Professional Documents

Culture Documents

A Simple Preparative Polyacrylamide Gel Electrophoresis For The Purification of Chymotrypsin Inhibitor Isoforms From Ganoderma Lucidum

Uploaded by

chavi1310Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Simple Preparative Polyacrylamide Gel Electrophoresis For The Purification of Chymotrypsin Inhibitor Isoforms From Ganoderma Lucidum

Uploaded by

chavi1310Copyright:

Available Formats

Notes

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 10

1531

A Simple Preparative Polyacrylamide Gel Electrophoresis for the Purification of Chymotrypsin Inhibitor Isoforms from Ganoderma lucidum

Jin Ik Lim, Boon Nam Bae, Bong Sook Jhun, In-Sug Kang, and Soo-Ja Kim* Department of Chemistry, College of Sciences and Research Institute of Basic Sciences, Kyunghee University, Seoul 130-701, Korea Department of Molecular Biology, College of Medicine, Kyunghee University, Seoul 130-701, Korea Received July 10, 2003 Key Words : Reverse field electroelution, Chymotrypsin inhibitor, Ganoderma lucidum, Preparative electrophoresis

Protein protease inhibitors are widely distributed in biological world1-3 and believed to be involved in controlling functions in a variety of fundamental physiological proteolytic processes.4-6 Some purified exogenous protease inhibitors are found beneficial in regulating certain disease states where proteolytic enzymes are related to pathological situations.7-10 In general, protease inhibitors or isoinhibitors have been purified by a number of steps of various chromatographical methods.11-13 Due to the similarities in their structures and chromatographical properties, the purification of these isoinhibitors is usually a time consuming, tedious work. In this report we described a simple and fast preparative polyacrylamide gel electrophoresis (PAGE) method involving reverse field electroelution for purification of chymotrypsin inhibitor isoforms from a fruit body of Ganoderma lucidum. Although the preparative electrophoresis with electroelution has been used for years,14-17 they usually require a separate preparative electrophoresis kit, dialysis membrane or high salt buffer. Preparative electrophoresis technique described here includes separation of target protein by conventional PAGE in native or denatured state followed by electroelution of the protein of interest from the gel using the same electrophoresis kit with a minor modification. No expensive device or membranes are required. By applying this reverse field electroelution method, chymotrypsin inhibitor isoforms from Ganoderma lucidum (GCI) could be easily purified even in one step from the crude extract. Experimental Section Polyacrylamide gel electrophoresis (PAGE). The reagents and gel preparations for PAGE were followed as the method of Laemmli.18 Electrophoresis was run in native state in a vertical slap gel electrophoresis unit, HSI SE 250 Mighty Small II (Hoefer Scientific Instruments) at 30-35 mA. After termination, one of the glass plates is removed and cut the gel vertically 0.5 cm strip from the both ends and the strips were stained with Coomassie blue. The stained gel strips were then aligned with each side of the remainder gel and the band of interest protein of the slap was excised horizontally with the guide of stained bands. The electoelution

was carried out as follows. 4 mL of 5% polyacrylamide (PA) supporting gel was made in a glass plates sandwich and the excised unstained gel strip was placed on top of the supporting gel and fixed by addition of small amount of 5% PA solution. The electrode solution (0.5 M Tris) was placed into the rest of sandwich no higher than to 0.5 cm from the top of the plates (about 3.0 mL). Instead of the anodic electrode equipped with the kit, a new platinum electrode was connected to the anode. Then the red cable was plugged into the black connector on the power supply and black cable into the red connector. Electrophoresis was run at 30 mA for one hour upward instead of usual running down. Figure 1 depicts the summary of electroelution process in reverse field. After elution, all the electrode solution were collected using a loading pipette tip or a syringe and the pH of the solution was adjusted to the optimum pH for the assay. Gel strip was taken out and stained to be certain that all the proteins were eluted out during the run. Purification of GCI.19,20 10 g of dried Ganoderma lucidum (Korean cultured, 6 years old) were homogenized in

Figure 1. A schematic representation of the reverse field electroelution process: (A) platinum anodic electrode; (B) upper buffer (electrode solution); (C) gel strip containing protein band; (D) supporting gel (5% polyacrylamide gel); (E) cathodic electrode. Arrows indicate the direction of migration.

