Professional Documents

Culture Documents

Mechanical Failure Modes

Uploaded by

Sankara RaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Failure Modes

Uploaded by

Sankara RaoCopyright:

Available Formats

Buckling

Buckling is the failure of a long, slender column that has been subjected to a compressive,

axial load. As the load is applied, the center of the column span bulges outward, and then

either cracks or yields, depending on the material properties of the specific component.

Corrosion

Corrosion is the chemical alteration (generally, but not always, oxidation), of a material due to

environmental exposure to corrosive elements. For example, iron or steel that is exposed to

air can undergo oxidation, forming iron oxide, commonly known as rust.

Creep

Creep is the slow deformation of a solid material over time due to applied loads and often

increased temperatures. Creep can result in changes in material properties and part

geometries that can cause failures.

Primary mechanical failure modes

Fatigue

Fatigue is a reduction in the ultimate strength of a material due to cyclic loading of a part.

Even elastic deformations can result in material changes that can reduce the ultimate strength

over a large number of cycles.

Fracture

Fracture begins as a localized micro crack in a part that slowly grows over time, or grows

rapidly when exposed to a large overload. Failure occurs when the crack growth becomes

critical and the part breaks. Crack growth often begins in areas of high stress concentration,

such as corners.

Impact

Impact failure, just as it sounds, is the failure of a part due to impact with or by another

object. A baseball shattering a window is an impact failure.

Primary mechanical failure modes

Rupture

Rupture generally occurs in pressure vessels or other containers when the pressure within the

vessel exceeds the strength of a vessel, either globally or locally.

Thermal Shock

Thermal shock is the result of a component moving quickly from one temperature extreme to

another. For example, brittle materials such as cast iron experience thermal shock if a hot part

is suddenly cooled.

Wear

Wear is the gradual removal of material by two parts rubbing against each other, or

environmental contact with a part, such as water or sand.

Yielding

The yield point is essentially the peak load that the part can hold before the material stretches

apart.

Primary mechanical failure modes

Metal Fatigue is a process which causes premature irreversible damage or failure of a

component subjected to repeated loading.

Fatigue is a sequence of several complex phenomena encompassing several disciplines:

motion of dislocations

surface phenomena

fracture mechanics

stress analysis

probability and statistics

Fatigue takes many forms:

fatigue at notches

rolling contact fatigue

fretting fatigue

corrosion fatigue

creep-fatigue

Fatigue is a not a cause of failure, but it leads to the final failure/damage

Fatigue

There are many harmful factors to the materials beyond the scope of strength of materials.

The accumulation of one or several of these factors eventually shorten the service life of

materials. The combined effect of these factors is called "fatigue mechanism". Some common

fatigue mechanisms include:

Time-varying Loading Fatigue

Thermal Fatigue

Corrosion Fatigue

Surface/Contact Fatigue

Combined Creep and Fatigue

Definition: Fatigue is the process of progressive localized permanent structural change

occurring in a material subjected to conditions which produce fluctuating stresses and strains

at some point or points and which may culminate in cracks or complete fracture after a

sufficient number of fluctuations. (ASTM standard definition)

Fatigue

Versailles rail accident occurred on May 8, 1842

Examination of several broken axles from British railway vehicles by William John Macquorn

Rankine showed that they had failed by brittle cracking across their diameters, a problem

now known as fatigue. At the time, there was considerable confusion about the problem.

First fatigue failure

Drawing of a fatigue failure in an axle, 1843. Versailles train disaster

1840s Fatigue failure of railroad axles stress concentration at shoulders

1850 1860 Whler (German), The father of systematic fatigue testing introduced S-N

diagram

1870 1890 Gerber and Goodman provide analysis tools to account for superimposed

mean and alternating stresses

1920s Gough examined slip lines and analyzed the mechanisms of fatigue

1920s Griffith studied brittle fracture

1930s Haigh notch strain analysis

1930s Almen shot peening to create residual compressive surface stresses

1945s Miner cumulative damage concept to account for stress regime of varying

amplitude (suggested by Palmgren in 1924)

1950s Irwin introduced stress intensity factor, the basis for linear elastic fracture

mechanics (LEFM)

1960s Manson and Coffin introduced LCF (low cycle fatigue)

Fatigue in history

Appearance of failure surfaces caused by various modes of loading (SAE Handbook)

Appearance of failure surfaces

Time-Varying Loading

Time-varying Loading Fatigue can be defined as a process caused by time-varying loads

which never reach a high enough level to cause failure in a single application, and yet results

in progressive localized permanent damages on the material.

