Professional Documents

Culture Documents

Butt and Gas Charging

Uploaded by

Roshan RamachandranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butt and Gas Charging

Uploaded by

Roshan RamachandranCopyright:

Available Formats

butt clearence: i told him three cases....

1)if the liner also has been taken out during decarb then job is very easy, adjust the piston ring below the scavenge port area, he asked why??(i told as it is least wear zone), put copaslip on top surface of piston ring i.e. piston ring surface perpendicular to that of liner surface (nd not on side surface i.e. parallel to that of liner surface), nd take impression on a chart paper,u will get obliquue cut impression on chart paper, measure it with vernier caliper....2)when liner is inside the cyl. block, just go down in the liner and repeat the above procedure...3) if one faces ny difficulty in above two procedure then he can also take it by putting the ring in new liner at any place and then repeat the same procedure.

thanks..!!! for gas charging a special T-piece v/v block with mounted press. gauge (diagram u can c at marine insight website), is provided to combine three components nd they r...vacuum pump, charging cylinder and charging point on ac line. after connecting the pipes to these components, start the vacuum pump, which will suck all the air from the pipes nd will discharge it into the recovery bottle. also purge some refrigerant gas from charging cyl. nd collect them in recovery bottle...upto nw its ok and later part i explained the procedure which we follow during (liquid charging)...i m nt sure whether same is followed in gas charging or not but surveyor didnt say nything nd just said ok...nd procedure is.....close the receiver outlet v/v, start the compressor (during this charging point v/v on ac line is shut)...hence all the refrigerant will get collected in the receiver nd finally, compressor will trip on l.p. cut-out. now bypass the lp cutout,close the vacuum p/p v/v,open the charging point v/v and start the comressor...regrigerant filling will take place...keep an eye on ref. level in receiver nd charging cyl. should be kept on weighing machine. finally stop the comp, reset the lp cutout and purge the receiver for ny air in recovery bottle only nt in atm.

: person must be in proper ppe and leather hand glove is must. changeover the filter by turning handle, check whether v/v is holding or not by opening the purging cock.(on my ship there was purging bolt but he said its not possible that a hot filter does not has purging cock, so i just agreed with him), nw crack open the filter cover bolts to check the v/v is holding or not(again, as purging cock passage may be chocked), take out the filter in an empty bucket, allow it to cool, and then put it in the bucket containing diesel oil, clean it, and put it back. in the end changeover the filter and purge the air inside.

You might also like

- Wartsila Fuel Pump - MaintenanceDocument15 pagesWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

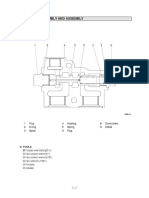

- Starting Air Distributor: Plate 90703-0086Document2 pagesStarting Air Distributor: Plate 90703-0086Roshan RamachandranNo ratings yet

- Class 4 OralsDocument11 pagesClass 4 OralsRoshan RamachandranNo ratings yet

- IPL 2011 ScheduleDocument2 pagesIPL 2011 ScheduleGarima B MehtaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IT175GDocument43 pagesIT175GKarl ClarkNo ratings yet

- Case Study 01Document19 pagesCase Study 01ilmu2No ratings yet

- Hydraulic HammerDocument7 pagesHydraulic HammerUbaldo Enrique Caraballo EstradaNo ratings yet

- Maxxforce 13 Manual de Servicio PDFDocument506 pagesMaxxforce 13 Manual de Servicio PDFDenia Isalia Santana Anguiano80% (5)

- Linhai ATV Engine Service Manual (Up To 300cc)Document341 pagesLinhai ATV Engine Service Manual (Up To 300cc)TLGold80% (15)

- CF&T-Pumps (Outrigger Loads)Document24 pagesCF&T-Pumps (Outrigger Loads)sethhoffman85No ratings yet

- Amte 116 - Lesson 1-3Document15 pagesAmte 116 - Lesson 1-3Bhryan Hans TulaylayNo ratings yet

- Hvac Notes With Heat Load Calculation For 2 ProjectsDocument256 pagesHvac Notes With Heat Load Calculation For 2 ProjectsAjayNo ratings yet

- Alfa Laval Koltek MH Valve enDocument8 pagesAlfa Laval Koltek MH Valve enjpsingh75No ratings yet

- Jonway 150 Long Gy6 Engine Parts Catalogue 图 1: Draft 1Document13 pagesJonway 150 Long Gy6 Engine Parts Catalogue 图 1: Draft 1jetionNo ratings yet

- Zero Headspace Extractor (ZHE) Manual 08.2016Document6 pagesZero Headspace Extractor (ZHE) Manual 08.2016Mari Sherlin Salisi-ChuaNo ratings yet

- Various Type of Steam TrapsDocument46 pagesVarious Type of Steam TrapsRamesh VenugopalNo ratings yet

- Festo Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Document66 pagesFesto Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Parinpa Ketar100% (1)

- Railway SignallingDocument118 pagesRailway Signallingjonathan30100% (1)

- ASL RB L3C 8991 2712 00 BomDocument140 pagesASL RB L3C 8991 2712 00 BomjuangomezsanNo ratings yet

- Scania Industrial DC1383A - 550hpDocument4 pagesScania Industrial DC1383A - 550hpnathandem100% (1)

- 3500 Tool List SimpleDocument7 pages3500 Tool List Simplemohamed hamedNo ratings yet

- Yamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesDocument10 pagesYamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesAdinath UpadhyeNo ratings yet

- 6479A1 3500-72 RodropDocument168 pages6479A1 3500-72 RodropUbirajara Cavaco100% (1)

- Series 20 Axial Piston Pumps Service ManualDocument36 pagesSeries 20 Axial Piston Pumps Service Manualvrosalio100% (1)

- Thermodynamics Tutorial ProblemsDocument20 pagesThermodynamics Tutorial ProblemsRishabh Sharma100% (1)

- Doosan D12T and P126ti Workshop Manual PDFDocument186 pagesDoosan D12T and P126ti Workshop Manual PDFMuhammad rizki100% (4)

- Injin DiselDocument119 pagesInjin DiselScalperNo ratings yet

- C7.1 Reusabilidad de BlockDocument20 pagesC7.1 Reusabilidad de BlockJorge ZamoraNo ratings yet

- Masalta - Pechy - Nahradni - Dily Manual Apisonador Tipo CanguroDocument10 pagesMasalta - Pechy - Nahradni - Dily Manual Apisonador Tipo CanguroYeison SuarezNo ratings yet

- SSP 252 14l 77kw With Petrol Direct Injection in The Lupo FsiDocument56 pagesSSP 252 14l 77kw With Petrol Direct Injection in The Lupo FsiAndrei RuseiNo ratings yet

- Rexroth: Spare Parts ListDocument26 pagesRexroth: Spare Parts ListRafael RodriguezNo ratings yet

- HL740 (TM) - 7 5-4Document43 pagesHL740 (TM) - 7 5-4REMZONANo ratings yet

- Intro To Pneumatics PDFDocument30 pagesIntro To Pneumatics PDFTEUKUNo ratings yet

- PERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREDocument7 pagesPERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREJASH MATHEWNo ratings yet