1532

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 10

Notes

200 mL of lysis buffer (0.05 M Tris-HCl buffer, pH 7.6, 0.1 M NaCl, 5 mM mercaptoethanol) containing 1 mM PMSF. The homogenate was centrifuged and resulting supernatant was heated at 60 oC for 20 min and centrifuged. The supernatant was fractionated by 30%-60% ammonium sulfate saturation and resulting precipitates were dissolved in a small amount of 0.05 M Tris-HCl buffer (pH 7.6). 5 mL of this crude inhibitor preparation was applied onto a Sephadex G-75 column (1.6 80 cm, GradiFrac, Phamacia Biotec.) and proteins were eluted using the equilibration buffer and fractions (4 mL/fraction) were collected at a flow rate of 0.4 mL/min. Fractions corresponding to chymotrypsin inhibitory activity were pooled and concentrated in an Amicon ultrafiltration apparatus using a PM 10 membrane (Amicon, Beverly, MA. USA). 250 L of concentrated sample from gel filtration chromatography was applied onto a UNO-Q1 column (1 5 cm), in fast protein liquid chromatography (Biologic HR, Bio-Rad). Bound proteins were eluted by a linear gradient of ionic strength (0-1 M NaCl in 0.05 M Tris buffer, pH 7.6). Fractions (0.3 mL/fraction) were collected at a flow rate of 0.3 mL/min and those corresponding to chymotrypsin inhibitory activity were pooled and concentrated by ultrafiltration. Assays of enzyme and inhibitor activity. Chymotrypsin (Sigma, bovine pancreas) activity was assayed according to the modified method of Fritz et al..21 Standard assay mixture contained 0.05 M Tris-HCl buffer, pH 7.6, 2 105 M peptide substrate, N-Suc-Ala-Ala-Pro-Phe-p-nitroanilide and chymotrypsin in 0.5 mL total volume. One unit of enzyme is defined as the amount of enzyme that induces the conversion of 1 mol substrate/min. The chymotrypsin inhibitory activities were assayed in a similar manner with the addition of the inhibitor to the reaction mixtures. Protein was determined by the method of Bradford22 using BSA as the standard. Results and Discussion The IEC-chromatogram of GCI presents multiple inhibitor active regions indicating that GCI exists in multiple isoforms.20 Instead of applying additional chromatographic steps, a preparative electrophoresis technique was designed in order to simplify the purification of isoforms of GCI. A conventional analytical electrophoresis unit was used for both separation and elution of proteins from the gel. In the elution step, proteins were mobilized upward in the gel and eventually driven out into the electrode solution in the reversed electric field. In Figure 2, the result of electroelution of hemoglobin (Sigma, bovine, substrate powder) as a model protein is shown. 0.5 mg hemoglobin was electrophoresed in native state in a 10% PA gel and eluted in reversed field. Since the protein band could be identified in the gel by its own color, the staining step for guidance was not required. At each indicated time of elution period, 200 L of electrode solution was taken and observed the absorption spectrum at

Figure 2. Absorption spectrum of electroeluted hemoglobin at various times during reverse field electroelution.

Figure 3. The efficiences of electroelutions of hemoglobin and chymotrypsin inhibitor. At indicated times, recoveries were determined by measuring A410 (hemoglobin) and chymotrypsin inhibitory activities (for chymotrypsin inhibitor) of the electrode solution.