The damages, usually cracks, initiate and propagate in regions where the strain is most

severe. When the local damages grow out of control, a sudden fracture/rupture ends the

service life of the structure.

Thermal fatigue

Thermal fatigue is the gradual deterioration ad eventual cracking of a material by alternate

heating and cooling during which free thermal expansion is partially or completely

constrained.

Constraint of thermal expansion causes thermal stresses which may eventually initiate and

propagate fatigue cracks.

Mostly thermal fatigue will be classified under low cycle fatigue . Because thermal

fatigue cracks usually starts in less than 50000 cycles.

Thermal fatigue was classified as thermal fatigue and isothermal fatigue

Fatigue

Corrosion fatigue

Corrosion Fatigue (CF) is the metal cracking caused by combined action of a cyclic loading

and a corrosive environment.

Classified as Corrosion fatigue and Stress corrosion fatigue. The principal difference is static

stress in corrosion fatigue & alternating/ fluctuating stress in stress corrosion fatigue.

Surface / Contact fatigue

CONTACT FATIGUE is a surface-pitting-type failure commonly found in ball or roller bearings.

This type of failure can also be found in gears, cams, valves, rails, and gear couplings.

Contact fatigue differs from classic structural fatigue (bending or torsion) in that it results

from a contact or Hertzian stress state.

This localized stress state results when curved surfaces are in contact under a normal load.

Fatigue

Fatigue

loading

Fatigue

loading

Constant

amplitude

Constant

amplitude

Proportional

loading

Proportional

loading

Non

proportional

loading

Non

proportional

loading

Variable

amplitude

Variable

amplitude

Proportional

loading

Proportional

loading

Non

proportional

loading

Non

proportional

loading

Note: Loading ratio = 1, for proportional loading { ratio of second load to first load}

Fatigue loading

Proportional loading

Loading ratio = 1

Principal stress axes do not

change over time

Single set FE result study

can identify critical fatigue

location

No, cycle counting and

cumulative damage

calculations

Non proportional loading

Loading ratio 1

Principal stress axes are

free to change between 2

load sets

Critical fatigue location may

appear in spatial

Cycle counting, damage

summation need to be done

to identify total fatigue

damage

Fatigue loading

2

stress, Mean

min max

m

+

=

2

stress, g Alternatin

min max

a

=

max

min

R

ratio, Stress

=

min max r

range, Stress

=

m

a

A

amplitude, Stress

=

Fatigue loading

German engineer August Whler conducted the first systematic fatigue investigation. Whler

conducted cyclic tests on full-scale railway axles and also on small-scale bending, torsion and

push-pull specimens of several different materials. Typically, the S-N relationship is

determined for a specific value of MEAN STRESS, STRESS RATIO or AMPLITUDE RATIO.

Most determinations of fatigue properties have been made in completely reversed bending,

i.e. R = -1, by means of the so-called rotating bend test.

The usual laboratory procedure for determining an S-N curve is to test the first specimen at

a high stress, about two thirds of the static tensile stress of the material, where failure is

expected in a fairly small number of cycles. The test stress is decreased for each succeeding

specimen until one or two specimens do not fail before at least 10

7

cycles. For materials

which exhibit it, the highest stress at which no failure occurs, a run out, is taken to be the

fatigue limit.

S-N Curve (or) Whler curve

S-N Curve (or) Whler curve

R. R. Moore rotating beam experimental setup.

S-N Curve

S-N Curve

Haigh proposed and conducted series of tests to investigate different combinations of stress

amplitude and mean stress for a given number of cycles to failure.

The diagram plots the mean stress, both tensile and compressive, along the x-axis and the

alternating constant stress amplitude along the y-axis.

This is commonly referred as the Haigh diagram.

Failure appears to be more sensitive to tensile mean stress, than compressive mean stress.

