Professional Documents

Culture Documents

Manual of Under Ground Structer Method

Uploaded by

lkovijayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual of Under Ground Structer Method

Uploaded by

lkovijayCopyright:

Available Formats

4. Waterproofing treatment of Pump house/ Under ground structure. 4.1. 4.1.

1 Waterproofing treatment on horizontal surface: Surface Preparation Preparing surface of lean concrete/ leveling course dust-free etc. The waterproofing over the lean concrete/ leveling course should be roughened when the lean concrete is still green. In case the surface is not made rough in the initial stages it-self i.e. before the lean concrete is set, the work of waterproofing should not be permitted. Application of First layer cement with chemicals slurry Providing and laying first layer of cement slurry 0.375 kg./sq.m mixed with Supercrete- SB/ Chembond/ Warrior- W-4 (IS : 13435, Part-3) @0.250 kg./sq. by brush. Application of Second layer cement with chemicals slurry. (i) The second layer shall be applied over the first layer after a gap of 4 hours. (ii) The slurry of chemicals with cement for application of second layer shall be prepared and the application shall be exactly the same as described in clause 4.1.2. Application of protective layer (Coat) Providing 20 mm thick cement plaster with ratio of (1 blended gray cement : 4 coarse sand) first backing coat of 12 mm and second coat of 8 mm thick mixed with Doncrete- RMW/ Chembond- Mix/ Warrior- I (IS: 2645) @150ml Per bag of cement. Injection grouting in Raft/ RCC floor: (i) Placing and fixing the nozzle by drilling machine but never use PVC nozzle for this work. Minimum DIA of nozzle 15mm and maximum 20mm which shall be provided on a regular interval not exceeding 1.0 M, including the construction joints. (ii) Injection of Don Grout- ADD/ Chemgrout/ Warrior-W-5 (Polymer based on shrinkage high strength grout) admixed with cement through nozzles under pressure by pump @ 200 gm per bag of cement. (iii) Sealing the nozzle after grouting with polymer product mixed with cement. Waterproofing treatment on the vertical surface. Preparing the surface and providing ancillary arrangements:(i) The surface of structure to be treated shall be roughened properly either by raking joints or by hacking the cement concrete surface with a specially made hacking tool. Just after removing of shuttering. (ii) If any reason the above system not possible to use properly on alternative method to make the surface rough and dust-free is providing spatter key or wire brush. (iii) It should be very clear under stood that the vertical surface waterproofing treatment either from in inside or outside shall be undertaken only when the entire work is structure complete. (iv) For doing the waterproofing treatment all-round scaffolding shall be eructed. conti.

4.1.2

4.1.3

4.1.4.

4.1.5

4.2. 4.2.1

4.2.2

4.2.3

4.2.4.

4.2.5.