380-500 nm and then returned back to the electrode solution. Most of the proteins were eluted in between 40-60 min. The elution pattern of pure chymotrypsin inhibitor (Sigma, soybean) was compared to that of hemoglobin (Figure 3). The recoveries were determined by comparing the A410 of hemoglobin eluate or chymotrypsin inhibitor activity of electrode solution at indicated times to the respective control solutions. Under the standard condition, two proteins follow similar elution paths and the recoveries were quantitative (>98%) at the end of 1-hour elution for both model proteins. Since a limited amount of upper buffer is used in the reverse field electroelution, the progressive decrease of pH ensues in the upper buffer (electrode solution) during electroelution, and thus prevents the eluting out of protein

Notes

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 10

1533

Figure 4. pH changes in three different volumes of upper buffer solution during reverse field electroelution in HIS SE 250 Mighty Small II.

into the electrode solution.23-25 To overcome this problem, basic 0.5 M Tris solution was chosen as the electrode solution. In Figure 4, the pH changes of this electrode solution in three different volumes during elution are shown. In 3 mL electrode solution, pH varied from 8.4 to 7.8 during 40 min-60 min of elution period, during which, most of proteins are eluted. In our preliminary purification of GCI by FPLC-IEC and PAGE, four chymotrypsin inhibitor isoforms, namely GCI-I, II, III, and IV, as numbered in the order of increased retention time in the IEC- chromatography could be identified. Inhibitor fractions, GCI-I and GCI-II were further purified by reverse field electroelution and the purity of the final inhibitor fractions were confirmed by the single peaks in the reverse-phase HPLC (Waters, M996 GPC system). The molecular weights of these purified inhibitor isoforms were determined to be 17,585 Da and 17,565 Da for GCI-I and GCI-II, respectively, by MALDI-TOF analyses. The rest of GCI isoforms were not completely purified yet. In Table 1, the purification details of GCIs by chromatography and also by direct preparative electrophoresis from the crude extract are shown. Besides the timesaving, one-step purification enhanced the specific activities of purified inhibitor isoforms about 3 folds as compared to chromatog-

raphic purification. As a rough approximation, if we assume the even distribution of four GCI isoforms in Ganoderma lucidum extract, the recoveries of GCI isoforms in one step preparative electrophoresis can be calculated as 41% and 34% for GCI-I and GCI-II, respectively. Sa'-Pereira et al.17 applied the preparative electrophoresis to the purification of xylanase from Bacillus sp and reported the recovery of less than 5% of enzyme activity from ammonium sulfate precipitate. Recently Radko et al.23 developed a new electroelution method of direct elution orthogonal to the direction of migration showing that six different model proteins worked with the recoveries from 25% to 33% depending on the proteins. Preparative PAGE had been used for years in order to simplify the purification of protein. Although several different types of preparative electrophoresis cells have been available, they are difficult to set up and are often leak besides they take long time. The gel excision and elution method usually requires dialysis membrane or very high salt solution to receive the eluted protein.26,27 Certain proteins may be adsorbed by membrane and some present solubility problem in using very high salt concentration. The preparative electrophoresis method described in this article uses an analytical vertical slap gel kit, which is used routinely in every lab in the world. Just simple modifications of reversing the electric field and using a new electrode (anode) are sufficient for a fast and efficient elution of protein from gel. By selecting the basic electrode solution, proteins in the gel can be eluted quantitatively even into a small volume (2-3 mL) of electrode solution. In conclusion, the reverse field electroelution is fast and reliable method for the purification of protein provided that the protein can be separated and visualized in the gel. This study has proven that this preparative electrophoresis is applicable even to crude extract as well as model proteins. It should be particularly useful to those who want to purify the enzymes or enzyme inhibitor isoforms, which are often difficult to separate by chromatographic method because of the structural similarity and/or their low concentrations. Acknowledgements. This research was supported by Research Grant (2001) from Kyunghee University. References

1. Laskowski, M., Jr.; Kato, I. Ann. Rev. Biochem. 1980, 49, 593.

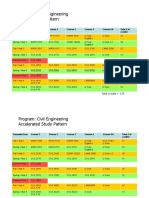

Table 1. Purification details of chymotrypsin inhibitor isoforms from Ganoderma lucidum

Purification step Crude extract Gel filtration + UNO-Q1 Reverse Field Electroelution

a

Inhibitor Isoforms GCI-I, II, III, IV GCI-I GCI-II GCI-I GCI-II

Protein (mg) 33.80 0.60 0.57 0.20 0.17

Activity (Unit) 2275 244 203 231 196

Specific activity (U/mg) 67.3 409.4 355.5 1172.6 1152.9

Yielda (%) 100 (400) 10.7 (42.8) 8.9 (35.6) 10.2 (40.8) 8.6 (34.4)

