Professional Documents

Culture Documents

Winding Coils - Page 4: Oscillator Coil

Uploaded by

Osmar ContreirasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Winding Coils - Page 4: Oscillator Coil

Uploaded by

Osmar ContreirasCopyright:

Available Formats

Winding Coils - Page 4

Oscillator Coil

This coil is needed in all of the superheterodyne radios.. It has two separate windings. Here are the steps for winding the oscillator coil. 1. Cut 2 inches of the mailing tube. A hacksaw is recommended but any fine toothed saw will do the job. Don't waste your time and effort on scissors or knives. You'll likely break the scissors and it's almost a certainty that you will cut yourself with a knife. The material is too tough for these tools and even if you do succeed in using them the cut end of the mailing tube will look extremely ragged and you will be ashamed to show it to friends. 2. Use a pencil or pen to mark off the cut piece of mailing tube as follows. Mark 1, 3/8 inch from one end. Mark 2, 3/8 inch from mark 1. 3. Use a 1/16 inch drill bit to make a hole in the mailing tube at mark 2. 4. Now mark three points for drilling holes spaced about 1/4 of the circumference of the tube apart. These holes should be on mark 1. Drill these holes with a 7/64 bit. Offset the center hole by about 30 degrees from the 1/16 inch hole as shown in the figure below.

5. Now wrap the coil form (mailing tube) with Double Stick Scotch Tape. Be as careful as you can not to leave any wrinkles or bulges in the tape. If you don't do a perfect job it's not the end of the world. Don't cover up the 7/64 inch holes if you can help it. 6. Use the drill or a small nail to punch through the tape at the 1/16 inch hole. 7. Now you are ready to start the first winding. Use the Green wire which is 26 gauge. 8. Remove the plastic from the spool of green wire and place it over something that will allow it to turn while holding it in place. I used a small screwdriver clamped in a small vise. 9. Push one end of the wire through the hole at mark 2 from the outside. Pull 3 or 4 inches of wire through on the inside of the tube. 10. Hold the wire on the inside of the tube and begin the first turn. The sticky tape will hold the wire in place and after about half a turn you won't need to hold the wire inside the tube any more. Tuck the end of the wire inside to keep it out of your way. 11. Wind the turns so each turn is touching the previous one. This will

not cause a short circuit because the wire is coated with insulating enamel. 12. Wind 3 turns. The picture below shows how to setup for winding the coil.

DON'T WIND THE COIL BY HOLDING THE FORM STILL AND MOVING YOUR HAND AROUND AND AROUND THE COIL FORM. When you do this every turn puts a twist in the wire. After a while the wire will start to kink and then get into a hopeless tangle. Roll the cylinder (mailing tube) around in your hand like the take up spool on a real to real tape recorder. (Rotate the coil form [mailing tube] around its axis.) 13. The Double Stick tape makes it possible to set the coil down in mid winding and come back to it later. It won't unwind while you take out the garbage or answer the telephone. But if your 2-year old grandchild gets a hold of it all promises are cancelled.

14. After you have wound 3 turns use the 1/16 inch drill to make a hole at the location indicated for the coil tap and just so the drill bit does not touch the last turn of the coil. 15. Wind two more turns for a total of 5 so far. The fifth turn should cross over the middle of the hole. 16. Push about 3 inches of the wire through the hole for the tap you just made. 17. Now pull some more green wire off the spool and push the end through the same hole where the end of the first green coil goes to the inside of the coil form. (Mailing tube.) 18. Hold the end inside the tube and start winding in the direction as if this coil were a continuation of the first coil. THIS IS VERY IMPORTANT! The new coil MUST go as if it is a continuation of the first coil. In fact it is. 19. Wind 38 turns. 20. Make a 1/16 inch hole at the location shown in the figure for the end of the coil and almost touching the last turn. 21. Wind 2 more turns, cut the wire and push the end through the hole. 22. Now get 3 4-40 x 1/4 machine screws, 3 4-40 nuts and 6 number 4 solder lugs. The screws and nuts are available at any hardware store worthy of the name. For the solder lugs you may have to go to an electronics supply store either brick and mortar or on line. 23. Mount a solder lug on the inside and outside of the tube at all 3 7/64 inch holes.