Mean stress influence

Mean stress influence

SAE Master diagram AISI4340 steel

stress) fracture True - (

1

S

S

S

: s) 1960' (USA, Morrow

1

S

S

S

S

: 1930) (USA, Soderberg

1

S

S

S

S

: 1874) (Germany, Gerber

1

S

S

S

S

: 1899) (England, Goodman

f

f

m

e

a

y

m

e

a

2

u

m

e

a

u

m

e

a

= +

= +

=

|

|

.

|

\

|

+

= +

All methods should only be used for tensile mean stress values.

The Soderberg method is very conservative. It is used in applications where neither fatigue

failure nor yielding should occur.

For hard steels (brittle), where the ultimate strength approaches the true fracture stress, the

Morrow and Goodman curves are essentially equivalent.

For ductile steels (

f

> S

u

), the Morrow model predicts less sensitivity to mean stress.

Empirical relations

Applied Stresses

Stress range The basic cause of plastic deformation and consequently the accumulation of

damage

Mean stress Tensile mean and residual stresses aid to the formation and growth of fatigue

cracks

Stress gradients Bending is a more favorable loading mode than axial loading because in

bending fatigue cracks propagate into the region of lower stresses

Materials

Tensile and yield strength Higher strength materials resist plastic deformation and hence

have a higher fatigue strength at long lives. Most ductile materials perform better at short

lives

Quality of material Metallurgical defects such as inclusions, seams, internal tears, and

segregated elements can initiate fatigue cracks

Temperature Temperature usually changes the yield and tensile strength resulting in the

change of fatigue resistance (high temperature decreases fatigue resistance)

Frequency (rate of straining) At high frequencies, the metal component may be self-

heated.

Factors Influencing Fatigue Life

Size and shape of the component or structure

Type of loading and state of stress

Stress concentration

Surface finish

Operating temperature

Service environment

Method of fabrication

e

= k

a

k

b

k

c

k

d

k

e

k

f

k

g

k

h

where

e

= endurance limit of component

e

= endurance limit experimental

k

a

= surface finish factor (machined parts have different finish)

k

b

= size factor (larger parts greater probability of finding defects)

k

c

= reliability / statistical scatter factor (accounts for random variation)

k

d

= operating T factor (accounts for diff. in working T & room T)

k

e

= loading factor (differences in loading types)

k

f

= stress concentration factor

k

g

= service environment factor (action of hostile environment)

k

h

= manufacturing processes factor (influence of fabrication parameters)

Factors effecting the Fatigue life

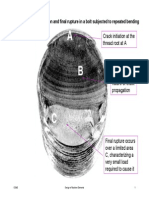

There are typically three stages to fatigue failure.

1. First, a small crack is initiated or nucleates at the surface and can include scratches, pits,

sharp corners due to poor design or manufacture, inclusions, grain boundaries or

dislocation concentrations.

2. Second, the crack gradually propagates as the load continues to cycle.

3. Third, a sudden fracture of the material occurs when the remaining cross-section of the

material is too small to support the applied load.

Stages of fatigue failure

The total number of cycles to failure is the sum of cycles at the first and the second stages:

N

f

= N

i

+ N

p

N

f

: Number of cycles to failure

N

i

: Number of cycles for crack initiation

N

p

: Number of cycles for crack propagation

High cycle fatigue (low loads): N

i

is relatively high. With increasing stress level, N

i

decreases

and N

p

dominates

Cycles to failure

Fatigue analysis Fatigue analysis

FEA based FEA based

Stress life

approach

Stress life

approach

Strain life

approach

Strain life

approach

Crack propagation Crack propagation Vibration approach Vibration approach

Experimental based Experimental based

High cycle fatigue

Subjected to less

sever loads

Stress with in

elastic limit

First fatigue

analysis

Uses S-N curves

Low cycle fatigue

Heavy duty

applications

Crack initiation life

Elastic & plastic

strains

Uses -N curves

Developed in

1960s

Fracture

mechanics

LEFM, EPFM

Rate of crack

growth

Life left

Can combine with

LCF

Complex analysis

Resonance effect

Need dynamic

stress as input

FRF and PSD

based analysis

Fatigue analysis

Generally high cycle fatigue involves high frequencies 1000 Hz (cycles/sec)

Assumes that all stresses in the component, even local stress, stay below elastic limit at all

time

Easy to use and simple approach based on S-N curve

Availability of ample data

High cycle fatigue

Generally low cycle fatigue involves lower frequencies but using higher forces to test the

plastic properties of a material.