Values in parentheses represent the % yield calculated for individual inhibitor isoform on the basis of the even distribution of isoforms of GCI

1534

Bull. Korean Chem. Soc. 2003, Vol. 24, No. 10

Notes

1990; p 488. 16. Galland-Irmouli, A. V.; Pons, L.; Lucon, M.; Villaume, C.; Mrabet, N. T.; Gueant, J. L. J. of Chromatography 2000, 739, 117. 17. Sa-Pereira, P.; Duarte, J.; Costa-Ferreira, M. Enzyme and Microbial Technology 2000, 27, 95. 18. Laemmli, U. K. Nature 1970, 227, 680. 19. Jhun, B. S. Master's Thesis; Kyunghee University: Seoul, Korea, 2001. 20. Bae, B. N. Master's Thesis; Kyunghee University: Seoul, Korea, 2002. 21. Frit, H.; Hantwich, G.; Werde, E. Hoppe-Seylers Z. Physiol. Chem. 1966, 345, 150. 22. Bradford, M. M. Anal. Biochem. 1976, 72, 248. 23. Radko, S. P.; Chen, H. T.; Zakharov, S. F.; Bezrukov, L.; Yergey, A. L.; Vieira, N. E.; Chrambach, A. Electrophoresis 2002, 23, 985. 24. Yefimov, S.; Sjomeling, C.; Yergey, A. L.; Chrambach, A. Anal. Biochem. 2000, 284, 288. 25. Yefimov, S.; Yergey, A. L.; Chrambach, A. Electrophoresis 2001, 14, 2881. 26. Otto, M.; Snejdarkova, M. Anal. Biochem. 1981, 111, 111. 27. Stralfors, P.; Belfrage, P. Anal. Biochem. 1983, 128, 7.

2. Laskowski, M., Jr.; Kato, I.; Leary, T.; Schrode, J.; Sealock, R. In Baeyer Symposium V Proteinase Inhibitors 1974, 597. 3. Travis, J.; Salvesen, G. S. Ann. Rev. Biochem. 1983, 52, 655. 4. Trumpower, B. L.; Katki, A.; Horowitz, P. Biochem. Biophys. Res. Commun. 1974, 57, 523. 5. Schapira, M. Semin Thromb Hemost. 1987, 13, 69. 6. Hiraichi, E.; Schiripa, L. N.; Yamanouye, N.; Abdalla, F. M.; Picarelli, Z. P. Gen Pharmacol. 1992, 23, 595. 7. Troll, W.; Frenkel, K.; Wiesner, R. In Nutritional and Toxicological Significance of Enzyme Inhibitors of Foodsl; Friedman, M., Ed.; Plenum Press: New York, 1986; p 153. 8. Troll, W.; Frenkel, K.; Wiesner, R. Pro. Clin. Biol. Res. 1987, 239, 297. 9. Lee, H. S.; Kim, D. H. Bull. Korean Chem. Soc. 2002, 23, 593. 10. Witschi, H.; Kennedy, A. R. Carcinogenesis 1989, 12, 2275. 11. Pekkarinen, A. I.; Jones, B. L. J. Agric. Food Chem. 2003, 12, 1710. 12. Yamashita, M.; Konagaya, S. J. Biochem (Tokyo) 1991, 110, 762. 13. Kim, J. W.; Min, T. J. J. Korean Chem. Soc. 1985, 29, 295. 14. Lewis, U. J.; Clark, M. O. Analytical Biochem. 1963, 6, 303. 15. Harrington, M. G. Methods in Enzymology; Academic press:

You might also like

- Studies of Fluorescent Imaging For MRNA Detection in Living CellsDocument183 pagesStudies of Fluorescent Imaging For MRNA Detection in Living Cellschavi1310No ratings yet

- Gene Delivery Into Plant Cells For Recombinant Protein ProductionDocument11 pagesGene Delivery Into Plant Cells For Recombinant Protein Productionchavi1310No ratings yet

