Professional Documents

Culture Documents

Regenerative Braking System in Automobiles: Vishwakarma Institute of Information Technology, Pune, Maharashtra, India

Uploaded by

Dawit Getachew MelsselOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Regenerative Braking System in Automobiles: Vishwakarma Institute of Information Technology, Pune, Maharashtra, India

Uploaded by

Dawit Getachew MelsselCopyright:

Available Formats

ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print)

IJRMET Vol. 2, Issue 2, May - Oct 2012

Regenerative Braking System in Automobiles

Vishwakarma Institute of Information Technology, Pune, Maharashtra, India

Abstract As in todays world, where there are energy crises and the resources are depleting at a higher rate, there is a need of specific technology that recovers the energy, which gets usually wasted. So, in case of automobiles one of these useful technology is the regenerative braking system. Generally in automobiles whenever the brakes are applied the vehicle comes to a halt and the kinetic energy gets wasted due to friction in the form of kinetic energy. Using regenerative braking system in automobiles enables us to recover the kinetic energy of the vehicle to some extent that is lost during the braking process. In this paper the author discusses two methods of utilising the kinetic energy that is usually wasted by converting it into either electrical energy or into mechanical energy. Regenerative braking system can convert the kinetic energy into electrical energy with help of electric motor. And it can also convert the kinetic energy into mechanical energy, which is supplied to the vehicle whenever it is needed, with the help of a flywheel. Keywords Conventional Braking System, Regenerative Braking, Electric Motor, Flywheel Energy Storage I. Introduction A. Introduction to Conventional Braking System Braking in a moving vehicle means the application of the brakes to slow or stop its movement, usually by depressing a pedal. The braking distance is the distance between the time the brakes are applied and the time the vehicle comes to a complete stop. When brakes are applied to a vehicle using conventional braking system, kinetic energy is converted into heat due to the friction between the wheels and brake pads. This heat is carried away in the airstream and the energy is wasted. The total amount of energy lost in this process depends on how often, how hard and for how long the brakes are applied. B. Introduction to Regenerative Braking System Regenerative braking is one of the emerging technologies which can prove very beneficent. The use of regenerative braking in a vehicle not only results in the recovery of the energy but it also increases the efficiency of vehicle(in case of hybrid vehicles) and saves energy, which is stored in the auxiliary battery. In cities, driving involves many braking events resulting in much higher energy losses with greater potential savings. With buses, taxis, delivery vans and so on there is even more potential for economy. Since regenerative braking results in an increase in energy output for a given energy input to a vehicle, the efficiency is improved. The amount of work done by the engine of the vehicle is reduced, in turn reducing the amount of energy required to drive the vehicle. This technology of regenerative braking controls the speed of the vehicle by converting a portion of the vehicles kinetic energy into another useful form of energy. The energy so produced could then be stored as electrical energy in the automobile battery, or as mechanical energy in flywheels, which can be used again by the vehicle.

Siddharth K. Patil

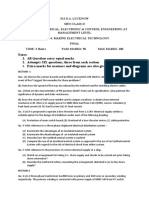

Fig. 2: Block Diagram of Regenerative Braking System Regenerative braking refers to a process in which a portion of the kinetic energy of the vehicle is stored by a short term storage system. Energy normally dissipated in the brakes is directed by a power transmission system to the auxiliary battery during deceleration [1]. The energy that is stored by the vehicle, is converted back into kinetic energy and used whenever the vehicle is to be accelerated. The magnitude of the portion available for energy storage varies according to the type of storage, drive train efficiency, drive cycle and inertia weight [1]. The effect of regenerative brakes is less at lower speeds as compared to that at higher speeds of vehicle. So the friction brakes are needed in a situation of regenerative brake failure, to stop the vehicle completely. II. Working of Regenerative Braking using Electric Motor The working of the regenerative braking system depends upon the working principle of an electric motor, which is the important component of the system.