Strain is the basic cause of fatigue.

At some point in the component being loaded the strain must be plastic (i.e. non reversible)

for a crack to start.

This method calculates crack initiation life.

It is important for situations in which components or portions of components undergo either

mechanically or thermally induced cyclic plastic strains that cause failure within relatively few

cycles.

LCF is also referred as LLC (life limited components)

Low cycle fatigue

You might also like

- Mechanical Failure of Materials 9789814560375-c2Document23 pagesMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- Spontaneous Unfastening and Fatigue of Bolted Joints PDFDocument3 pagesSpontaneous Unfastening and Fatigue of Bolted Joints PDFIvan KlyuchkaNo ratings yet

- Mechanical Seal Design, Operation and Maintenance ProblemsDocument5 pagesMechanical Seal Design, Operation and Maintenance Problemschazz29hkNo ratings yet

- Fractography SteelDocument42 pagesFractography SteelRebeccaNandaNo ratings yet

- FATIGUE FAILURE ANALYSIS: S-N CURVES, ENDURANCE LIMITS, AND STRESS CONCENTRATIONSDocument27 pagesFATIGUE FAILURE ANALYSIS: S-N CURVES, ENDURANCE LIMITS, AND STRESS CONCENTRATIONSAdityaKumarMaharana100% (1)

- ARTIGO Chapter 8 Solidification ShrinkageDocument67 pagesARTIGO Chapter 8 Solidification Shrinkagemarcotulio123No ratings yet

- The Importance of Proper Bearing LubricationDocument7 pagesThe Importance of Proper Bearing LubricationSRINIVASA RAO DUVVADANo ratings yet

- FractographyDocument17 pagesFractographysultanrandhawa100% (3)

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Bolted Connection FatigueDocument12 pagesBolted Connection FatigueMahfuzur Rahman100% (1)

- Failure Analysis Master Course V1Document21 pagesFailure Analysis Master Course V1manu6969aNo ratings yet

- Failure AnalysisDocument7 pagesFailure AnalysisbefoaNo ratings yet

- Bolts and ConnectionsDocument11 pagesBolts and ConnectionsSafrul EfendiNo ratings yet

- Failure Analysis of Engineering MaterialsDocument2 pagesFailure Analysis of Engineering Materialsmahesh0% (1)

- Stress Corrosion CrackingDocument2 pagesStress Corrosion Crackingfawmer61No ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument21 pagesAn Introduction To Failure Analysis For Metallurgical EngineersNavneet SharmaNo ratings yet

- Creep MechanismDocument5 pagesCreep MechanismJai BhavaniNo ratings yet

- Technical Brief: Avoiding Bolt Failures: F E A T U R EDocument2 pagesTechnical Brief: Avoiding Bolt Failures: F E A T U R EkanosriNo ratings yet

- Receive Hardcopy Magazine PublicationDocument3 pagesReceive Hardcopy Magazine PublicationInspection EngineerNo ratings yet

- CorrosionDocument20 pagesCorrosionDhruv SharmaNo ratings yet

- Failure MechanismsDocument14 pagesFailure Mechanismsho-faNo ratings yet

- Fatigue FailureDocument47 pagesFatigue FailureOmar KhanNo ratings yet

- Fracture Failure Analysis of AISI 304L Stainless Steel ShaftDocument11 pagesFracture Failure Analysis of AISI 304L Stainless Steel ShaftPedro HenriqueNo ratings yet

- Corrosion Problems and Alloy SolutionsDocument61 pagesCorrosion Problems and Alloy Solutionszuudee100% (1)

- In Axial Loading: Types StressDocument6 pagesIn Axial Loading: Types StressPaúlNinaquispeNo ratings yet

- Reverted austenite causes fastener corrosionDocument3 pagesReverted austenite causes fastener corrosionmp87_ingNo ratings yet

- Avoiding Bolt Failures PDFDocument2 pagesAvoiding Bolt Failures PDFyh1.yuNo ratings yet

- Machine Component Failure AnalysisDocument9 pagesMachine Component Failure Analysiskanakarao1No ratings yet

- Yield Point PDFDocument12 pagesYield Point PDFengineer bilal100% (1)