4.2.6. 4.2.7. Note: -

Injection grouting in vertical surface/ wall. (i) Placing and fixing the nozzle by drilling machine but never use PVC nozzle for this work. Minimum DIA of nozzle 15mm and maximum 20mm which shall be provided on a regular interval not exceeding 1.0 M, including the construction joints. (ii) Injection of Don Grout- ADD/ Chemgrout/ Warrior-W-5 (Polymer based on shrinkage high strength grout) admixed with cement through nozzles under pressure by pump @ 200 gm per bag of cement. (iii) Sealing the nozzle after grouting with polymer product mixed with cement. Application of cement slurry with chemical:Providing and laying first layer 0.375 kg./sq.m mixed with SupercreteSB/Chembond/ Warrior- W-4, (IS : 13435, Part-3) @0.250 kg./sq. by brush. Application of Second layer. (i) The second layer shall be applied over the first layer after a gap of 4 hours. (ii) The slurry of chemicals with cement for application of second layer shall be prepared and the application shall be exactly the same as for first layer detailed in clause 4.2.3. Application of protective layer (Coat) Providing 20 mm thick cement plaster with ratio of (1 Blended gray Cement : 4 Coarse sand) first backing coat of 12 mm and second coat of 8 mm thick mixed with Doncrete- RMW/ Chembond- MIX/ Warrior- I (IS: 2645) @150ml per bag of cement. Curing and Testing The exposed face of the water proofing course shall be kept wet for 14 days. No back filling shall be done before expiry of 14 days from the date of completing the waterproofing course from outside. If waterproofing coarse shall be done from inside, scaffolding shall be removed and waterproofing coarse shall be kept 14 days. Measurement Length, width/ height shall be measured along the finished surface to a cm and the area shall be worked out correct to nearest 0.01 sq.m. Rate The rate shall include the cost of all labours and materials etc. 1.The waterproofing work to be carried out by specialized agencies. 2. The eligibility of waterproofing agencies defined by Chief Engineer, Level I (Building), U.P.P.W.D. vide letter No. 781/CAMP/Chief Engineer (Building), Dated: 30-10-2008.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- LOILOPRenewal PDFDocument41 pagesLOILOPRenewal PDFlkovijayNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Laga Ka SaransDocument4 pagesLaga Ka SaranslkovijayNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- PDFDocument1 pagePDFlkovijayNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Laga Ka Sarans AsDocument4 pagesLaga Ka Sarans AslkovijayNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

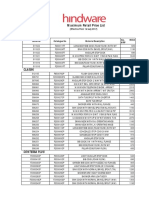

- Hindware Bathroom Fittings PricelistDocument31 pagesHindware Bathroom Fittings PricelistlkovijayNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 55@4059 TH - KKSZ) KJ en Ds Vurxzr Fo'Os'Ojs K Izs (KK X'G Ds LQ/KKJHDJ.K, Oa LKSN HZZDJ.K, Oa Fofhkuu DK ZaDocument6 pages55@4059 TH - KKSZ) KJ en Ds Vurxzr Fo'Os'Ojs K Izs (KK X'G Ds LQ/KKJHDJ.K, Oa LKSN HZZDJ.K, Oa Fofhkuu DK ZalkovijayNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- AnalysisDocument39 pagesAnalysislkovijayNo ratings yet

- E-in-C Residence ADocument51 pagesE-in-C Residence AlkovijayNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Boq PraneenDocument2 pagesBoq Praneenlkovijay100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 32mm Thick Flush Doors Rs 140Document9 pages32mm Thick Flush Doors Rs 140lkovijayNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Bar ChartDocument46 pagesBar ChartlkovijayNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Toilet BlockDocument21 pagesToilet BlocklkovijayNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Izfrosnu: DK Z DKDocument29 pagesIzfrosnu: DK Z DKlkovijayNo ratings yet

- Analysis New Oct 14Document526 pagesAnalysis New Oct 14lkovijayNo ratings yet

- Budget Mannual - BhadohiDocument9 pagesBudget Mannual - BhadohilkovijayNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- DK Kzy VF/K'KKLH VFHK Urk Vuqj (K.K (K.M Ua0&1 Flfoy Yks0 Fu0 Fo0 Y (KuåDocument21 pagesDK Kzy VF/K'KKLH VFHK Urk Vuqj (K.K (K.M Ua0&1 Flfoy Yks0 Fu0 Fo0 Y (KuålkovijayNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SWPPP InformationDocument2 pagesSWPPP InformationlkovijayNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Acceptance of Materials in Contact With Drinking Water: Belgian Federation For The Water SectorDocument24 pagesAcceptance of Materials in Contact With Drinking Water: Belgian Federation For The Water SectorJagdish PatelNo ratings yet

- Drugs Used in Current Physical Therapy PracticeDocument22 pagesDrugs Used in Current Physical Therapy PracticeAngelic khanNo ratings yet

- Kromatogram Mimyak JintanDocument2 pagesKromatogram Mimyak JintanPutri ElafifahNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- TMS 23 AlZero FinalDocument10 pagesTMS 23 AlZero FinalMuhammad Zulfikar FauziNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Spider 3 - 4 - 5 - DO-160 Sec 26Document13 pagesSpider 3 - 4 - 5 - DO-160 Sec 26Jacob MillerNo ratings yet