Fig. 1: Simple Representation of Regenerative Braking System

w w w. i j r m e t. c o m International Journal of Research in Mechanical Engineering & Technology 45

IJRMET Vol. 2, Issue 2, May - Oct 2012

ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print)

VI. Conclusion The regenerative braking system used in the vehicles satisfies the purpose of saving a part of the energy lost during braking. Also it can be operated at high temperature range and are efficient as compared to conventional braking system. The results from some of the test conducted show that around 30% of the energy delivered can be recovered by the system. Regenerative braking system has a wide scope for further development and the energy savings. The use of more efficient systems could lead to huge savings in the economy of any country. References [1] S.J.Clegg,A Review of Regenerative Braking System, Institute of Transport Studies, University of Leeds, Working paper of 471, 1996. [2] Chibulka.J,Kinetic Energy Recovery System by means of Flywheel Energy Storage, Advanced Engineering, Vol. 3, No. 1, 2009, pp. 27-38. [3] Saharat Chanthanumataporn, Sarawut Lerspalungsanti and Monsak Pimsarn,Design of Regenerative Braking System for an electric vehicle modified from used car, Second TSME International Conference on Mechanical Engineering, 19-21 Oct, 2011, Krabi. [4] Dr. Iqbal Husain,Electric and hybrid Vehicles: Design Fundamentals, CRC press, Taylor and Francis Group, USA, 2010. [5] Gao, Y., Chen, L., Ehsani, M.,Investigation of the Effectiveness of Regenerative Braking for EV and HEV, SAE Paper 1999-01-2910, August 1999. [6] Sudhir Kumar Saxena,Automobile engineering, Laxmi publications Pvt Ltd, INDIA, 2009. [7] John M. Miller,Propulsion Systems for Hybrid Vehicles, Institute of Electrical Engineers, UK, 2004. [8] Chen, J-X., Jiang, J-Z. Wang, X-J.,Research of Energy Regeneration Technology in Electric Vehicle, Shanghai University Press, Vol. 7, No 2, 2003. Siddharth Kishor Patil received his bachelor degree in mechanical engineering, from Vishwakarma Institute of Information Technology, Pune, under University of Pune, in 2012. At, present he is working on a project in Computational Fluid Dynamics. His research interests to include Fluid mechanics, automobile engineering and Computational fluid dynamics.

Fig. 3: Operation of Electric Motor Generally the electric motor, is actuated when electric current is passed through it. But, when some external force is used to actuate the motor (that is during the braking process) then it behaves as a generator and generates electricity. That is, whenever a motor is run in one direction the electric energy gets converted into mechanical energy, which is used to accelerate the vehicle and whenever the motor is run in opposite direction it functions as a generator, which converts mechanical energy into electrical energy. This makes it possible to employ the rotational force of the driving axle to turn the electric motors, thus regenerating electric energy for storage in the battery and simultaneously slowing the car with the regenerative resistance of the electric motors [2]. This electricity is then used for recharging the battery. III. Flywheel Energy Storage The energy (mechanical) stored in the flywheel is directly given to the vehicle so as to boost its acceleration instantaneously, whenever needed. Generally, the method of transmission of energy directly to the vehicle is more efficient rather than storing it in the battery, as it does not consists of the conversion of energies. As, during the recharging of battery, mechanical energy is converted into electrical energy and during discharging electrical energy is converted into mechanical energy. So, due to these conversions transmission loses occur and the efficiency reduces. As, in the other case, there are no transmission loses since mechanical energy stored in the flywheel is directly transferred to the vehicle in its original form. Because of the instant energy supply and high efficiency these type of system is used in F-1 cars. IV. Advantages Better fuel economy. Reduced CO2 emissions. Approximately 30% saving in fuel consumption. The lower operating and environment cost of the vehicle with regenerative braking system. V. Future Scope As in regenerative braking system about 30% of the energy is recuperated, also the system of regenerative braking increases the weight of the vehicle by approximately 25 kgs. So rather than manufacturing the metallic gears and metallic flywheel, carbon fibre can be used which will not only reduce the weight of the system but also it will reduce the transmission loses.