- A. Palmgren RevisitedDocument12 pagesA. Palmgren RevisitedahmedbeaetNo ratings yet

- Creep & SpheroidizationDocument10 pagesCreep & Spheroidizationabet_singkong8930No ratings yet

- A Hardness-Based Creep Rupture Model For NewDocument15 pagesA Hardness-Based Creep Rupture Model For NewzhangxingzydNo ratings yet

- Stainless Steels and Alloys - Why They Resist Corrosion and How They FailDocument15 pagesStainless Steels and Alloys - Why They Resist Corrosion and How They FailMarcos LeiteNo ratings yet

- Basics of Failure AnalysisDocument78 pagesBasics of Failure AnalysisEvolveengNo ratings yet

- RotordamageDueToElectromagneticShaftCurrentsDocument13 pagesRotordamageDueToElectromagneticShaftCurrentsJose PradoNo ratings yet

- ME 251 Materials Engineering Lab: Fatigue Test ReportDocument19 pagesME 251 Materials Engineering Lab: Fatigue Test ReportKen VuNo ratings yet

- MEE Avoiding Bolt FailuresDocument2 pagesMEE Avoiding Bolt Failuresridwan347No ratings yet

- Bolt Tightening Hadbook-SKF PDFDocument44 pagesBolt Tightening Hadbook-SKF PDFamirthraj74No ratings yet

- Environmentally Assisted Cracking - Predictive Methods For Risk Assessment and Evaluation of Materials, Equipment, and Structures (ASTM Special Technical Publication, 1401) PDFDocument491 pagesEnvironmentally Assisted Cracking - Predictive Methods For Risk Assessment and Evaluation of Materials, Equipment, and Structures (ASTM Special Technical Publication, 1401) PDFNA Sleeper100% (1)

- Stress Corrosion CrackingDocument50 pagesStress Corrosion CrackingssjunedNo ratings yet

- 6 Reasons Why Mechanical Seals FailDocument3 pages6 Reasons Why Mechanical Seals Failgustavo rivaroliNo ratings yet

- ART Threaded Fastener Design and AnalysisDocument40 pagesART Threaded Fastener Design and AnalysisAarón Escorza MistránNo ratings yet

- Superlite: Superlite Asbestos Free Gp-150Document4 pagesSuperlite: Superlite Asbestos Free Gp-150blahblahNo ratings yet

- Failure Analysis of AISI 410 Stainless-Steel Piston Rod in Spillway Floodgate (2019)Document12 pagesFailure Analysis of AISI 410 Stainless-Steel Piston Rod in Spillway Floodgate (2019)Dzaky ArizsaNo ratings yet

- Fatigue of Threaded Fasteners: Alex Hudgins Brad James, FasmDocument5 pagesFatigue of Threaded Fasteners: Alex Hudgins Brad James, Fasmyh1.yuNo ratings yet

- Galvanic and Corrosion Compatibility Dissimilar Metal Corrosion GuideDocument21 pagesGalvanic and Corrosion Compatibility Dissimilar Metal Corrosion Guidehitesh_tilalaNo ratings yet

- Brief Study on Nickel-Based Superalloys (39Document22 pagesBrief Study on Nickel-Based Superalloys (39VIMAL JOSHYNo ratings yet

- Monotectic AlloysDocument8 pagesMonotectic Alloysandrea usugaNo ratings yet

- Failure Analysis Case History No. 001: Industry: Specimen Description: Material: Environment: BackgroundDocument45 pagesFailure Analysis Case History No. 001: Industry: Specimen Description: Material: Environment: Backgroundgunasekar100% (1)

- ASTM - STP436 Electron FractographyDocument236 pagesASTM - STP436 Electron Fractographyacadjournals. comNo ratings yet

- A Review On Low Cycle Fatigue FailureDocument4 pagesA Review On Low Cycle Fatigue FailureIJSTENo ratings yet

- Failure Analysis of Helical Gear Shaft in Hot Rolling MillDocument7 pagesFailure Analysis of Helical Gear Shaft in Hot Rolling Millvasundhara singhNo ratings yet

- Hydrodynamic BearingsDocument14 pagesHydrodynamic BearingsShobhit MishraNo ratings yet

- Effect of Ozone On Rubbers - Countermeasures and Unsolved ProblemsDocument34 pagesEffect of Ozone On Rubbers - Countermeasures and Unsolved ProblemsNguyen Hoang SonNo ratings yet

