Professional Documents

Culture Documents

SteelDesign LTB Fu New

Uploaded by

Luis MoranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SteelDesign LTB Fu New

Uploaded by

Luis MoranCopyright:

Available Formats

ENCE 710

Design of Steel Structures

V. Lateral-Torsional Buckling of

Beams

C. C. Fu, Ph.D., P.E.

Civil and Environmental Engineering Department

University of Maryland

2

Introduction

Following subjects are covered:

Lateral Torsional Buckling (LTB)

Flange Local Buckling (FLB)

Web Local Buckling (WLB)

Shear strength

Lateral Bracing Design

Reading:

Chapters 9 of Salmon & Johnson

AISC LRFD Specification Chapters B (Design Requirements)

and F (Design of Members for Flexure)

3

Introduction

A beam can fail by reaching the plastic moment and

becoming fully plastic (see last section) or fail

prematurely by:

1. LTB, either elastically or inelastically

2. FLB, either elastically or inelastically

3. WLB, either elastically or inelastically

If the maximum bending stress is less than the

proportional limit when buckling occurs, the failure

is elastic. Else it is inelastic.

For bending

b

M

n

(

b

= 0.9)

4

Design of Members for Flexure

(about Major Axis)

5

Lateral Torsional Buckling (LTB)

Compact Members (AISC F2)

Failure Mode

Plastic LTB (Yielding)

Inelastic LTB

Elastic LTB

Moment Gradient Factor C

b

6

Lateral Torsional Buckling (cont.)

Failure Mode

A beam can buckle in a

lateral-torsional mode

when the bending

moment exceeds the

critical moment.

7

Lateral Torsional Buckling (cont.)

Nominal Flexural Strength M

n

plastic when and

inelastic when and

elastic when and

p b

L L s

p n

M M =

r b p

L L L s <

r n p

M M M > >

r b

L L >

r n

M M <

inelastic plastic elastic

1.0 C

b

=

n

M

r

M

p

M

p

L

b

L

r

L

8

Lateral Torsional Buckling (cont.)

I-Beam

in a

Buckled

Position

9

Lateral Torsional Buckling (cont.)

Elastic LTB

coupled differential equations for rotation and lateral

translation (8.5.10)

where

M

z

= moment at location z along member axis

z = axis along member length

= angle of twist

G = shear modulus

J = torsional constant (AISC Table 1-1 for torsional prop.)

E = modulus of elasticity

C

w

= warping constant (AISC Table 1-1 for warping)

3

3

dz

d

EC

dz

d

GJ M

w z

|

|

=

10

Lateral Torsional Buckling (cont.)

Plastic LTB (Yielding)

Flexural Strength (AISC F2-1)

where Z= plastic section modulus & F

y

= section yield stress

Limits

Lateral bracing limit

(AISC F2-5)

Flange and Web width/thickness limit (AISC Table B4.1)

(Note: L

pd

in Salmon & Johnson Eq. (9.6.2) is removed from AISC 13

th

Ed.)

Z F M M

y p n

= =

y

y p b

F

E

r L L 76 . 1 = <

11

Lateral Torsional Buckling (cont.)

Inelastic LTB

Flexure Strength (straight line interpolation)

(9.6.4)

or

(AISC F2-2)

( )

p

p r

p b

r p p b n

M

L L

L L

M M M C M s

(

(

|

|

.

|

\

|

=

( )

p

p r

p b

x y p p b n

M

L L

L L

S F M M C M s

(

(

|

|

.

|

\

|

= 7 . 0

r b p

L L L s <

12

Lateral Torsional Buckling (cont.)