46

International Journal of Research in Mechanical Engineering & Technology

w w w. i j r m e t. c o m

You might also like

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- LINEAR MOTION IN THREE DIMENSIONSDocument51 pagesLINEAR MOTION IN THREE DIMENSIONSOsmany Madrigal100% (1)

- Design and Analysis of Power Generating Speed BreakerDocument23 pagesDesign and Analysis of Power Generating Speed BreakerIJRASETPublicationsNo ratings yet

- Regenerative Braking SystemDocument15 pagesRegenerative Braking SystemVinay KumarNo ratings yet

- Railway TechnicalDocument440 pagesRailway TechnicalFrancisco Abraham Baeza92% (13)

- Regenerative Braking Research PaperDocument8 pagesRegenerative Braking Research PaperPavas12No ratings yet

- H Pss TechnicalDocument16 pagesH Pss TechnicalDawit Getachew MelsselNo ratings yet

- H Pss TechnicalDocument16 pagesH Pss TechnicalDawit Getachew MelsselNo ratings yet

- H Pss TechnicalDocument16 pagesH Pss TechnicalDawit Getachew MelsselNo ratings yet

- Regenerative Braking System by DEEPAK CHANDRADocument25 pagesRegenerative Braking System by DEEPAK CHANDRADeepakUpadhyay50% (2)

- Regenerative Braking SystemDocument16 pagesRegenerative Braking SystemTanvi KhuranaNo ratings yet

- Regenerative Braking SystemDocument27 pagesRegenerative Braking Systemapi-1977578380% (5)

- Project Report On Regenerative Braking SystemDocument23 pagesProject Report On Regenerative Braking SystemKrishna Yadav44% (16)

- "Regenerative Braking": Project Report OnDocument64 pages"Regenerative Braking": Project Report OnArun Kumar YadavNo ratings yet

- Apple Park "The SpaceshipDocument13 pagesApple Park "The SpaceshipPrajwal GuraoNo ratings yet

- Regenerative Braking System: Mee396: Automotive Mini ProjectDocument14 pagesRegenerative Braking System: Mee396: Automotive Mini ProjectAngad BangaNo ratings yet

- Introduction to Hybrid Vehicle System Modeling and ControlFrom EverandIntroduction to Hybrid Vehicle System Modeling and ControlRating: 4 out of 5 stars4/5 (1)

- Regenerative Braking System in AutomobilDocument2 pagesRegenerative Braking System in AutomobilAryan AmeenNo ratings yet

- Modification of Existing Regenerative Braking System For Electric VehicleDocument7 pagesModification of Existing Regenerative Braking System For Electric VehicleAvengersNo ratings yet

- Modification of Existing Regenerative Braking System For Electric VehicleDocument4 pagesModification of Existing Regenerative Braking System For Electric VehicleAvengersNo ratings yet

- Regenerative Braking Systems (RBS) (Future of Braking Systems)Document4 pagesRegenerative Braking Systems (RBS) (Future of Braking Systems)Sushant VanveNo ratings yet

- Research Rbs 2Document4 pagesResearch Rbs 2Raju KumarNo ratings yet

- JETIRFH06117Document6 pagesJETIRFH06117DevNo ratings yet

- Department of Mechanical EngineeringDocument23 pagesDepartment of Mechanical EngineeringMail ManNo ratings yet

- Ankit Project Final-1Document44 pagesAnkit Project Final-1Ankit SinghNo ratings yet

- Regenerative Braking Systems RBS FutureDocument4 pagesRegenerative Braking Systems RBS Futuresmabhibidkar2001No ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewPrajay BhavsarNo ratings yet

- Regenerative Braking: Review PaperDocument4 pagesRegenerative Braking: Review PaperEditor IJRITCCNo ratings yet

- Recuperation of Kinetic Energy - Regenerative BrakingDocument5 pagesRecuperation of Kinetic Energy - Regenerative BrakingAbhishek KumarNo ratings yet