- Plant-Derived Transfer DNAsDocument13 pagesPlant-Derived Transfer DNAschavi1310No ratings yet

- Blue-Native PAGE in PlantsDocument13 pagesBlue-Native PAGE in Plantschavi1310No ratings yet

- InTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological ApplicationDocument15 pagesInTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological Applicationchavi1310No ratings yet

- Riboswitch Control of Gene Expression in Plants by SplicingDocument14 pagesRiboswitch Control of Gene Expression in Plants by Splicingchavi1310No ratings yet

- Protocol For ZymogramDocument1 pageProtocol For Zymogramchavi1310No ratings yet

- InTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological ApplicationDocument15 pagesInTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological Applicationchavi1310No ratings yet

- The Cap and Poly (A) Tail FunctionDocument10 pagesThe Cap and Poly (A) Tail Functionchavi1310No ratings yet

- Identification and Characterisation of The Bacillus Subtilis Gtac Gene, Encoding The Phosphoglucomutase Involved in Glucosylation of Teichoic Acid and Phage SusceptibilityDocument9 pagesIdentification and Characterisation of The Bacillus Subtilis Gtac Gene, Encoding The Phosphoglucomutase Involved in Glucosylation of Teichoic Acid and Phage Susceptibilitychavi1310No ratings yet

- A Specific b-Glucosidase-Aggregating Factor Is Responsible For The B-Glucosidase Null Phenotype in Maize1Document10 pagesA Specific b-Glucosidase-Aggregating Factor Is Responsible For The B-Glucosidase Null Phenotype in Maize1chavi1310No ratings yet

- How To Measure and Predict The Molar Absorption Coefficient of A ProteinDocument13 pagesHow To Measure and Predict The Molar Absorption Coefficient of A Proteinchavi1310No ratings yet

- Calculation of Protein Extension CoefficientDocument8 pagesCalculation of Protein Extension Coefficientchavi1310No ratings yet

- RNAi A Novel Antisense Technology and ItsDocument9 pagesRNAi A Novel Antisense Technology and Itschavi1310No ratings yet

- ZymographyDocument29 pagesZymographychavi1310No ratings yet

- 10b-Glucosidase Responsible For Bioactivation of Cyanogenic Hydroxynitrile GlucosidesDocument13 pages10b-Glucosidase Responsible For Bioactivation of Cyanogenic Hydroxynitrile Glucosideschavi1310No ratings yet

- RNA Interference in Crop PlantsDocument5 pagesRNA Interference in Crop Plantschavi1310No ratings yet

- The RNA-Induced SilencingDocument5 pagesThe RNA-Induced Silencingchavi1310No ratings yet

- Chapter1 ETDDocument35 pagesChapter1 ETDchavi1310No ratings yet

- RNA LAbeling Kit (Pierce)Document4 pagesRNA LAbeling Kit (Pierce)chavi1310No ratings yet

- InTech-Mutational Analysis of Effectors Encoded by Monopartite Begomoviruses and Their SatellitesDocument24 pagesInTech-Mutational Analysis of Effectors Encoded by Monopartite Begomoviruses and Their Satelliteschavi1310No ratings yet

- ImmunoblottingDocument20 pagesImmunoblottingchavi1310No ratings yet

- pET 30aDocument2 pagespET 30aKrunal PatelNo ratings yet

- Chemical Equations LabDocument2 pagesChemical Equations Labchavi1310No ratings yet

- Development of Chromogenic Reactands For Optical SensingDocument9 pagesDevelopment of Chromogenic Reactands For Optical Sensingchavi1310No ratings yet

- MicroRNA Target PredictionDocument37 pagesMicroRNA Target Predictionamir0824No ratings yet

- 8 Approaches To Random MutagenesisDocument12 pages8 Approaches To Random Mutagenesischavi1310No ratings yet

- Xenopus Whole Mount in Situ HybridizationDocument6 pagesXenopus Whole Mount in Situ Hybridizationchavi1310No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Emerging Technology SyllabusDocument6 pagesEmerging Technology Syllabussw dr100% (4)