Elastic LTB

Flexure Strength

(AISC F2-3)

(AISC F2-4)

(The square root term may be conservatively taken equal to 1.0)

(c in AISC F2-8a,b for doubly symmetric I-shape, and channel, respectively)

Limit (AISC F2-6)

(AISC F2-7)

p x cr n

M S F M s =

2

7 . 0

76 . 6 1 1

7 . 0

95 . 1

|

|

.

|

\

|

+ + =

J c

h S

E

F

h S

J c

F

E

r L

o x y

o x y

ts r

x

w y

ts

S

C I

r =

2

2

2

2

078 . 0 1

|

|

.

|

\

|

+

|

|

.

|

\

|

=

ts

b

o x

ts

b

b

cr

r

L

h S

J c

r

L

E C

F

t

r b

L L >

13

Lateral Torsional Buckling (cont.)

Moment Gradient Factor C

b

The moment gradient factor C

b

accounts for the variation

of moment along the beam length between bracing

points. Its value is highest, C

b

=1, when the moment

diagram is uniform between adjacent bracing points.

When the moment diagram is not uniform

(9.6.3)

(AISC F1-1)

where

M

max

= absolute value of maximum moment in unbraced length

M

A

, M

B

, M

C

= absolute moment values at one-quarter, one-half, and

three-quarter points of unbraced length

C B A

b

M M M M

M

C

3 4 3 5 . 2

5 . 12

max

max

+ + +

=

14

C

b

for a Simple Span Bridge

15

Nominal Moment Strength M

u

as

affected by C

b

16

Flange Local Buckling (FLB)

Compact Web and Noncompact/Slender

Flanges (AISC F3)

Failure Mode

Noncompact Flange

Slender Flange

Nominal Flexural strength, M

n

= Min (F2, F3)

17

Flange Local Buckling (cont.)

Failure Mode

The compression flange

of a beam can buckle

locally when the

bending stress in the

flange exceeds the

critical stress.

18

Flange Local Buckling (cont.)

Nominal Flexural Strength M

n

plastic when and

inelastic when and

elastic when and

p n

M M =

r n p

M M M > >

r n

M M <

p f

f t b s 2 /

r f

f

p

t b s s 2 /

r f

f t b > 2 /

noncompact compact slender

n

M

r

M

p

M

p

f

f

t

b

=

r

19

Flange Local Buckling (cont.)

Noncompact Flange (straight line

interpolation)

Flexure Strength

(AISC F3-1)

( )

|

|

.

|

\

|

=

pf rf

pf

x y p p n

S F M M M

7 . 0

20

Flange Local Buckling (cont.)

Slender Flange

Flexure Strength

(AISC F3-2)

(kc shall not be less than 0.35 and not greater than 0.76)

Limit (AISC Table B4.1)

2

9 . 0

x c

n

S Ek

M =

w

c

t h

k

/

4

=

21

Web Local Buckling (WLB)

Compact or Noncompact Webs (AISC F4)

Failure Mode

Compact Web (Yielding)

Noncompact Web

Slender Web

Nominal Flexural Strength, M

n

=min (compression

flange yielding, LTB, compression FLB, tension

flange yielding)

22

Web Local Buckling (cont.)

Failure Mode

The web of a beam can

also buckle locally

when the bending

stress in the web

exceeds the critical

stress.

23

Web Local Buckling (cont.)

Nominal Flexural Strength M

n

plastic when and

inelastic when and

elastic when and

p n

M M =

r n p

M M M > >

r n

M M <

p

s

r p

s <

r

>

noncompact compact slender

n

M

r

M

p

M

p

w

t

h

=

r

24

Web Local Buckling (cont.)

Compression Flange Yielding

Flexural Strength

(AISC F4-1)

where R

pc

= web plasticification factor (AISC F4-9a, b) &

F

y

= section yield stress

Limits (AISC Tables B4.1)

xc y pc yc pc n

S F R M R M = =

y

t p b

F

E

r L L 1 . 1 = <

25

Web Local Buckling (cont.)

LTB (Inelastic)

Flexure Strength

(AISC F4-12)

where F

L

= a stress determined by AISC F4-6a, b

( )

p

pf rf

pf

xc L yc pc yc pc b n

M S F M R M R C M s

(

(

|

|

.

|

\

|

=

r b p

L L L s <

26

Web Local Buckling (cont.)