- Regenerative Braking SystemDocument14 pagesRegenerative Braking Systemmonu patelNo ratings yet

- Engineering Rox - Regenerative Braking SystemDocument7 pagesEngineering Rox - Regenerative Braking SystemVivek SinghNo ratings yet

- Design and Static Analysis of Regenerative Shock Absorber PDFDocument6 pagesDesign and Static Analysis of Regenerative Shock Absorber PDFKarthek SpNo ratings yet

- Regenerative Braking System A ReviewDocument5 pagesRegenerative Braking System A ReviewIJRASETPublicationsNo ratings yet

- Mini Project ReportDocument24 pagesMini Project ReportbharathahsNo ratings yet

- Design and Analysis of Electromagnetic Regenerative Shock AbsorberDocument6 pagesDesign and Analysis of Electromagnetic Regenerative Shock AbsorberArun GargNo ratings yet

- Regenerative Braking Increases e-Bike RangeDocument35 pagesRegenerative Braking Increases e-Bike RangeEr Dinesh TambeNo ratings yet

- Irjet V4i4595 PDFDocument3 pagesIrjet V4i4595 PDFUjash VasaniNo ratings yet

- Irjet V3i5290Document5 pagesIrjet V3i5290Kuroko TetsuyaNo ratings yet

- Regenerative Braking Extends EV RangeDocument21 pagesRegenerative Braking Extends EV RangeSHUBHAM GUPTA BTechNo ratings yet

- Design and Analysis of Regenerative Braking System of All-Terrain VehicleDocument5 pagesDesign and Analysis of Regenerative Braking System of All-Terrain VehicleAmit TogreNo ratings yet

- "Regenerative Braking System": A Major Project Report ONDocument35 pages"Regenerative Braking System": A Major Project Report ONPushpendra KumarNo ratings yet

- ELECTROMAGNETIC ENERGY HARVESTER FOR VEHICLE SUSPENSIONDocument21 pagesELECTROMAGNETIC ENERGY HARVESTER FOR VEHICLE SUSPENSIONNamrta DeokateNo ratings yet

- Literature Review of BLDCDocument6 pagesLiterature Review of BLDCsushil63666No ratings yet

- Energy Efficient Electric Vehicle Using Regenerative Braking SystemDocument4 pagesEnergy Efficient Electric Vehicle Using Regenerative Braking SystemRrdbjdNo ratings yet

- Regenerative Braking System With Self-Power Generating Electrical BicycleDocument35 pagesRegenerative Braking System With Self-Power Generating Electrical BicycleEr Dinesh TambeNo ratings yet

- Fabrication of Power Production From Exhaust Gas of An EngineDocument6 pagesFabrication of Power Production From Exhaust Gas of An EngineIJRASETPublicationsNo ratings yet

- Design and Testing of Regenerative Suspension SystemDocument6 pagesDesign and Testing of Regenerative Suspension SystemSayed azharNo ratings yet

- Theme Project PresentationDocument14 pagesTheme Project PresentationMail ManNo ratings yet

- Tom ProjectDocument18 pagesTom ProjectAditya SinghNo ratings yet

- Regenerative Braking Project ReportDocument23 pagesRegenerative Braking Project Reportraghu raghuNo ratings yet

- Fuzzy Logic Control Based Regenerative Braking in Electric VehicleDocument3 pagesFuzzy Logic Control Based Regenerative Braking in Electric VehicleAnonymous KhhapQJVYtNo ratings yet

- Fuelless Heat EnergyDocument22 pagesFuelless Heat EnergyMurali VannappanNo ratings yet

- Matecconf Eureca2018 02011Document15 pagesMatecconf Eureca2018 02011Aseel QasaimehNo ratings yet

- Regenerative Braking SystemDocument20 pagesRegenerative Braking SystemMahesh DondapatiNo ratings yet

- Mini Project Report Phase 2Document21 pagesMini Project Report Phase 2bharathahsNo ratings yet