- Application HydrostaticsDocument23 pagesApplication HydrostaticsHASSAN ARSHADNo ratings yet

- Seccionalizador ENTECDocument4 pagesSeccionalizador ENTECedwin_rollyNo ratings yet

- Worcester Danesmoor Utility Boiler ManualDocument12 pagesWorcester Danesmoor Utility Boiler ManualdavidraeburnNo ratings yet

- P0340Document5 pagesP0340Freddie Kemp100% (1)

- Literature ReviewDocument18 pagesLiterature ReviewRaymond Manalo Panganiban100% (1)

- Hex1 Specification SheetDocument2 pagesHex1 Specification SheetMoodNo ratings yet

- Multi-Band Spectrum Sensing and Resource Allocation For Iot in Cognitive 5G NetworksDocument15 pagesMulti-Band Spectrum Sensing and Resource Allocation For Iot in Cognitive 5G NetworksYounes BalboulNo ratings yet

- Series Production of The FL 2500 Is Starting Up: The World S Highest Wind TurbineDocument4 pagesSeries Production of The FL 2500 Is Starting Up: The World S Highest Wind TurbineuploadertoolNo ratings yet

- 10W Single Output Industrial DIN Rail Power Supply: SeriesDocument2 pages10W Single Output Industrial DIN Rail Power Supply: SeriesCiprian BalcanNo ratings yet

- Wet Granulation End-Point DeterminationDocument18 pagesWet Granulation End-Point DeterminationPreeti Wavikar-PanhaleNo ratings yet

- Environmental Test Chamber - Envisys TechDocument13 pagesEnvironmental Test Chamber - Envisys TechEnvisys Technologies Pvt LtdNo ratings yet

- Wireless Mobile Networks - Ch2Document16 pagesWireless Mobile Networks - Ch2Mohammed ZohlofNo ratings yet

- Ceramics Science IntroductionDocument68 pagesCeramics Science IntroductionLaura BárbaroNo ratings yet

- 6MW Wind Turbine Control Design AnalysisDocument8 pages6MW Wind Turbine Control Design Analysisoat_sohoNo ratings yet

- Renewable Energy WebquestDocument3 pagesRenewable Energy Webquestapi-264756260No ratings yet

- Zero BezzelDocument2 pagesZero BezzelkhoerulmuftiNo ratings yet

- En 609-1 PDFDocument14 pagesEn 609-1 PDFSURESHKUMARNo ratings yet

- Report On Study of Power Generating System and Distribution in Captive Power PlantDocument30 pagesReport On Study of Power Generating System and Distribution in Captive Power PlantrajuNo ratings yet

- CSE Engineering Course DetailsDocument233 pagesCSE Engineering Course DetailsVenkatesh Kumar0% (1)

- DryingDocument8 pagesDryingGeeva Prasanth ANo ratings yet

- Lithium-Ion BetteriesDocument9 pagesLithium-Ion BetteriesTasya OsipovaNo ratings yet

- Motorcycle CatalogDocument24 pagesMotorcycle CatalogCarsten JakobsenNo ratings yet

- DC Testing Solar InverterDocument5 pagesDC Testing Solar Inverterzeljkoc21No ratings yet

- Field Bus CommunicationDocument30 pagesField Bus CommunicationArun KumarNo ratings yet

- Lecture 7 8 Synchronous MotorDocument19 pagesLecture 7 8 Synchronous MotorCHATHURA MADURANGANo ratings yet

- Service Manual: Chassis & Mast MC/FCDocument9 pagesService Manual: Chassis & Mast MC/FCyojar apazaNo ratings yet

- Lect01 (MT 353)Document14 pagesLect01 (MT 353)Afzal Khan sulemaniNo ratings yet

- Jet A or Jet A-1 aviation fuel specification sheetDocument1 pageJet A or Jet A-1 aviation fuel specification sheetnishilgeorgeNo ratings yet

- The Effect of Heat On Matter (Melting&Freezing) .Ppt2Document17 pagesThe Effect of Heat On Matter (Melting&Freezing) .Ppt2Farah Dinah HassanNo ratings yet

- Busduct PDFDocument7 pagesBusduct PDFrohith87nairNo ratings yet