LTB (Elastic)

Flexure Strength

(AISC F4-3)

(AISC F4-5)

Limit (AISC Table B4.1)

(AISC F4-8)

yc pc xc cr n

M R S F M s =

2

2

2

078 . 0 1

|

|

.

|

\

|

+

|

|

.

|

\

|

=

t

b

o x

t

b

b

cr

r

L

h S

J

r

L

E C

F

t

2

76 . 6 1 1 95 . 1

|

.

|

\

|

+ + =

J

h S

E

F

h S

J

F

E

r L

o x L

o x L

t r

r b

L L >

27

Web Local Buckling (cont.)

Compression FLB (Noncompact Flange)

Flexure Strength

(AISC F4-12)

Compression FLB (Slender Flange)

Flexure Strength

(AISC F4-13)

(k

c

shall not be less than 0.35 and not greater than 0.76)

( )

p

pf rf

pf

xc L yc pc yc pc n

M S F M R M R M s

(

(

|

|

.

|

\

|

=

2

9 . 0

x c

n

S Ek

M =

w

c

t h

k

/

4

=

28

Web Local Buckling (cont.)

Tension Flange Yielding

Flexure Strength

(AISC F4-14)

R

pt

= web plastification factor to the tension flange yielding limit

xt y pt yt pt n

S F R M R M = =

xc xt

S S <

(a) h

c

/t

w

pw

R

pt

=M

p

/M

yt

(AISC F4-15a)

(b) h

c

/t

w

>

pw

(AISC F4-15b)

yt

p

pw rw

pw

yt

p

yt

p

pt

M

M

M

M

M

M

R s

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

1

29

Shear Strength

Failure Mode

Shear-Buckling Coefficient

Elastic Shear Strength

Inelastic Shear Strength

Plastic Shear Strength

For shear

v

V

n

(

v

= 0.9 except certain rolled I-

beam h/t

w

2.24E/F

y

,

v

= 1.0)

V

n

=0.6F

y

A

w

C

v

(AISC G2-1)

30

Shear Strength (cont.)

Failure Mode

The web of a beam or

plate girder buckles

when the web shear

stress exceeds the

critical stress.

31

Shear Strength (cont.)

Nominal Shear Strength V

n

(

v

= 0.9)

plastic when and

inelastic when and

elastic when and

r

>

y

t = t

r

s

y t = t 8 . 0

p

s

cr

t = t

inelastic plastic elastic

n

V

r

V

p

V

p

r

>

32

Shear Strength (cont.)

AISC G2 Nominal Shear Strength V

n

(a) For (AISC G2-3)

(a) For (AISC G2-4)

(a) For (AISC G2-5)

yw

v

w

F

E k

t

h

10 . 1 s

y

v

w y

v

F

E k

t

h

F

E k

37 . 1 10 . 1 s s

(

(

(

(

=

w

y

v

v

t

h

F

E k

C

10 . 1

w yw

v

t

h

F

E k

s 37 . 1

(

(

(

(

|

.

|

\

|

=

y

w

v

v

F

t

h

Ek

C

2

51 . 1

0 . 1 =

v

C

33

Lateral Bracing Design

34

Lateral Bracing Design

AISC Provisions Stability

Bracing Design for Beams

1. For stiffness

reqd

,

reqd

= 2

ideal

2. For nominal strength F

br

,

(a) F

br

=

ideal

(2

0

);

(b) F

br

=

ideal

(0.004L

b

)

Where

ideal

= P

cr

/L

b

35

Lateral Bracing Design (cont.)

AISC Provisions LRFD Stability Bracing Design for Beams

1. Relative bracing

=0.75

2. Nodal bracing

0

008 . 0

Re

h

C M

P quired

d r

rb

=

|

|

.

|

\

|

=

0

4 1

Re

h L

C M

quired

b

d r

rb

|

|

0

02 . 0

Re

h

C M

P quired

d r

rb

=

|

|

.

|

\

|

=

0

10 1

Re

h L

C M

quired

b

d r

br

|

|

36

Lateral Bracing Design (cont.)