- Regenerative Braking Control Strategy For Electric Vehicle With Four In-Wheel MotorsDocument6 pagesRegenerative Braking Control Strategy For Electric Vehicle With Four In-Wheel MotorsMarcel BabiiNo ratings yet

- Toyota Hybrid System-IiDocument27 pagesToyota Hybrid System-IiArun KrishnanNo ratings yet

- Fabrication and Analysis of Regenerative Braking SystemDocument5 pagesFabrication and Analysis of Regenerative Braking SystemJournal 4 ResearchNo ratings yet

- Eco Hybrid Scooter: Advanced Materials Research December 2014Document9 pagesEco Hybrid Scooter: Advanced Materials Research December 2014Andrey MantaNo ratings yet

- BTech Mechanical Engineering Project on Regenerative Braking SystemDocument46 pagesBTech Mechanical Engineering Project on Regenerative Braking Systemkishan chauhanNo ratings yet

- Chapter - 1Document39 pagesChapter - 1ritesh chauhanNo ratings yet

- Power Generation by Shock AbsorberDocument8 pagesPower Generation by Shock AbsorberIJRASETPublicationsNo ratings yet

- Shubh Me Final ProjectDocument7 pagesShubh Me Final ProjectShubh prakash TiwariNo ratings yet

- REGENRATIVE BRAKING SYSTEM FOR B.E.V BALOGUN DAVID AyooluwaDocument36 pagesREGENRATIVE BRAKING SYSTEM FOR B.E.V BALOGUN DAVID Ayooluwabalogun davidNo ratings yet

- RBS PROJECT Final Report..Document7 pagesRBS PROJECT Final Report..aakashNo ratings yet

- Power-to-Gas: Bridging the Electricity and Gas NetworksFrom EverandPower-to-Gas: Bridging the Electricity and Gas NetworksNo ratings yet

- RosenDocument12 pagesRosenDawit Getachew MelsselNo ratings yet

- A Pa Style 1Document2 pagesA Pa Style 1bookseeker860No ratings yet

- Mua prc004 Dec02Document116 pagesMua prc004 Dec02Dawit Getachew MelsselNo ratings yet

- 2012 01 0645Document14 pages2012 01 0645Dawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Wear, 100: 1.1. The Practical ProblemDocument17 pagesWear, 100: 1.1. The Practical ProblemDawit Getachew MelsselNo ratings yet

- 3 Automotive Chassis Design v2Document62 pages3 Automotive Chassis Design v2Leela Krishna VegiNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Bibliobhhnfjjefjgesejggraphy 1Document1 pageBibliobhhnfjjefjgesejggraphy 1Dawit Getachew MelsselNo ratings yet

- 0994 NmkyuuuDocument11 pages0994 NmkyuuuDawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Gay DissertationDocument326 pagesGay DissertationDawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Magnetic Braking: FQ (VB)Document23 pagesMagnetic Braking: FQ (VB)Anshul AroraNo ratings yet

- 0994 NmkyuuuDocument11 pages0994 NmkyuuuDawit Getachew MelsselNo ratings yet

- Gay DissertationDocument326 pagesGay DissertationDawit Getachew MelsselNo ratings yet

- Magnetic Braking: FQ (VB)Document23 pagesMagnetic Braking: FQ (VB)Anshul AroraNo ratings yet

- MTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDocument10 pagesMTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDawit Getachew MelsselNo ratings yet

- MTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDocument10 pagesMTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDawit Getachew MelsselNo ratings yet

- 0994 NmkyuuuDocument11 pages0994 NmkyuuuDawit Getachew MelsselNo ratings yet

- 0994 NmkyuuuDocument11 pages0994 NmkyuuuDawit Getachew MelsselNo ratings yet

- MTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDocument10 pagesMTBSeries MoghftrredfghhytghhdularTensionBrakes PDFDawit Getachew MelsselNo ratings yet

