Engines On Ships3AE to 2AE Kenneth Roseller JoseNo ratings yet

- 05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateDocument16 pages05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateGiovanniJara100% (1)

- Sistema Hidraulico PilotoDocument6 pagesSistema Hidraulico PilotoRafael RodriguezNo ratings yet

- 2ZZGE Engine - Part of ManualDocument46 pages2ZZGE Engine - Part of ManualDavide Faelli100% (2)

- Ch10Feed CircuitDocument12 pagesCh10Feed CircuitManuelNo ratings yet

- Diagram 64-6. Single Circuit Control System FHDocument2 pagesDiagram 64-6. Single Circuit Control System FHAgus Sholehudin AnzieNo ratings yet

- Fuel SystemDocument4 pagesFuel SystemHassan Ali CheemaNo ratings yet

- Funcionamiento Valvula de ControlDocument8 pagesFuncionamiento Valvula de Controlseba6487No ratings yet

- Hydraulic System: Systems OperationDocument28 pagesHydraulic System: Systems OperationRoberto BaierNo ratings yet

- Cessna 208b Ch. 61Document42 pagesCessna 208b Ch. 61Amar kushwahNo ratings yet

- PPPC Excavator 390d CatDocument4 pagesPPPC Excavator 390d CatJosé Carlos Camino GonzálezNo ratings yet

- SM - VOLVO L50D WHEEL LOADER Service Repair ManualDocument20 pagesSM - VOLVO L50D WHEEL LOADER Service Repair ManualJulio CesarNo ratings yet

- KWU Text GoverningDocument43 pagesKWU Text GoverningSam100% (2)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- 2014 Instrumentation Training BrochureDocument4 pages2014 Instrumentation Training BrochurePopeyeElectricmanNo ratings yet

- Bearing Checker TD 249 BDocument1 pageBearing Checker TD 249 BPopeyeElectricmanNo ratings yet

- Over-Voltage and Insulation PDFDocument8 pagesOver-Voltage and Insulation PDFPopeyeElectricmanNo ratings yet

- Ch. 11a PDFDocument41 pagesCh. 11a PDFPopeyeElectricmanNo ratings yet

- Ch. 11a PDFDocument41 pagesCh. 11a PDFPopeyeElectricmanNo ratings yet

- Harga Besi Baja 18 Maret 2013Document1 pageHarga Besi Baja 18 Maret 2013lupaloginNo ratings yet

- Osisense Xs xs4p30mb230 PDFDocument2 pagesOsisense Xs xs4p30mb230 PDFPopeyeElectricmanNo ratings yet

- Osisense Xs Xs630b1mal2 PDFDocument2 pagesOsisense Xs Xs630b1mal2 PDFPopeyeElectricmanNo ratings yet

- A Report of Training ONGCDocument33 pagesA Report of Training ONGCmohan_17No ratings yet

- Basic Aerodynamics Bristol Basics WorkbookDocument16 pagesBasic Aerodynamics Bristol Basics WorkbookИлларион ПанасенкоNo ratings yet

- Theory of FlightDocument217 pagesTheory of FlightLenard Mico LirioNo ratings yet

- Achieving Hover Equilibrium in Free Flight With A Flexible Flapping WingDocument23 pagesAchieving Hover Equilibrium in Free Flight With A Flexible Flapping Wingiwe1234No ratings yet

- Seaplane Take Off Calculation 2006-12-03Document7 pagesSeaplane Take Off Calculation 2006-12-03Elmer Villegas100% (1)

- Helicopter FundamentalsDocument66 pagesHelicopter FundamentalsYuvaraj Tingiri100% (1)

- Well Performance SoftwaresDocument3 pagesWell Performance SoftwaresMotaz IbrahimNo ratings yet

- Charles R. O'Neill: 1. Thin Airfoil TheoryDocument8 pagesCharles R. O'Neill: 1. Thin Airfoil TheoryBalram MandalNo ratings yet

- ME463 Automobile EngineeringDocument4 pagesME463 Automobile EngineeringLinto VargheseNo ratings yet

- Stability Control ReportDocument15 pagesStability Control Reportvidic971No ratings yet

- Jumbo Lift 3200 NT PDFDocument55 pagesJumbo Lift 3200 NT PDFAvishay TufikianNo ratings yet

- Piab Datasheet Vgs3010 b75p en 2010Document2 pagesPiab Datasheet Vgs3010 b75p en 2010MaskbassNo ratings yet

- Anderson Chapter 4Document44 pagesAnderson Chapter 4saintanddevilNo ratings yet

- CFD Analysis With Fluid-Structure Interaction of Opening High-Pressure Safety ValvesDocument9 pagesCFD Analysis With Fluid-Structure Interaction of Opening High-Pressure Safety ValvesPEUSABOIANo ratings yet

- Laboratory Experiment 3: Mohd Ashraf Mohd IsmailDocument29 pagesLaboratory Experiment 3: Mohd Ashraf Mohd IsmailMohd Ashraf Mohd IsmailNo ratings yet

- Aeroplane Performance OXFORD PPLDocument23 pagesAeroplane Performance OXFORD PPLStefania TamasNo ratings yet

- Fluid Mechanics II (MEng 3306)Document2 pagesFluid Mechanics II (MEng 3306)Addisu DagneNo ratings yet

- The Coanda EffectDocument3 pagesThe Coanda Effectali jafNo ratings yet

- Mechanical Properties of Fluids All DervationsDocument12 pagesMechanical Properties of Fluids All DervationsAmiya Kumar Das100% (1)

- Gas Lift SystemDocument12 pagesGas Lift SystemIsmail AlmokaterNo ratings yet

- The Aerodynamics of An Inverted Wing and A Rotating Wheel in Ground EffectDocument205 pagesThe Aerodynamics of An Inverted Wing and A Rotating Wheel in Ground EffectVyssion100% (1)

- Elements of Aerospace EngineeringDocument12 pagesElements of Aerospace Engineeringrattan5No ratings yet

- MS-364 - Bernard Lindenbaum Vertical Flight Research CollectionDocument214 pagesMS-364 - Bernard Lindenbaum Vertical Flight Research CollectionStargazerNo ratings yet

- Physics of KnuckleballsDocument14 pagesPhysics of KnuckleballsukrikeNo ratings yet

- Determination of Drag and Lift Related Coefficients of An Auv Using Computational and Experimental Fluid Dynamics MethodsDocument15 pagesDetermination of Drag and Lift Related Coefficients of An Auv Using Computational and Experimental Fluid Dynamics MethodsSajad MansooriNo ratings yet

- Toyota Forklift PDFDocument2 pagesToyota Forklift PDFsaronNo ratings yet

- Offshore HydromechanicsDocument516 pagesOffshore HydromechanicsNiels SpekNo ratings yet

- SPE 169923-MS Integrated Asset Modeling in Mature Offshore Fields: Challenges and SuccessesDocument15 pagesSPE 169923-MS Integrated Asset Modeling in Mature Offshore Fields: Challenges and SuccessesboynadauNo ratings yet

- 081 Principles of Flight (JAA ATPL Theory)Document508 pages081 Principles of Flight (JAA ATPL Theory)Sarah Schroeder50% (2)

- Co-Flow Jet (CFJ) Airfoils Practicality in Engineless AirplanesDocument25 pagesCo-Flow Jet (CFJ) Airfoils Practicality in Engineless Airplanesinam vfNo ratings yet