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesNo ratings yet

- TB 60 Repair Parts PDFDocument282 pagesTB 60 Repair Parts PDFvatasa100% (2)

- Communicating Value - PatamilkaDocument12 pagesCommunicating Value - PatamilkaNeha ArumallaNo ratings yet

- Pediatric Fever of Unknown Origin: Educational GapDocument14 pagesPediatric Fever of Unknown Origin: Educational GapPiegl-Gulácsy VeraNo ratings yet

- Vq40de Service ManualDocument257 pagesVq40de Service Manualjaumegus100% (4)

- Chapter1 Intro To Basic FinanceDocument28 pagesChapter1 Intro To Basic FinanceRazel GopezNo ratings yet

- Solutions DPP 2Document3 pagesSolutions DPP 2Tech. VideciousNo ratings yet

- Learning English Through The Educational Games of Wordwall Website For Elementary Students by Group 1 (R4E)Document6 pagesLearning English Through The Educational Games of Wordwall Website For Elementary Students by Group 1 (R4E)NurulNo ratings yet

- Equilibrium of A Rigid BodyDocument30 pagesEquilibrium of A Rigid BodyChristine Torrepenida RasimoNo ratings yet

- Linux ProgramDocument131 pagesLinux ProgramsivashaNo ratings yet

- SCIENCE 11 WEEK 6c - Endogenic ProcessDocument57 pagesSCIENCE 11 WEEK 6c - Endogenic ProcessChristine CayosaNo ratings yet

- City Limits Magazine, December 1981 IssueDocument28 pagesCity Limits Magazine, December 1981 IssueCity Limits (New York)No ratings yet

- Polyether Polyol Production AssignmentDocument9 pagesPolyether Polyol Production AssignmentanurdiaNo ratings yet

- Catalogo PukangDocument41 pagesCatalogo PukangClarita Muller LeigueNo ratings yet

- EP07 Measuring Coefficient of Viscosity of Castor OilDocument2 pagesEP07 Measuring Coefficient of Viscosity of Castor OilKw ChanNo ratings yet

- Collecting, Analyzing, & Feeding Back DiagnosticDocument12 pagesCollecting, Analyzing, & Feeding Back DiagnosticCaroline Mariae TuquibNo ratings yet

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsNo ratings yet

- Journal of Molecular LiquidsDocument11 pagesJournal of Molecular LiquidsDennys MacasNo ratings yet

- Unit 1 Bearer PlantsDocument2 pagesUnit 1 Bearer PlantsEmzNo ratings yet

- HKUST 4Y Curriculum Diagram CIVLDocument4 pagesHKUST 4Y Curriculum Diagram CIVLfrevNo ratings yet

- Brain Injury Patients Have A Place To Be Themselves: WHY WHYDocument24 pagesBrain Injury Patients Have A Place To Be Themselves: WHY WHYDonna S. SeayNo ratings yet

- BV DoshiDocument6 pagesBV DoshiNimNo ratings yet

- Chapter 30 - HypertensionDocument70 pagesChapter 30 - HypertensionSakaC.TanayaNo ratings yet

- Leather PuppetryDocument8 pagesLeather PuppetryAnushree BhattacharyaNo ratings yet

- E Voting PPT - 1Document11 pagesE Voting PPT - 1madhu100% (2)

- JIMMA Electrical&ComputerEngDocument219 pagesJIMMA Electrical&ComputerEngTewodros71% (7)

- Driver Drowsiness Detection System Using Raspberry PiDocument7 pagesDriver Drowsiness Detection System Using Raspberry PiIJRASETPublicationsNo ratings yet

- Fertilisation and PregnancyDocument24 pagesFertilisation and PregnancyLopak TikeNo ratings yet

- 2.ed - Eng6 - q1 - Mod3 - Make Connections Between Information Viewed and Personal ExpiriencesDocument32 pages2.ed - Eng6 - q1 - Mod3 - Make Connections Between Information Viewed and Personal ExpiriencesToni Marie Atienza Besa100% (3)