24. On the outside point the lugs at right angles to the axis of the tube and on the inside point the lugs inwards away from the nearest end. 25. Tighten all screws. 26. You now have 4 wires coming through the tube to the inside and 3 solder lugs on the inside to solder them to. 27. To prepare the end of a wire to be soldered to a lug do the following. 1. Pull the end of the wire to the lug where you want it to go. 2. Leave quite a bit of slack in case you break the wire before you solder it. 3. Cut off the excess and bring the end of the wire out of the end of the tube so you can get at it. 4. Tare off a small piece of sand paper about 1 inch by 1/2 inch. Fold it in the middle of the long dimension with the sand on the inside. 5. Place the end of the wire inside the sand paper, pinch it between thumb and for-finger and pull it along the wire to its end. You will see the green enamel come off and the copper wire underneath will be revealed. Work around the wire until there is a bright copper area at the end of the wire. 6. On the two wires that come through the same hole remove the enamel as far into the tube as you can reach. 7. Twist these two wires together to become effectively one wire. 8. Pass the end of this double wire through a hole in the center solder lug of the three, pull it tight, wrap it around and solder it in place. 9. Solder the remaining two wires to the solder lugs that are closest to where they come through to the inside of the tube. 28. The picture shows the solder lugs.

29. Now solder lengths of colored insulated hookup wire to the lugs on the coil form as follows. 1. Yellow wire to the lug where the two wires come together. This is the tap on the coil. 2. Green wire to the end of the coil as indicated in the drawing above. 3. Black wire to the beginning of the coil as indicated in the drawing above. This completes the oscillator coil. Now, that didn't hurt a bit did it! The colors for the wires were not selected on a personal whim. Traditionally in tube equipment certain wire colors have been associated with certain functions. B+ or plate supply wires are red, wires from plate coils to the plate of a tube are blue, wires from grid coils to the grid are green, and wires to the opposite end of grid coils are yellow. These last may supply grid bias or AGC/AVC (Automatic Gain Control/Automatic Volume Control). Use your back button to return to where you were before. Home This page last updated June 11, 2002

You might also like

- How To Wire Wrap A Coin Pendant TutorialDocument5 pagesHow To Wire Wrap A Coin Pendant TutorialBeadinggem100% (13)

- Build Your Own Wind TurbineDocument9 pagesBuild Your Own Wind Turbinemarintraian100% (1)

- How To Build Your Own Magnetic PulserDocument5 pagesHow To Build Your Own Magnetic PulserWb Warnabrother HatchetNo ratings yet

- Build Your Own Wind GeneratorDocument14 pagesBuild Your Own Wind GeneratorClaude-Michel Prevost100% (1)

- Kumihimo Cord and Seed Bead NecklaceDocument1 pageKumihimo Cord and Seed Bead NecklaceluyawinNo ratings yet

- Dual Core Balun Construction ProjectDocument7 pagesDual Core Balun Construction ProjectCarlos MerelloNo ratings yet

- How To Make Paintball GunDocument10 pagesHow To Make Paintball GunAinis ŠtelemėkasNo ratings yet

- Triple Helix Wire Jewellery With PhotoDocument6 pagesTriple Helix Wire Jewellery With Photohugssw2gmailcom100% (2)

- Wire Wrapping JewelryDocument12 pagesWire Wrapping JewelryAlice M. Martelo100% (1)

- $20 Combat Crossbow, TheDocument8 pages$20 Combat Crossbow, TheKaryllongNo ratings yet

- Fractal Magic DIY HDTV AntennaDocument56 pagesFractal Magic DIY HDTV Antennadetroit_me2553100% (3)

- Crossbow 20 PDFDocument8 pagesCrossbow 20 PDFGeoffrey Hamilton-adamsNo ratings yet

- How To Make Plant HangersDocument36 pagesHow To Make Plant Hangersanimalitoacuatico80% (5)

- Wire Work: The JigDocument10 pagesWire Work: The JigChhaya100% (1)

- Travel AntennaDocument5 pagesTravel Antennanw2sNo ratings yet

- 5438 - BridgePort - 96541645 ProgManual DXF EZ Trak Programming and Operating Manual March 2001Document289 pages5438 - BridgePort - 96541645 ProgManual DXF EZ Trak Programming and Operating Manual March 2001July SenNo ratings yet

- Panel Relay Remoto PDFDocument12 pagesPanel Relay Remoto PDFroberto sanchezNo ratings yet

- P60X901 Service ManualDocument143 pagesP60X901 Service ManualChristopher A ArcherNo ratings yet

- Jacksons Tesla Wireless Coil Instructions Apr 21 2011Document50 pagesJacksons Tesla Wireless Coil Instructions Apr 21 2011zunder12100% (1)

- Macrame Bangle BraceletDocument6 pagesMacrame Bangle Braceletmahira_tippu100% (1)

- Make A 3 Phase GeneratorDocument12 pagesMake A 3 Phase GeneratorLaterNo ratings yet

- Solar Mars 100 Technical and Commercial-Rev0Document20 pagesSolar Mars 100 Technical and Commercial-Rev0Jojo Aboyme Corcilles100% (1)