AISC Provisions LRFD Stability Bracing Design for Columns

1. Relative bracing

=0.75

2. Nodal bracing

r rb

P P quired 004 . 0 Re =

|

|

.

|

\

|

=

b

r

rb

L

P

quired

2 1

Re

|

|

r rb

P P quired 01 . 0 Re =

|

|

.

|

\

|

=

b

r

br

L

P

quired

8 1

Re

|

|

You might also like

- SteelDesign LTB Fu NewDocument36 pagesSteelDesign LTB Fu Newjuan victorNo ratings yet

- SteelDesign LTB Fu NewDocument36 pagesSteelDesign LTB Fu NewAnonymous UibQYvc6No ratings yet

- ENCE 710 Design of Steel Structures: V. Lateral-Torsional Buckling of BeamsDocument36 pagesENCE 710 Design of Steel Structures: V. Lateral-Torsional Buckling of BeamsMinh Tâm TrầnNo ratings yet

- Beams Calculation - AISC SummaryDocument40 pagesBeams Calculation - AISC SummarycooL_whO_saint100% (2)

- 7 Unrestrained BeamsDocument39 pages7 Unrestrained BeamsImran SaikatNo ratings yet

- Structural Design of Beams and Plate GirdersDocument49 pagesStructural Design of Beams and Plate GirdersHandoko CocoNo ratings yet

- Unrestrained BeamDocument40 pagesUnrestrained Beamdanielsu87100% (1)

- 6 Unrestrained Beams - 2011 (Compatibility Mode)Document21 pages6 Unrestrained Beams - 2011 (Compatibility Mode)susan87No ratings yet

- CE202L4 UnrestrainedBeam (Compatibility Mode)Document18 pagesCE202L4 UnrestrainedBeam (Compatibility Mode)asdasNo ratings yet

- 3.design For Flexure V1Document29 pages3.design For Flexure V1November RainNo ratings yet

- 2 LaterallySupportedBeams 2012Document129 pages2 LaterallySupportedBeams 2012msenerNo ratings yet

- Design of Beams: Part ADocument47 pagesDesign of Beams: Part AMorad AJNo ratings yet

- Unrestrained BeamDocument36 pagesUnrestrained BeamstellaNo ratings yet

- Flexural Members - 2Document8 pagesFlexural Members - 2Rifat HasanNo ratings yet

- Structural Steelwork Eurocodes: LTB Design of Unrestrained BeamsDocument16 pagesStructural Steelwork Eurocodes: LTB Design of Unrestrained BeamsxangNo ratings yet

- Set 5b Desain Balok LenturDocument43 pagesSet 5b Desain Balok LenturJessica PrimaulyNo ratings yet

- Design of Steel BeamsDocument108 pagesDesign of Steel BeamsNajif IsmailNo ratings yet

- Topic 06 Mechanical Properties - Compatibility ModeDocument34 pagesTopic 06 Mechanical Properties - Compatibility ModeSelviya AvaurumNo ratings yet

- Design of Timber Beams PDFDocument38 pagesDesign of Timber Beams PDFRoiven Dela Rosa Trinidad100% (2)

- LTB Part2 F14 OptDocument15 pagesLTB Part2 F14 OptNejib GhazouaniNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 43Document1 page4597 AAB SC 07 Addendum 2 R0v0 43danieldumapitNo ratings yet

- Slide 5 Metal Forming IntroDocument72 pagesSlide 5 Metal Forming IntrogunjanNo ratings yet

- Design of Steel Beams ModuleDocument61 pagesDesign of Steel Beams ModuleShazNo ratings yet

- Beam Flexural MembersDocument51 pagesBeam Flexural Membersvongaishe busheNo ratings yet

- Beam Design FundamentalsDocument112 pagesBeam Design FundamentalskbkwebsNo ratings yet