- 0994 NmkyuuuDocument11 pages0994 NmkyuuuDawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Brake Pad Actuation Using Electromagnetic Coils: Original ArticleDocument5 pagesBrake Pad Actuation Using Electromagnetic Coils: Original ArticleDawit Getachew MelsselNo ratings yet

- Proposal For National Energy Development Scoping StudyDocument3 pagesProposal For National Energy Development Scoping StudyEsstii MahnNo ratings yet

- Reliability Centered Maintenance A Case StudyDocument8 pagesReliability Centered Maintenance A Case Studyagus sugiantoNo ratings yet

- DCG Generator Sets FinalDocument4 pagesDCG Generator Sets FinalStephen Gooberman-HillNo ratings yet

- Robot PetroleroDocument2 pagesRobot PetroleroMariannaNo ratings yet

- Buddy Mig 500iDocument2 pagesBuddy Mig 500iKe RaNo ratings yet

- Ee 307Document2 pagesEe 307Kester TeodoroNo ratings yet

- ABB HVAC Webinars - Power Quality in Buildings 26082020Document31 pagesABB HVAC Webinars - Power Quality in Buildings 26082020dave chaudhuryNo ratings yet

- Jak 0cDocument4 pagesJak 0cOliver MendozaNo ratings yet

- Work Energy TheoremDocument12 pagesWork Energy TheoremJother AmutanNo ratings yet

- ĐỀ 1Document3 pagesĐỀ 1Nguyễn Tùng MinhNo ratings yet

- STS5000 enDocument28 pagesSTS5000 enBruno AlvesNo ratings yet

- Programmable Logic Control Lab BasicsDocument6 pagesProgrammable Logic Control Lab BasicsRajesh KumarNo ratings yet

- Eaton 12v 540w Battery Brochure PA162003ENDocument2 pagesEaton 12v 540w Battery Brochure PA162003ENRafael AguileraNo ratings yet

- Yambaling Hydro - RevisedDocument3 pagesYambaling Hydro - RevisedSudan KhatiwadaNo ratings yet

- Drive Rating SelectionDocument1 pageDrive Rating SelectionAnish ShrivastavaNo ratings yet

- Vishay Capacitor CatalogueDocument14 pagesVishay Capacitor Catalogueviren72100% (1)

- NHE2486-Main12-Power Year 4 Past PaperDocument7 pagesNHE2486-Main12-Power Year 4 Past Paperlynx101No ratings yet

- Aftron - Split AC Unit SpecDocument2 pagesAftron - Split AC Unit Specjhay rarezaNo ratings yet

- Steam Turbines: A Concise Guide to Design, Operation and MaintenanceDocument104 pagesSteam Turbines: A Concise Guide to Design, Operation and MaintenancePRAVEENNo ratings yet

- Calculate Size of Contactor - Fuse - CB - OL Relay of Star-Delta Starter - Electrical Notes & ArticlesDocument8 pagesCalculate Size of Contactor - Fuse - CB - OL Relay of Star-Delta Starter - Electrical Notes & Articleshemant kumarNo ratings yet

- Paper 4 Marine Electrical TechnologyDocument2 pagesPaper 4 Marine Electrical TechnologysuveshNo ratings yet

- Rectifier, +24 VDC, 2175W: DescriptionDocument2 pagesRectifier, +24 VDC, 2175W: DescriptionCharmer JiaNo ratings yet

- Fusibles NH FEDERALDocument11 pagesFusibles NH FEDERALantonioNo ratings yet

- Siemens GT SGT800Document2 pagesSiemens GT SGT800hrsotherNo ratings yet

- Ch.2.Regenerative Rankine Cycle With Closed Feed Water HeaterDocument55 pagesCh.2.Regenerative Rankine Cycle With Closed Feed Water Heaterlayanalfar0No ratings yet

- DPS2400B-48 Fact Sheet PDFDocument2 pagesDPS2400B-48 Fact Sheet PDFmazenkhodr1983No ratings yet

- Ansaldo-Original Service Provider BrochureDocument4 pagesAnsaldo-Original Service Provider BrochureaniekanNo ratings yet