- Electronic Drum PadDocument44 pagesElectronic Drum PadMarinko TikvickiNo ratings yet

- Butterfly Wire PendantDocument4 pagesButterfly Wire PendantSaponetta91100% (1)

- Splices and Joints 1 1Document38 pagesSplices and Joints 1 1Ivan PaderesNo ratings yet

- Wire Jewelry Tutorial: Grapes Chandelier EarringsFrom EverandWire Jewelry Tutorial: Grapes Chandelier EarringsRating: 4 out of 5 stars4/5 (1)

- Fundamentals of Telecommunications Engineering (TC-101) PDFDocument72 pagesFundamentals of Telecommunications Engineering (TC-101) PDFraymon6666No ratings yet

- Easy To Build Stirling Engine FanDocument14 pagesEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- Esmeralda PendantDocument13 pagesEsmeralda PendantAnto Nella100% (4)

- How To Build A Paracord FloggerDocument9 pagesHow To Build A Paracord FloggerReaperGod 245No ratings yet

- Bud Die PoleDocument5 pagesBud Die PoleDennis OszuscikNo ratings yet

- Easy Wire Art: How to Make 21 Stylish & Decorative ProjectsFrom EverandEasy Wire Art: How to Make 21 Stylish & Decorative ProjectsNo ratings yet

- Wired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsFrom EverandWired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsRating: 1 out of 5 stars1/5 (1)

- 6 Lab Making A Foxhole RadioDocument6 pages6 Lab Making A Foxhole RadioMaddy SjiicroNo ratings yet

- Fly Can Be Pretty Too: Wire & Jewelry Making Tutorial Series T99From EverandFly Can Be Pretty Too: Wire & Jewelry Making Tutorial Series T99Rating: 3.5 out of 5 stars3.5/5 (2)

- Manual Festo DidacticoDocument51 pagesManual Festo DidacticoEmilio Contreras VieraNo ratings yet

- 2 Meter VerticalDocument16 pages2 Meter VerticalEndarika Yulianto Eka100% (1)

- Stator Generator EolianDocument40 pagesStator Generator EolianCatalin BordeiNo ratings yet

- E Igniter2 PDFDocument19 pagesE Igniter2 PDFWilliam OsburnNo ratings yet

- SudentreedguideDocument5 pagesSudentreedguideapi-81080683No ratings yet

- NISAMAX Solar Lantern Construction ManualDocument11 pagesNISAMAX Solar Lantern Construction ManualSourabh SalgiaNo ratings yet

- Reedmaking NotesDocument3 pagesReedmaking Notesapi-201119152No ratings yet

- BuddyPole Antenna PlansDocument23 pagesBuddyPole Antenna PlansJose MesquitaNo ratings yet

- Fractal Magic DIY HDTV Antenna PDFDocument56 pagesFractal Magic DIY HDTV Antenna PDFDarin ArmsteadNo ratings yet

- Alt Manual RaDocument4 pagesAlt Manual RaMR XNo ratings yet

- Mojotone PAF Humbucker Kit Instructions: Before You Get Started ConsiderDocument12 pagesMojotone PAF Humbucker Kit Instructions: Before You Get Started ConsiderlorenzoNo ratings yet

- Horrocks - Trinity Wand Picture Tutorial (Orgonite Wand)Document20 pagesHorrocks - Trinity Wand Picture Tutorial (Orgonite Wand)Rafita100% (5)

- Wb3ayw Wire Collinear For 2 MetersDocument7 pagesWb3ayw Wire Collinear For 2 MetersEduard Gabi OrdeanNo ratings yet

- Splicing and Jointing Electrical WiresDocument35 pagesSplicing and Jointing Electrical WiresApril John ArbutanteNo ratings yet

- ConstructionDocument3 pagesConstructionlordbravoriousNo ratings yet

- Narrative ReportDocument1 pageNarrative Reportlac garcia100% (2)

- Rovinstructions @mrabiDocument20 pagesRovinstructions @mrabiSai SharanNo ratings yet

- Cromwell BeanieDocument6 pagesCromwell BeanieDominic RetschlagNo ratings yet

- Homebrew BuddipoleDocument10 pagesHomebrew Buddipole10sd156No ratings yet

- Taps Splices and JointsDocument10 pagesTaps Splices and Jointsrowell ramosNo ratings yet

- 2 Meter Vertical DipoleDocument16 pages2 Meter Vertical DipoleMubinNo ratings yet

- Balun Intro and Construction 1Document6 pagesBalun Intro and Construction 1Robson Batista do nascimentoNo ratings yet

- Transcript of Wire TapsDocument5 pagesTranscript of Wire TapsReynante AlabataNo ratings yet