- Design and Failure Modes of Timber BeamsDocument38 pagesDesign and Failure Modes of Timber BeamsPaula HoNo ratings yet

- Structural Steel Beam Design FundamentalsDocument69 pagesStructural Steel Beam Design FundamentalsHala MNo ratings yet

- KULIAH3 EC3 UNRESTRAINED BEAM-kl PDFDocument66 pagesKULIAH3 EC3 UNRESTRAINED BEAM-kl PDFZazliana Izatti100% (1)

- Chapter 4 - Unrestrained BeamDocument50 pagesChapter 4 - Unrestrained BeamMADHURJO MEHENAZ A20EA3003No ratings yet

- ENCE 710 Design of Steel Structures: VI. Plate GirdersDocument8 pagesENCE 710 Design of Steel Structures: VI. Plate GirdersohnmarzawNo ratings yet

- Mechanical Properties and BehaviorDocument28 pagesMechanical Properties and BehaviorZain FarhanNo ratings yet

- Beam Buckling Modes: M M Compression, Possible BucklingDocument1 pageBeam Buckling Modes: M M Compression, Possible BucklingmNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 44Document1 page4597 AAB SC 07 Addendum 2 R0v0 44danieldumapitNo ratings yet

- Chapter 8 - Mechanical Properties of Metals - Week 6&7Document40 pagesChapter 8 - Mechanical Properties of Metals - Week 6&7Soineth Guzmán100% (1)

- Mechanical Properties: Issues To Address..Document33 pagesMechanical Properties: Issues To Address..HaroonNo ratings yet

- CH 06Document43 pagesCH 06Najam Ul QadirNo ratings yet

- Design of Laterally Restrained BeamsDocument111 pagesDesign of Laterally Restrained BeamsLovely Mae Cruza GawinganNo ratings yet

- CE134P (Flexural Members)Document50 pagesCE134P (Flexural Members)Lemuel TeopeNo ratings yet

- Issues To Address... : Stress Strain Elastic PlasticDocument25 pagesIssues To Address... : Stress Strain Elastic Plasticroxy8marie8chanNo ratings yet

- Values of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2Document31 pagesValues of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2MarkNo ratings yet

- EEAQ 2118 - 5 Mechanical PropertiesDocument34 pagesEEAQ 2118 - 5 Mechanical PropertiesOdhiambo AustinNo ratings yet

- Mechanical Properties: Issues To Address..Document44 pagesMechanical Properties: Issues To Address..riaNo ratings yet

- Analysis - Design of BeamsDocument67 pagesAnalysis - Design of BeamsAnwaar SafdarNo ratings yet

- Steel 2022 BeamDocument26 pagesSteel 2022 BeamRaven Von DizonNo ratings yet

- 1st - Design of Steel Beams (I)Document37 pages1st - Design of Steel Beams (I)krainajackaNo ratings yet

- Mechanical Properties: Issues To Address..Document51 pagesMechanical Properties: Issues To Address..Mohammed JehadNo ratings yet

- Design review of arch compression structureDocument3 pagesDesign review of arch compression structurevibishnanNo ratings yet

- Chapter06 PDFDocument60 pagesChapter06 PDFRanjeet kumarNo ratings yet

- Design of Beam-Column Splice Connections According To Eurocode 3Document3 pagesDesign of Beam-Column Splice Connections According To Eurocode 3xerxes92005No ratings yet

- Mechanical Properties: Issues To Address..Document51 pagesMechanical Properties: Issues To Address..Hassan HabibNo ratings yet

- Chapter 7 Mechanical PropertiesDocument29 pagesChapter 7 Mechanical Propertiesapi-269630671No ratings yet

- AISC Seismic Design-Module6-Special Plate Shear WallsDocument97 pagesAISC Seismic Design-Module6-Special Plate Shear WallsMaria Goretti Colin EspinozaNo ratings yet