- Marten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsDocument391 pagesMarten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsJed MansouriNo ratings yet

- Welding DefectsDocument69 pagesWelding DefectsSaravanan Saran100% (1)

- Proteins Amino Acids: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellDocument12 pagesProteins Amino Acids: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellAdelaTeresaNo ratings yet

- Class IX Holiday HomeworkDocument9 pagesClass IX Holiday Homeworkanubh50No ratings yet

- Chang ElectrochemistryDocument1 pageChang Electrochemistryg bhargaviNo ratings yet

- A Review On Anthraquinones Isolated From Cassia Species and Their ApplicationsDocument29 pagesA Review On Anthraquinones Isolated From Cassia Species and Their ApplicationsAnne Calyx100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 0625 s12 QP 13Document20 pages0625 s12 QP 13Ahmed Hany ElGezawyNo ratings yet

- Construction and Evaluation of Composite Boards Made From High Density Polyethylene and Corn (Document51 pagesConstruction and Evaluation of Composite Boards Made From High Density Polyethylene and Corn (Kristine Erica BaculodNo ratings yet

- Nymax 1200 Processing GuideDocument4 pagesNymax 1200 Processing GuideJanaka MangalaNo ratings yet

- Somethinc-Jakartaxbeauty2023 (Booth XL) (21.12)Document16 pagesSomethinc-Jakartaxbeauty2023 (Booth XL) (21.12)ARIF WIDIANTORO 211212138No ratings yet

- Circulaire Filtration Fume Cabinets With VisionaireDocument9 pagesCirculaire Filtration Fume Cabinets With VisionaireAkhmad Rosul RaisNo ratings yet

- The Form of Sulphur Which Is The Most Stable at Ordinary Temperature IsDocument2 pagesThe Form of Sulphur Which Is The Most Stable at Ordinary Temperature IsSalman HaroonNo ratings yet

- 1 Batching of Aggregates For ConcreteDocument52 pages1 Batching of Aggregates For ConcreteSamreen KhawajaNo ratings yet

- Calculation of The Platinum's Active Surface PDFDocument3 pagesCalculation of The Platinum's Active Surface PDFUriel Cedeño AntunezNo ratings yet

- H2 - Prelim 2009 Paper1Document16 pagesH2 - Prelim 2009 Paper1Augustine NgNo ratings yet

- Learning From The Past? Fatigue Failures in Engineered SystemsDocument79 pagesLearning From The Past? Fatigue Failures in Engineered SystemsSabino LaraNo ratings yet

- Macromolecules PRACTICE Test 2012 2013Document8 pagesMacromolecules PRACTICE Test 2012 2013edeceNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Procare An (TDS)Document2 pagesProcare An (TDS)liniaxcitoNo ratings yet

- Bainite Transformation During Continuous Cooling: Analysis of Dilatation DataDocument6 pagesBainite Transformation During Continuous Cooling: Analysis of Dilatation DataVanina DuttoNo ratings yet

- Types of Hydroponics Set Up SystemsDocument7 pagesTypes of Hydroponics Set Up SystemsZike SunitNo ratings yet

- The Turbine Lubricating Oil System: ObjectivesDocument23 pagesThe Turbine Lubricating Oil System: Objectivesefmaggio100% (2)

- Rpt-sales-Fundamentals of Sand ControlDocument8 pagesRpt-sales-Fundamentals of Sand ControlDidier MorenoNo ratings yet

- Synthesis of Methylamine - OrgSynDocument5 pagesSynthesis of Methylamine - OrgSynzodd01No ratings yet

- Activated Carbon For Water TreatmentDocument9 pagesActivated Carbon For Water TreatmentmorizoneNo ratings yet

- Vendor List-IOCLDocument67 pagesVendor List-IOCLsubudhiprasanna50% (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)From EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)No ratings yet

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)