- Wire Woven EarringsDocument3 pagesWire Woven EarringssammysmithaztNo ratings yet

- Design and Construction of A Quadrifilar Helix Antenna For Receiving NOAA Satellites 1Document6 pagesDesign and Construction of A Quadrifilar Helix Antenna For Receiving NOAA Satellites 1Luis MartinezNo ratings yet

- Dynamos LessonDocument10 pagesDynamos Lessonmuhammad nadeemNo ratings yet

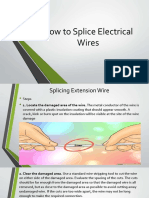

- How To Splice Electrical Wires: By: Raymar M. BaquilarDocument18 pagesHow To Splice Electrical Wires: By: Raymar M. BaquilarShema MerchsNo ratings yet

- TVET 1 (Info. Sheet 12)Document4 pagesTVET 1 (Info. Sheet 12)zaidoNo ratings yet

- Integrating Technology in The Classroom 1Document12 pagesIntegrating Technology in The Classroom 1api-457024644No ratings yet

- AN EL9800 V1i1Document33 pagesAN EL9800 V1i1mikeNo ratings yet

- Apps Guide 2nd Edition DSAQ Down Syndrome Association Queensland AUSTRALIADocument28 pagesApps Guide 2nd Edition DSAQ Down Syndrome Association Queensland AUSTRALIAKathleen EdwardsNo ratings yet

- Concrete Duct Cable Chambers - Highways Agency Cable Pits PDFDocument28 pagesConcrete Duct Cable Chambers - Highways Agency Cable Pits PDFAdhitya DwijayanthoNo ratings yet

- 65F710 SpecsDocument1 page65F710 SpecsEARLPOKIE100% (2)

- Reference Manual: Date: 8-11-06Document31 pagesReference Manual: Date: 8-11-06Shobhit GargNo ratings yet

- Changzhou Wantai Electrical Appliance Co., LTD: User Guide For 3 Axis TB6560 Driver BoardDocument9 pagesChangzhou Wantai Electrical Appliance Co., LTD: User Guide For 3 Axis TB6560 Driver Boardjulio cesar rosales mendezNo ratings yet

- MPR4200 12 Channels Color Paperless RecorderDocument7 pagesMPR4200 12 Channels Color Paperless RecorderHilde GoebelNo ratings yet

- M2150 MultiCab Elevator Controller Installation Instructions Issue 1.2Document2 pagesM2150 MultiCab Elevator Controller Installation Instructions Issue 1.2Anonymous IQJwSTNo ratings yet

- v60G - User Manual - v1.8Document129 pagesv60G - User Manual - v1.8Gabo CirauloNo ratings yet

- Disable UEFI SEcure BootDocument2 pagesDisable UEFI SEcure BootnurNo ratings yet

- Introduction To COBOLDocument26 pagesIntroduction To COBOLLk SoniNo ratings yet

- TTL Texas Instruments: 7400 Series Integrated CircuitsDocument14 pagesTTL Texas Instruments: 7400 Series Integrated CircuitsRickey Castillo ValenzuelaNo ratings yet

- Bravia ManualDocument24 pagesBravia ManualMargie QuintiaNo ratings yet

- MB90F337Document85 pagesMB90F337Bin WangNo ratings yet

- Canon CanoScan 9000F Detail SpecificationDocument2 pagesCanon CanoScan 9000F Detail Specificationbelonk_182No ratings yet

- 2012 iOS DEVELOPER Interview QuestionsDocument6 pages2012 iOS DEVELOPER Interview QuestionsAleks KoporgeNo ratings yet

- Introduction To The CD-ROM Edition: The ARRL Handbook For Radio CommunicationsDocument4 pagesIntroduction To The CD-ROM Edition: The ARRL Handbook For Radio CommunicationsHeribertus BudhihartoNo ratings yet

- ¡ IMS 8.2¡¿UGC3200 Supporting New R3 BoardsDocument16 pages¡ IMS 8.2¡¿UGC3200 Supporting New R3 BoardssirjimyNo ratings yet

- Ladder Logic ProjectDocument20 pagesLadder Logic ProjectIonescu ViorelNo ratings yet

- Usb To CanDocument12 pagesUsb To CanZamir HussainNo ratings yet

- Overhead Stirrers of Selection CriteriaDocument11 pagesOverhead Stirrers of Selection Criteriamailtorubal2573No ratings yet

- Galil Galiltools CatalogDocument2 pagesGalil Galiltools CatalogElectromateNo ratings yet

- Linux CommandsDocument22 pagesLinux CommandsNaru Madhu Sudhan ReddyNo ratings yet