- CSE 29362 Structural Steel Design: Dr. H. C. HO Prof. K. F. CHUNGDocument8 pagesCSE 29362 Structural Steel Design: Dr. H. C. HO Prof. K. F. CHUNGTszwun CheungNo ratings yet

- Vezetett Neopren Saruk Lead Rubber Bearing enDocument2 pagesVezetett Neopren Saruk Lead Rubber Bearing enAlberto SalvatierraNo ratings yet

- Slides Part 2 2Document79 pagesSlides Part 2 2Fatih KESKİNo ratings yet

- 3 Mechanical Properties of Materials Metals Lecture 1Document84 pages3 Mechanical Properties of Materials Metals Lecture 1Hung HimmyNo ratings yet

- CE371 - Compression MemberDocument53 pagesCE371 - Compression MemberDhanya SagarNo ratings yet

- Cybulski - Introduction of Stiffness Investigation of ABM K-Span Arch StructuresDocument6 pagesCybulski - Introduction of Stiffness Investigation of ABM K-Span Arch StructuresRavil GizatulinNo ratings yet

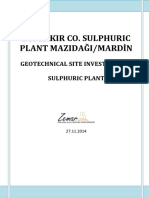

- 01 - Sulphuric PlantDocument114 pages01 - Sulphuric PlantyusamengNo ratings yet

- FiyatDocument8 pagesFiyatyusamengNo ratings yet

- L15 - Lightweight Structures-Connections PDFDocument98 pagesL15 - Lightweight Structures-Connections PDFyusamengNo ratings yet

- C Purlin enDocument6 pagesC Purlin enGamieYlnoNo ratings yet

- ETEM - E85 - Technical CatalogueDocument372 pagesETEM - E85 - Technical CatalogueAnonymous YyqUEErUoNo ratings yet

- Load Calculation For Portal Framed Shed With Wind Asce 7-10Document10 pagesLoad Calculation For Portal Framed Shed With Wind Asce 7-10msb100% (1)

- Rolatube SystemDocument1 pageRolatube SystemyusamengNo ratings yet

- Spazzer Bar Guard-1Document1 pageSpazzer Bar Guard-1yusamengNo ratings yet

- Metal Furring Channel Clip (MFCC) - 2Document1 pageMetal Furring Channel Clip (MFCC) - 2yusamengNo ratings yet

- Zirve2019 Sunum Dennis Hansen Herkesicin Arttrilmis GerceklikDocument18 pagesZirve2019 Sunum Dennis Hansen Herkesicin Arttrilmis GerceklikyusamengNo ratings yet

- NonLoad Bearing Window OpeningDocument1 pageNonLoad Bearing Window OpeningyusamengNo ratings yet

- Tank Foundation Design ProcedureDocument53 pagesTank Foundation Design ProcedureMichael Teo82% (11)

- Eurocode IçerikDocument1 pageEurocode IçerikyusamengNo ratings yet

- SAFE TutorialDocument112 pagesSAFE Tutorialkevinvnn80% (5)

- Example Anchor BoltsDocument5 pagesExample Anchor BoltsyusamengNo ratings yet

- 3 D Wind GeneratorDocument15 pages3 D Wind Generatorpopaciprian27No ratings yet

- Steel Frame DesignDocument7 pagesSteel Frame DesignZayyan RomjonNo ratings yet

- Material Unit WeightDocument4 pagesMaterial Unit WeightyusamengNo ratings yet

- Csi BridgesDocument71 pagesCsi Bridgessolucionessigloxxi100% (2)

- SAP2000 TutorialDocument169 pagesSAP2000 Tutorialgolovamasina100% (5)

- Material Unit WeightDocument4 pagesMaterial Unit WeightyusamengNo ratings yet

- CD Hollow in FireDocument95 pagesCD Hollow in FireyusamengNo ratings yet

- Lectures On Quadratic FormsDocument170 pagesLectures On Quadratic FormsyusamengNo ratings yet

- TowerDocument3 pagesTowerDG GarciaNo ratings yet

- Open Well Stair CaseDocument5 pagesOpen Well Stair CaseNikhilNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANMr. SinghNo ratings yet

- BS5400 - 10Document57 pagesBS5400 - 10Mhd ThrNo ratings yet

- EASIMATE Datiya Dam 15-4-19Document13 pagesEASIMATE Datiya Dam 15-4-19ankitNo ratings yet

- Ms Box 75x75x3mmDocument4 pagesMs Box 75x75x3mmNadir Khattak Jr.No ratings yet

- Ordinary Portland Cement (OPC) Properties and UsesDocument23 pagesOrdinary Portland Cement (OPC) Properties and UsesMS PMNo ratings yet

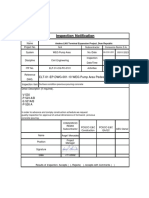

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDocument5 pagesIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoNo ratings yet

- Bridge Beam Manual: Precast Concrete SolutionsDocument25 pagesBridge Beam Manual: Precast Concrete SolutionsJoeNo ratings yet

- Block A Structure CombinedDocument32 pagesBlock A Structure CombinedUdit AmatNo ratings yet

- Earthquake Demand On Buildings - p2Document15 pagesEarthquake Demand On Buildings - p2Alejo Martin MartinNo ratings yet

- S-2 Computation Midas Critical SectionDocument8 pagesS-2 Computation Midas Critical SectionDannica YanoNo ratings yet

- CH 11Document58 pagesCH 11tewele brhaneNo ratings yet

- 9.6 Safety Provisions For ColumnsDocument1 page9.6 Safety Provisions For ColumnsNwar BoainyNo ratings yet

- Bridge Truss Analysis ExampleDocument5 pagesBridge Truss Analysis ExampleARSLAN ASHRAFNo ratings yet

- STR Final 02112319473547375Document20 pagesSTR Final 02112319473547375Muhammad AfrasiyabNo ratings yet

- Detail DrawingDocument6 pagesDetail DrawingDorothy CastroNo ratings yet

- Stand Off DesignDocument2 pagesStand Off DesignMartinNo ratings yet

- Is 2770Document12 pagesIs 2770Ankur SinghNo ratings yet

- Structural Systems Factors in Senior Housing DesignDocument8 pagesStructural Systems Factors in Senior Housing DesignAbdoullah AlbizrehNo ratings yet

- Perhitungan Shoring Pier HeadDocument10 pagesPerhitungan Shoring Pier HeadPurwo PrihartonoNo ratings yet

- Glossary of Construction TermsDocument126 pagesGlossary of Construction TermsNINPOJ100% (2)

- Metal Furring Installation GuideDocument7 pagesMetal Furring Installation GuideKiran D AnvekarNo ratings yet

- Water Tank..Document487 pagesWater Tank..31 Gunjal AniketNo ratings yet

- Concrete Volume II Guide Reinforced StructuresDocument4 pagesConcrete Volume II Guide Reinforced StructuresPrasanthPrashuNo ratings yet

- Final Preboard for Civil Engineering Board ExamDocument7 pagesFinal Preboard for Civil Engineering Board ExamIcz Fuentes100% (1)

- Method Statement - RC Retaining WallDocument9 pagesMethod Statement - RC Retaining WallAnang Sdj100% (1)

- Design of Reinforced Concrete Deep Beams For Strength andDocument390 pagesDesign of Reinforced Concrete Deep Beams For Strength andWallen Jusri SihotangNo ratings yet

- A Project Report On: " Manufacturing of Concrete Pipes "Document8 pagesA Project Report On: " Manufacturing of Concrete Pipes "Adnan SyedNo ratings yet

- Title Page: Modeling & Load Rating of Two Bridges Designed With AASHTO and Florida I-Beam GirdersDocument13 pagesTitle Page: Modeling & Load Rating of Two Bridges Designed With AASHTO and Florida I-Beam Girdersعبدالوهاب بركاتNo ratings yet